Choosing windows for metal buildings isn’t as simple as picking a style. It’s about achieving the ideal balance between energy efficiency, durability, and cost-effectiveness. After all, the right windows can reduce heating and cooling costs while keeping your space secure and well-lit. Whether you’re working in a warehouse or a sleek office, what you choose will affect the building’s performance. In this article, we’ll walk you through the essentials—materials, energy ratings, and design tips—to make sure you pick the best option without the guesswork. The right windows do more than look good—they work hard for you.

Can I Add Windows to a Prefabricated Steel Structure?

It’s certainly doable, but there are a few important factors to consider before getting started. Installing a window isn’t as simple as cutting a hole in the wall and placing it in. Here’s a quick guide on what you should think about beforehand.

Assessing the Load-Bearing Capacity

Before adding windows, assess how much weight your steel structure can handle. Cutting into the walls changes how it distributes stress, especially if you’re adding large windows or multiple openings. Removing too much steel could weaken the structure. Consult a structural engineer to assess whether the building can support the additional load, considering the original design and existing structure.

Reinforcing the Structure

If the engineer spots weak spots, reinforcing the structure may be necessary. This typically means adding extra steel beams or columns around the openings to redistribute weight. For example, steel beams on either side of a large floor-to-ceiling window help ensure the structure remains solid, preventing any shifting or potential damage over time.

Fireproofing

Steel buildings often have a fireproof coating.

Don’t damage this coating during installation—repair any damage immediately.

Also, ensure the windows meet fire resistance standards, especially in industrial settings. For example, in factories, fire-rated windows help prevent fire from spreading.

Choosing Sealing Materials

Steel expands and contracts with temperature changes, so use elastic, weather-resistant sealants. High-quality sealants ensure your windows stay airtight and water-resistant, keeping the building comfortable year-round. This also prevents moisture damage, like rusting.

Insulation and Energy Efficiency

windows are key to insulation.

Opt for thermal-insulated materials like thermal break aluminum or PVC and double-glazed glass. This minimizes heat transfer and boosts energy efficiency, reducing heating and cooling expenses.

Accurate Measurements

When measuring window openings, it’s important to account for slight variations in steel structures due to factors like thermal expansion or settling.

These small changes can affect the fit, so always double-check your measurements. Leave 5–10mm of extra space around the opening for adjustments during installation. If the opening is off, windows like fixed accent or split slider might not fit properly, leading to gaps and installation headaches.

Material Compatibility

Be mindful of material compatibility. If different metals come into contact, they could cause electrochemical corrosion. For example, if you’re using aluminum windows with a steel frame, use insulating spacers to prevent corrosion and protect both materials.

Adding windows to a steel structure is doable but requires careful planning. Focus on load-bearing capacity, reinforcement, fireproofing, sealing, insulation, and accurate measurements. With the right materials and professional advice, your building will be stronger, more energy-efficient, and safe.

What Types of Windows Can I Add to My Metal Building?

When choosing windows for steel buildings, many suppliers offer only lightweight plastic windows, the most common option. However, these windows may not suit every use case or environment. Over time, they can cause issues with durability and maintenance, requiring significant effort to keep them functional, and may not be ideal for certain steel structures.

That’s why it’s crucial to know that you have more options available. Depending on your building’s style, material, and purpose, many alternatives exist. Here’s a breakdown of what works best.

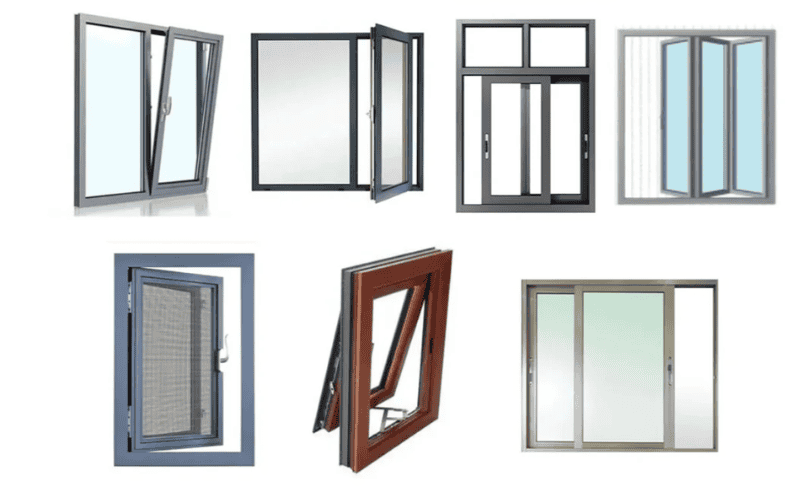

By Opening Style

Split Slider

This window style gives you flexibility—both the top and bottom sections can move, making it perfect for spaces that need airflow, like warehouses. If a fixed window isn’t an option, this is your go-to.

Fixed Accent

Fixed accent windows don’t open, but they’re a fantastic way to bring in light and add some style without compromising energy efficiency. Since they don’t risk drafts, they’re ideal for spaces with air conditioning, like industrial facilities.

Single Hung

Classic, simple, and space-efficient. Only the bottom sash moves, which makes it perfect for tight spaces. It’s a preferred choice for both residential and commercial steel buildings, offering a blend of security and convenience.

For our modular buildings, we also offer additional window options, such as casement windows for easy operation and awning windows for increased ventilation while protecting against rain.

By Material

Wood Windows: Gives a natural, warm feel and great insulation, but it does come with upkeep. Wood can be a good fit if you’re aiming for an eco-friendly or traditional look—but be prepared for maintenance.

Steel Windows: Steel frame windows are hard to beat for security and strength. They last longer than plastic but can be heavier and pricier. They’re perfect for high-security buildings but may not be the best fit everywhere.

Metal Windows: For those who prefer a modern and industrial look, metal windows offer superior strength and durability. Whether you opt for metal building windows or a custom solution, metal frames are resistant to wear and tear, making them ideal for harsh environments.

Aluminum Windows: Lightweight, stylish, and resistant to corrosion. Aluminum windows are a popular choice for steel buildings but don’t offer the best energy efficiency. If insulation is a top priority, you might want to consider alternative materials.

PVC Windows: For superior energy efficiency, PVC windows are an excellent option. They offer superior insulation, need little maintenance, and are durable enough to withstand various climates. A solid alternative to aluminum and steel.

Vinyl Windows: Like PVC, vinyl windows shine in energy efficiency and are built to last. They’re more stable than aluminum and won’t expand or contract as much. Resistant to corrosion, they’re perfect for humid or coastal environments.

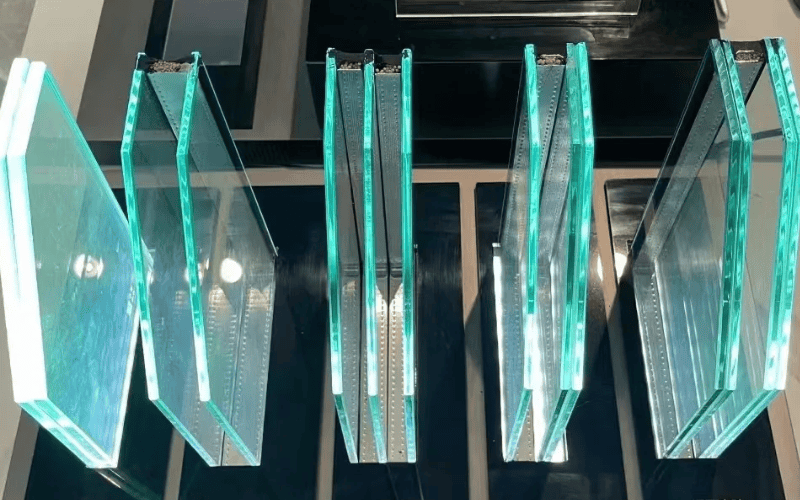

Glass for Your Steel Building

The right glass is key to your building’s functionality and look. Here’s a quick rundown of the most common types:

| Glass Type | Description | Ideal Use |

| Flat Glass | Simple, transparent, but lacks insulation and soundproofing. | Temporary buildings, low-performance areas. |

| Tempered Glass | Impact-resistant, shatters into blunt pieces for safety. | High-traffic areas, factory, stairwells. |

| Insulated Glass | Two panes with air gap for insulation. | Cold storage, warehouses, and temperature-sensitive areas. |

| Vacuum Glass | Vacuum between panes ensures superior insulation. | Labs, precision environments, high insulation needs. |

| Low-E Glass | Reflects infrared/UV light, regulates indoor temperature. | Energy-efficient buildings, reduces heating/cooling costs. |

| Laminated Glass | Multi-layered glass with soundproofing properties. | High-risk areas, hurricane zones, chemical plants. |

Metal Building Window Selection Tips

Choosing the right windows for your metal building is crucial—it directly impacts factors like lighting, insulation, soundproofing, and security. A carefully selected window can greatly enhance the functionality and comfort of your space.

Choosing the Right Glass

- For Hot Climates: Opt for Low-E glass with insulated glazing to block heat and keep interiors cool.

- For Cold Climates: Choose vacuum glass or triple glazing to trap warmth and protect against the cold.

- For Office Spaces: Use ultra-clear glass with a Low-E coating for natural light and energy efficiency.

- For Factories: Go for laminated glass and double glazing for soundproofing and dust control.

Checking Window Quality

- Visual Check: Look for scratches, bubbles, or imperfections in the glass. Ensure the frame is clear of rust and dents.

- Seal Test: Place paper between the window and frame. If it pulls out easily, the seal is compromised.

- Hardware Check: Test the window by opening and closing it. It should function smoothly without any resistance.

- Structural Strength: Push or shake the frame to ensure it’s sturdy and reinforced, especially for larger windows.

By keeping these tips in mind, you can choose windows that not only enhance your building’s appearance but also improve its overall performance and durability.

Once you’ve selected the best windows for your space, the next step is installation. Check out our complete guide on Adding windows and doors to prefabricated steel buildings to ensure a smooth and efficient setup.

Your Trusted Metal Building Manufacturer

When it’s time to finalize and order your windows, we recommend using lifting equipment for installation. It’s important to keep windows—especially sliding ones—away from high areas and out of reach of children.

We offer modular metal buildings with high-quality windows made from materials like aluminum, PVC, and vinyl, which are all more durable than traditional plastic windows. If you’re planning to pre-prepare window openings in your steel structure, we can help you visualize everything with a 3D animation to ensure the windows open and close properly.

If you’d like to know more about adding windows to your prefabricated metal building kit, feel free to reach out to our experts on this website!