Fascia in steel structures plays a vital role in protecting roof edges, sealing joints, and improving a building’s overall appearance. It’s the metal strip fixed along the roofline — often where the roof meets the wall — that prevents water intrusion, wind uplift, and corrosion. In pre-engineered buildings (PEB), fascia also supports gutters and defines the building’s architectural finish.

This guide explains everything you need to know:

- What fascia is and how it functions as a structural and aesthetic element in PEB systems;

- The common types of fascia and how to choose the right profile for industrial or commercial projects;

- Material comparison between galvanized steel, aluminum, and stainless fascia — helping you balance cost, durability, and performance;

- Why fascia is essential to protecting and extending the lifespan of steel structures.

Whether you’re designing a factory, warehouse, or modern steel building, these insights will help you select a fascia system that’s both functional and built to last.

What Is Fascia in Steel Structures?

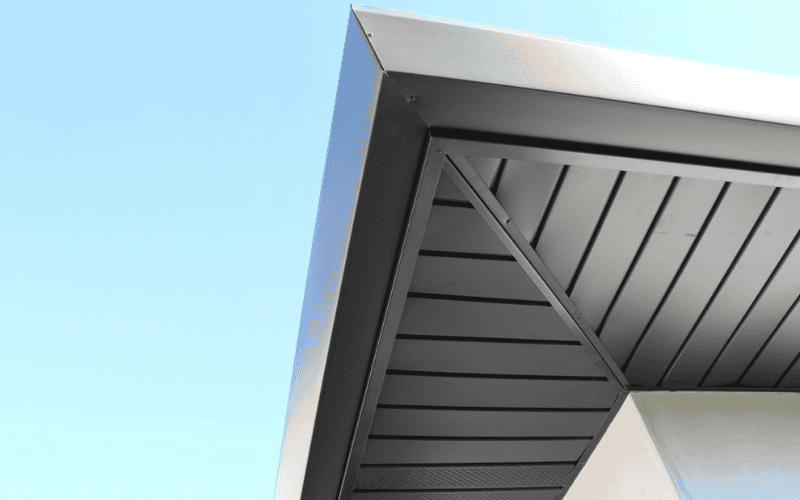

Fascia board is a small but critical part of steel and PEB buildings. It is typically located at the roof edge, where it covers the exposed steel beams or purlins, creating a clean and continuous roofline. In Pre-Engineered Building (PEB) systems, fascia panels are connected to eave struts or purlins to protect the roof edge from wind uplift, corrosion, and water penetration while maintaining a professional architectural finish.

Typically installed at the outermost part of the roof, fascia connects the roofline to the walls and serves several important functions:

- Keeps Water Out: Blocks rain from entering gaps between the roof and walls, preventing corrosion and extending building life.

- Stops Wind Damage: Reinforces the roof edge against strong winds, ensuring stability in large-span steel structures.

- Supports Gutters: Provides a solid base for gutter installation, ensuring proper drainage.

- Improves Fire Resistance: Can be coated with fire-resistant finishes to slow flame spread.

- Enhances Appearance: Covers exposed structural edges, creating a polished, professional look.

- Prevents Pests: Seals off gaps to keep birds and insects out of the roof area.

In short, fascia is a functional and architectural component that strengthens and protects the building envelope. Without it, a structure is vulnerable to water damage and visual imbalance, much like a frame missing from an otherwise complete design.

Common Types of Fascia and How to Choose the Right One

Fascia board isn’t a one-size-fits-all component. Different types are designed to meet diverse structural, aesthetic, and environmental requirements. Below are the most common fascia types used in PEB and steel structures, along with their key features and ideal applications.

| Type | Key Features | Best Applications |

| Standard Vertical Fascia | Straight-line profile, stable and cost-effective | Industrial buildings, warehouses, logistics centers, steel workshops |

| Ventilated Fascia | Built-in perforations for improved airflow and reduced condensation | Humid or rainy regions, equipment rooms |

| Curved / Decorative Fascia | Arched or wavy design for enhanced aesthetics | Commercial buildings, exhibition halls, modern industrial facilities |

| Insulated Fascia | Integrated thermal insulation to minimize heat transfer | Cold storage warehouses, temperature-controlled logistics centers |

| Bottom Curved Fascia | Smooth visual transition at the lower edge | Commercial buildings, modern factories |

| Top and Bottom Curved Fascia | Dual curved edges for premium architectural appeal | High-end commercial projects |

| Parapet Fascia | Extends wall to roofline for flat-roof appearance | Shopping malls, industrial and office complexes |

| Aluminum Fascia | Lightweight, corrosion-resistant, and long-lasting | Coastal or humid steel structures |

| Galvanized Steel Fascia | Durable, affordable, excellent for large-scale production | Factories, warehouses, logistics centers |

| Stainless Steel Fascia | Premium, corrosion-proof, minimal maintenance | Marine structures, high-end industrial projects |

At SteelPRO PEB, fascia frame details and customized profiles can be fabricated directly from engineering drawings. Our production facility supports precision CNC cutting and automated bending, ensuring accuracy and consistency across every fascia component, ideal for industrial workshops, warehouses, and commercial buildings.

When selecting fascia board, consider these three key factors:

1. Climate Conditions

- Humid/Coastal/Industrial Environments → Aluminum, Stainless Steel, or Galvanized Steel Fascia for better corrosion resistance.

- High-Temperature Facilities → Insulated Fascia to reduce heat transfer and improve energy efficiency.

- Rain-Prone Areas → Ventilated Fascia to prevent condensation buildup and extend durability.

2. Building Purpose

- Industrial Facilities, Warehouses, Logistics Centers → Standard Vertical, Ventilated, or Galvanized Steel Fascia for affordability and durability.

- Commercial Steel Buildings → Decorative, Curved, or Parapet Fascia to enhance aesthetics.

- Cold Storage or Temperature-Controlled Spaces → Insulated Fascia to minimize energy loss.

3. Budget Considerations

- Cost-Effective Options → Galvanized Steel Fascia offers the best balance of durability and price.

- Premium, Low-Maintenance Solutions → Aluminum or Stainless Steel Fascia for long-term investment with minimal upkeep.

Fascia Material Comparison & How to Pick the Right One

The material you choose for fascia board affects durability, maintenance, and overall appearance. It’s important to balance environmental conditions, budget, and performance needs. Here’s a breakdown of the most common fascia materials and their pros and cons:

| Material | Pros | Cons | Best For |

| Galvanized Steel | Strong, budget-friendly, easy to fabricate | Needs rust protection, may corrode over time | Industrial plants, warehouses, logistics centers |

| Aluminum | Lightweight, corrosion-resistant, low maintenance | Less impact-resistant, pricier than galvanized steel | Coastal areas, humid environments, commercial buildings |

| Stainless Steel | Extremely durable, corrosion-proof, maintenance-free | Expensive, heavier than other metals | Chemical plants, food processing, marine structures, high-end projects |

| PVC-Coated Steel | UV-resistant, customizable colors, weatherproof | Limited fire resistance, not ideal for extreme heat | Commercial buildings, shopping centers |

| Pre-Painted Galvanized Steel (PPGI) | Long-lasting finish, good corrosion resistance, color variety | Can scratch easily, requires touch-ups if damaged | Offices, industrial buildings, retail spaces |

| Insulated Composite Steel Panel | Built-in thermal insulation, moisture-resistant | Higher cost, requires professional installation | Cold storage, temperature-controlled spaces, healthcare facilities |

All fascia components at SteelPRO PEB are processed using CNC cutting, precision drilling, and automatic welding lines to ensure dimensional accuracy and long-term stability. Every surface undergoes shot blasting and protective coating for enhanced corrosion protection, meeting ISO and CE international standards.

When selecting fascia material, please consider:

1. What’s Your Budget?

- Need a cost-effective option? → Galvanized Steel (affordable but requires maintenance).

- Looking for a long-term investment? → Stainless Steel or Aluminum (higher upfront cost, but minimal upkeep).

2. What’s the Environment Like?

- High humidity, coastal areas, or chemical exposure? → Stainless Steel or Aluminum (top-notch corrosion resistance).

- Hot or temperature-sensitive environments? → Insulated Composite Steel Panels (best for climate control).

- General warehouses and industrial use? → Galvanized Steel or PPGI (solid durability at a reasonable cost).

3. Does Appearance Matter?

- Need custom colors for commercial projects? → PVC-Coated Steel or PPGI (variety of colors and finishes).

- Want a tough, industrial look? → Galvanized Steel or Stainless Steel (functional and durable).

Why Is Fascia Essential for Steel Structures?

Fascia might not be the most visible component of a steel building, but it is one of the most important for structural protection and architectural integrity. Here are the key reasons fascia systems are essential in PEB and steel structure design:

- Prevents Structural Damage: Without fascia, roof edges remain exposed to moisture and wind, causing corrosion and compromising roof integrity over time.

- Reduces Maintenance Costs: Once properly installed, fascia systems minimize future waterproofing and repainting work, lowering long-term maintenance expenses.

- Ensures Code Compliance: Modern fascia assemblies are designed to meet international standards for fire resistance, wind load, and drainage performance.

- Improves Building Value: Professionally finished fascia lines enhance the appearance and perceived quality of the structure, increasing its resale or leasing value.

- Adds Integrated Functionality: Beyond protection, fascia can support lighting, drainage systems, and gutter integration — a common feature in SteelPRO’s industrial fascia systems used in warehouses and manufacturing facilities.

In essence, for PEB and steel buildings, fascia is not an accessory but a structural and aesthetic necessity — providing both engineering protection and visual balance for every project.

Is fascia part of the roof?

Yes. In steel and PEB buildings, fascia is a key part of the roofing system. It is installed along the roof’s outer edge, covering the ends of purlins or rafters. This not only provides a smooth transition between the roof and wall panels but also protects the steel frame from moisture, corrosion, and uplift forces.

What is the difference between fascia and soffit?

Fascia is the vertical panel attached to the roof edge, protecting rafter ends and serving as a mounting base for gutters. Soffit is the horizontal panel placed underneath the eave, connecting the fascia to the wall and improving attic ventilation. In steel structures, fascia focuses on protection and appearance, while soffit focuses on airflow and condensation control.

What is fascia vs. trim?

While fascia is technically a type of trim, it has a specific structural role — covering and sealing the roofline to prevent water ingress and wind lift. Trim, in contrast, includes all finishing components such as corner flashings, ridge caps, and base trims. In engineered steel buildings, fascia panels are load-bearing secondary members, not just decorative elements.

What is fascia in PEB buildings?

In Pre-Engineered Buildings (PEB), fascia panels are integrated into the roof and wall system to create a continuous weather barrier. They are typically fixed to eave purlins or edge beams, forming a clean edge and enhancing both aesthetic value and wind resistance. Fascia also conceals gutter lines and acts as part of the rainwater management system, protecting the steel structure beneath.

Can fascia be customized for steel warehouses or factories?

Absolutely. At SteelPRO PEB, fascia systems can be custom-engineered according to project drawings, including:

- Precise dimensions for alignment with roof and wall panels,

- Curved or ventilated profiles for specific design requirements,

- Pre-coated finishes (galvanized, aluminum, or stainless) for environment-specific protection.

Our design team ensures that every fascia installation is both functional and visually consistent with the building’s steel framework.

Final Thoughts

Fascia is more than an architectural finish, it is a functional edge protection system that directly impacts a steel building’s weatherproofing, corrosion control, and visual uniformity. In PEB structures, fascia forms the critical interface between roof panels and wall cladding, sealing vulnerable joints that would otherwise allow water or wind infiltration.

Engineered Fascia Systems by SteelPRO PEB Manufacturer

At SteelPRO PEB, fascia systems are not treated as decorative trims, but as engineered components integrated into the building envelope. Each fascia panel is designed in coordination with the eave purlins, gutters, and wall panels, ensuring structural continuity and simplified installation. Our automated fabrication lines cut, fold, and coat fascia plates with precision — guaranteeing uniform thickness, tight tolerances, and superior anti-rust performance for long-term exposure.

Because fascia performance depends on both design accuracy and installation quality, we provide complete technical support, including:

- Custom fascia detailing based on PEB drawings and load requirements;

- Optimized drainage and gutter alignment to eliminate leakage risk;

- Corrosion-resistant finishes tested for marine and industrial environments.

Contact SteelPRO PEB to get a project-specific fascia solution — designed, fabricated, and tested to perform as part of your building’s steel structure. Precision fascia, engineered for durability and seamless integration.