Understanding the difference between a girder and a beam is essential for anyone involved in structural or steel building design. While both are load-bearing members, their roles, capacities, and placement within a structure are not the same.

This guide explains what a girder is and how it differs from a beam, outlining their key structural differences, such as load path, material use, and span. You’ll also learn when each should be used, based on project type and engineering requirements, and discover practical examples of how these elements work together in pre-engineered steel buildings (PEB). Finally, we’ll share insights on how to choose the right component to ensure safety, efficiency, and long-term performance.

At SteelPRO PEB, our engineers and fabrication teams apply over a decade of field experience and internationally certified standards to design and produce steel structures where every girder and beam performs as intended — ensuring reliability from factory to foundation.

What is a Girder?

A girder is a large, primary structural element used to support the weight of beams and other structures, distributing loads across a wide area. It is typically the main horizontal support in larger buildings or bridges. Girders bear the brunt of the load from the floors or roof, transferring this weight to vertical supports such as columns or walls. They are crucial in maintaining the stability and strength of the entire structure.

Materials and Applications of Girders

Girders are made from various materials depending on structural demands and span requirements.

| Material | Typical Applications |

| Steel | Widely used in large commercial buildings, industrial structures, and bridges for its strength and long-span capacity. |

| Reinforced Concrete | Common in bridges, overpasses, and multi-story buildings where heavy loads and rigidity are required. |

| Wood | Occasionally used in small-scale or residential buildings with lighter loads. |

In modern steel structures, especially in large-span or pre-engineered buildings, girders serve as the backbone of the framing system, supporting beams, columns, and other load-bearing members.

What is a Beam?

A beam is a horizontal structural component designed to support loads applied perpendicular to its axis. Beams transfer these loads from floors, roofs, or other structural parts to vertical supports such as columns or walls. In most buildings, beams act as secondary structural members, working together with girders to distribute loads safely and maintain the stability of the overall framework.

Materials and Applications of Beams

Beams are made from different materials based on project size, span, and load conditions.

| Material | Typical Applications |

| Wood | Common in residential houses and small structures to support roofs or floors. |

| Steel | Used in commercial and industrial buildings where strength and long-span performance are needed. |

| Reinforced Concrete | Applied in multi-story buildings, bridges, and heavy-duty construction requiring durability and stiffness. |

| Composite Materials | Combine steel and concrete for improved load-bearing performance and reduced deflection. |

In pre-engineered steel structures, beams often serve as secondary framing members that connect to girders, roof purlins, or floor systems, helping maintain load distribution and structural balance.

Key Differences Between Girders and Beams

In building structures, girders and beams work together as key load-bearing elements. Girders serve as the primary members, supporting and distributing loads from multiple beams, while beams act as secondary components that transfer loads from floors or roofs to the girder. Together, they form a complete load path that ensures the overall stability and safety of the structure.

Size and Load-Bearing Capacity

Girders are generally larger and stronger than beams. They are designed to support heavy loads across long spans and carry the combined weight of multiple beams.

Beams, by contrast, are smaller secondary members that support localized loads such as floor slabs or roof panels.

In short, a girder supports beams, while a beam supports smaller structural elements.

Placement and Structural Role

Girders serve as the main horizontal supports in a structural system and are usually positioned on top of columns or other vertical supports. They distribute the building’s overall weight to the foundation.

Beams are typically placed on or between girders, carrying secondary loads from floors, roofs, or decks.

This hierarchical arrangement defines the structural order within most steel and concrete frameworks.

Support and Span Differences

Girders are engineered to handle longer spans and heavier loads, often found in bridges, factories, and high-rise buildings. Their design allows them to transfer loads efficiently across wide distances between supports.

Beams, on the other hand, typically span shorter distances and support localized structural sections such as floors or roofs.

Material and Design Differences

Girders are commonly made of high-strength steel or reinforced concrete, enabling them to resist large bending moments and shear forces.

Beams, while also strong, may be made from a broader range of materials including wood, composite steel-concrete, or light-gauge steel, depending on load demands.

Girders are designed to distribute loads from beams to columns, while beams primarily transfer floor or roof loads to girders.

Load Transfer Path

Every structure relies on a clear load transfer system. In typical building design, the load path follows this sequence:

Slab → Beam → Girder → Column → Foundation

This ensures that the entire structure functions as a unified system, preventing stress concentration and structural instability.

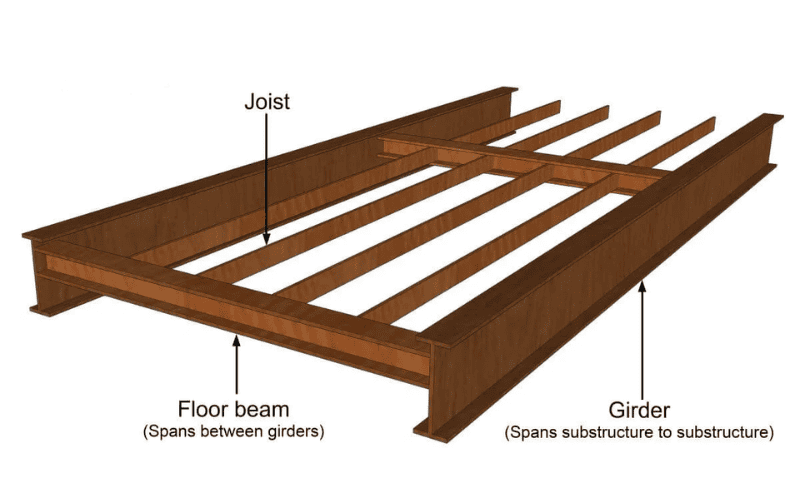

Girder vs Beam vs Joist: Understanding Structural Hierarchy

In many steel and concrete buildings, the terms girder, beam, and joist describe members at different structural levels:

| Component | Function | Typical Span | Load Role |

| Girder | Primary horizontal support that carries beams and transfers load to columns | Long | Main load distributor |

| Beam | Secondary member supporting floors or roofs and transferring load to girders | Medium | Secondary load carrier |

| Joist | Small, closely spaced members supporting floor decks or roof sheathing | Short | Local load distributor |

This hierarchy clearly defines how structural loads flow downward through a building, forming the foundation of both conventional and pre-engineered steel structures.

When to Use a Girder vs. a Beam

Selecting between a girder and a beam depends on the structure’s span, load requirements, and design complexity. In general, girders are used where heavy loads or large spans must be supported, while beams are employed in smaller or secondary framing areas.

Use a Girder When

- Large spans and heavy loads are involved, such as in bridges, industrial buildings, and multi-story structures.

- The structure requires primary horizontal support that carries other beams or major load-bearing members.

- The project demands load distribution from multiple secondary components to main columns or walls.

Use a Beam When

- The span length is shorter and the load requirements are moderate.

- The beam serves as a secondary support member within a floor, roof, or ceiling framing system.

- The structure does not require the heavy-duty strength of a girder but still needs rigidity for local load transfer.

Practical Engineering Scenarios

In modern Pre-Engineered Steel Buildings (PEB) and industrial steel frameworks:

- Girders act as the main framing members, carrying roof beams, trusses, or crane girders, and transferring major loads to the columns.

- Beams serve as secondary members, connecting to girders and supporting roof purlins, floor joists, or mezzanine decks.

- This configuration ensures efficient material usage, fast assembly, and balanced load transfer throughout the structure.

What is the difference between a box girder and an I-beam?

A box girder has a hollow rectangular or square cross-section, offering high torsional rigidity—ideal for bridges and long-span applications. An I-beam, shaped like the letter “I,” features a web and flanges that provide excellent bending resistance for building frames and moderate spans.

How is a girder different from a secondary beam?

A girder is a primary support member that carries other beams or structural components, while a secondary beam is smaller, supporting floors, ceilings, or roofs and transferring loads to the girder. This distinction ensures an efficient load path and prevents excessive structural stress.

Choosing the Right Girder or Beam for Safe Steel Structures

Choosing between a girder and a beam is more than a matter of terminology. It determines how safely and efficiently a structure performs over time. A clear understanding of their respective roles helps engineers and builders design stable frameworks where every component functions as intended.

Proper alignment between girders and beams ensures uniform stress distribution and minimizes bending moments in critical sections. Understanding this relationship allows designers and contractors to make data-driven decisions that reduce material waste and enhance long-term reliability.

At SteelPRO PEB, each structure is engineered under internationally recognized codes such as AISC and Eurocode, combining precise fabrication with over a decade of field-proven expertise. This integration of theory and practice ensures every steel element—whether girder or beam—achieves both structural integrity and design efficiency, supporting safe, high-performance buildings worldwide.