In short, steel alone is not soundproof, but when designed correctly with insulation systems, acoustic layers, and sealed joints, it can deliver excellent noise control for warehouses, factories, and commercial buildings.

Soundproofing in steel structures involves more than just heavy materials — it requires understanding how sound insulation and sound absorption work together. Many misconceptions exist, such as the belief that steel can absorb sound or that thickness alone determines performance. In reality, while steel reflects noise, its high density, rigid structure, and design versatility make it a powerful component in composite noise-control systems.

This article explores:

- what soundproofing really means and how it works;

- the common myths about steel and sound insulation;

- the limitations and advantages of steel in soundproofing;

- factors that affect performance, from structure to installation; and

- real-world soundproofing solutions for steel buildings — including practical measures used in modern warehouses and industrial projects.

By the end, you’ll know exactly how to design or choose a soundproof steel building that balances strength, cost, and acoustic performance.

What is Soundproofing?

Soundproofing refers to the techniques and materials used to block or reduce the transmission of sound. Its primary goals are:

- Prevent external noise from entering indoor spaces, enhancing comfort.

- Reduce internal noise from escaping, preserving privacy, or minimizing disturbance to the surroundings.

Soundproofing technologies are widely applied in construction, industrial settings, and transportation, especially in steel-structured buildings where noise control is critical.

Two Main Aspects of Soundproofing

Soundproofing can be broadly divided into two key aspects:

1) Sound Insulation

Sound insulation aims to block noise from traveling between spaces, such as between rooms or from the outdoors to indoors. Effective sound insulation typically involves materials and designs that prevent sound waves from passing through walls, floors, or ceilings. Dense and heavy materials and multilayered constructions are commonly used because they make it harder for sound to pass through. Flexible connections can also reduce vibrations.

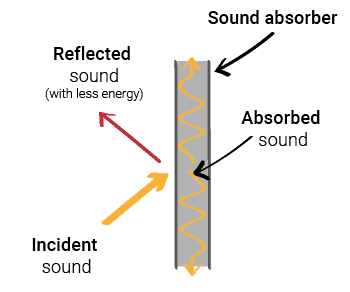

2) Sound Absorption

Sound absorption reduces echoes and improves the acoustic quality within a space. Materials like soft fabrics, carpets, or specially designed panels can trap sound waves, preventing them from bouncing around and causing noise buildup. This is particularly important in spaces where sound clarity is needed, such as auditoriums or offices.

Common Misconceptions About Soundproofing

Misconception 1: Sound Absorption Equals Sound Insulation

Many people confuse sound absorption with sound insulation, assuming that materials like acoustic foam or panels can block noise. However, these two approaches address different issues:

- Sound Absorption focuses on reducing echoes and improving sound clarity within a space. Soft and porous materials like acoustic foam are commonly used for this purpose.

- Sound Insulation prevents sound from traveling between spaces (such as walls, ceilings, or floors), and it typically requires dense, heavy materials or specialized structural designs.

Example: Placing acoustic foam on walls may reduce echoes in a room but will not stop noise from leaking to or from the outside. For true sound insulation, materials like soundproof doors or multi-layered walls are necessary.

Misconception 2: A Single Material Can Completely Soundproof

Some believe a “soundproof material” can fully block noise. In practice, effective soundproofing requires multilayer structures and combinations of materials (e.g., gypsum boards + acoustic mats + air gaps).

Misconception 3: Thickness Alone Determines Soundproofing

While thickness contributes to soundproofing, factors like mass density, damping properties, and structural design play more significant roles. For instance, high-density steel can help block noise but may transmit vibrations due to its rigidity.

Misconception 4: All Noise Can Be Completely Eliminated

The goal of soundproofing is to reduce noise to an acceptable level, not to eliminate it—particularly low-frequency noise (e.g., vibrations from traffic), which is challenging to block.

Misconception 5: Steel Can Absorb Sound

Some people believe that steel can absorb sound effectively due to its density. In reality, steel has little to no capacity for absorbing sound waves. Instead, it reflects sound, often amplifying noise within a space.

This is why industrial designers often pair steel with insulation systems such as mineral wool panels or sandwich composite walls, which can reduce reflected noise while maintaining structural integrity.

Is Steel a Good Material for Soundproofing Buildings and Warehouses?

By now, you already have a vague idea of the answer. Steel is not an ideal material for soundproofing due to its inherent properties. While it can contribute to soundproofing when combined with other materials in composite structures, steel alone is typically insufficient to achieve optimal soundproofing performance. Typically, in steel-framed buildings, the primary function of steel is to provide structural support, not to serve as a soundproofing material.

However, this limitation does not mean the issue is unsolvable. Potential solutions for improving steel’s soundproofing capabilities will be explored in later sections of this article.

Limitations of Steel in Soundproofing

- Poor Sound Absorption: Steel is a hard, rigid material with a smooth surface that reflects sound waves rather than trapping them. The sound tends to bounce back in spaces with exposed steel surfaces, often amplifying noise and creating echoes.

- High Rigidity and Vibration Transmission: Steel’s rigidity makes it prone to transmitting structure-borne noise, such as impacts or low-frequency vibrations.

- Weakness in Blocking Low-Frequency Noise: Steel is less effective at isolating low-frequency sounds (e.g., heavy machinery or traffic vibrations).

Potential Advantages of Steel

- High Density: According to the Mass Law, dense materials are effective at blocking high-frequency noise.

- Versatility in Combination: Steel can be combined with insulating materials like mineral wool and damping layers to create efficient composite structures.

- Durability and Strength: Steel is highly durable and supports long-term use in demanding environments.

In practical projects, especially factories and warehouse buildings, steel is rarely used alone. Instead, composite panels, acoustic insulation, and sealing systems are integrated during the design stage to achieve the desired noise control level.

Factors Affecting Steel’s Soundproofing Performance and Improvement Measures

1. Structural Forms and Design

Impact: The structural form of a steel-framed building plays a crucial role in soundproofing:

- Open Frames: Steel frames with open or exposed designs allow noise and vibrations to propagate more easily.

- Large Spans: Vibrations in large-span structures, like industrial halls or warehouses, travel farther due to the lack of intermediate supports.

- Lightweight Designs: Modern lightweight steel structures often lack the mass required to block sound effectively.

Improvement:

- Introduce partitions or intermediate supports to break vibration pathways.

- Add mass layers, such as concrete slabs or composite panels, to address noise transmission in lightweight or large-span designs.

- Optimize the layout of steel frames to minimize continuous rigid connections between noisy and quiet zones.

2. Rigidity and Vibration Transmission

Impact: Steel’s rigidity makes it an excellent conductor of structure-borne noise, such as impact sounds or low-frequency vibrations. This effect is more pronounced in rigidly connected designs, where vibrations travel freely across beams and columns.

Improvement:

- Use resilient connections or damping materials at key joints to reduce vibration transmission.

- Apply viscoelastic coatings or rubberized layers to beams, columns, and floor systems to dissipate vibrations.

3. Thickness and Mass Density

Impact: Thicker and denser steel components improve sound insulation for high-frequency noise. However, steel struggles with low-frequency sounds and increasing thickness adds weight and cost, which may not always be feasible for lightweight designs.

Improvement:

- Combine steel with high-density materials like concrete or masonry in walls and floors.

- Use layered construction with soundproofing materials (e.g., acoustic mats or mineral wool) to maintain performance while reducing weight.

4. Combination with Sound-Absorbing Materials

Impact: Steel’s smooth and reflective surfaces amplify noise by increasing echoes and reverberation, particularly in open-plan steel-framed spaces.

Improvement:

- Add sound-absorbing materials, such as mineral wool or acoustic panels, to walls and ceilings.

- Combine perforated steel panels with absorbent backings to balance sound absorption and aesthetic requirements.

5. Structural Design and Sealing

Impact: Poorly sealed joints or gaps in steel-framed buildings allow airborne noise to leak, reducing soundproofing effectiveness. Walls and ceilings with improper designs may fail to isolate sound between spaces.

Improvement:

- Use acoustic sealants to fill gaps and joints.

- Employ layered walls or staggered connections with air gaps and dense fillers to block sound transmission paths.

6. Frequency-Specific Challenges

Impact:

- Low-Frequency Noise: Steel structures struggle to block low-frequency sounds, such as vibrations from traffic or heavy machinery.

- High-Frequency Noise: While steel naturally blocks high-frequency sounds better, its reflective surface can amplify noise within spaces.

Improvement:

- Add mass (e.g., concrete) or damping materials to address low-frequency sounds.

- For high-frequency noise, use multilayered constructions with air gaps and porous absorptive materials to enhance performance.

7. Installation Practices

Impact: Poor installation, such as misaligned joints or loosely fastened steel panels, creates gaps that allow noise to escape or amplify noise leakage.

Improvement:

- Ensure precise alignment and fastening of steel panels.

- Train construction teams in soundproofing techniques, including proper sealing and alignment of steel components.

Real-World Soundproofing Solutions for Steel Buildings

In real-world applications, soundproofing steel buildings often involves combining dense structural materials with acoustic barriers and sealing systems. For example, using double-layer wall panels filled with mineral wool or perforated steel sheets backed by insulation can effectively reduce echo and vibration in industrial workshops and warehouses.

These construction methods help balance durability, cost, and acoustic performance, making them practical for large-span steel warehouses, factories, and commercial buildings. Additionally, applying viscoelastic damping layers between steel panels or using acoustic gaskets in joints can further improve overall sound insulation without increasing weight excessively.

Can steel warehouses be made soundproof?

Yes. While steel itself reflects sound, warehouses and industrial buildings can be made soundproof by using layered wall systems that combine steel panels, insulation (such as mineral wool), and air gaps. Proper acoustic sealing and damping materials can further enhance sound isolation to meet industrial-grade standards.

What are the best soundproof panels for steel structures?

For industrial and commercial applications, mineral wool sandwich panels and perforated acoustic steel sheets are the most effective solutions. These materials not only reduce echo and vibration but also maintain the building’s strength and energy efficiency.

Does soundproofing affect the durability of steel buildings?

No. When designed correctly, soundproofing systems improve overall performance. Insulation materials add thermal efficiency and corrosion protection, enhancing both comfort and the long-term durability of the steel structure.

Conclusion

So, is steel good for soundproofing? The answer, as discussed throughout this article, is both straightforward and nuanced. Steel, due to its inherent properties, is not an ideal standalone material for soundproofing. Its rigidity and reflective surface amplify vibrations and noise, and its inability to absorb sound creates challenges in noise control. While steel’s density provides some insulation for high-frequency sounds, it struggles with low-frequency vibrations and structure-borne noise.

However, this does not mean steel is unsuitable for soundproofing in all contexts. By combining steel with other materials, such as mineral wool or viscoelastic layers, and adopting thoughtful structural designs like layered walls, floating floors, and acoustic sealing, its soundproofing capabilities can be significantly enhanced. Furthermore, steel’s strength, durability, and versatility, in combination with other materials, make it a valuable component in composite soundproofing solutions.

For projects requiring robust soundproofing and structural integrity, sound insulation steel buildings offer an excellent solution. These buildings are designed with advanced acoustic materials and techniques to achieve superior noise control without compromising the benefits of steel.

Ultimately, while steel alone may fall short as an effective soundproofing material, it remains an indispensable part of modern construction, including noise-controlled steel-framed buildings, when integrated with complementary materials and techniques. Soundproofing in steel structures is not about relying solely on the metal but about leveraging its strengths while mitigating its weaknesses.

Looking for customized sound insulation steel buildings?

Contact SteelPRO PEB, a certified manufacturer specializing in steel structure design, fabrication, and installation, for a factory-direct quote and engineering support.