Wondering how to add or install windows and doors in a metal building? You can, and when done right, it improves lighting, ventilation, energy efficiency, and overall functionality. Whether you’re upgrading an existing steel workshop or designing a new prefabricated structure, this guide walks you through every essential step.

You’ll learn:

- The key considerations before cutting openings in metal wall panels.

- The types of prefabricated windows and doors suited for industrial, commercial, or residential steel buildings.

- How to choose the right materials for insulation, strength, and corrosion resistance.

- The exact installation process for airtight, weatherproof performance.

- How to maintain and care for your windows and doors to ensure long-term durability.

- Why selecting a certified steel structure manufacturer makes installation faster and more reliable.

This guide, built on the engineering experience of SteelPRO PEB, a global manufacturer of prefabricated steel structures — helps you transform your metal building with factory-precision windows and doors that last.

Key Considerations When Adding Windows and Doors to Prefabricated Steel Buildings

Adding doors and windows to steel structure buildings is entirely feasible, but proper planning and engineering are essential. Before cutting into your metal panels, keep these key factors in mind to ensure strength, energy efficiency, and long-term durability.

Structural Reinforcement and Framing Considerations

When creating openings in a metal building, reinforcing the frame around each window or door is critical. This helps maintain load-bearing capacity and prevents panel distortion.

For larger openings or heavy-duty doors, additional steel supports or welded frames may be required to distribute stress evenly and prevent structural movement.

Insulation and Weatherproofing

Because steel is a conductor of heat, choosing the right insulation and sealant is vital. Use double-sealed aluminum or vinyl frames with thermal breaks to minimize heat transfer and avoid condensation. Proper flashing and sealant application around frames prevent water infiltration, improving energy efficiency in both hot and cold climates.

In areas with heavy rainfall or temperature fluctuations, consider adding both interior and exterior sealing for maximum protection.

Aesthetic and Functional Balance

Windows and doors should enhance both the appearance and function of your building. Select frame styles, colors, and placements that match your building’s purpose — from industrial workshops that prioritize ventilation and durability to commercial or office spaces emphasizing natural light and design consistency.

Customization and Factory-Prepared Options

Many modern PEB manufacturers now provide factory-prepared wall panels with pre-punched openings for doors and windows. This reduces on-site cutting, ensures precise alignment, and saves installation time.

If you’re planning a new project, ask your supplier about pre-installed window kits or pre-fabricated openings that can simplify installation and improve fit quality.

Types of Prefabricated Windows and Doors for Metal Buildings

When selecting doors and windows for your metal building, both the design and material type play a key role in long-term performance. Prefabricated components not only simplify installation but also ensure a consistent, high-quality fit straight from the factory.

Doors for Steel Buildings

Choosing the right prefabricated doors enhances security, energy efficiency, and ease of access. Depending on your building’s use — industrial, commercial, or residential — different door types serve distinct functions.

- Sliding Doors: Ideal for large-span openings in workshops or storage barns. Prefabricated aluminum or galvanized steel sliding doors offer smooth operation, excellent durability, and minimal maintenance.

- Roll-Up Doors: Perfect for areas with limited clearance, such as warehouses or garages. Factory-supplied roll-up doors, typically made from galvanized steel, provide strong corrosion resistance and space-saving convenience.

- Swing Doors: A reliable choice for personnel access points. Steel or fiberglass swing doors combine durability with thermal insulation, maintaining interior comfort and energy efficiency.

- High-Speed Doors: Commonly used in industrial or logistics facilities requiring frequent entry and exit. These doors, made from heavy-duty PVC or aluminum panels, ensure fast operation and weather-tight performance.

Tip: For heavy-duty applications, request factory-prepared door frames that include built-in reinforcements for faster on-site installation.

Windows for Steel Buildings

Windows enhance both the functionality and aesthetics of metal structures, improving light, ventilation, and energy performance. Prefabricated steel or aluminum-framed windows are engineered for easy integration into pre-punched wall panels.

- Fixed Windows: Best for spaces that prioritize natural light without ventilation needs. These prefabricated aluminum or vinyl windows offer modern looks and low maintenance, ideal for industrial workshops or warehouses.

- Sliding Windows: Space-saving and easy to operate. Prefabricated sliding windows, often constructed from aluminum or fiberglass frames, balance strength with lightweight performance.

- Casement Windows: Provide excellent airflow control and tight sealing. These windows, typically framed in steel or aluminum, are suitable for office areas or living spaces inside a PEB building.

- Skylights and Roof Windows: Allow natural light to flood interior spaces. Polycarbonate or tempered glass skylights with factory-integrated flashing systems offer superior weatherproofing and UV protection.

Custom Options and Factory-Prepared Solutions

Modern PEB manufacturers now offer a range of factory-prepared window and door solutions:

- Pre-punched wall panels for precise alignment

- Integrated frames for quick installation

- Optional thermal-break or double-glazed systems for better energy efficiency

Choosing factory-supplied components not only reduces on-site cutting and errors but also ensures compliance with international standards like ISO and CE.

How to Choose Materials for Doors and Windows in Steel Buildings

Selecting the right material for your doors and windows determines not only the appearance of your metal building but also its durability, insulation, and energy performance. Each material has distinct advantages depending on your project’s environment, function, and design goals.

Material Selection by Application

| Application Scenario | Recommended Material | Key Advantages |

| Industrial Workshops / Warehouses | Aluminum or Stainless Steel | High strength, corrosion resistance, low maintenance, ideal for high-traffic or heavy-duty environments. |

| Office or Residential Spaces | Vinyl or Fiberglass | Superior insulation, lightweight, cost-effective, and aesthetically flexible. Great for energy savings and thermal comfort. |

| Coastal or High-Humidity Areas | Galvanized or Marine-Grade Steel | Exceptional corrosion resistance, suitable for harsh weather and salt-laden air. |

| Design-Focused or Mixed-Use Buildings | Fiberglass or Powder-Coated Aluminum | Combines modern design with energy efficiency, available in various finishes and colors. |

Material Overview

- Aluminum: Lightweight and durable, aluminum is widely used in industrial and commercial metal buildings. It offers excellent corrosion resistance and supports powder coating for a modern appearance. However, for better insulation, choose versions with thermal breaks.

- Stainless Steel: Designed for environments exposed to moisture, chemicals, or heavy wear. Its strength and anti-rust properties make it ideal for industrial plants or coastal structures.

- Vinyl: A top choice for cost-effective and energy-efficient windows in offices or residential PEB structures. Vinyl frames prevent thermal bridging and require minimal upkeep.

- Fiberglass: Highly versatile and thermally efficient. Fiberglass frames provide superior insulation and can mimic the texture of wood, adding warmth to modern metal buildings.

- Galvanized Steel: Often used for prefabricated doors or large entry frames, galvanized steel is coated to resist corrosion. It ensures stability in heavy-duty or long-span steel structures.

Final Recommendation

The best material depends on your project’s location and function.

For instance:

- Use aluminum or stainless steel in production environments.

- Choose vinyl or fiberglass to enhance comfort in offices or residential extensions.

- Opt for galvanized steel in coastal or industrial applications where corrosion resistance is key.

Choosing the right material not only affects durability and maintenance, but also improves insulation and energy efficiency — essential for modern steel workshops and warehouses seeking long-term performance.

Related Reading:

How to Choose Windows for Metal Buildings

How to Install Windows and Doors in a Metal Building

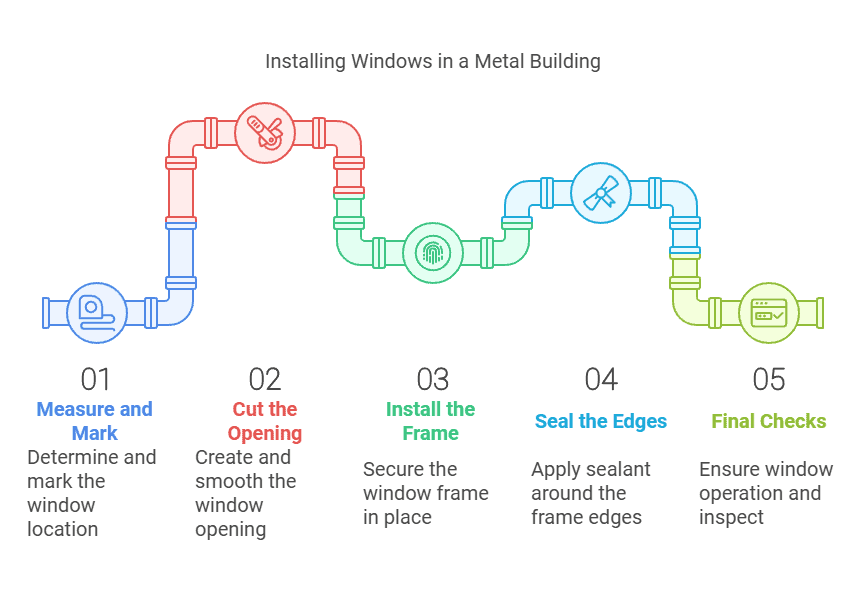

Installing windows or doors in a metal building requires accuracy, proper tools, and careful sealing to maintain both structural integrity and weather resistance. Whether you’re retrofitting an existing structure or adding openings to a new PEB system, following these steps ensures a smooth, durable result.

Tip: Many steel building manufacturers now offer factory-prepared wall panels with pre-punched openings. These make installation faster and more precise — reducing cutting time and alignment issues on site.

Step 1: Measure and Mark the Window or Door Opening in Metal Panels

Accurate measurements are the foundation of a proper installation.

- Use a laser level or tape measure to mark the exact location of your window or door.

- Ensure alignment with framing members or girts to maintain load support.

- Mark the outline with chalk or a removable marker, allowing clearance for the frame and sealant.

Pro Tip: Always measure each opening individually — even small variations in panel placement can cause misalignment.

Step 2: Cut the Opening Using a Plasma Cutter or CNC Tool

Once marked, carefully cut the metal sheet.

- Use a plasma cutter for large openings or a CNC metal saw for precision cuts.

- If working on insulated sandwich panels, cut slowly to avoid damaging internal insulation.

- Smooth sharp edges with a file or grinder to prevent sealant gaps and injuries.

Pro Tip: Avoid excessive heat during cutting to prevent warping thin-gauge metal sheets.

Step 3: Install and Level the Frame

With the opening ready, it’s time to position and secure the frame.

- Place the frame into the opening and check alignment using a spirit level.

- Fasten the frame with expansion bolts or screws; for structural applications, welding may be required.

- For larger or heavier windows and doors, add internal reinforcement plates to resist wind pressure and frame stress.

Pro Tip: Use factory-supplied frames when possible — they’re pre-fitted for exact panel depth and screw alignment.

Step 4: Seal and Weatherproof the Edges

Proper sealing ensures durability and energy efficiency.

- Apply a high-quality silicone or polyurethane weatherproof sealant around all edges.

- Install flashing strips or foam closures for added protection against water leaks.

- In high-moisture or coastal environments, double-seal the exterior and interior for long-term performance.

Pro Tip: Smooth sealant joints immediately after application to prevent air pockets and ensure a continuous waterproof barrier.

Step 5: Perform Final Checks and Finishing Touches

After installation, verify the functionality and finish.

- Open and close the window or door several times to check smooth operation.

- Inspect for visible gaps, misalignment, or sealant voids.

- Clean all edges, remove excess sealant, and apply touch-up paint or coating if needed.

Pro Tip: From a distance, visually inspect alignment across all openings — even slight misalignment can be noticeable in large façades.

Additional Notes for Retrofitting Existing Buildings

If installing into an existing metal building:

- Inspect the wall panels for corrosion or deformation before cutting.

- Reinforce the perimeter frame with additional steel tubing if necessary.

- For older structures, ensure the new frame connects to load-bearing columns, not just cladding panels.

Safety Reminder: Always wear gloves, goggles, and protective gear when cutting or welding metal components.

By following these steps — or working with a certified steel structure manufacturer that offers factory-prepared window and door kits — you’ll ensure a cleaner, safer, and more efficient installation process that aligns with modern PEB building standards.

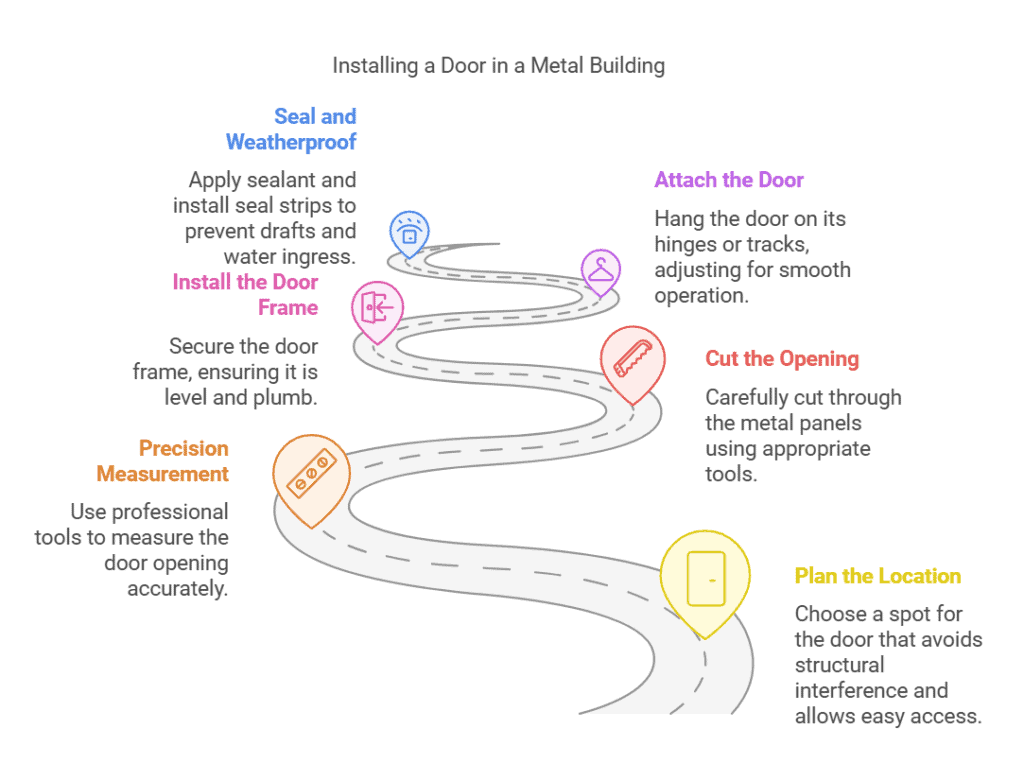

How to Install a Door in an Existing Metal Building

Installing windows in a steel building might sound like a big job, but with the right tools and a bit of patience, it’s totally doable! Follow these steps to make the process smooth and hassle-free.

Step 1: Measure and Mark

- Grab a laser level or measuring tape to mark exactly where your window will go.

- Double-check the dimensions so the opening fits the window snugly, including space for the frame.

Step 2: Cut the Opening

- Use a metal-cutting tool, like an angle grinder or plasma cutter, to cut out the marked section.

- Smooth out the edges with a file or deburring tool—this helps prevent injuries and ensures a clean fit.

Step 3: Install the Frame

- Set the window frame into the opening, making sure it’s perfectly level (a spirit level helps!).

- If the wall has built-in steel supports, weld the frame directly for extra stability. Otherwise, use metal or plastic expansion bolts to keep it secure.

Step 4: Seal the Edges

- Apply weatherproof sealant (silicone or polyurethane works best) around the frame to keep out moisture and drafts.

- For extra protection, add an exterior seal strip—cutting the corners at a 45-degree angle helps improve the seal.

Step 5: Final Checks

- Open and close the window a few times to make sure it operates smoothly.

- Look for any gaps or misalignments and add more sealant if needed.

Pro Tips:

- ✅ Safety First: Wear gloves, goggles, and sturdy shoes—cutting metal isn’t a barefoot kind of job!

- ✅ Energy Efficiency Matters: Go for double-glazed insulated glass or thermal-break windows to keep the heat (or cold) out.

- ✅ Reinforce for Strength: For larger windows, consider adding extra bracing to handle wind loads and keep everything solid.

- ✅ Call in the Pros: If you’re unsure about cutting into your metal building, consult a professional—fixing mistakes can be costly!

Pre-Installation Advantage:

When constructing a steel building, manufacturers (like us) pre-prepare door locations in the factory, ensuring the door frame aligns perfectly with the structure. This guarantees an exact fit, reducing installation time and providing a sleek, professional finish.

Maintenance and Care for Windows and Doors in Steel Buildings

Proper maintenance ensures that your factory-installed or prefabricated windows and doors continue to perform like new for decades. Regular inspection and care not only preserve appearance and function but also sustain the energy efficiency and weather resistance of your steel building.

Inspect Seals and Frames Regularly

Check seals, weatherstripping, and frame joints at least twice a year. Look for cracks, gaps, or peeling sealant that could lead to air or water leaks.

Pro Tip: Replace any damaged gaskets immediately — compromised seals are the main cause of condensation and energy loss.

Clean and Lubricate Moving Components

Keep all hinges, rollers, and sliding tracks clean and free of debris. Apply silicone-based lubricant to maintain smooth operation and prevent corrosion. Avoid oil-based lubricants, as they attract dust.

Regular lubrication extends hardware lifespan and ensures quiet, stable function.

Monitor Alignment and Hardware Integrity

Over time, structural shifts or repeated use may cause minor misalignment. Check that doors close evenly and windows open smoothly. Tighten or adjust fasteners as needed to prevent long-term frame stress.

For large industrial doors or heavy frames, schedule a professional inspection once a year.

Maintain Surface Protection and Finish

Wipe down painted or coated surfaces to remove dirt and pollutants that can accelerate corrosion. For galvanized or aluminum frames, use neutral cleaners — never abrasive chemicals. Touch up scratches or chips promptly to prevent rust.

In coastal regions, rinsing frames with fresh water every few months helps remove salt buildup.

Check Insulation and Energy Efficiency

Inspect insulation materials around frames to ensure they remain intact and effective. Replace worn foam or sealant to avoid thermal bridging.

Pro Tip: A quick infrared scan or temperature test can reveal insulation leaks that affect HVAC efficiency.

Routine Maintenance Schedule (Recommended)

| Task | Frequency | Responsible |

| Visual inspection of frames and seals | Every 6 months | Owner / Maintenance team |

| Lubrication of hinges and rollers | Every 6 months | Maintenance team |

| Repainting or coating touch-up | Every 12 months | Professional contractor |

| Structural alignment check | Every 12–18 months | Professional inspection |

| Full weatherproofing reseal | Every 2–3 years | Certified installer |

Consistent maintenance ensures your steel structure’s doors and windows maintain their airtight seal, visual appeal, and operational reliability.

Regular inspection protects against corrosion and helps your PEB building retain optimal insulation and energy efficiency throughout its lifespan.

Can I add windows or doors to an existing metal building?

Yes, with the right engineering approach. Modern PEB structures allow for retrofit installations using factory-prepared window and door kits. Reinforcing the frame around the new opening ensures strength and prevents panel distortion. SteelPRO PEB provides precision-cut frames and technical drawings for safe retrofitting.

What’s the best window type for a PEB workshop or warehouse?

It depends on the balance between light, ventilation, and durability.

- For warehouses → fixed aluminum windows with clear tempered glass.

- For workshops → sliding or casement styles for airflow control.

- For humid or coastal areas → powder-coated aluminum or vinyl frames.

Are prefabricated windows and doors more efficient than custom site-built ones?

Absolutely. Prefabricated units are built in controlled factory conditions, ensuring airtight seals, uniform dimensions, and quicker installation. They perform better in energy efficiency, water resistance, and long-term durability.

How much does it cost to add windows or doors to a steel building?

Costs vary based on size, material, and installation complexity. As a guide:

- Prefabricated aluminum windows: mid-range cost, long lifespan.

- Steel-framed doors: higher cost but superior security and resistance.

Getting factory-engineered components often saves 15–25% on labor and reduces installation time significantly.

Do manufacturers provide pre-punched panels or ready-to-install kits?

Yes, leading manufacturers like SteelPRO PEB offer factory-prepared wall panels and pre-punched frames. These allow faster, cleaner installation with perfect alignment to your PEB structure. This precision eliminates on-site cutting errors and ensures consistent quality across all openings.

Why the Right Manufacturer Defines the Quality of Your Metal Building’s Windows and Doors

Behind every well-installed metal building window or door, there’s precision — and that precision starts at the factory.

A reliable PEB manufacturer doesn’t just supply parts; it engineers factory-prepared openings, pre-punched wall panels, and perfectly aligned frames that fit your building’s structure without guesswork.

That means tighter seals, smoother installation, and long-term performance that stands up to wind, water, and time.

At SteelPRO PEB, every frame is cut, welded, and inspected under ISO and CE-certified standards, ensuring the same accuracy from the first bolt to the final seal. Whether your project is an industrial workshop or a steel warehouse retrofit, you get components that arrive ready to install — saving days on site while delivering a cleaner, more airtight finish.

Upgrade your steel building the smart way — with factory-engineered windows and doors built for perfect fit, energy efficiency, and lasting durability.

Talk to SteelPRO PEB today and get expert support from the people who build precision into every panel.