As industries continue to choose steel structure factory buildings for their strength and cost-effectiveness, one key element often gets overlooked—the enclosure system. While the steel frame gets most of the attention, it’s the enclosure that really drives the building’s efficiency, insulation, safety, and long-term durability. A well-designed enclosure can make all the difference, saving energy, cutting maintenance costs, and extending your facility’s lifespan. In this article, we’ll walk you through the essentials of enclosure systems for steel factory buildings and explain why choosing the right one is more important than ever.

What Does the Enclosure System of a Steel Factory Building Include?

The enclosure system plays a crucial role in keeping your steel factory building running smoothly and lasting longer. It’s made up of key components like the roof, walls, and insulation layers systems, all working together to boost thermal efficiency, safety, and overall strength.

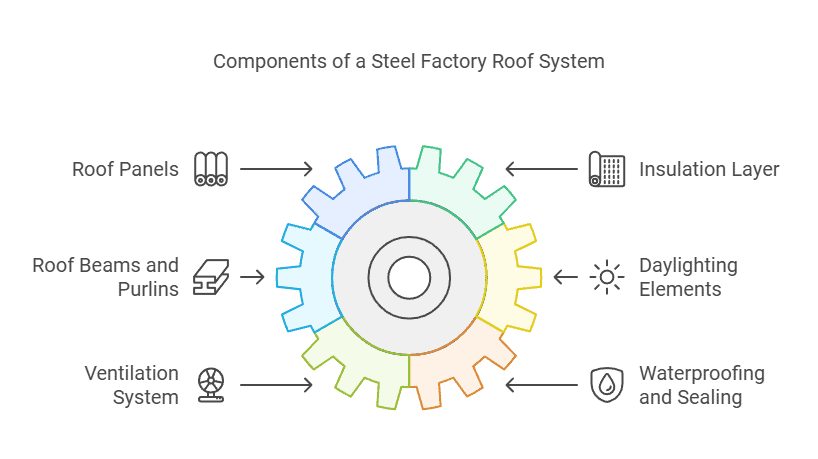

Roof System

The roof system plays a key role in the enclosure of a steel factory, taking on external loads and keeping out rain and water, ensuring the internal environment stays safe and stable.

In a typical steel factory, the roof structure is made from a steel frame, supported by beams and purlins. The following are the other important components that complete the roof structure:

When it comes to materials, the roof is often built using color-coated steel panels or galvanized steel sheets, known for their strength, durability, and easy installation. For areas exposed to harsh weather, SS400 galvanized steel sheets or PPGI with Z275 coating are highly recommended, offering outstanding corrosion resistance and long-lasting performance.

Optional Features for Roof System of a Steel Factory Building

Beyond the basics, there are a few optional features that can make your steel factory’s roof work even harder. These additions help improve lighting, ventilation, and overall comfort, boosting efficiency and creating a better working environment.

Daylighting Features: To let natural light flood the space, daylighting elements like PC or FRP panels are often integrated into the roof, usually as translucent panels or strips. These materials not only cut down energy consumption by reducing the need for artificial lighting but also create a more comfortable and productive atmosphere inside the factory.

Ventilation Options:

For better ventilation, consider incorporating roof vents or ventilation skylights into the roof system. These natural ventilation elements help air circulate freely and regulate indoor temperatures, creating a fresh and comfortable environment. While not every steel factory may include these features, they are highly recommended for factories where airflow and temperature control are important for both comfort and operational efficiency.

For more efficient airflow, mechanical ventilation systems such as exhaust fans or HVAC (Heating, Ventilation, and Air Conditioning) systems can also be added. These systems help to expel hot air, moisture, or fumes, maintaining a fresh, comfortable environment inside the factory.

Wall System

The wall system is a key component in the enclosure of a steel factory building, offering vital protection from external elements and enhancing the building’s thermal performance. It helps maintain a stable internal environment, regulates temperature, and ensures the structure remains secure and durable under various conditions, such as high winds or extreme temperatures.

The Wall System of Industrial Factory:

Wall Panels: Steel factory walls are typically made from metal panels, which offer excellent protection against harsh weather while boosting thermal performance. These panels are typically insulated with rock wool, minimizing heat transfer and helping to maintain a consistent indoor temperature.

Wall beams: Horizontal beams (purlins) and vertical beams (girts) provide support, securing the panels and ensuring stability. They help the structure withstand loads like wind pressure, snow, and other environmental factors, contributing to the building’s strength and durability.

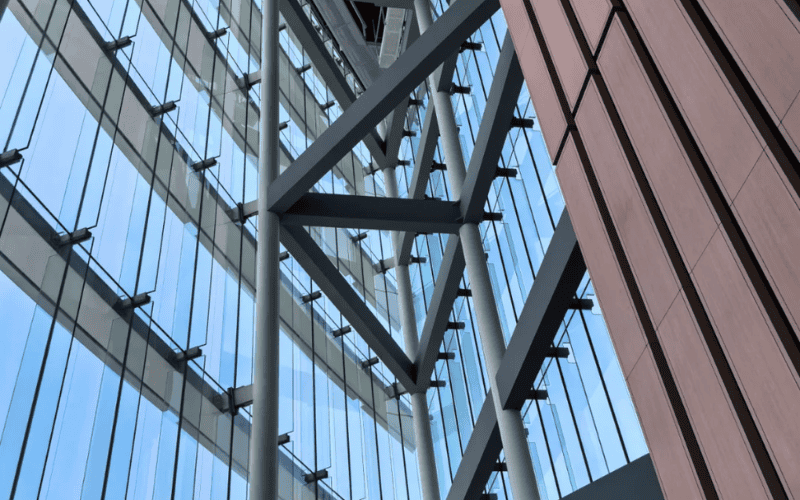

Doors and windows: They are key to the wall system, allowing light and ventilation into the space. Made from aluminum or steel-framed glazing systems, they maintain insulation and security while brightening the interior and improving airflow.

Joints and openings: They are critical for preserving the integrity of the wall system. Properly sealed joints prevent air and water infiltration, ensuring the building stays energy-efficient and safe. The use of high-quality sealants around joints and openings minimizes the risk of leaks, further enhancing insulation and protecting against environmental factors.

We have a variety of high-performance panel options for your wall system needs, including PebSeam, PebWall, SEAMLOCK, Roll-Formed, and Snap-Lock. These panels are built for durability, energy efficiency, and easy installation, giving you the best in protection and thermal performance for your steel factory building.

Insulation and Sealing System

Steel structure Insulation is a critical component of the enclosure system, contributing significantly to energy efficiency, structural protection, and comfort. These materials aid in regulating indoor temperature, preventing water ingress, and improving the overall durability of the building.

1. The Role of Insulation and Sealing

- Energy Efficiency: Insulation minimizes heat transfer, keeping the interior temperature stable. This lowers the demand for heating and cooling, resulting in reduced energy costs.

- Moisture Protection: Sealing materials prevent water infiltration through joints and openings, protecting steel structures from corrosion and extending the life of the building.

- Comfort: Effective insulation and sealing help create a more comfortable indoor environment by eliminating drafts and maintaining steady temperatures.

- Structural Durability: Effective sealing also prevents air leakage, which can lead to water condensation and structural damage over time.

2. Recommended Insulation and Sealing Materials for Steel Factory Enclosures

| Building Component | Recommended Insulation Materials | Recommended Sealing Materials |

| Roof | Glass wool, Polystyrene foam, Rock wool | Waterproof membranes, Silicone sealants |

| Walls | Polyurethane foam, Glass wool, Mineral wool | Butyl rubber sealants, Gaskets, Foam strips |

| Doors/Windows | Extruded polystyrene (XPS), Polyurethane foam | EPDM gaskets, Silicone-based sealants |

| Joints & Openings | / | High-quality silicone sealants, Foam strips |

3. What to Avoid

Not all materials are suitable for steel factory enclosures. Here are some that should be avoided:

- Low-Quality Insulation: Materials like fiberglass batt insulation (without vapor barriers) or low-density foam may not perform well in steel buildings, leading to poor thermal performance and moisture buildup.

- Inadequate Sealing Materials: Low-grade sealants, such as standard acrylic caulks, are not recommended for areas exposed to extreme weather conditions, as they tend to degrade over time and allow air or water infiltration.

Considerations in the Design of Steel Factory Building Enclosure Systems

When designing the enclosure system of a steel factory, there are several factors that must be carefully evaluated to ensure optimal performance, durability, and cost-effectiveness.

Climate Considerations

The local climate is a key factor in selecting materials and shaping the design approach for the enclosure system.

Cold Regions: In colder climates, additional insulation is crucial to minimize heat loss and manage snow loads.

- Materials with higher R-values, like rock wool or expanded polystyrene, are ideal for maintaining a stable indoor temperature while also withstanding the added weight of snow accumulation.

- Properly sloped roofs are also recommended to prevent snow build-up and avoid overloading the structure.

Hot Climates: For factories in hotter regions, ventilation and shading become the top priorities.

- Natural ventilation systems, including roof vents and louvered openings, can greatly enhance airflow and indoor comfort.

- Additionally, reflective coatings or shading elements such as overhangs can minimize heat absorption, keeping the building cooler and lowering the reliance on costly air conditioning.

Wind-Prone Areas: In areas with frequent high winds, strengthened panels and superior sealing are essential to ensure the structural integrity of the factory.

- Panels with high wind resistance, like galvanized steel or composite materials, should be prioritized. Properly sealing all joints and openings is essential to prevent water infiltration and structural damage during storms.

Functionality Requirements

Every factory has unique functional needs based on its production process and storage requirements. Below are expert recommendations derived from our extensive experience in industrial building construction, tailored to meet the specific demands of different factory types.

| Factory Type | Key Design Considerations | Recommended Materials/Features |

| Heavy Machinery | Vibration resistance, structural stability, insulation for temperature control | Reinforced panels, vibration-dampening insulation, multi-layered walls |

| Temperature-Sensitive Storage | Moisture resistance, temperature control, humidity monitoring | High-performance thermal barriers, vapour barriers, smart monitoring systems |

| High-Output Manufacturing | Insulation against temperature fluctuations, durability under load | Stronger insulated walls, multi-layered panels, high R-value materials |

| Wind-Prone Areas | Wind resistance, panel durability | Galvanized steel, wind-resistant panels, enhanced sealing |

| Hot Climates | Ventilation, shading, heat reduction | Roof vents, reflective coatings, overhangs for shading |

| Cold Climates | Heat retention, snow load management | Rock wool, expanded polystyrene, high R-value insulation |

By customizing the design to meet specific operational needs, we ensure that the building performs at its best, year after year.

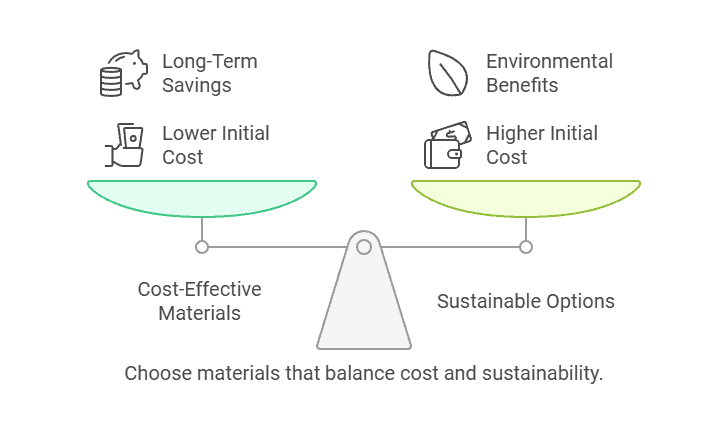

Balancing Economy and Sustainability

Cost is always a consideration in factory design, but there is an increasing focus on balancing economic and environmental factors. While opting for cost-effective materials is important, we recommend using sustainable options that may have a slightly higher initial cost but deliver significant savings in maintenance and energy use over time. For instance, recycled steel and low-VOC insulation materials can contribute to the factory’s sustainability while improving indoor air quality. It’s about making smart decisions that safeguard both your budget and the environment over time.

These considerations are the foundation for designing a steel factory building that meets the functional and environmental requirements and stands the test of time.

Leading Steel Structure Factory Manufacturers

When it comes to designing your steel factory building, we ensure that both the roof and wall systems are optimized for the best load-bearing performance. Our advanced panels and roofing systems are designed to meet the highest standards of durability and energy efficiency. Plus, we offer insulated sandwich panels that are perfect for withstanding varying climates—ensuring your factory keeps your inventory safe and sound no matter the weather.Interested in learning more? Check out our steel structure factory building page now to discover how we can customize solutions that perfectly fit your needs!