A steel beam splice connection is a method to join two steel beams so they act as one continuous unit. It is needed when a single beam is not long enough, when transportation limits the beam size, or when special designs require it.

In this guide, you will learn:

- What a beam splice is and why it matters for safety, cost, and sustainability

- Where a steel beam splice should be placed, and where it should be avoided

- The main splice methods, including bolted, welded, and hybrid connections

- The step-by-step process of splicing beams according to standards

As a certified Steel Structures / PEB manufacturer and producer, SteelPRO PEB supplies factory-direct splice plates, bolts, and welded solutions. Our products meet IS, AISC, and GB standards, helping contractors and engineers complete projects efficiently and at wholesale cost.

Table of Contents

What Is a Steel Beam Splice in Steel Structures?

A steel beam splice in steel structures is a connection that joins two steel beams into one continuous member. This method allows beams to transfer loads safely across the splice zone while acting as a single structural element.

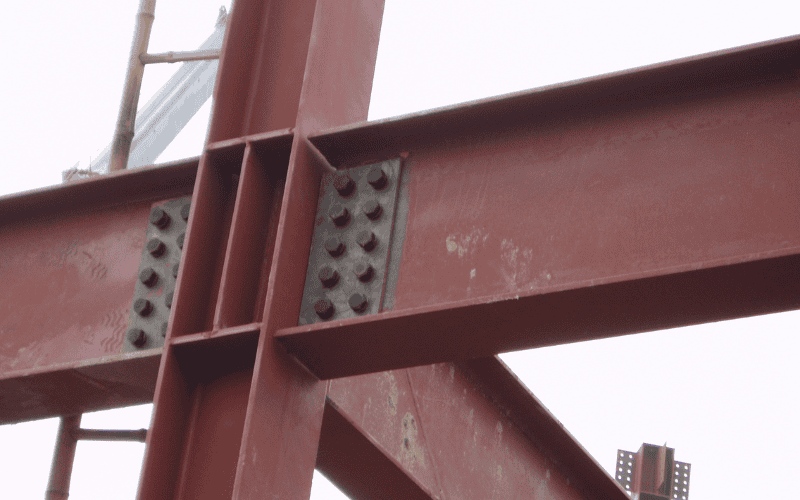

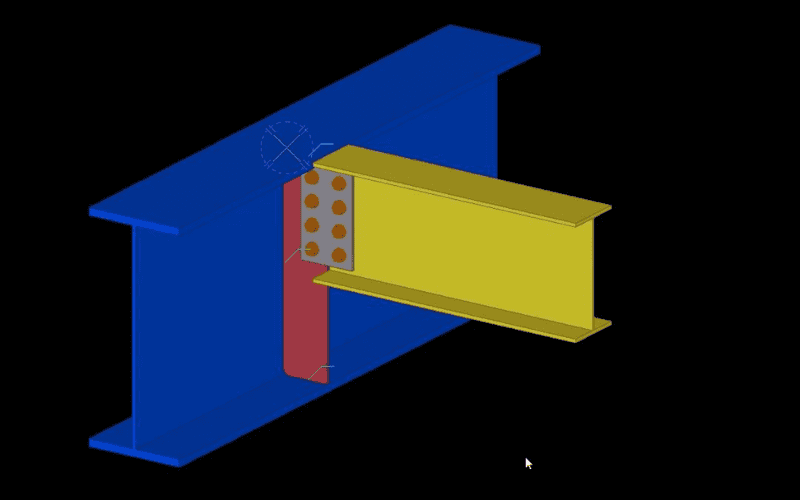

A typical steel beam splice includes:

- Splice plates: steel plates attached to the web or flanges

- Fasteners: bolts or welds that hold the splice plates in place

- Reinforcement elements: stiffeners or additional support to increase stability

Splicing is necessary because beams cannot always be manufactured, transported, or installed in one piece. By joining shorter sections, engineers can achieve long spans, reduce transport costs, and adapt to complex designs.

As a certified PEB structures manufacturer, SteelPRO PEB produces and supplies splice plates, bolt kits, and welded splice solutions directly from the factory. All products are tested and delivered with certification to meet international design codes.

Why Beam Splicing Matters

Steel beam splicing matters because it improves safety, reduces cost, supports sustainability, and gives more design flexibility.

Safety and Reliability

- A well-designed splice makes the joint as strong as a single beam.

- It helps spread bending and shear forces evenly.

- It improves resistance against wind, earthquakes, and fatigue.

Cost Savings

- Shorter beams are easier to produce and transport.

- Leftover sections can be reused through splicing, reducing waste.

- Standardized splice kits speed up installation and lower labor costs.

Sustainability

- Less waste and optimized transport reduce carbon emissions.

- Spliced beams last longer and can be reused in new projects.

- Supports circular economy principles in construction.

Design Flexibility

- Allows creation of long spans that single beams cannot cover.

- Enables curved, tapered, or irregular beam designs.

- Improves efficiency for projects like airports, stadiums, and bridges.

SteelPRO PEB provides factory-direct splice plates, bolts, and welded joints, ensuring projects achieve both structural safety and cost efficiency under certified standards.

Where Should a Steel Beam Splice Be Placed? And Where to Avoid It

Steel beam splice location is critical for structural safety and cost. The wrong location can weaken the beam, while the right one ensures strength and efficiency.

Recommended Splice Locations

A splice should be placed in low-stress areas to keep the beam strong after connection. Common practices include:

- Near the support: within the first third of the span, where bending moments are lower.

- Zones with low shear force: avoiding high-shear ends reduces risk of failure.

Code-compliant positions: always follow IS, AISC, or GB standards to ensure safe splice placement.

Special Case: Load-Bearing Beams

When splicing a primary load-bearing beam:

- Use thicker splice plates or additional stiffeners.

- Apply high-strength bolts or full-penetration welds.

- Perform non-destructive testing (e.g., ultrasonic testing) to check integrity.

Locations to Avoid for Beam Splicing

Never place splices in areas with high stress or frequent dynamic loads. Risk zones include:

- High-stress zones – near beam connections, cantilever ends, or complex stress areas.

- Dynamic load regions – bridges in seismic zones, industrial floors with heavy vibration.

- Design-sensitive areas – where fireproofing or corrosion coatings are critical, since splices disrupt protection layers.

SteelPRO PEB engineering team provides design support for splice locations, ensuring each project meets international safety codes while keeping costs under control.

When Is Steel Beam Splicing Needed in Construction?

Steel beam splicing is needed when structural design, transportation limits, or cost considerations make it impossible to use a single long beam. It is also used in special projects with complex shapes or extreme conditions.

Structural Considerations

- Long-span structures: Airports, stadiums, and exhibition centers often require beam lengths beyond manufacturing limits. Splicing allows multiple sections to form continuous spans.

- Renovation and reinforcement: In upgrades or repairs, splicing replaces damaged sections or extends existing beams.

Transportation Constraints

- Road and bridge transport regulations often restrict beam length.

- Beams are manufactured in shorter sections, delivered to site, and spliced during installation.

- This method reduces both logistics challenges and transportation costs.

Cost-Driven Considerations

- Standardized production: Shorter beams can be mass-produced at lower cost.

- Efficient material use: Leftover segments from other projects can be reused through splicing, minimizing waste.

Special Design Requirements

- Complex architectural forms: Curved, tapered, or irregular beams require splicing to achieve desired shapes.

- Extreme environments: Offshore platforms, high-altitude bridges, and other challenging conditions often need on-site splicing to adapt to constraints.

SteelPRO PEB’s factory supplies precision-fabricated splice plates, bolt kits, and welded solutions at wholesale prices. Our engineering team provides design support so contractors can handle long spans, complex structures, and transport restrictions with confidence.

Four Main Types of Steel Beam Splicing Methods

In steel structures, the main splice joints include bolted, welded, hybrid, and innovative connections. Each method has different applications, advantages, and limitations.

| Splicing Method | Best Suited For | Advantages | Disadvantages |

| Bolted Splice | Fast installation, temporary frames, equipment supports, sites with poor welding conditions | – Quick and simple installation – Easy to remove for maintenance – Works well in remote or high-altitude sites | – Lower fatigue resistance – Precise hole alignment required, higher fabrication cost |

| Welded Splice | High-rise buildings, bridge girders, projects needing high integrity | – Strong and seamless connection – No extra fasteners, clean appearance – Works for complex beam profiles | – Slower construction – Needs skilled welders – Sensitive to weather (wind, rain) – Welding stress may need treatment |

| Hybrid Splice (Bolting + Welding) | Industrial plants, heavy-duty platforms, structures with both dynamic and static loads | – Combines strength of welding and flexibility of bolting – Suitable for heavy-load projects | – Complex process, higher cost – Requires careful sequencing of bolts and welding |

| Innovative Methods (e.g., Mechanical Locking) | Offshore platforms, high-altitude bridges, specialized fast installations | – Very fast, high precision – No need for bolts or welding – Modular design for easy transport and assembly | – Expensive – Requires high design and manufacturing accuracy – Not widely adopted |

SteelPRO PEB manufactures and supplies splice plates, bolt kits, and welded solutions directly from our factory. For heavy projects, we also provide custom hybrid designs, ensuring compliance with IS, AISC, and GB standards.

How to Properly Splice Steel Beams: 6-Step Standardized Process

Steel beam splicing is a high-skill task with complex procedures. To ensure that the spliced steel beams meet design requirements and safety standards, a standardized construction process must be followed. Below are the 6 key steps in the steel beam splicing process:

Splicing steel beams is a high-skill task. To ensure safety and compliance, engineers follow a 6-step standardized process.

Step 1: Design Phase

- Load calculation: check bending, shear, and axial forces.

- Method selection: choose bolted, welded, or hybrid splice based on loads and conditions.

- Drawing confirmation: prepare detailed splice drawings, including plate size, bolt layout, and weld specs.

Step 2: Material Preparation

- Beam end treatment: bevel or mill ends for accurate fit.

- Splice plate fabrication: produce plates to required thickness, material, and dimensions.

- Bolt hole fabrication: drill with precision to ensure proper alignment.

SteelPRO PEB supplies precision-fabricated splice plates and bolt kits, ensuring all materials meet IS, AISC, and GB standards.

Step 3: On-Site Alignment

- Temporary supports keep beams stable during splicing.

- Laser alignment ensures accurate positioning.

- Pre-splice inspection checks plates, bolt holes, and weld surfaces.

Step 4: Connection Construction

- Bolted splice: tighten bolts in sequence to specified torque.

- Welded splice: weld from center to edges, control current and speed to reduce stress.

- Hybrid connection: pre-tighten bolts, then weld for combined strength.

Step 5: Quality Inspection

- Ultrasonic testing (UT) checks welds for cracks and defects.

- Torque verification ensures bolts meet design tension.

- Deformation monitoring confirms beam alignment and straightness.

Step 6: Corrosion and Fire Protection

- Weld seam grinding for smooth coating surface.

- Corrosion protection applied to match beam durability.

- Fireproofing coatings or wraps added as per design requirements.

SteelPRO PEB not only supplies splice components but also provides engineering guidance for quality inspection, protection coatings, and compliance with international standards.

What is the best location for a steel beam splice?

The best location is in low-stress areas, such as the first third of the span near supports or zones with low shear force. Avoid high-stress zones, cantilever ends, and areas with frequent dynamic loads.

What is the difference between bolted and welded splice joints in steel structures?

- Bolted splice joints are faster to install, removable, and suitable for temporary or remote projects.

- Welded splice joints provide seamless strength and are used in permanent structures like high-rise buildings and bridges.

Can splice plates be customized for PEB structures?

Yes. SteelPRO PEB manufactures custom splice plates in different thicknesses, hole patterns, and materials to meet project-specific needs.

How to design a steel beam splice connection as per IS or AISC code?

Engineers must calculate loads, select the splice method, and design plates and bolts according to IS 800, AISC 360, or GB 50017 standards. SteelPRO PEB provides design support and certified splice components that comply with these codes.

Does SteelPRO PEB supply factory-direct splice plates and bolts?

Yes. As a certified PEB structures manufacturer, SteelPRO PEB supplies splice plates, bolts, and welded solutions at wholesale prices, directly from our factory.

Factory-Direct Supply of Steel Beam Splice Solutions

At SteelPRO PEB, we are more than a supplier — we are a certified global manufacturer and producer of steel structures. Since 2013, our factory has delivered over 1,000 projects worldwide, supported by 24 production lines with an annual capacity of 120,000 tons.

We provide:

- Factory-direct splice plates, bolts, and welded splice solutions at wholesale prices

- Custom fabrication and engineering support, designed to meet IS, AISC, GB, Eurocode and other international standards

- High-quality production with ISO and CE certifications

- Comprehensive services: design, fabrication, installation, and after-sales warranty

- Long-term durability guarantee with up to 50 years of structural warranty and 25 years of corrosion resistance

From airports and stadiums to industrial plants and high-rise buildings, SteelPRO PEB ensures your beam splicing project is delivered with precision, efficiency, and certified quality.

Contact us today at peb@steelprogroup.com or via WhatsApp for a free consultation and a factory-direct quotation.