Steel structure mezzanines are a great way to make the most of your warehouse or factory space. Whether you need extra storage or a workspace, these mezzanines are built for strength and flexibility. They help you add space without expanding the building, making them perfect for a variety of industrial needs.

What is Mezzanine in Steel Structure?

A steel structure mezzanine is a temporary or permanent floor built with steel, typically located between the roof and the ground floor, to increase usable space. These mezzanines are often constructed using steel beams and columns, sometimes combined with metal decking or concrete for added strength. Steel warehouse mezzanine creates extra space without expanding the warehouse’s footprint, making it ideal for offices, storage, or other purposes. Similarly, an industrial mezzanine maximizes vertical space and is designed to support heavy loads, offering flexibility in industrial environments.

Types of Steel Structure Warehouse Mezzanines

Steel structure mezzanines are assembled on-site using hot-rolled steel and other materials. While the steel framework is pre-fabricated, welding or bolting is needed on-site for final assembly. These mezzanines are categorized by platform type or structural composition. The following are the types of mezzanines in steel structure warehouses and industrial mezzanine design tips.

By Platform Type:

Indoor Platform

Used for storage, workspace, or operational areas in warehouses, factories, and retail spaces. These platforms can support up to 5 tons per square meter, handling both static (e.g., stored goods) and moderate dynamic loads (e.g., moving equipment). They maximize vertical space without expanding the building’s footprint. A steel warehouse mezzanine offers an excellent solution for optimizing space in facilities with limited floor area.

Design Considerations:

- Safety: Guardrails, non-slip flooring, and clear signage are a must. Workers should be trained regularly.

- Clearance: A minimum of 1.8 meters clearance ensures safe movement of people and equipment.

- Maintenance: Regular checks on surfaces and supports are essential, especially in high-traffic areas.

Static and Dynamic Load Platforms

These platforms handle both static (e.g., stored materials) and dynamic loads (e.g., moving machinery, conveyor systems). Steel structure mezzanine floors must be designed to handle both the weight and the forces from movement, with reinforced beams and floor systems. They can support up to 10 tons per square meter in heavy-duty applications, making them ideal for warehouse mezzanine systems in industries that require strong structural support.

Design Considerations:

- Safety: In addition to guardrails, anti-vibration features should be added for dynamic loads. Emergency exits are vital in high-traffic areas.

- Clearance: A minimum of 1.8 meters clearance is necessary for safe passage.

- Maintenance: Inspect beams, bolts, and flooring regularly to avoid wear or accidents.

Production Support Platform

Located in steel warehouse mezzanines within warehouses or industrial facilities, these platforms support production or material handling. They maximize vertical space, adding extra storage, workspace, or sorting areas. These platforms can bear between 250 kg/m² and 2000 kg/m², depending on design.

Design Considerations:

- Safety: Guardrails, anti-slip surfaces, and clear access are essential. Emergency exits and equipment security are key.

- Clearance: A clearance of 1.8 meters ensures safe movement of materials and workers.

- Maintenance: Regular inspections of load-bearing components help prevent wear or excessive load damage.

Medium and Heavy-duty Operational Platforms

Used for heavy equipment in manufacturing or logistics. Medium-duty platforms use light steel and H-beams for supports, with capacities from 500 kg/m² to 1000 kg/m². Heavy-duty platforms use high-strength steel and require denser support, often including extra beams and columns, with load capacities exceeding 1000 kg/m².

Design Considerations:

- Safety: Robust guardrails, safety ladders, and well-defined safety zones are essential. Stability for heavy machinery should be ensured.

- Clearance: A 2.5-meter clearance is recommended for safe operation of equipment like forklifts.

- Maintenance: Regular inspections of welds and supports are critical for long-term safety.

By Structure Type:

Full Steel Structure

Made entirely of steel, this structure offers high strength and durability, supporting up to 10 tons per square meter. Steel components are pre-fabricated, but welding and assembly are done on-site.

Design Considerations:

- Stability: Steel ensures high stability under heavy loads, so load distribution is key to prevent structural failure.

- Space Utilization: The structure is highly adaptable, ideal for various uses like storage or machinery.

- Seismic and Fire Resistance: Steel is strong and offers decent seismic performance, though fireproof coatings are necessary in high-risk zones.

Steel Frame with Concrete Composite Mezzanine

Combines steel frames and concrete for enhanced load-bearing capacity, making it ideal for heavy-duty use with up to 12 tons per square meter. The steel frame is pre-fabricated, but concrete is poured on-site.

Design Considerations:

- Stability: Concrete enhances load capacity, perfect for heavy equipment or storage.

- Space Utilization: Great for spaces requiring both strength and flexibility.

- Seismic and Fire Resistance: Concrete offers strong fire resistance and improves seismic performance, though additional reinforcements may be needed in seismic zones.

Steel Frame with Wood Composite Mezzanine

Used for lighter loads, combining steel framing with wood panels, supporting around 2 to 3 tons per square meter. The steel frame is pre-fabricated, but wood panels and connections must be assembled on-site.

Design Considerations:

- Stability: This design offers moderate stability, suitable for light-duty applications.

- Space Utilization: Maximizes vertical space for lightweight storage.

- Seismic and Fire Resistance: Wood requires fireproof treatments and seismic design to account for its flexibility.

For warehouses with ultra-high loads or specialized equipment storage, custom steel structures are engineered and fabricated on-site to meet unique requirements. These are tailored to the specific load needs and spatial conditions.

Differences Between Steel Structure Warehouse Mezzanine and Prefabricated Steel Structure Mezzanine

Design & Construction

- Steel Structure Mezzanine: Built on-site with flexibility for custom layouts, making it great for complex or oddly shaped spaces. It can also be adjusted during construction based on site-specific conditions, offering more flexibility than prefabricated options.

- Prefabricated Steel Structure Mezzanine: Pre-engineered and mostly assembled in the factory, so it’s faster to install, ideal for simpler designs.

If you’re looking to understand how What is Prefab Warehouse Mezzanine System works, it’s crucial to note that the system offers streamlined installation processes and faster setup time.

Material Usage

- Steel Structure Mezzanine: Uses hot-rolled steel (e.g., H-beams, I-beams) for strength and load capacity. Materials are customized based on project needs, with options like concrete or wood as well.

- Prefabricated Steel Structure Mezzanine: Relies on lightweight, high-strength steel (e.g., cold-formed steel) for standardization. Components are pre-treated for corrosion resistance and mass-produced for faster assembly on-site.

Construction Method

- Steel Structure Mezzanine: Constructed entirely on-site, requiring welding, bolting, and custom adjustments to fit the specific space. This process takes more time and labor due to the flexibility needed for unique designs.

- Prefabricated Steel Structure Mezzanine: Pre-manufactured components are delivered to the site for quick assembly. No welding is needed on-site, as parts are bolted together, making the construction process faster and more efficient.

Application Scenarios

- Steel Structure Mezzanine: Perfect for projects needing design flexibility, such as large industrial sites.

- Prefabricated Steel Structure Mezzanine: Best for standard projects with quick installation needs, like warehouses or factories with predefined layouts.

In short,steel structure warehouse mezzanines are built on-site, offering custom designs for unique spaces, but take more time to complete. On the other hand, prefabricated steel structure mezzanines come pre-engineered and ready for quick assembly, making them ideal for projects with standard layouts. So, if you need flexibility, go for the first; if speed is your priority, the second is a great fit!

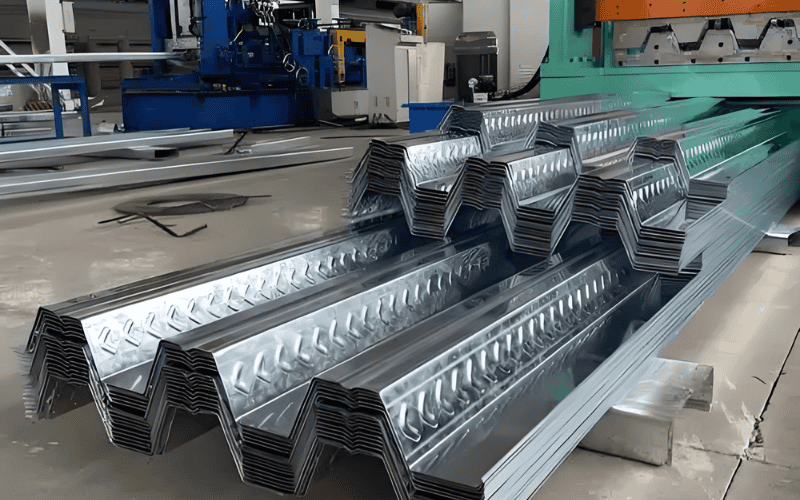

Can I Use Floor Decking as My Steel Structure Mezzanine Floor?

Yes, you can use floor decking as a steel structure mezzanine floor. It offers several benefits, including being cost-effective, quick to install, and lightweight yet strong for moderate loads. It’s a durable option, resistant to wear and corrosion.

The floor decking is cost-effective for projects with standard load requirements, making it a more affordable choice than custom steel mezzanines, which are pricier due to tailored designs and complex installations. However, a steel mezzanine is more suitable for heavier or specialized loads.

Applications of Steel Structure Warehouse Mezzanine

Steel structure mezzanines offer more flexibility in design and installation. They are suitable for projects needing customization or specific site conditions. Below are the detailed applications of steel structure mezzanines:

| Application | Example Case | Description |

| Large or Complex Industrial Facilities | Industrial Factory X | For production lines or heavy machinery, on-site assembly allows flexibility. |

| Irregular or Unconventional Building Spaces | Warehouse Y with uneven flooring | Custom-built mezzanines fit better in warehouses with irregular layouts. |

| High Load Demands | Heavy Machinery Storage Facility Z | Custom mezzanines ensure proper load distribution for heavy equipment or large warehouse storage areas. |

| Customized Commercial or Retail Spaces | Retail Space A with office areas | Steel mezzanines can be tailored for special equipment or office spaces. |

| Time-sensitive Projects | Fast-track Distribution Hub B | On-site construction offers faster and more adaptable solutions for urgent projects. |

Steel Sructure Warehouse Manufacturer

We bring years of experience in designing and building industrial warehouse buildings, including custom mezzanines. Our steel mezzanines are engineered to handle the specific loads and requirements of your project, ensuring they last for over 50 years. Our team of engineers works closely with you to determine the best layout and design to optimize space while maintaining functionality.

All our designs and construction processes comply with Eurocodes, EN 1090, BS 5950, and other relevant building standards. With us, you can trust that your mezzanine will be strong, durable, and perfectly tailored to your needs.

FAQ

What Is the Mezzanine Floor in a Warehouse?

A mezzanine floor in a warehouse is an intermediate floor built between the main floors, maximizing vertical space for storage or operational areas without expanding the building’s footprint.

How Does Mezzanine Improve Warehouse Efficiency?

By adding extra usable space, a mezzanine floor allows better organization, efficient storage, and improved workflow, reducing the need for additional warehouse expansion.

What Are the Benefits of Installing a Mezzanine Floor?

A mezzanine floor increases storage capacity, optimizes space utilization, and enhances operational flexibility without the high costs of expanding the building.

Is Mezzanine Flooring Expensive to Install?

While steel mezzanine floors are more expensive than traditional flooring, they offer long-term cost savings through efficient space usage and fewer infrastructure changes.

What’s the Difference Between a Steel Mezzanine Floor and a Steel Platform?

A steel mezzanine floor is a multi-level structure built inside a building to maximize vertical space, often for storage or offices. A steel structure platform, on the other hand, is a single-level raised surface used for specific functions like equipment or workspaces. Both are made of steel, but mezzanines are integrated into the building, while platforms are more specialized.