Metal roofing has become a staple in modern construction, admired for its durability, energy efficiency, and sleek look. One key component that’s often overlooked is —expansion joints. These unsung heroes are key to keeping your metal roof performing at its best, especially when faced with environmental shifts and structural movements. In this article, we’ll dive into why expansion joints matter, how to design and install them properly, and share some tips for maintaining them to ensure your roof stands the test of time.

What is Expansion Joint?

An expansion joint is a specially designed assembly used to join parts of a structure while safely absorbing the expansion and contraction caused by temperature fluctuations. These joints are essential for accommodating movement due to thermal changes and structural shifts. Without expansion joints, metal roofs may experience stress, leading to cracks, leaks, or even structural failure. In essence, expansion joints act like the “shock absorbers” of a roofing system, allowing the roof to flex and move without compromising its overall integrity.

Types of Expansion Joints

Expansion joints come in various types, each designed to suit specific application requirements:

- Surface-Mounted Expansion Joints: These are visible and often used in retrofitting existing roofs. They provide flexibility and ease of installation, making them ideal for upgrades.

- Concealed Expansion Joints: Hidden within the roofing system, these joints maintain a seamless appearance while offering effective movement accommodation.

- Modular Expansion Joints: Perfect for large-scale projects, these joints can handle significant movement and are highly durable, making them suitable for expansive roof areas.

- Metal Panel Expansion Joints: Made from materials like galvanized steel or aluminum, these joints consist of two metal panels with a gap filled with flexible sealants, allowing for expansion and contraction. These joints are frequently utilized in industrial and warehouse structures.

- Sliding Expansion Joints: Featuring a track and slider system, these joints allow for large shifts in roof movement, offering excellent flexibility for roofs with substantial temperature fluctuations.

Materials Matter

Expansion joints are constructed from materials like rubber, metal, and foam, selected for their flexibility, durability, and ability to withstand weathering. For example, EPDM rubber is a popular choice due to its excellent thermal and UV resistance.

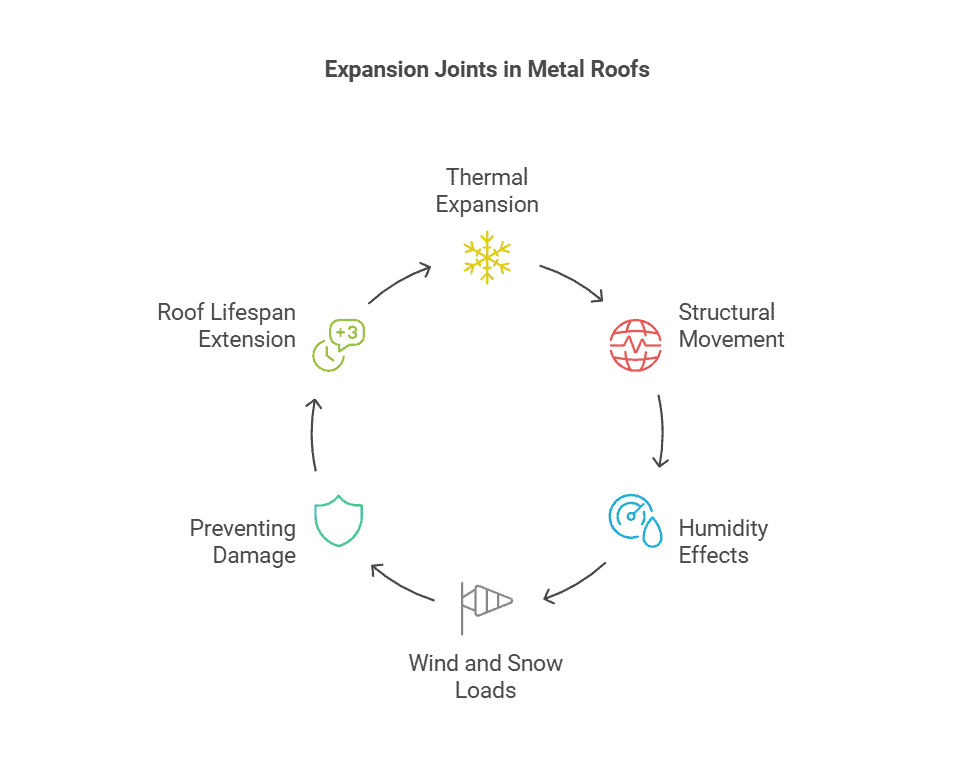

Why Metal Roofs Need Expansion Joints

Metal roofs are tough, but they still need space to breathe. Expansion joints let the roof flex with natural forces, helping to prevent damage from stress and environmental changes. Let’s dive into why these joints are a must-have!

Thermal Expansion and Contraction

Steel roofs undergo expansion and contraction as a result of changes in temperature. Such motion may result in buckling or distortion if roof expansion joints are absent, compromising the roof’s structural stability. A metal roof may undergo substantial dimensional shifts in areas with extreme temperature variations. Roof expansion joints act as a buffer, allowing the roof to move freely without causing damage.

Structural Movement

Buildings are not static. Factors like settlement, wind pressure, and seismic activity can cause shifts in the structure. Over time, even minor movements can accumulate, leading to stress points in the roof. Expansion joints allow for these shifts, protecting both the roof and the structure from harm. In earthquake-prone areas, they are critical for absorbing dynamic forces that could otherwise tear a roof apart.

Humidity and Moisture Effects

Humidity changes can also cause subtle but significant dimensional changes in metal roofs. In high-humidity environments, metal absorbs moisture and expands slightly, while dry conditions cause it to contract. Over time, these repeated cycles can result in cumulative stress. Expansion joints offer the essential flexibility to adapt to these changes, maintaining the roof’s stability and functionality.

Wind and Snow Loads

Wind and snow exert both dynamic and static forces on a roof. Strong winds create horizontal pressure, causing the roof to vibrate or shift, while snow accumulation adds vertical weight. These forces can lead to micro-deformations in the metal panels. Expansion joints act as a buffer, allowing the roof to adjust to these loads without being overly constrained, preventing stress concentrations that could lead to cracks or other damage.

Preventing Damage

By allowing controlled movement, expansion joints help prevent issues like cracking, leaks, and fastener failure. This extends the roof’s durability while reducing upkeep costs over time. For example, in a commercial building with a large metal roof, properly installed expansion joints can prevent costly repairs caused by stress-induced damage.

The Bigger Picture

Expansion joints are more than just structural components; they are critical to the long-term health of your metal roof. They work together with other roofing elements to provide overall flexibility and durability, ensuring the roof can adapt to environmental stresses without losing integrity. Regular inspection and proper maintenance of these joints can help avoid expensive repairs, improve energy efficiency, and extend the overall lifespan of the roofing system.

Related Reading: Steel Roof System: Composition & Design Points

Design Considerations for Expansion Joints

When designing metal roof expansion joints, factors like placement and materials are key to ensuring durability and performance. Here’s what to consider:

Location Matters

Expansion joints should be placed in areas prone to movement, like roof edges, ridges, and valleys. This placement ensures the roof can handle stress and perform well over time.

Sizing and Spacing

The size and spacing of joints depend on roof dimensions, material, and climate. In areas with extreme temperature changes, joints may need to be closer together to allow for more movement.

Integration with the Roofing System

Metal roof expansion joints must work well with other roofing elements, like flashing and insulation. Poor integration can lead to leaks or damage, so it’s crucial to ensure all components fit together seamlessly.

Roof Slope Considerations

Roof slope impacts water runoff. Steeper roofs require joints with better waterproofing, while flatter roofs need joints that can handle standing water to avoid sealant damage.

Corrosion Resistance

Since metal roofs face outdoor conditions, expansion joint components should be made of galvanized or aluminized steel, or treated with protective coatings to prevent rust and extend lifespan.

Weatherproofing and Sealing

Effective sealing is essential to block water intrusion, which can lead to corrosion and leakage. Use durable, flexible sealants like silicone or polyurethane can handle temperature changes, UV exposure, and moisture. Regularly check and replace seals to ensure long-lasting protection and maintain your roof’s energy efficiency.

Related Reading: Steel Roof Truss Design: Key Considerations and Expertise

Installation of Expansion Joints

Pre-Installation Planning

A successful installation starts with careful planning and preparation. We recommend a thorough site evaluation to consider factors like design, movement, and climate for optimal performance. This proactive approach prevents future problems and ensures your roof is equipped to tackle any challenges.

Step-by-Step Installation

The installation process varies depending on the type of expansion joint, but it generally involves:

- Preparing the Surface – Ensure that the area where the expansion joint will be placed is clean, dry, and free of debris. This is crucial for proper adhesion and sealing.

- Positioning the Joint – The expansion joint must be accurately placed in a location that allows it to perform its function effectively. This may include aligning it with the natural movement points of the roof.

- Securing and Sealing the Joint – Once in place, the joint needs to be securely fastened and sealed to prevent water infiltration. Proper sealing is critical to ensure the joint’s durability and the roof’s overall waterproofing.

Common Installation Mistakes

While the installation of expansion joints might seem straightforward, there are a few common errors to be mindful of:

- Improper Sealing – A major issue is failing to properly seal the joint, which can lead to leaks and water damage over time. Sealing materials need to be compatible with both the expansion joint and roofing material to ensure long-lasting protection.

- Incorrect Spacing – Expansion joints must be spaced correctly to accommodate the roof’s natural movement. Proper calculations based on roof size and expected movement are essential to avoid these issues.

Maintenance and Inspection

Regular Inspections

Routine checks are essential to identify issues like wear and tear or sealant degradation before they become major problems. We recommend conducting inspections of expansion joints at least twice a year, particularly following extreme weather events.

Addressing Common Issues

Leaks and material fatigue are the most common problems. Prompt repairs, such as reapplying sealant or replacing damaged sections, can prevent further damage.

Long-Term Maintenance Tips

To increase the lifespan of your expansion joints, ensure they are kept clean and free from debris. Additionally, ensure that any repairs or modifications to the roof do not compromise the joints’ functionality.

Additional Considerations

Climate and Environmental Factors

In regions with harsh climates, such as extreme heat or cold, expansion joints must be designed to withstand these conditions. For example, in coastal areas, joints should resist corrosion from saltwater exposure.

Building Codes and Standards

Compliance with local building codes is non-negotiable. These standards ensure that expansion joints comply with safety and performance requirements.

Cost Considerations

Although high-quality expansion joints may involve a higher initial investment, they provide long-term savings by minimizing maintenance and repair costs.

Partnering for Excellence in Metal Roofing

We focus on delivering top-tier metal roofing solutions that ensure both durability and performance. Here’s how we can support your upcoming project:

- Custom Metal Roofing Systems: A variety of materials, finishes, and designs to match your needs.

- Advanced Roofing Solutions: Energy-efficient insulation and weather-resistant coatings to boost longevity.

- Expert Installation Services: Certified professionals providing precise and efficient installation.

- Comprehensive Maintenance: Tailored maintenance programs to extend your roof’s lifespan.

We collaborate with trusted industry partners to integrate every roofing component seamlessly. Get in touch with us today to discover more about our products and services, and let us assist you in creating a durable, aesthetically pleasing, and functional roof.