A steel elevator shaft is a prefabricated steel structure that houses elevator systems. Compared with concrete shafts, steel is faster to build, more flexible in design, and certified for safety and sustainability. This makes it the preferred solution for modern high-rise, residential, and commercial projects.

In this guide, you will learn the main components of a steel elevator shaft, the different types for various buildings, design options and section details, a clear comparison with concrete, and the top advantages including speed, cost savings, and adaptability.

At SteelPRO PEB, we are not just providing information—we are the Steel Structures / PEB Manufacturer & Producer behind these solutions. With ISO and CE certifications, EN 81-20 compliance, and factory-direct supply, we deliver certified elevator shafts, construction drawings, and wholesale pricing to clients worldwide.

Table of Contents

Structural Components of Steel Elevator Shafts

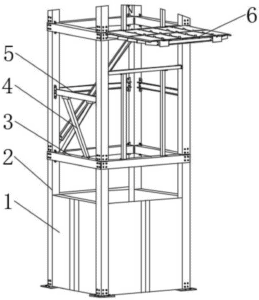

A steel elevator shaft is made of several key components: the frame, protective skin, motion system, and optional add-ons. Each part is designed to ensure safety, durability, and compliance with international standards such as EN 81-20 and ISO certifications. Below we explain the main structural elements and their role in performance and long-term reliability.

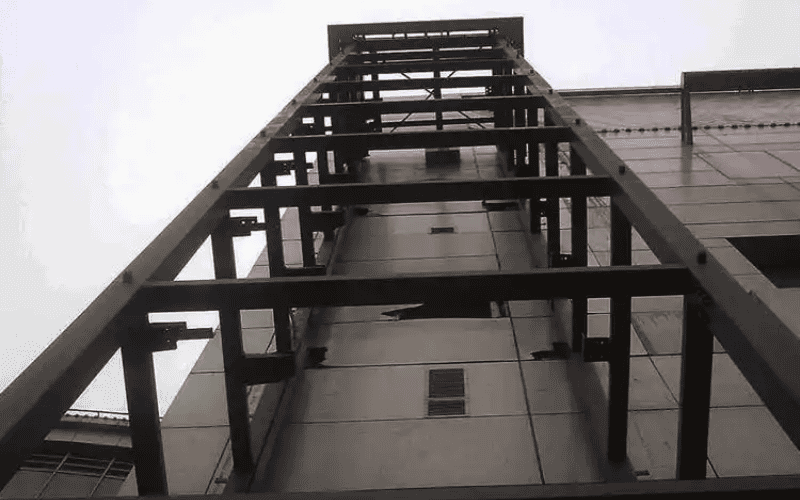

1. Steel Frame Network

The steel frame is the load-bearing skeleton of the elevator shaft.

- Vertical Columns: High-strength steel columns (H-beam, box, or lattice type) spaced for load efficiency.

- Horizontal Beams: Connect columns and distribute floor loads.

- Diagonal Braces: Add lateral stability against wind and earthquakes.

- Connections: High-grade bolts or robotic welds for precise, certified joints.

This frame ensures stability and allows customized framing details and section layouts according to building codes.

2. Protective Skin

The protective layer ensures safety and resistance.

- Cladding Panels: Corrugated or flat steel sheets (galvanized or coated).

- Fireproofing: Mineral wool boards or spray coatings, certified to 2-hour fire rating (EN 81-20).

- Weather Protection: Corrosion-resistant finishing (zinc/aluminum-magnesium alloy).

This skin protects the structure from fire, moisture, and corrosion while meeting international safety certification requirements.

3. Motion Control System

This system keeps the elevator moving smoothly.

- Guide Rails: T-shaped rails installed with laser alignment.

- Damping Pads: Reduce noise and vibration.

- Hoist Beams: Integrated in the frame for lift operation (common query “hoist beam”).

Designed for precision and compliance with ISO 9001 quality control.

4. Smart Add-Ons (Optional)

Steel shafts can be upgraded with smart features:

- Utility Channels: Pre-installed for cables, sensors, and ventilation.

- Access Panels: Bolt-on doors for easy inspection and maintenance.

- IoT-ready Integration: Sensors for predictive maintenance and load monitoring.

These add-ons improve future adaptability and meet modern construction demands.Looking for detailed construction drawings or section details? SteelPRO PEB, as a certified PEB manufacturer, provides factory-direct elevator shaft components with full documentation.

Types of Steel Elevator Shafts: Choose the Right Fit

Steel elevator shafts are designed in three main types: freestanding, building-integrated, and modular. Each type meets different project needs, whether it’s a skyscraper, hospital, or fast-track housing. Choosing the right type depends on speed, cost, and building codes. Below we explain each type with applications and benefits.

Freestanding Shafts

- Definition: A self-supporting steel framework built independently from the main building.

- Best for: High-rise towers, airports, mega-malls.

- Features:

- Requires dedicated foundation (mat or pile).

- Can integrate seismic damping systems.

- Handles ultra-high elevator speeds (10–20 m/s).

- Manufacturer Perspective: Supplied as large prefabricated modules from factory, reducing site welding. Certified to EN 81-20 for safety.

- Advantage: Stability and performance for tall buildings, direct from manufacturer with quality control.

Building-Integrated Shafts

- Definition: Steel shaft tied directly into the building’s load-bearing system.

- Best for: Mid-rise offices, hospitals, residential complexes.

- Features:

- Saves 15–20% materials compared to freestanding.

- Compact cross-section (1.5–3m wide).

- Enhances building’s lateral stability.

- Manufacturer Perspective: SteelPRO PEB designs shafts custom to local codes, with full construction drawings and load capacity calculations.

- Advantage: Cost-effective and space-saving, while ensuring certified structural safety.

Modular Shafts

- Definition: Prefabricated steel shaft units, factory-built and shipped in sections.

- Best for: Schools, factories, mass housing, metro stations.

- Features:

- Bolt-together sections with RFID tagging.

- Reduces on-site labor by 60–70%.

- Delivered with guide rails, doors, and cladding pre-installed.

- Manufacturer Perspective: As a factory-direct supplier, we ship ISO/CE certified modular shafts worldwide, meeting urgent project timelines.

- Advantage: Fastest installation and lowest labor cost, ideal for repetitive projects.

| Type | Best For | Key Features | Manufacturer Advantage |

| Freestanding | Skyscrapers, airports | Independent frame, high speed, seismic damping | Large prefabricated modules, EN-certified |

| Building-Integrated | Mid-rise, hospitals | Cost saving, compact design | Customized load design, full drawings |

| Modular | Schools, metro, housing | Bolt-together, pre-installed systems | Factory-direct, fastest delivery |

Not sure which type of steel elevator shaft fits your project? Contact SteelPRO PEB, a global PEB manufacturer, for factory-direct recommendations and certified design options.

Steel Structure Elevator Shaft Designs

Steel elevator shaft designs are usually divided into frame systems, truss systems, and hybrid systems. Each design affects load capacity, section details, installation speed, and noise resistance. Choosing the right design ensures safety and efficiency, and all designs can be customized by our factory to meet EN 81-20 and ISO 9001 standards.

1. Frame Systems

- Definition: Rectangular grids made of columns and beams, with welded or bolted moment connections.

- Applications: High-rise buildings, seismic zones, shafts needing wide open sections.

- Framing Details:

- Roof beams and hoist beams integrated for lift operation.

- Cross-section layouts can be customized per project load.

- Braced connections improve earthquake resistance.

- Manufacturer Advantage: SteelPRO PEB provides full construction drawings with load calculations, ensuring compliance with international codes.

- Best for: Earthquake resistance and heavy-load shafts.

2. Truss Systems

- Definition: Steel lattices arranged in triangular patterns, reducing shaft weight.

- Applications: Long-span shafts in airports, terminals, or exposed architectural designs.

- Section Details:

- Triangular trusses cut shaft weight by 40%.

- Integrated service walkways within truss voids.

- Manufacturer Advantage: Delivered as factory-welded panels, reducing site assembly time by 25%.

- Best for: Lightweight shafts with architectural appeal.

3. Hybrid Systems

- Definition: Combination of steel frames, trusses, and concrete elements.

- Applications: Ultra-high-speed elevators (>10 m/s), mixed-use towers, noise-sensitive environments.

- Section Details:

- Steel frames provide structural strength.

- Concrete-encased rails improve noise reduction and fire resistance.

- Manufacturer Advantage: SteelPRO PEB designs custom hybrid shafts, balancing cost, acoustic needs, and certification (EN 1090, CE).

- Best for: Noise-sensitive projects and complex mixed-use towers.

| Design Type | Key Features | Best For | Manufacturer Advantage |

| Frame System | Strong load capacity, seismic bracing | Earthquake zones, high-rise | Full load drawings & framing details |

| Truss System | 40% weight reduction, long spans | Airports, exposed shafts | Prefabricated truss panels |

| Hybrid System | Combines steel & concrete, noise control | High-speed, mixed-use | Custom hybrid design & certification |

Need detailed elevator shaft design drawings and load calculations? Contact SteelPRO PEB, your PEB manufacturer, for factory-direct, certified design solutions tailored to your project.

Steel vs. Concrete Elevator Shafts: Key Considerations

When comparing steel elevator shafts vs concrete elevator shafts, the key factors are construction speed, long-term cost, design flexibility, sustainability, and structural performance. Below we break down each aspect with clear pros and cons.

Speed of Construction

- Steel: Prefabricated modules, no curing, installed in days. Example: a 20-story hotel completed shafts in 18 days.

- Concrete: Requires formwork, pouring, and 28-day curing. Weather delays common.

Winner: Steel – saves 50–70% of project time.

Long-Term Costs

- Steel: Higher material cost but lower labor and maintenance. No spalling or rebar corrosion.

- Concrete: Lower upfront cost but frequent repairs and waterproofing issues.

Winner: Steel – ~25% lower lifecycle cost.

Design Freedom

- Steel: Span up to 15m, curved or sloped shafts possible. Slim wall thickness frees floor space.

- Concrete: Limited to straight box shapes with thick walls.

Winner: Steel – more usable space and architectural freedom.

Sustainability

- Steel: 90% recyclable, prefab cuts waste by 80%. Contributes to LEED credits.

- Concrete: Cement responsible for ~8% global CO₂. Difficult to recycle.

Winner: Steel – greener and more sustainable.

Structural Limitations

- Concrete: Inherent fire and sound resistance.

- Steel: Modern coatings and EN 81-20 certified fireproofing close the gap. Acoustic panels add insulation.

Winner: Balanced – concrete still strong in fire resistance, but steel is safer and certified for modern use.

Manufacturer Perspective: SteelPRO PEB provides ISO/CE certified coatings and load-tested designs, ensuring compliance with international safety codes.

| Factor | Steel Shaft | Concrete Shaft |

| Speed | Installed in days, no curing | Long curing time, weather delays |

| Cost | Lower lifecycle cost | Higher maintenance |

| Design | Flexible, slim walls, custom shapes | Rigid, thick walls |

| Sustainability | 90% recyclable, low waste | High CO₂ footprint |

| Fire & Sound | Needs certified coating (EN 81-20, ISO) | Naturally resistant |

Top 5 Advantages of Steel Elevator Shafts

The key advantages of steel elevator shafts are fast installation, flexible design, sustainability, earthquake safety, and future adaptability. These benefits make steel shafts the preferred choice for modern construction projects worldwide.

1. Unrivaled Speed-to-Completion

- Prefabricated in factory → installed on site in days.

- No curing delays → works in all weather.

- Example: Hospital in Brazil added 8 shafts in 12 days.

Manufacturer Advantage: SteelPRO PEB supplies factory-ready modules, reducing on-site labor by 60–70%.

2. Design Agility for Bold Visions

- Slim steel walls free up 8–12% more usable space.

- Curved, sloped, or ultra-slim shafts possible.

- Fits both high-rise towers and micro-apartments.

Manufacturer Advantage: Custom framing details and section drawings provided for each project.

3. Sustainability That Pays Dividends

- 90% of steel recyclable.

- 40–70% recycled content in every shaft.

- Prefabrication reduces waste by 80%.

Certification: Meets green building standards (LEED, ISO 14001).

4. Earthquake Resilience Built In

- Steel frames with braces absorb seismic energy.

- Proven to reduce repair costs by 80% vs concrete shafts.

- Load-tested for compliance with EN 81-20 and ISO seismic design standards.

Manufacturer Advantage: SteelPRO PEB designs shafts for custom seismic loads, ensuring global code compliance.

5. Future-Proof Adaptability

- Easy to widen shafts by replacing panels.

- IoT-ready for sensors and monitoring.

- Supports future upgrades (5G, energy recovery).

Manufacturer Advantage: We offer custom load design, certified construction drawings, and modular adaptability.

Choose SteelPRO PEB steel elevator shafts for faster construction, certified quality, and factory-direct pricing. Contact us today for a customized solution.

Why Choose Steel Elevator Shafts from a Certified Manufacturer

Choosing between concrete and steel may feel complex, but the truth is simple:

A steel elevator shaft is faster to build, lighter on cost in the long run, and certified for safety. Instead of waiting weeks for concrete to cure, steel arrives prefabricated, ready to install, with ISO, CE, and EN 81-20 compliance built in.

At SteelPRO PEB, we are not just giving you information—we are the manufacturer. That means:

- Factory-direct supply without middlemen

- Certified drawings and load-tested designs tailored to your project

- Wholesale pricing with full after-sales support

If you want an elevator shaft that saves time, cuts maintenance, and keeps your project future-ready, steel is the proven choice.

Contact SteelPRO PEB, your PEB Manufacturer & Producer, today to get a factory-direct certified quote for steel elevator shafts, customized to your building needs.