What are Corrugated Metal Sheets?

Corrugated metal sheets are pre-formed metal sheets characterized by a series of parallel, repetitive wavy ridges and grooves. These sheets are typically made from steel, aluminum, or galvanized metal and are primarily used in roofing, cladding, and wall applications in steel structures.

Why the corrugated design

The wavy corrugation pattern of metal sheets enhances their strength compared to flat sheets. The ridges help to disperse forces, increasing load-bearing capacity and preventing bending, warping or sagging. This design functions similarly to an I-beam, with the material positioned for optimal strength, allowing the sheet to withstand heavy loads and environmental stresses.

The corrugated design also enhances weather resistance, preventing damage from wind, rain, snow and UV rays, making it ideal for harsh climates.

Our corrugated metal sheets are manufactured to the highest standards, ensuring they meet industry safety and durability requirements. Particularly suitable for industrial buildings, warehouses and large projects, these sheets offer exceptional strength and longevity.

Advantages of Corrugated Metal in Steel Structures

Strength and Durability

The unique wave-shaped design of corrugated metal significantly enhances its structural strength. This design allows the metal sheet to better disperse external forces when under pressure, effectively resisting problems such as bending, sagging and warping. Just like an I-beam, corrugated metal moves metal material to where it is most needed, enhancing the rigidity of the sheet and allowing it to withstand more loads without damage.

Our corrugated metal sheets are produced to the highest standards, ensuring that they provide strong and reliable support in a variety of steel structure projects. Whether it is industrial buildings, warehouses or large-scale infrastructure, corrugated metal sheets are designed to withstand the test of time and use, ensuring that each piece of material can maximize its durability and safety.

Weather Resistance

Corrugated metal sheets are not only structurally strong, they can also withstand the challenges of extreme weather. Whether it is storms, ice and snow or strong sunlight, corrugated metal sheets will maintain good performance and protect the building from damage. We focus on providing customers with weather-resistant solutions so that your buildings are strong and reliable in harsh environments.

Long Life and Low Maintenance

The durability of corrugated metal sheets makes them an ideal choice for low maintenance. When compared to traditional roofing materials, corrugated metal sheets boast a longer lifespan and are simpler to maintain. You only need to check and re-tighten the fixings occasionally, and it will continue to provide reliable protection for your building. We are committed to providing customers with high-durability products that do not require frequent maintenance, so you can save time and effort and enjoy stable performance for a long time.

Sustainability

Corrugated metal sheets are not only strong and durable, but also have excellent energy-saving effects. Through excellent thermal insulation and heat reflection properties, corrugated metal sheets can effectively reduce the energy consumption of buildings, thereby reducing air conditioning and heating costs. As an environmentally friendly company, we are committed to providing recyclable building materials to help you achieve sustainable building goals and create a green and environmentally friendly future.

Application of Corrugated Metal Sheets in Steel Structures

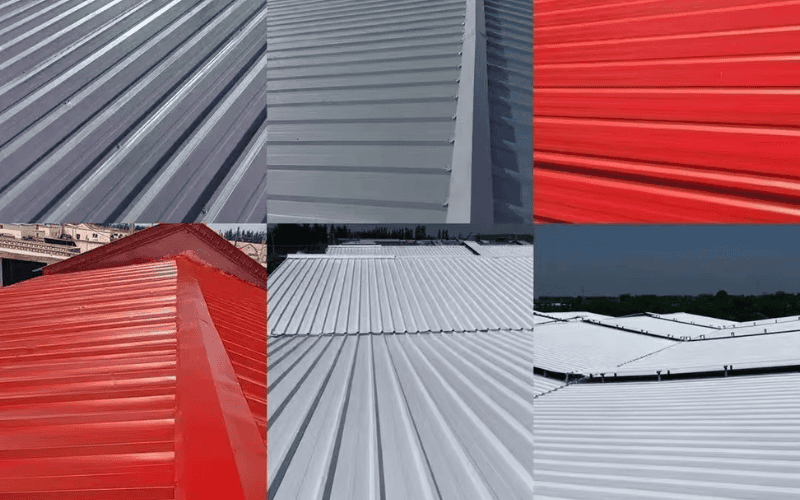

Roofing and Cladding

Corrugated metal sheets are widely used in steel structure roofing and cladding, especially in industrial and commercial buildings. Due to its lightness and high strength, corrugated metal sheets can effectively support large areas of roofs, withstand pressure under severe weather conditions, and ensure the stability and safety of buildings. On the roofs of industrial plants, warehouses and commercial facilities, corrugated metal sheets not only provide good waterproofing, but also enhance the bearing capacity of the structure through its unique corrugated design.

Cladding

In addition to roofing, corrugated metal sheets are also widely used in wall cladding for steel structure buildings. Its unique wavy design not only adds a modern and beautiful look to the building facade, but also effectively improves the wind pressure resistance and corrosion resistance of the wall. The durability and strength of corrugated metal sheets ensure that the building exterior wall is not easily damaged during long-term use, and the maintenance requirements are low, making it an ideal choice for modern steel structure buildings.

Partitions and Walls

Corrugated metal sheets are also suitable for partition walls and partition walls inside buildings. They not only provide a solid structural support for space division, but also add a modern visual effect. Their durable properties and high-strength design ensure the structural integrity of the wall, while their surface treatment technology helps improve corrosion resistance and extend service life.

Comparison of Corrugated Roof and Traditional Roof

| Comparison Aspect | Corrugated Roofing | Traditional Roofing |

| Weight & Installation | Lightweight, easy to install, reducing construction time and cost. | Heavier, requires more structural support, more complex installation, longer construction time. |

| Weather Resistance & Durability | Excellent weather resistance, withstands extreme weather, corrosion-resistant, long lifespan. | Prone to weather damage, may crack or fade, requires repairs over time. |

| Strength & Structural Stability | The corrugated design enhances rigidity, offering superior bending and compression resistance, suitable for large spans and heavy loads. | Requires stronger support structures, may deform under strong winds or heavy snow. |

| Maintenance & Cost | Low maintenance, highly durable, and cost-effective over time. | Requires regular repairs and replacement, higher maintenance costs. |

| Aesthetics & Design Flexibility | Modern and sleek design, fits well with steel structures, offers flexibility in architectural design. | Traditional look, but may not complement the appearance of modern steel structures. |

| Environmental Impact | Recyclable, reflective, reduces energy consumption, and sustainable. | Difficult to recycle, absorbs heat, and lowers energy efficiency. |

| Energy Efficiency | Insulated, reduces energy consumption for heating and cooling, significantly lowers energy costs. | Poor insulation, higher energy consumption. |

How to Choose the Right Corrugated Metal Sheet for Your Steel Structure

Key Considerations: Material Selection, Thickness, Coating Type and Surface Treatment

When choosing the right corrugated metal sheet, there are several key factors to consider:

Material Selection: Different materials (such as steel, aluminum, stainless steel, etc.) have different corrosion resistance, weight and strength. Choosing the right material can ensure the long-term durability and reliability of the sheet.

Thickness: The thickness of the corrugated metal sheet affects its load-bearing capacity and wind pressure resistance. For large buildings or buildings exposed to harsh environments, choosing thicker metal sheets can provide stronger structural support.

Coating Type and Surface Treatment: Coatings can effectively protect metal sheets from environmental corrosion. Common coating types include polyester, fluorocarbon, etc. Surface treatments such as galvanizing (or galvanizing, although typically referred to as galvanizing in this context to avoid repetition) can further enhance its corrosion resistance and aesthetic appeal.

The Importance of Professional Consultation to Ensure Correct Specifications

- Choosing the right corrugated metal sheet is no easy task, especially for complex steel structure projects. Considering the diversity of materials, sizes, coatings and installation requirements, professional consultation is essential. Selecting the right product not only enhances the durability and aesthetics of the building but also results in long-term savings on maintenance costs.

How SteelPRO’s Expert Team Assists with Product Selection and Project Planning

At SteelPRO, our professional team will provide one-on-one consultation services based on your specific needs. We have extensive experience and technical background to help you select the corrugated metal sheet that best suits your project from a wide range of products.

Whether it is material selection, thickness determination, or surface treatment options, we will provide the most appropriate advice based on the characteristics of the project to ensure that your steel structure project achieves the best results. Our team will guide you through your project from its inception to completion, ensuring a seamless process from design to construction.

SteelPro PEB’s Corrugated Metal Products

Product Types

SteelPro PEB offers a wide range of corrugated metal sheets to suit different steel structure requirements. Our corrugated metal sheets are available in steel, aluminum and stainless steel, etc. for a variety of building and engineering projects.

- Steel Corrugated Sheets: These are the most common and are used in both roofing and walling. They can be galvanized, pre-painted, or stainless steel, depending on the level of corrosion resistance required.

- Aluminum Corrugated Sheets: Known for being lightweight and resistant to rust. These are ideal for areas with high humidity or corrosive environments.

- Plastic (PVC or Polycarbonate) Corrugated Sheets: Lightweight and flexible, these sheets are often used for skylights or greenhouses. They have good UV resistance but are less durable than metal sheets.

- Fiberglass Corrugated Sheets: These are transparent and commonly used for applications where light transmission is important, like in agricultural or industrial settings.

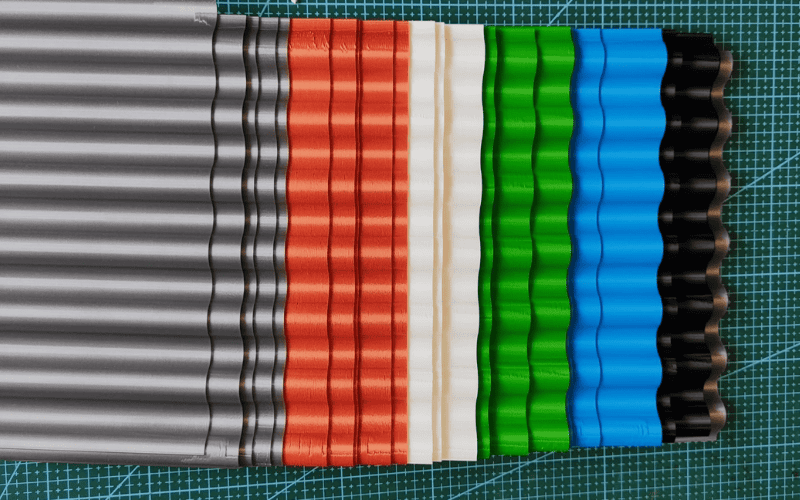

In addition, they are available in different thicknesses to provide the right solution for specific load-bearing requirements and environmental conditions. To accommodate different design requirements, we also offer a variety of surface treatments, including clear, sprayed and corrosion-resistant treatments to enhance durability and appearance.

Customization Options

SteelPro PEB is committed to providing customers with precision customized corrugated metal solutions. Whether it is special size, thickness requirements or personalized surface treatment requirements, we provide customized services based on specific projects.

You can choose:

- Regular Corrugated: The most common corrugation shape, with continuous waves, suitable for general use.

- Trapezoidal Corrugated: The corrugation is trapezoidal, with higher strength, often used in situations where greater support is required.

- Sinusoidal Corrugated: The corrugation shape is similar to a sine curve, with a smooth appearance, suitable for scenes with high aesthetic requirements.

- V-Corrugated: The corrugation is V-shaped, with a simple structure, and is often used in light applications.

- U-Corrugated: The corrugation is U-shaped, with good strength and durability, suitable for medium loads.

- Box Corrugated: The corrugation shape is similar to a box shape, with higher strength and stability, suitable for heavy-duty use.

Product Quality and Standards

As an industry leader, every corrugated metal sheet of SteelPro PEB strictly adheres to international quality standards and industry specifications. We implement rigorous quality control measures on our products to guarantee their superior strength, durability, and safety. Our corrugated metal sheets not only meet European CE certification standards, but have also been tested for compression, bending and corrosion resistance to effectively ensure long-term performance.

FAQs

1. How long is the life of a corrugated metal sheet?

The lifespan of a corrugated metal sheet typically ranges from 20 to 50 years, depending on the material (e.g., galvanized steel, aluminum), coating, environmental conditions, and maintenance.

2. Will corrugated metal sheet rust?

Yes, corrugated metal sheets can rust, especially if they are made of steel and not properly coated or maintained. However, materials like galvanized steel or aluminum are more resistant to rust.

3. How to deal with corrugated metal sheets after rusting?

- Clean the surface: Remove rust using a wire brush or sandpaper.

- Apply a rust converter: Use a chemical solution to neutralize the rust.

- Repaint or recoat: Apply a primer and paint or a protective coating to prevent future rust.

- Replace severely damaged sheets: If rust has caused structural damage, replace the affected sheets.

4. How to prevent corrugated metal sheets from rusting?

Avoid scratches: Handle and install carefully to prevent damage to the protective layer.

Choose the right material: Use galvanized steel, aluminum, or pre-coated sheets.

Apply protective coatings: Use paint, powder coating, or anti-rust sealants.

Regular maintenance: Inspect and clean the sheets periodically.

Ensure proper drainage: Avoid water pooling on the sheets.