Steel roof rafters are the backbone of any prefabricated building. They carry the load, set the spacing, and decide how long a roof will last. For most projects, rafter spacing falls between 12 and 24 inches, depending on span, climate, and panel thickness. Yes, metal roofing can be installed directly on rafters—but only with the right support, insulation, and ventilation.

In this guide, you’ll learn:

- What steel rafters are and how they differ from beams and trusses.

- The main types and sizes of rafters, from 2×4 to 2×12, and their applications.

- Standard rafter spacing guidelines and how purlins help distribute loads.

- Insulation options to prevent condensation and improve energy efficiency.

- Cutting and installation practices for accuracy and durability.

- A comparison of rafters vs. steel trusses for different building needs.

- Our perspective as a prefabricated steel structures manufacturer, delivering factory-direct rafters for global projects.

By the end, you’ll know exactly how to choose, size, and space your rafters—and where to get certified, factory-direct solutions built to last.

What is a Steel Roof Rafter?

A steel roof rafter is a sloped structural member that supports the roof and transfers loads to the walls. It is different from beams, which carry floor loads, because rafters are designed specifically for roofs.

- Function: Steel rafters provide stability and distribute the weight of snow, wind, or roofing sheets evenly.

- Material: In traditional buildings, rafters are often wood. In prefabricated steel buildings, rafters are made of high-strength steel (Q235, Q345), ensuring better load-bearing and long-term durability.

- Connections: Steel rafters are typically fixed to the ridge beam and wall plates using bolting or welding, which guarantees a rigid and stable roof system.

Beam vs Rafter (Quick Note): A rafter supports a sloped roof, while a beam is usually horizontal and carries floor or roof loads. This distinction is important when designing steel structure buildings.

Types of Steel Roof Rafters

Steel roof rafters come in different types depending on the roof design and load requirements. Choosing the right type ensures stability, cost efficiency, and long service life for prefabricated steel buildings.

- Common Rafters (Straight Rafters): Standard rafters that run from the ridge to the wall plate, mainly used in simple roof systems.

- Principal Rafters: Larger rafters that carry more load and are used in large-span steel structures.

- Hip Rafters: Diagonal rafters that support the sloping edges of hip roofs, common in commercial and architectural steel buildings.

- Trussed Rafters: Pre-engineered triangular units, suitable for longer spans where efficiency and quick installation are important.

Steel vs. Aluminum Rafters

While some projects use aluminum or alloy rafters, steel rafters remain the preferred choice for industrial, agricultural, and commercial applications because they offer:

- Higher load capacity for heavy roofing panels.

- Longer durability and better corrosion resistance with galvanizing or coatings.

- Lower overall cost in large-scale projects.

For certified quality and wholesale supply, SteelPRO PEB manufactures and exports steel rafters worldwide, meeting ISO and CE standards.

Choosing the Right Steel Roof Rafter Size

The right steel roof rafter size depends on three key factors: the roof span, the load requirements, and the type of building. Selecting the correct size ensures safety, cost efficiency, and long-term durability in prefabricated steel structures.

| Rafter Size | Typical Span | Application | Key Features |

| 2×4 | Up to 10–12 ft | Small sheds, garages, light-load projects | Lightweight and cost-effective, not suitable for heavy loads |

| 2×6 | 10–14 ft | Residential homes, small commercial buildings | Balance of strength and weight, widely used in light steel buildings |

| 2×8 | 12–20 ft | Warehouses, mid-size industrial buildings | Stronger support, ideal for heavier roofing panels |

| 2×10 | 16–24 ft | Large warehouses, logistics centers | High load capacity, supports heavy equipment or machinery |

| 2×12 | 20–30 ft | Heavy-load and large-span projects | Maximum strength, used in factories, snow-load regions, or specialized facilities |

In PEB structures, steel rafters are usually manufactured from Q235 or Q345 high-strength steel, ensuring stability even under demanding loads.

At SteelPRO PEB, we provide factory-cut steel rafters in certified sizes, available for wholesale supply. This ensures:

- Precision cutting with CNC and laser machines.

- Compliance with ISO and CE standards.

- Faster installation on-site, reducing labor costs.

Why Steel Rafter Sizes Matter

- Correct sizing prevents sagging or failure under heavy snow, wind, or equipment loads.

- Larger spans require thicker rafters to maintain structural integrity.

- Choosing the right size helps reduce unnecessary material costs while ensuring safety.

What’s the Ideal Metal Roof Rafter Spacing?

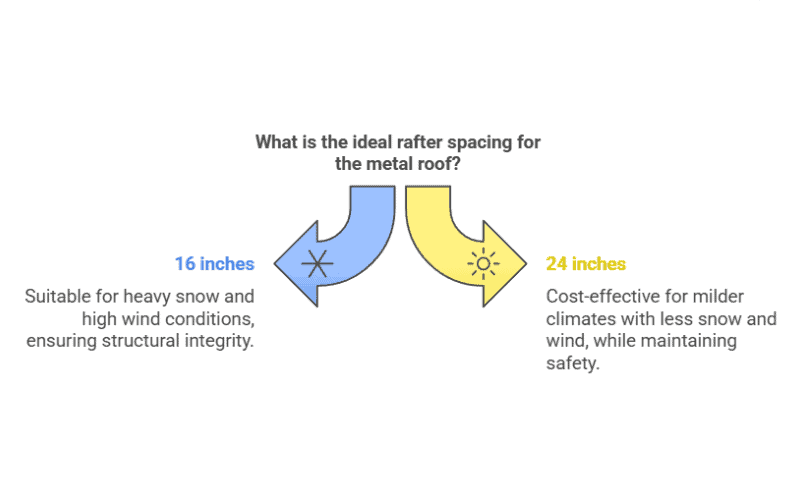

The ideal metal roof rafter spacing depends on climate, roof load, and building design. In most cases, rafters are spaced between 12 and 24 inches on center, following international standards such as the IRC (International Residential Code).

| Rafter Spacing | Best For | Key Benefits |

| 12 inches (30 cm) | Heavy snow loads, high-wind regions | Maximum strength and resistance to deformation |

| 16 inches (40 cm) | Snowy or windy climates | Good balance of strength and cost |

| 19.2 inches (49 cm) | Medium spans, moderate loads | Optimized for materials like metal panels |

| 24 inches (61 cm) | Mild climates, lighter loads | Cost-effective, less material required |

Closer spacing increases strength but raises material and labor costs. Wider spacing reduces costs but requires careful load calculations.

Why Rafter Spacing Matters

- Heavy Snow Loads: Narrow spacing prevents sagging or collapse.

- High Wind Zones: Closer rafters improve resistance to uplift.

- Roof Panel Thickness: Thicker metal panels often allow wider spacing.

- Long-Term Durability: Proper spacing ensures your roof lasts longer with fewer repairs.

Rafter and Purlin Spacing in Steel Buildings

In many prefabricated steel structures, rafters are combined with C-purlins to distribute loads more efficiently.

- Typical C-purlin span: 1.0 – 1.5 m, depending on roof design.

- Rafters provide the main load-bearing structure, while purlins support roofing sheets between rafters.

- Proper design of both rafters and purlins ensures long-term durability and cost efficiency.

How far apart should rafters be for a metal roof?

Common spacing is 12″, 16″, 19.2″, or 24″ on center. The choice depends on span, load, and climate.

Can metal roofing be installed directly on rafters?

Yes, but additional support such as purlins or underlayment may be required for durability and insulation. (See section: Can You Put Metal Roofing Directly on Rafters).

What is the difference between rafter spacing and purlin spacing?

Rafters are the main sloped beams that carry roof loads. Purlins are horizontal members placed across rafters to support roof panels. Both must be designed together.

Metal Roof Rafter Insulation

Roof rafter insulation is essential in steel buildings. It prevents heat loss, controls condensation, and improves energy efficiency. Without proper insulation, metal roofs can suffer from moisture buildup, rust, and reduced lifespan.

Common Insulation Options for Steel Rafters

| Insulation Type | Advantages | Limitations | Best Use Cases |

| Spray Foam | Seamless coverage, excellent thermal protection, prevents condensation | Higher cost, requires professional installation | Industrial buildings, cold or humid regions |

| Batt Insulation | Affordable, easy to install, fits between rafters | Lower R-value, may leave gaps if not fitted properly | Small warehouses, residential steel structures |

| Rigid Board Insulation | High performance, durable, adds structural strength | More expensive, harder to cut and fit | Large-span PEB projects, energy-efficient buildings |

Key Considerations for Steel Roof Rafter Insulation

- Moisture Control: Always use a vapor barrier to stop condensation in humid climates.

- Ventilation: Ridge and soffit vents improve airflow and maintain insulation performance.

- Durability: High-quality materials such as rigid boards last longer and reduce maintenance.

At SteelPRO PEB, our prefabricated steel buildings are designed with integrated insulation systems. This ensures:

- Energy efficiency and compliance with green building standards.

- Reduced condensation and rust risks in steel rafters.

- Tailored insulation solutions for different climates and load requirements.

Whether you need spray foam, batt, or rigid board insulation, SteelPRO PEB provides factory-direct solutions to ensure long-lasting steel roof performance.

How to Cut Steel Roof Rafters

Cutting steel roof rafters requires precision, the right tools, and strict safety practices. Unlike wood rafters, steel rafters must be measured and cut with advanced equipment to ensure accuracy and durability.

Step 1: Planning and Measuring

- Measure the roof span and slope with a laser tool or level.

- Mark dimensions carefully, as errors will affect roof alignment.

- Choose the correct steel grade, typically Q235 or Q345, for strength and compliance with building standards.

Step 2: Materials and Tools

- CNC plasma cutter: for precise cuts on thick steel.

- Fiber laser cutter: for high-speed, clean cuts.

- Metal saws: for smaller adjustments.

- Protective gear: gloves, goggles, helmets for safety.

Step 3: Cutting the Rafters

- Mark cut lines clearly on the steel.

- Use steady, controlled motions with cutting tools.

- For complex angles, start with small cuts and adjust gradually.

Step 4: Finishing and Protection

- Smooth sharp edges with a grinder.

- Apply anti-rust coating or galvanization for long-term durability.

- Store cut rafters in a dry, ventilated space before installation.

Step 5: Safety First

- Work in a ventilated area to avoid fumes.

- Secure steel pieces firmly before cutting.

- Follow safety protocols for welding and cutting equipment.

At SteelPRO PEB, rafters are factory-cut with CNC and laser machines. This ensures:

- Precision: every cut meets international standards.

- Speed: faster project timelines with pre-cut rafters.

- Wholesale Supply: direct from the factory, ISO and CE certified.

Save time and reduce risk by choosing factory-prepared steel rafters from SteelPRO PEB, ready for installation on-site.

Can You Put Metal Roofing Directly on Rafters?

Yes, you can install metal roofing directly on steel rafters, but only if certain conditions are met. Skipping these steps can lead to condensation, rust, or structural problems.

Key Conditions for Direct Installation

- Insulation: Proper insulation prevents condensation. Spray foam or rigid board insulation is recommended for steel structures.

- Ventilation: Ridge vents and soffit vents allow moisture to escape and extend roof life.

- Support Layers: In most prefabricated steel buildings, C-purlins or an underlayment layer are installed between rafters and panels. This ensures better load distribution and longer durability.

- Fasteners: Use corrosion-resistant screws and washers to keep roofing panels secure under wind and weather stress.

Can I put metal roofing directly on rafters without purlins?

Yes, but it’s not always recommended. Adding purlins improves load distribution and increases roof lifespan.

Do I need insulation under metal roofing?

Yes. Insulation prevents condensation and protects rafters from rust.

What happens if ventilation is missing?

Trapped moisture may cause corrosion, mold, or reduced insulation performance.

At SteelPRO PEB, we supply factory-designed roof systems that integrate:

- Steel rafters, purlins, and metal roofing sheets.

- Pre-installed insulation and ventilation options.

- ISO- and CE-certified materials for durability and safety.

By choosing SteelPRO PEB’s factory-direct roofing systems, you save time on installation and ensure long-term performance backed by professional design.

If you’re exploring how a steel roof system is designed and composed to complement these factors, check out our article on Steel Roof System: Composition & Design Points.

Roof Rafters vs. Steel Trusses

Both steel rafters and steel trusses support roofs, but they differ in design, span, and application. Choosing the right option depends on your project’s size, budget, and functional needs.

| Aspect | Steel Rafters | Steel Trusses |

| Design Flexibility | Highly customizable for complex roof shapes | Fixed triangular design, less adaptable |

| Span Capacity | Best for small to mid-span roofs | Ideal for very long spans without interior supports |

| Load Distribution | May require extra bracing for large spans | Pre-engineered to distribute loads efficiently |

| Installation | Requires precise cutting, welding, or bolting | Faster to install, delivered pre-assembled |

| Space Usage | Leaves more open interior space | May reduce usable interior height |

| Cost | Higher in custom projects | More cost-efficient for simple, large spans |

| Maintenance | Easier to modify or repair | Harder to adjust once installed |

When to use rafters vs. trusses:

Steel Rafters: Best for factories, workshops, and commercial buildings that require flexible roof design and open space for modifications.

Steel Trusses: Best for warehouses, logistics centers, and stadiums that need long spans without interior columns.

At SteelPRO PEB, we manufacture both steel rafters and trusses, designed according to international standards (ISO, CE). Our engineering team helps you:

- Choose the right option based on span, load, and cost.

- Get factory-direct supply with CNC cutting and automated welding.

- Ensure quick, safe installation with professional design support.

Whether your project requires custom rafters or long-span trusses, SteelPRO PEB provides a certified solution tailored to your building needs.

Related Reading: Truss vs Rafter: Choosing the Right Roof Support System

Our Perspective as a Prefabricated Steel Structure Manufacturer

Every steel building stands or falls on its rafters. Cut wrong, spaced wrong, or undersized, and the whole structure pays the price. That is why at SteelPRO PEB, rafters are never treated as just components—they are engineered, produced, and delivered as the foundation of reliability.

We don’t hand you a catalog; we deliver precision. From Q235/Q345 certified steel to CNC and laser processing, every rafter leaves our factory with one promise: it will carry the load it was designed for. Whether you build a warehouse in snow country or a logistics hub in the tropics, our rafters arrive ready, matched to span, climate, and code.

This is the difference between information and certainty. Others tell you “how to space” or “how to cut.” We ship rafters that already solve those questions.

If your project demands rafters you can trust—not just in design, but in delivery—talk to SteelPRO PEB. Factory-direct, certified, and built to last.