H Beam Steel is one of the most widely used structural components in modern construction and PEB structures. Known for its distinctive H-shaped profile, it delivers high strength, stability, and efficiency in projects ranging from warehouses and industrial plants to bridges and high-rise buildings.

In this guide, you will learn:

- What an H Beam is and how it differs from other beam types.

- Applications of H Beams in primary and secondary structural support.

- Advantages such as load-bearing capacity, buckling resistance, and cost efficiency.

- Standard sizes from 100×100 mm for 1-storey houses to 300×300 mm for heavy-duty projects.

- H Beam vs I Beam: key differences and when to choose each.

- How to choose the right structural beam for your project.

As a certified steel structures and PEB manufacturer, SteelPRO PEB provides factory-direct H Beam supply, wholesale solutions, and customized production that meet ISO and CE international standards. With more than 1,000 global projects, we ensure both technical expertise and cost-effective solutions for your construction needs.

What is an H-Beam?

In structural engineering, a beam stands for a horizontal load-bearing member that transfers weight across a span. An H-Beam, also called a wide flange beam, is a type of steel beam with a distinctive H-shaped cross-section.

Its structure includes:

- Two wide horizontal flanges: offering a large surface area for load distribution.

- One vertical web: providing strong resistance to shear forces.

Compared with an I-Beam, H-Beams have wider flanges and thicker webs, which makes them stronger and more stable for heavy-duty applications such as industrial buildings, PEB structures, and long-span frameworks.

Manufacturing process:

H-Beams are produced through rolling or welding, ensuring strength, durability, and precision. This design makes them highly resistant to bending and buckling, which is why they are widely chosen in modern construction projects.

Applications of H-Beams in Steel Structures

H Beam Steel is one of the most common components in modern steel and PEB structures, thanks to its strength, wide flange design, and stability. It is used in both primary support and secondary support, ensuring safety and efficiency in construction projects.

Primary Support

H-Beams often serve as the main load-bearing elements in:

- Vertical Columns: providing the structural framework for high-rise buildings.

- Primary Girders: spanning long distances in bridges and heavy industrial platforms.

- Main Framework: forming the backbone of warehouses, factories, and crane runways.

Secondary Support

H-Beams also play a key role in distributing loads and stabilizing structures:

- Floor Beams: supporting slabs and transferring weight to primary columns.

- Bracing Elements: improving resistance to wind and seismic forces.

- Roof Trusses: reinforcing large-span roofs in commercial and industrial buildings.

- Mezzanine Floors: creating extra usable space without affecting overall stability.

For contractors and developers, Construction H Beams are available in a wide range of sizes and grades. SteelPRO PEB, as a certified steel structures manufacturer, offers:

- Factory-direct supply of H-Beams for construction projects.

- Customization to meet specific engineering standards and load requirements.

- Wholesale solutions for industrial warehouses, PEB buildings, and infrastructure projects.

With over 1,000 global projects completed, SteelPRO ensures that every H-Beam delivered meets ISO and CE standards, guaranteeing both strength and cost efficiency for your project.

Advantages of H-Beams in Steel Structures

H Beam Steel is widely preferred in construction and PEB projects because it combines strength, efficiency, and cost-effectiveness. Compared with other beam types, H-Beams deliver several clear advantages:

- High Strength-to-Weight Ratio: supports heavy loads without unnecessary material usage.

- Superior Load-Bearing Capacity: wide flanges distribute weight evenly, suitable for both vertical and horizontal applications.

- Resistance to Buckling: thicker web and flanges improve stability in tall buildings and long-span structures.

- Versatility: can be used as columns, beams, or bracing elements across industrial, commercial, and residential projects.

- Ease of Fabrication & Installation: standardized shapes allow efficient cutting, welding, and assembly, saving time and cost.

- Cost-Effectiveness: durable design ensures long service life, reducing long-term maintenance costs.

Choosing factory-direct H Beams from SteelPRO PEB ensures not only these structural benefits but also compliance with ISO and CE certifications, wholesale pricing, and reliable quality for PEB structures and global construction projects.

Common Standard Sizes of H-Beams

H Beam Steel is produced in a wide range of sizes to meet different structural requirements. Dimensions are defined by height, flange width, and web thickness. The most common sizes include:

| H-Beam Size | Typical Application |

| 100 × 100 mm | Small structures, residential houses, 1-storey buildings |

| 150 × 150 mm | Light industrial projects, residential construction |

| 200 × 200 mm | Medium-sized buildings, warehouses, commercial facilities |

| 300 × 300 mm | Heavy-duty projects such as bridges, high-rise buildings, and industrial plants |

Small H-Beams like 100 × 100 mm are ideal for residential and low-rise projects, including 1-storey houses. Medium sizes such as 200 × 200 mm are commonly used in warehouses and steel workshops. Large H-Beams like 300 × 300 mm are designed for bridges and long-span industrial structures.

As a certified PEB structures manufacturer, SteelPRO PEB provides factory-direct H Beams in all standard sizes, and also offers customization to meet project-specific load requirements and international standards (ISO, CE).

Other Common Types of Steel Beams

Besides H Beams, several other steel beams are commonly used in construction, each designed for specific applications:

- I-Beam: Narrower flanges than H-Beam, often used for vertical load support in residential and light commercial buildings.

- W-Beam: A variant of H-Beam with slightly different proportions, suitable for heavy construction projects.

- C-Beam (Channel Beam): C-shaped profile, typically used in frames, supports, and connections.

- T-Beam: T-shaped design, often applied in bridges and floor systems where one side needs to be flush with the surface.

As a certified steel structures manufacturer, SteelPRO PEB provides not only H-Beams but also I-Beams, C-Beams, T-Beams, and other structural components, ensuring a complete supply solution for diverse construction and PEB projects.

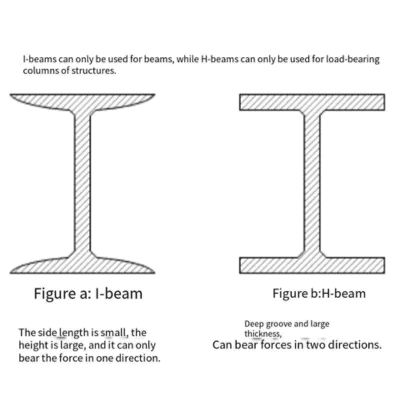

H-Beam vs I-Beam: What’s the Difference?

The main difference between H Beams and I Beams is the flange width and load capacity. H Beams have wider flanges and thicker webs, making them stronger and better suited for heavy-duty projects. I Beams are lighter with narrower flanges, commonly used in residential and light commercial construction.

| Feature | H-Beam | I-Beam |

| Cross-Section | Wide flanges, H-shaped | Narrow flanges, I-shaped |

| Flange Width | Wider, better load distribution | Narrower, mainly for vertical loads |

| Load Capacity | High, supports both vertical & horizontal loads | Moderate, best for vertical loads |

| Resistance to Buckling | Stronger, stable for long spans | Weaker, may need extra support |

| Applications | High-rise buildings, bridges, PEB structures, heavy industry | Residential buildings, elevators, lighter structures |

| Cost Efficiency | More economical for large projects | Lower cost for small projects |

For PEB and industrial steel structures, SteelPRO PEB recommends using H Beams due to their superior load capacity, longer span capability, and factory-direct supply with ISO and CE certifications.

What Structural Beam Should You Choose?

The right beam depends on your project:

- Heavy-duty projects (PEB structures, warehouses, bridges): choose H Beam for strength, long spans, and safety.

- Light projects (houses, small commercial buildings): choose I Beam for a lighter, economical option.

- Special needs (frames, floors, connections): use C Beams or T Beams as complements.

Not sure which beam is right? That’s where SteelPRO PEB comes in. As a certified manufacturer with 1,000+ global projects, we supply factory-direct beams with ISO/CE certifications—and our engineers guide you to the best choice.

Tell us your project. We’ll tell you the beam—and the factory-direct price.

What does “beam” stand for in construction?

A beam in construction is a horizontal load-bearing member that transfers weight across a span. An H Beam is one of the strongest types, widely used in PEB and industrial structures.

What sizes of H Beams are available?

Common sizes include 100 × 100 mm, 150 × 150 mm, 200 × 200 mm, and 300 × 300 mm.

- 100 × 100 mm: small structures and light residential projects.

- 200 × 200 mm: warehouses and medium commercial buildings.

- 300 × 300 mm: bridges, factories, and heavy-duty projects.

SteelPRO PEB manufactures all standard sizes and provides custom sizes on request.

Which H Beam size is suitable for a 1-storey building?

For most 1-storey buildings or residential houses, 100 × 100 mm to 150 × 150 mm H Beams are commonly used. The final choice depends on design load and span.

SteelPRO engineers can recommend the exact size for your project and supply it factory-direct.

What is the difference between H Beam and I Beam?

- H Beam: wider flanges, thicker web, stronger load capacity, suitable for heavy-duty and PEB projects.

- I Beam: narrower flanges, lighter design, often used in residential and smaller structures.

For large-scale or industrial projects, SteelPRO recommends H Beams with ISO/CE certified quality and wholesale pricing.

Does SteelPRO supply H Beam (Besi H) for international markets?

Yes. Known as “Besi H” in Indonesia, SteelPRO supplies H Beams to Southeast Asia, Africa, and over 30 countries worldwide.

- Factory-direct supply

- International shipping

- Certified steel (ISO, CE)

Contact us to get a Besi H factory-direct quotation for your project.