You may not have noticed, but every time you walk into a skyscraper, cross a bridge, or watch a game in a spacious stadium, steel beams are silently supporting these magnificent structures. They are like the “skeleton” of a building, carrying the critical task of supporting and distributing loads. Steel beams, as the core components of steel structures, directly determine the stability and safety of a building.

In this article, we’ll explore the types of steel beams, their manufacturing process, applications, and their critical role in steel structures. We hope this information will give you a comprehensive understanding of steel beams and help you utilize them more effectively in future projects.

What is a Steel Structure Beam?

Steel structure beam is a broad concept, referring to any beam used in steel structure. They are the core components of steel structure and are usually used to support floors, roofs, bridges and other large structures.

What are structural steel beams

Structural Steel Beams are horizontal or inclined load-bearing members made of steel, used to transfer loads (such as gravity, wind loads, seismic forces, etc.) in buildings, bridges or industrial facilities to supporting structures (columns, walls or foundations).

Types of Steel Beams

Below is a summary of the most common types of steel beams, their shapes, and their primary applications:

| Type of Beam | Shape | Key Features | Applications |

|---|---|---|---|

| I-Beams |  | I”-shaped cross-section | High-rise buildings (floor and roof support) |

| Two horizontal flanges and a vertical web | Bridges (main load-bearing) | ||

| H-Beams |  | H”-shaped cross-section | Heavy-duty industrial plants |

| Wider flanges and shorter web than I-beams | High-rise building frames | ||

| T-Beams |  | T”-shaped cross-section | Floor and roof structures |

| One horizontal flange and a vertical web | Lightweight designs with reduced material usage | ||

| C-Channels |  | C”-shaped cross-section | Wall supports |

| Open on one side | Roof trusses | ||

| Framing for mechanical equipment | |||

| Box Beams |  | Hollow rectangular or square cross-section | Bridges |

| Excellent torsional resistance | Long-span structures requiring resistance to twisting forces |

Key Notes:

- I-Beams: Ideal for vertical load-bearing applications, commonly used in buildings and bridges.

- H-Beams: Stronger and more stable than I-beams, suitable for heavy-duty construction.

- T-Beams: Perfect for lightweight designs where material efficiency is critical.

- C-Channels: Versatile and lightweight, often used in framing and support structures.

- Box Beams: Excellent for applications requiring resistance to twisting, such as bridges.

Looking for more insights into specialized steel beams? Check out our article on Steel Structure Crane Beams, which dives into their unique features and critical role in industrial construction.

Manufacturing Process of Steel Beams

Steel beams are critical components in steel structures, and their manufacturing process involves precise control of techniques and stringent quality testing to ensure high performance and reliability. With efficient production processes and the selection of high-quality raw materials, we deliver steel beams that meet the unique requirements of various engineering projects.

What materials are steel beams made of?

Steel beams are usually made of the following materials:

- Carbon steel: common and inexpensive, suitable for most steel structures (such as Q235, Q345).

- Alloy steel: improves strength and corrosion resistance by adding alloy elements, suitable for special needs.

- Stainless steel: corrosion-resistant and high-temperature-resistant, suitable for harsh environments, but with a higher cost.

- High-strength steel: high strength, suitable for large spans and heavy-load structures.

The material selection of steel beams is usually determined by the force requirements of the structure, the working environment and the budget. For example, carbon steel or low-alloy steel is used in ordinary buildings, while stainless steel or corrosion-resistant alloy steel may be used in severe corrosion or special environments (such as offshore platforms or chemical plants).

Manufacturing Steps

- Melting and Casting: The production process begins by melting iron ore and scrap steel to produce molten steel, with carefully controlled additions of alloying elements to meet specific project requirements. By tightly managing the chemical composition and temperature during this stage, we ensure the optimal performance and durability of the steel beams.

- Hot Rolling: The molten steel is processed through advanced rolling equipment to shape it into various forms, such as I-beams, channel beams, and angles. With precise temperature control and strict rolling parameters, we ensure the dimensional accuracy and structural integrity of each beam, making them suitable for diverse construction needs.

- Cooling and Cutting: Once cooled, the steel beams are trimmed to the necessary lengths and subjected to surface treatments like galvanizing to enhance their corrosion resistance. Our production process meticulously controls every step, ensuring that the steel beams meet the highest standards of quality and performance.

Applications of Steel Beams in Steel Structures

Steel beams are widely used in various steel structure projects due to their excellent load-bearing capacity and flexible design. As a crucial part of the steel structure bracing system, these beams work in tandem with other components to ensure stability, strength, and safety in diverse applications. Below are several typical application areas:

Building Structures

- High-Rise Buildings: Steel beams are extensively used to support floors and roof structures in high-rise buildings, providing large-span spaces. These beams not only effectively bear heavy loads but also reduce the number of columns, maximizing space utilization.

- Industrial Warehouses: In supporting systems for heavy equipment and large machinery, steel beams serve as load-bearing components, ensuring the high-strength requirements of roofs and platforms. By utilizing tailored steel beam specifications, we can accommodate the unique requirements of diverse production lines and equipment arrangements. In a warehouse project in Madagascar, we provided steel beams with excellent wind resistance, corrosion resistance, and high durability to withstand high temperatures, humidity, and strong winds.

Bridge Engineering

- Beam Bridges: Steel beams are widely used as the primary load-bearing components in beam bridge designs, especially in bridges spanning rivers or valleys. By using high-strength steel beams, large-span designs are achievable while reducing the overall weight of the bridge structure.

- Suspension Bridges: In suspension bridge designs, steel beams and steel cables work together to form large-span bridges, maintaining stability under extreme conditions such as strong winds. In these bridges, steel beams not only support the weight of the deck but also effectively transmit loads.

Infrastructure

- Sports Venues: Steel beams are widely used in the roof structures of sports venues, especially where large, column-free spaces are needed. By efficiently using steel beams, these designs achieve greater structural stability and flexibility. For example, for the Hechuan Sports Center in Chongqing, we supplied steel beams that ensured both structural stability and aesthetic appeal, facilitating an unobstructed view of the entire venue.

- Airport Terminals: Steel beams are also commonly used in the design of airport terminals to support large areas of glass curtain walls and roof structures, ensuring transparency and natural lighting both inside and outside the terminal. In the construction of the new Jiaodong International Airport, the design and fabrication of steel beams provided excellent structural support for the building.

Steel Beams in Prefabricated and Modular Construction

In prefabricated and modular construction, steel beams offer strength and ease of assembly, reducing labor time and enabling faster construction. Prefab beams, such as steel I-beams and box beams, are manufactured off-site and assembled on-site, making them ideal for modular homes and modular offices.

Steel beams in modular construction provide the necessary load-bearing capacity, and their sizes can be tailored to fit specific designs. Steel construction beams offer advantages over traditional materials like timber, especially in residential construction, due to their strength and durability. These beams are used to support steel floor beams and roof steel beams, ensuring the stability and efficiency of modular structures.

By using steel structural beams, construction projects benefit from quicker builds, reduced labor, and greater structural integrity.

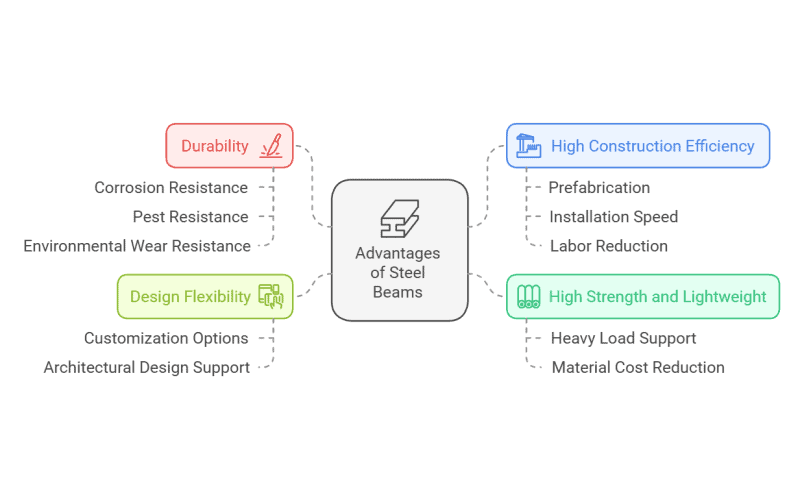

Advantages of Steel Beams in Steel Structures

High Strength and Lightweight: Steel beams can support heavy loads while being lightweight, allowing for longer spans and reducing material and foundation costs. This also helps lower the overall load on the building’s foundation.

Durability: Steel beams are highly resistant to corrosion, pests, and environmental wear, ensuring a long lifespan. Galvanization and similar coatings bolster their durability in harsh environments, including coastal and industrial zones. Our high-performance steel products further improve durability with advanced heat treatment.

Design Flexibility: Steel beams can be tailored to various shapes and sizes, providing versatility for intricate architectural designs. Whether for heavy loads or aesthetic purposes, steel beams provide strong support without compromising structural integrity.

High Construction Efficiency: Steel beams are pre-fabricated in controlled environments, which speeds up installation and reduces on-site labor. This results in quicker construction timelines and minimizes adjustments, making steel a prime option for projects with tight deadlines.

What Affects the Performance of Steel Beams?

The performance of steel beams is affected by the following factors:

Material type: Different types of steel (such as carbon steel, alloy steel, stainless steel) have different strength, toughness and corrosion resistance, which affect the load-bearing capacity and durability of steel beams.

Steel quality: The production process, chemical composition and internal structure of steel (such as grain size, inclusions, etc.) will affect the mechanical properties of steel beams, such as tensile strength and compressive strength.

Size and shape: The cross-sectional size and shape of steel beams (such as I-beams, box beams, etc.) directly affect their load-bearing capacity and stability. Larger cross-sections generally provide higher load-bearing capacity.

Connection method: The connection method of steel beams to other structural components (such as welding, bolting) will affect the overall performance, especially the shear and bending resistance.

Loading conditions: The type and size of loads (such as static loads, dynamic loads, impact loads) to which steel beams are subjected will affect their deformation and failure mode.

Temperature and environmental conditions: High temperature environments may reduce the strength of steel, while cold environments may cause brittle failure. Corrosive environments will also reduce the life of steel beams.

Construction quality: Quality control during the manufacture, transportation and installation of steel beams has a great impact on their final performance, especially in terms of welding and connection quality.

Steel Beam Aging

Steel beams, like any material, undergo a natural aging process over time due to exposure to environmental factors. This aging can affect their strength, durability, and performance, which is why regular maintenance and inspection are crucial. The primary causes of aging in steel beams include:

- Corrosion: Steel is prone to rust when exposed to moisture, oxygen, and pollutants. Corrosion weakens the structure, leading to potential failure if not addressed.

- Fatigue: Repeated load cycles can lead to fatigue in steel beams, gradually weakening them and potentially causing cracks or fractures.

- Thermal Expansion and Contraction: Over time, exposure to extreme temperatures can cause steel to expand and contract, which may lead to warping or distortion of the beam.

- Environmental Exposure: Exposure to harsh weather conditions, saltwater (in coastal areas), or industrial chemicals can accelerate the aging process and damage the steel.

Preventing Steel Beam Aging:

To extend the life of steel beams and maintain their structural integrity, regular inspections, protective coatings (such as galvanization or painting), and proper maintenance are essential. Early identification of issues like corrosion or fatigue can prevent more significant damage, ensuring the steel beams continue to perform safely and effectively over the long term.

How to Extend the Service Life of Steel Beams?

1. Regular inspection and timely maintenance

Inspect frequently to detect problems such as corrosion, cracks or deformation as early as possible. Especially inspect after major events such as storms or heavy loads. Address minor damage such as cracks or coating peeling as soon as they are found. For cracks in the steel itself, use welding or specialized treatment to prevent further deterioration.

2. Anti-corrosion

- Galvanize steel beams, especially in coastal or outdoor environments.

- Apply protective coatings (epoxy or polyurethane) to form a protective layer.

- In harsh environments, use cathodic protection or other advanced anti-corrosion methods. Chromate conversion coatings or zinc-rich paints can enhance corrosion resistance.

3. Routine cleaning and environmental control

Clean steel beams to remove contaminants that can cause corrosion or weaken the material, especially in highly polluted or coastal areas. Try to limit the exposure of steel beams to harsh conditions:

- Reduce moisture in areas with high humidity.

- Use dehumidifiers or control environmental factors to prevent corrosion.

4. Load management and structural reinforcement

Ensure beams are not overloaded by regularly checking weight limits. Reinforce beams if additional loads are added due to structural changes. The following reinforcement methods can be used:

- Add supplementary beams or reinforcing plates to increase load-bearing capacity.

- Use composite materials such as fiberglass to increase strength without significantly increasing weight.

By combining these practices, you can greatly extend the life of your steel beams, ensuring their long-term strength, stability, and performance.

Design and Selection of Steel Beams

When designing and selecting steel beams, several factors must be considered to ensure structural safety and efficiency:

- Load Calculations: Accurate calculation of static, live, and environmental loads (such as wind or seismic) is essential to determine the correct beam size and strength for the project.

- Span and Size: The beam’s dimensions depend on the load it must carry and the span it needs to cover. Larger spans require stronger beams, and advanced engineering helps optimize the beam size to avoid overuse or insufficiency of materials.

- Connection Methods: Steel beams are typically connected by welding or bolting. Welding provides high strength and stability, while bolting offers flexibility during installation. The choice depends on project needs and construction preferences.

- Material Selection: Steel’s properties can be enhanced by alloying elements or surface treatments. Weather-resistant steel is ideal for harsh environments, and coatings like galvanization or painting improve corrosion resistance.

We suggest:

- Working with professionals ensures the steel beam selection is safe, efficient, and cost-effective. We provide design support to help clients optimize structural solutions for their projects.

Tip: Deciphering Beam Dimensions

Beam dimensions are often expressed in a format similar to “W 27 x 178#” or “S 24 x 121#.” While this can be confusing for those new to steel beams, it’s pretty straightforward once you understand the format:

First letter: Indicates the type or shape of beam. For example, “W” stands for Wide Flange, while “S” stands for Standard American.

First number: Indicates the height of the beam in inches. For example, “W 27” means a Wide Flange beam is 27 inches tall.

Second number: Indicates the weight of the beam in pounds per foot. For example, “W 27 x 178#” means it weighs 178 pounds per foot.

Sometimes, there’s a third number after the size that indicates the length of the beam in feet.

Steel Structure Supplier

We offer high-quality steel beams as part of our comprehensive steel structure solutions. Made from premium materials, our steel beams offer exceptional strength and durability, which directly contributes to the overall performance of our steel structures, including warehouses and industrial buildings. Leveraging our expertise in steel beam production, we guarantee that each component adheres to the utmost standards of precision, reliability, and enduring performance.

FAQs

What is the difference between steel beams and concrete beams?

Steel beams are strong and lightweight, suitable for large-span structures; concrete beams are low-cost, but heavy and have a long construction period.

How long is the life of a steel beam?

With proper maintenance, the life of a steel beam can reach more than 50 years.

Is the cost of a steel beam high?

The initial cost of a steel beam is higher, but its durability and low maintenance cost make it more economical in long-term use.