A cable bracing system is a lightweight but strong solution that provides lateral stability for steel structures and PEB buildings. Using high-strength steel cables, it helps buildings resist wind and earthquakes while keeping construction cost-efficient and flexible.

As a certified Steel Structures Manufacturer & Producer, SteelPRO PEB supplies factory-direct cable bracing systems and hardware components, trusted by contractors worldwide. With over 120,000 tons annual capacity and projects delivered across Asia, America, Africa, and beyond , we ensure both structural safety and international quality standards.

In this guide, you’ll discover:

- What a cable bracing system is and how it works

- Key advantages over traditional bracing methods

- Applications across steel buildings and PEB structures

- Hardware components and design considerations

- Installation process and FAQs

By the end, you’ll understand why cable bracing is the preferred choice for modern steel construction, and how to get factory-direct wholesale supply for your project.

Table of Content

What is a Cable Bracing System in Steel Structures?

A cable bracing system is a structural solution that uses high-strength steel cables to provide lateral stability for steel structures and PEB buildings. Unlike rigid bracing made from heavy beams, cable bracing works in tension, resisting wind and seismic forces with flexibility and strength.

Main components of a cable bracing system:

- Steel Cables – Galvanized or stainless steel cables designed to carry high tension loads

- Anchors & Connectors – Secure the cables to the building’s primary steel frame

- Tensioning Devices – Adjust and control cable tension for stability and balance

How do cable bracing systems work:

When lateral forces act on a building, the cables absorb and redistribute the energy, then pull the structure back into alignment. This makes cable bracing systems especially effective for modern steel buildings where both strength and lightweight design are required.

Key Advantages of Cable Bracing Systems for Steel Buildings

Cable bracing isn’t just a modern alternative to traditional bracing systems—it’s a superior solution for many steel building projects. Here’s why it’s gaining popularity among architects, engineers, and builders:

Cable bracing systems offer unique benefits for steel buildings and PEB structures, making them a preferred choice over traditional rigid bracing. They combine strength, flexibility, and cost efficiency, while also supporting modern design needs.

- Lightweight Design:

Cable bracing uses high-strength steel cables instead of heavy beams. This reduces the building’s overall weight and lowers foundation costs. - Superior Resistance to Lateral Forces:

Cable systems absorb wind and seismic energy through slight tension adjustments, helping steel structures remain stable even in extreme conditions. - Faster and Easier Installation:

Prefabricated cables and connectors allow quicker on-site installation, reducing labor costs and construction timelines. - Unobstructed Space and Aesthetic Appeal:

Unlike rigid X-bracing that blocks openings, cable bracing keeps interiors open and visually clean—ideal for warehouses, arenas, and commercial buildings. - Cost-Effectiveness:

Less steel, lighter foundations, and lower maintenance = long-term savings. - Factory-Direct Supply Advantage:

As a certified PEB Manufacturer & Producer, SteelPRO PEB offers:- Factory-direct wholesale supply at lower costs than distributors

- International certifications (ISO, CE, ASTM) for quality assurance

- Bulk hardware availability for contractors and global projects

Cable Bracing vs. Traditional Bracing Systems in Steel Buildings

When choosing between a cable bracing system and traditional rigid bracing (such as X-bracing or K-bracing), builders must consider weight, flexibility, installation time, and cost. Below is a clear comparison.

| Feature | Cable Bracing System | Traditional Bracing (X/K) |

| Weight | Lightweight, reduces foundation load | Heavy, adds structural weight |

| Flexibility | Absorbs wind & seismic forces dynamically | Rigid, limited adaptability |

| Installation | Faster, less labor required | Slower, requires welding & heavy beams |

| Cost | Lower material & labor cost | Higher steel & labor cost |

| Aesthetic & Space | Minimal obstruction, open interiors | Can block windows/doors |

In most steel and PEB buildings, cable bracing systems provide the best balance of strength, speed, and cost efficiency. However, for very tall or heavy-load structures, rigid bracing may still be necessary.

As a PEB Manufacturer & Producer, SteelPRO PEB advises clients on the best solution for each project and supplies factory-direct bracing systems and hardware worldwide.

Cross Cable Bracing in Steel Structures

Cross cable bracing in steel structures is a system where high-strength steel cables form an “X” shape to stabilize a building frame. This type of bracing works in tension and provides excellent resistance against wind and seismic forces, while keeping the structure lightweight and cost-efficient.

Why use cross cable bracing:

- Lightweight solution: reduces steel consumption and foundation cost.

- High stability: absorbs lateral loads and maintains structural alignment.

- Open space: unlike rigid bracing, it does not block doors, windows, or interior layouts.

- Versatile applications: common in warehouses, hangars, arenas, and other long-span PEB buildings.

Comparison with diagonal cable bracing:

| Feature | Cross Cable Bracing (X) | Single Diagonal Cable Bracing |

| Stability | Higher resistance, tension in both directions | Works only in one tension direction |

| Space usage | Minimal obstruction | Slightly more intrusive |

| Applications | Warehouses, sports arenas, hangars | Smaller spans, light industrial buildings |

At SteelPRO PEB, cross cable bracing is part of our factory-direct steel structure solutions. We design and supply certified systems that meet ISO and CE standards, ensuring stable performance in warehouses, arenas, and large-span industrial buildings worldwide.

Applications of Cable Bracing Systems in Steel and PEB Structures

A cable bracing system is widely used in steel buildings and PEB structures. Its lightweight strength and flexibility make it suitable for industrial, commercial, and special construction projects where stability and open space are equally important.

| Application Area | How Cable Bracing Helps |

| Warehouses & Hangars | Reduces foundation cost, improves wind resistance with lightweight design |

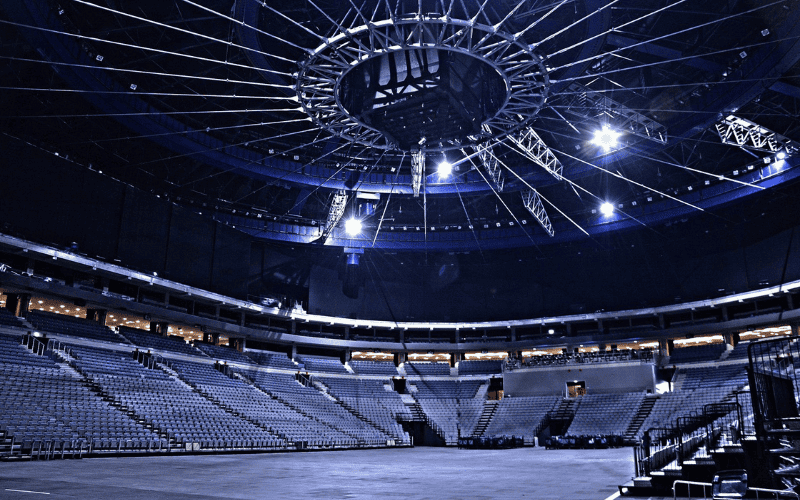

| Commercial Buildings (Malls, Offices, Arenas) | Supports large open spaces with unobstructed views |

| Industrial Buildings & Factories | Provides lateral stability without adding heavy loads |

| Sports Venues & Stadiums | Allows large-span roof support without blocking spectator views |

| Bridges & Towers | Handles heavy dynamic loads while keeping structures light |

| High-Rise Buildings | Improves stability against wind and earthquakes |

| Outdoor & Temporary Structures | Offers quick setup and removal with minimal weight |

At SteelPRO PEB, we provide factory-direct cable bracing systems and hardware tailored for these applications. With over 1,000 completed projects worldwide, our solutions are trusted in Asia, the Middle East, Africa, and the Americas .

Key Considerations in Cable Bracing System Design for Steel Structures

Designing a cable bracing system for steel buildings and PEB structures requires attention to technical details such as loads, tension control, material selection, and compliance. Each factor ensures long-term stability, safety, and cost-effectiveness.

Types of Loads

- Dead Loads: The building’s self-weight. Even though cable bracing is lightweight, the structure must account for overall stability.

- Live Loads: Wind, seismic activity, or occupancy forces create dynamic tension in cables. Proper design ensures safe energy absorption and redistribution.

Design software such as STAADPRO, ETABS, and TEKLA is often used to simulate real conditions and confirm stability.

Pre-Tension Control

- Too Much Tension → Risk of deformation and damage at anchor points

- Too Little Tension → Insufficient support against wind or seismic forces

- Solution → Use hydraulic tensioners or turnbuckles to maintain optimal balance during installation and operation

Accurate pre-tension measurement is critical for long-term performance.

Material Selection

- Tensile Strength: High-strength galvanized or stainless steel strands

- Corrosion Resistance: Galvanized coating or stainless steel for coastal/harsh climates

- Wear Resistance: Smooth surface finishing to withstand repeated tension cycles

Using factory-tested, certified materials ensures durability and safety.

Compliance & Standards

All cable bracing designs must meet international codes such as:

- AISC (U.S.)

- Eurocode 3 (EU)

- CSA S16 (Canada)

- GB 50017-2017 (China)

- ISO 9001

Following global standards ensures systems are accepted in international projects.

At SteelPRO PEB, our engineering team provides concept design, structural detailing, and construction drawings to ensure every cable bracing system meets international standards. With over 120,000 tons annual production capacity, we can supply both design services and factory-direct hardware components for global steel building projects.able bracing systems worldwide.

Cable Bracing Hardware Components for Steel Structures

A cable bracing system is not complete without its hardware. The right combination of cables, anchors, connectors, and tensioning devices ensures safety, durability, and easy installation. Below are the key hardware components used in steel building cable bracing systems.

- Steel Cables

- High-strength galvanized or stainless steel strands

- Designed for tension loads and long-term durability

- Anchors & Base Plates

- Connect cables to the primary steel frame

- Ensure secure load transfer

- Turnbuckles & Tension Rods

- Allow on-site adjustment of cable tension

- Maintain balance against wind and seismic forces

- Connectors & End Fittings

- Provide strong joints between cables and anchors

- Reduce wear and improve load distribution

- Protective Coatings

- Galvanization, painting, or aluminum-magnesium alloy coating

- Extend lifespan, especially in coastal or humid environments

At SteelPRO PEB, all cable bracing hardware is manufactured in-house under ISO and CE certifications. We offer factory-direct bulk supply for contractors and distributors, ensuring both quality assurance and competitive wholesale pricing.

How to Install a Cable Bracing System in Steel Buildings

Installing a cable bracing system in steel structures involves careful design, proper material selection, and step-by-step execution. Below is a simplified installation process used in most PEB and steel building projects.

Step 1: Structural Analysis & Design

- Engineers calculate loads (wind, seismic, dead load)

- Define cable locations and pre-tension levels

Step 2: Material Selection

- Choose galvanized or stainless steel cables

- Select anchors, connectors, and tension devices

Step 3: Site Preparation

- Inspect the steel frame for integrity

- Confirm anchor points and clear the installation area

Step 4: Installation Process

- Secure anchoring plates to the steel frame

- Attach cables at designed bracing points

- Use turnbuckles or hydraulic tensioners to apply pre-tension

- Conduct initial load test

Step 5: Final Inspection

- Verify tension, anchors, and alignment

- Record initial tension for maintenance reference

Step 6: Maintenance & Adjustment

- Regular inspections to check corrosion and cable tension

- Readjust after extreme weather or seismic events

At SteelPRO PEB, our engineering and installation teams provide on-site guidance and turnkey solutions. With more than 1,000 completed projects worldwide, we ensure cable bracing systems are installed safely, efficiently, and in compliance with ISO and CE standards.

How long does a cable bracing system last?

A high-quality cable bracing system can last for decades. When using galvanized or stainless steel, and proper protective coatings, the system is resistant to corrosion and requires minimal maintenance.

Does cable tension need to be adjusted over time?

Yes. Cable tension may loosen after years of use or after extreme weather. Turnbuckles and hydraulic tensioners allow quick readjustment to keep the system stable.

Can cable bracing be added to existing steel structures?

Yes. Cable bracing can be retrofitted into existing steel buildings to improve stability and extend service life, especially in areas with strong winds or seismic risks.

Is cable bracing suitable for harsh climates?

Yes. With proper material selection (e.g., stainless steel for coastal areas), cable bracing systems perform well in typhoon, hurricane, or earthquake-prone regions.

Do you supply cable bracing hardware components?

Yes. SteelPRO PEB manufactures all hardware—including anchors, turnbuckles, connectors, and galvanized cables—under ISO and CE certifications. Bulk hardware orders are available for contractors and distributors.

Can I order bulk quantities directly from the factory?

Yes. We offer factory-direct wholesale supply, ensuring lower prices compared to local distributors, while guaranteeing consistent quality.

Do you provide international shipping?

Yes. Our projects have been delivered to over 20 countries, including the U.S., Canada, Japan, Australia, Southeast Asia, Africa, and Latin America.

What certifications do your cable bracing systems meet?

Our products comply with ISO, CE, ASTM, and Eurocode standards, ensuring acceptance in global projects.

Order Certified Cable Bracing Systems Directly from the Manufacturer

Looking for a reliable cable bracing system for your steel building or PEB project?

At SteelPRO PEB, we design and supply factory-direct cable bracing systems complete with hardware components—including galvanized cables, anchors, connectors, and turnbuckles. Every system is engineered for wind and seismic resistance, tested for international compliance (ISO, CE, ASTM, Eurocode), and delivered with full engineering support.

Whether you need cable bracing for a warehouse, hangar, sports arena, or high-rise steel structure, our team provides customized designs and bulk supply at wholesale pricing.

Contact us now to get a project-specific quotation for cable bracing systems—direct from our factory to your site.