Steel vs aluminum in construction is a crucial comparison for architects and builders seeking the right balance of cost, strength, and durability. In most building applications, steel remains the more economical and structurally reliable choice, while aluminum offers lightweight and corrosion-resistant advantages in specific environments.

This guide compares the two materials across key factors — from mechanical properties and corrosion performance to real-world applications, pricing, manufacturing, and environmental impact — helping you choose the best option for your project’s scale and conditions.

As a certified steel structure manufacturer and PEB producer, SteelPRO PEB provides engineering insights based on real production data and international standards (ISO & CE). With over a decade of experience and 120,000 tons of annual steel output, we aim to help decision-makers evaluate materials through both technical performance and lifecycle cost efficiency, ensuring every project achieves optimal safety, sustainability, and value.

Steel vs Aluminum in Building Pros and Cons

Steel and aluminum are both essential materials in modern construction, each offering distinct benefits depending on project requirements. Below is a clear comparison highlighting their key strengths and trade-offs.

Pros and Cons of Steel

Advantages:

- Exceptional strength and load-bearing capacity make steel the top choice for large structures such as skyscrapers, bridges, and industrial buildings.

- Excellent fire resistance ensures safety in high-rise and commercial buildings.

- Highly durable with long service life, even under extreme conditions.

- 100% recyclable and sustainable when produced under certified manufacturing standards.

Disadvantages:

- Susceptible to corrosion without proper surface treatment, leading to maintenance needs over time.

- Heavier than aluminum, increasing transportation and installation costs in some projects.

- Higher initial material cost compared to certain lightweight alternatives.

Pros and Cons of Aluminum

Advantages:

- Lightweight nature significantly reduces structural load, ideal for facades, roofing, and cladding.

- Excellent corrosion resistance minimizes maintenance and eliminates the need for heavy protective coatings.

- Aesthetic appeal suits modern and high-tech architectural styles.

- Fully recyclable, aligning with green building standards.

Disadvantages:

- Lower tensile strength limits its use in heavy structural frameworks.

- Higher raw material cost compared to steel can affect cost-sensitive projects.

- Softer surface is prone to denting in high-traffic or industrial environments.

Overall, steel provides higher strength and cost efficiency for major structural frameworks and load-bearing elements, while aluminum offers lightweight and corrosion-resistant advantages for facades and architectural details.

Mechanical and Physical Properties: Steel vs Aluminum

The following table summarizes the main mechanical and physical differences between steel and aluminum used in construction:

| Property | Steel | Aluminum |

| Density (g/cm³) | 7.85 | 2.7 (≈66% lighter) |

| Melting Point (°C) | 1370–1530 | 660 |

| Thermal Conductivity (W/m·K) | 50 | 237 |

| Ductility (Elongation after fracture) | 20–30% | 40–50% |

Strength

Steel exhibits a tensile strength between 400–2000 MPa, significantly exceeding aluminum’s 80–600 MPa range. This makes steel ideal for high-rise buildings, bridges, and heavy-load frameworks where strength and stiffness are critical.

Although aluminum has a lower absolute strength, its excellent strength-to-weight ratio allows efficient use in lightweight structures such as curtain walls or roofing systems where load reduction matters more than total strength.

Corrosion Resistance and Maintenance

Steel:

- Naturally prone to corrosion when unprotected.

- Service life can be significantly extended through galvanizing, painting, or the use of weathering steel (Corten), which forms a self-protective rust layer.

- Requires periodic inspection and recoating every 10–15 years, especially in humid or industrial environments.

- When properly maintained, steel structures can last for decades and deliver consistent long-term performance.

Aluminum:

- Forms a dense oxide film that naturally resists corrosion even without coatings.

- Performs excellently in coastal, humid, or high-salt environments.

- Requires minimal maintenance and rarely needs repainting, reducing long-term upkeep costs.

- In acidic or alkaline environments, the oxide layer may deteriorate and require additional protective measures.

In general, aluminum structures experience fewer maintenance cycles throughout their lifespan, while steel’s lower upfront material cost makes it the more economical choice for large-scale or indoor projects.

While aluminum helps reduce maintenance frequency, steel’s overall lifecycle cost often remains lower when project scale, load capacity, and replacement intervals are considered.

Fire Resistance and Safety

Steel:

- Maintains strength at higher temperatures (softens at around 538 °C, melts above 1370 °C).

- With fireproof coatings, steel structures provide sufficient time for evacuation and maintain structural integrity longer.

Aluminum:

- Melts at around 660 °C and loses load-bearing capacity rapidly in fire.

- Not suitable for load-bearing fire-rated structures, though acceptable for non-structural facades and trims.

Steel offers superior fire resistance and safety performance, making it the preferred choice for industrial buildings, warehouses, and high-rise structures.

Aluminum vs Steel: Applications in Building Construction

Aluminum vs Steel: Applications in Building Construction

Steel and aluminum each play distinct roles in the construction industry. While both are durable and versatile, their performance and cost profiles determine the most suitable applications for different building types.

Structural Frameworks and High-Rise Buildings

- Steel: Steel remains the preferred material for load-bearing frameworks such as high-rise buildings, bridges, and factories. Its exceptional strength, rigidity, and fire resistance ensure long-term structural safety and stability.

- Aluminum: Aluminum is rarely used as a primary structural material but is common in secondary components, including window frames and facade systems. Its light weight simplifies handling and reduces installation loads.

Steel provides unmatched strength and cost efficiency for structural frameworks, whereas aluminum is mainly chosen for secondary and non-load-bearing elements.

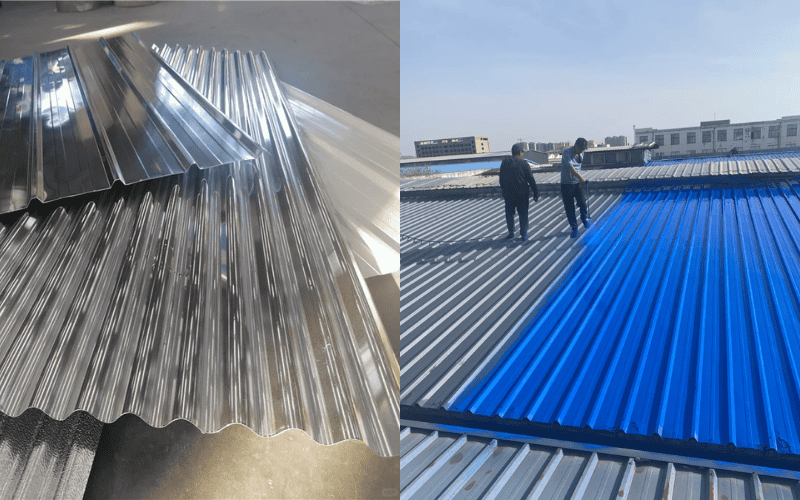

Facades, Roofing, and Curtain Walls

- Steel: Steel offers durability and excellent load-bearing capacity, making it suitable for large-span roofs and facade support systems in commercial or industrial buildings. Its fire resistance and strength provide extra safety in extreme weather or fire conditions.

- Aluminum: Aluminum’s corrosion resistance and low weight make it ideal for facades, curtain walls, and roofing in coastal or humid environments. It also supports complex geometric designs and modern aesthetics.

Choose steel for heavy-duty or long-span roofing and aluminum for modern architectural facades emphasizing design flexibility and corrosion resistance.

Interior Construction

- Steel: Commonly used in columns, beams, and mezzanine frames, steel provides solid support and durability in warehouses and industrial interiors. It is also valued for exposed structural aesthetics in modern interior design.

- Aluminum: Frequently used for doors, windows, ceiling grids, and partitions, aluminum combines lightweight performance with a sleek, modern appearance and minimal maintenance needs.

Steel suits load-bearing and industrial-style interiors, while aluminum is better for decorative, modular, or lightweight interior systems.

Sustainability and Environmental Efficiency

- Steel: Steel has a high recycling rate and can be reused repeatedly without degrading quality. Its long service life and strength reduce material consumption in the long term. However, traditional steelmaking emits significant CO₂, though modern electric arc furnace (EAF) technology has reduced emissions dramatically.

- Aluminum: Aluminum production is energy-intensive, but recycled aluminum (secondary aluminum) emits up to 95% less CO₂ than primary production. Its lightweight properties also reduce energy loads in buildings through improved thermal efficiency.

Both materials support sustainable construction goals. Steel offers long-term durability and recyclability, while aluminum contributes to lightweight, energy-efficient building envelopes.

When sourced from certified manufacturers following ISO and CE standards, both can meet modern green building requirements.

Steel vs Aluminum in Metal Building Price

The cost of steel and aluminum in construction depends on multiple factors—initial material prices, fabrication complexity, maintenance needs, and long-term performance.

Below is a breakdown comparing the overall cost efficiency of both materials across key economic stages of a project.

Initial Cost

- Steel: Steel is generally cheaper per kilogram than aluminum and benefits from mature global production systems. Its affordability and availability make it the preferred choice for large-scale industrial, warehouse, and commercial buildings. Because of its high strength, less material is required to achieve equivalent load capacity, further lowering overall cost.

- Aluminum: Aluminum’s production involves energy-intensive processes, which result in higher initial material prices. However, its light weight can lower transportation and installation costs, especially in structures requiring precision or height, such as curtain walls or canopies.

Steel offers a significant initial cost advantage and remains the standard material for structural applications, while aluminum’s upfront investment is justified in projects prioritizing lightweight performance or design flexibility.

Maintenance Cost

- Steel: Requires regular inspections and protective recoating (e.g., galvanization or paint) every 10–15 years to prevent corrosion. Maintenance expenses vary by environment—humid, coastal, or industrial zones typically require more frequent treatment. Despite this, steel’s spare parts and coatings are widely available and cost-effective, minimizing long-term upkeep complexity.

- Aluminum: Its natural oxide layer prevents corrosion, meaning it requires very little surface maintenance over its lifetime. No repainting or recoating is typically needed, which reduces maintenance-related labor and downtime. However, in acidic or highly polluted environments, occasional surface restoration may be necessary.

Aluminum generally has lower maintenance, while steel’s maintenance cycle is predictable and manageable. For long-term structural projects, the total upkeep cost difference narrows when steel’s lower material price is factored in.

Long-Term Value and Application Efficiency

- Steel: Offers long service life, high load-bearing capacity, and full recyclability. In large-span or industrial applications, steel’s performance stability and cost ratio make it the most economical option over decades of use. Modern steel production using electric arc furnace (EAF) technology further improves energy efficiency and reduces environmental impact.

- Aluminum: Despite its higher initial cost, aluminum delivers value through reduced maintenance, corrosion resistance, and lighter installation loads. Its aesthetic appeal and flexibility also enhance value in architectural facades or coastal buildings where longevity and appearance are key.

Both materials deliver long-term value depending on project priorities:

- Choose steel for heavy-duty, cost-driven, and large-scale structures.

- Choose aluminum for design-focused or corrosion-sensitive applications.

Steel structures remain more cost-effective for most industrial and commercial buildings, while aluminum offers specialized advantages in environments where corrosion resistance or design aesthetics take priority.

Manufacturing and Installation Considerations

When comparing steel and aluminum for construction, it’s important to understand not only their material performance but also how they differ in fabrication, transport, and on-site installation. These practical factors often determine overall project efficiency and cost.

Fabrication and Processing

- Steel: Steel offers straightforward fabrication and welding, with a wide range of established processes such as arc welding, gas welding, and bolted assembly. It can be heat-treated through annealing, quenching, or tempering, allowing engineers to adjust hardness and toughness based on structural requirements. Because of its strength and workability, steel fabrication is highly predictable and compatible with large-scale automated production systems.

- Aluminum: Aluminum is easier to shape and extrude, making it suitable for custom profiles and decorative components. However, aluminum welding requires more precise temperature control and surface cleaning, as it’s sensitive to oxidation and heat distortion. This means aluminum fabrication typically demands specialized equipment and skilled labor, slightly increasing production costs.

Steel fabrication is simpler and more standardized, while aluminum offers greater flexibility for aesthetic and lightweight designs but requires more precise handling during production.

Transportation and Installation Efficiency

- Steel: Due to its higher density, steel components are heavier and require heavy-lifting equipment during installation. This may increase logistical complexity but provides superior rigidity and fewer connection points, reducing the number of structural components overall. For large projects, modular steel systems can accelerate construction timelines despite the heavier material.

- Aluminum: Aluminum’s light weight allows for easier transportation, faster lifting, and reduced foundation loads. In prefabricated or modular projects, aluminum panels and curtain wall systems can cut installation time by up to 25%, minimizing on-site labor and project duration. However, the lighter material may require additional structural reinforcement in high-load areas.

Steel ensures stronger structural integrity and predictable performance, while aluminum excels in speed, mobility, and installation efficiency—making it ideal for modular or retrofit projects where time and logistics are key factors.

In practical construction:

- Steel provides easier large-scale fabrication, robust welds, and high load-bearing capacity.

- Aluminum offers faster assembly, lighter transport, and reduced installation time.

In short, steel is best for heavy-duty and permanent structures, while aluminum suits lightweight, modular, and fast-deployment projects.

Environmental Impact of Steel and Aluminum

In modern construction, sustainability is a key factor when choosing between steel and aluminum. Both materials are recyclable and contribute to green building practices, but their energy consumption and carbon emissions differ significantly depending on production methods.

Steel: Efficiency and Emission Reduction

- Traditional steelmaking through blast furnaces produces approximately 1.8 tons of CO₂ per ton of steel.

- However, new Electric Arc Furnace (EAF) technology can reduce this to as low as 0.6 tons per ton, cutting emissions by more than half.

- Steel’s long service life and high recyclability—up to 98% recovery rate—mean it can be reused multiple times without losing performance.

- These characteristics make steel a cornerstone of sustainable industrial and commercial construction, where durability and lifecycle performance are crucial.

Aluminum: Lightweight and Energy-Saving

- Primary aluminum production remains energy-intensive, with emissions averaging 12 tons of CO₂ per ton of aluminum.

- Yet, recycled aluminum (secondary aluminum) reduces that figure to just 0.5 tons per ton, achieving nearly 95% energy savings compared to primary production.

- Aluminum’s lightweight and corrosion resistance reduce long-term maintenance, while its reflective surface improves building energy efficiency by minimizing heat absorption.

- This makes aluminum an ideal choice for facades, cladding, and roofing in energy-conscious building designs.

Steel offers a lower carbon footprint in large-scale, long-life structures due to its exceptional strength, reusability, and reduced energy consumption per functional load. In contrast, aluminum excels in energy efficiency during use and demonstrates outstanding recyclability, particularly for lightweight and climate-adaptive building designs.

Ultimately, the best environmental choice depends on the building’s function, design, and expected lifespan—steel is better suited for heavy-duty, long-lasting projects, while aluminum is ideal for lightweight, energy-efficient constructions.

Should you choose steel or aluminum in construction?

Choosing between steel and aluminum depends on your project’s structural needs, budget, and environmental conditions. The following questions can help you determine which material is more suitable for your construction application.

Do you need high strength and load-bearing capacity?

- Steel: Steel offers superior tensile strength and stiffness, making it ideal for high-rise buildings, bridges, factories, and large-span structures. Its ability to bear heavy loads without deformation ensures long-term reliability and safety.

- Aluminum: While aluminum has a good strength-to-weight ratio, its overall strength is much lower than steel, limiting its role to non-structural or secondary applications.

→ Choose steel for projects where load-bearing and structural integrity are the top priorities.

Do you need lightweight materials?

- Aluminum: Aluminum is about 66% lighter than steel, significantly reducing the dead load of the building. It’s especially suitable for facades, curtain walls, modular panels, and transportable buildings where weight reduction enhances installation efficiency.

- Steel: Steel’s higher density increases transportation and lifting requirements, but its strength allows for fewer members, maintaining efficiency in large-scale construction.

→ Choose aluminum when lightweight performance and installation speed are critical factors.

Do you need corrosion resistance?

- Aluminum: Naturally forms a protective oxide layer that resists corrosion, making it ideal for coastal, humid, or high-salinity environments. It requires little to no maintenance for surface protection.

- Steel: Requires coatings or galvanization to prevent rust but remains the more economical choice for indoor or dry-climate projects. With proper surface treatment, steel can achieve excellent long-term durability at a lower overall cost.

→ Choose aluminum when your project demands long-term corrosion resistance with minimal maintenance.

Summary

- Choose Steel for:

- Structural frameworks, warehouses, factories, and cost-driven projects.

- Applications requiring strength, stability, and long-term performance.

- Choose Aluminum for:

- Facades, curtain walls, and modular designs emphasizing light weight or corrosion resistance.

- Projects in coastal or humid environments where minimal maintenance is essential.

In most structural applications, steel remains the more cost-effective and durable option, while aluminum provides design and corrosion-resistance advantages in specialized architectural or environmental conditions.

For project-specific recommendations, consult SteelPRO PEB — a certified steel structure manufacturer and PEB producer — to receive a factory-direct comparison and customized material quotation tailored to your building requirements.

Is steel cheaper than aluminum for buildings?

Yes. Steel is generally more cost-effective than aluminum in building applications. It has a lower price per kilogram and provides higher strength, meaning less material is needed. Aluminum’s lightweight advantages do not fully offset its higher raw material and fabrication costs in large-scale projects.

Which material offers better long-term cost efficiency?

Over the full lifecycle, steel often delivers better cost efficiency for structural projects. Although aluminum requires less maintenance, steel’s lower initial cost and durability balance total expenses over decades of service.

Which is better, aluminum or steel?

Neither material is universally better—it depends on project needs. Steel is ideal for heavy-duty and load-bearing structures, while aluminum excels in lightweight, corrosion-resistant architectural designs. In most construction projects, steel remains the standard choice for performance and value.

What lasts longer, aluminum or steel?

Both materials can last for decades, but steel typically offers longer structural life when properly coated or galvanized. Aluminum performs better in coastal or humid environments but can deform more easily under heavy loads.

Is aluminum good for buildings?

Yes. Aluminum is an excellent material for facades, roofing, and curtain walls, especially in humid or marine environments. However, for structural frameworks or heavy-load components, steel is the more reliable and economical option.