Why Insulation Matters for Metal Buildings

When you choose a metal building, you choose its durability and cost-effectiveness, but without the right insulation, all of these benefits are compromised. Insulation not only regulates the temperature within a building, but it also significantly reduces energy consumption and prevents damage from natural disasters. Proper insulation effectively maintains a comfortable temperature inside the building, reduces energy bills, and avoids corrosion and rust problems caused by condensation.

With years of experience in steel construction, SteelPRO PEB tailors efficient and cost-effective insulation solutions for each client, ensuring maximum building performance without compromising quality.

Understanding Insulation: Key Terms Explained

In the realm of insulation, technical jargon may seem somewhat perplexing. Allow us to elucidate some fundamental concepts in layman’s terms, enabling you to make better-informed choices.

- R-value: This indicates how effectively an insulation material blocks the movement of heat. The higher the R-value, the superior its insulating capability. When selecting insulation, a higher R-value signifies more efficient temperature regulation.

- U-value: This metric assesses a building material’s capacity to transmit heat. Contrary to R-value, U-value shows the speed of heat transfer; hence, a lower U-value implies better insulation.

- Thermal conductivity: This measures how well a material conducts heat. Materials with lower thermal conductivity are superior insulators, as they slow down the heat transfer process.

- Radiant heat: Heat that travels through electromagnetic waves, usually from the sun or other heat sources. Reflective insulation effectively reflects radiant heat, keeping buildings cooler in the summer.

- Condensation: Condensation occurs when water vapor transforms into liquid water upon coming into contact with a cold surface. In metal structures, if not addressed, condensation can result in rust formation and structural deterioration.

We understand these insulation principles and can help you design solutions that improve your building’s performance and durability. Whether you are familiar with these terms or not, our team will provide you with professional guidance every step of the way.

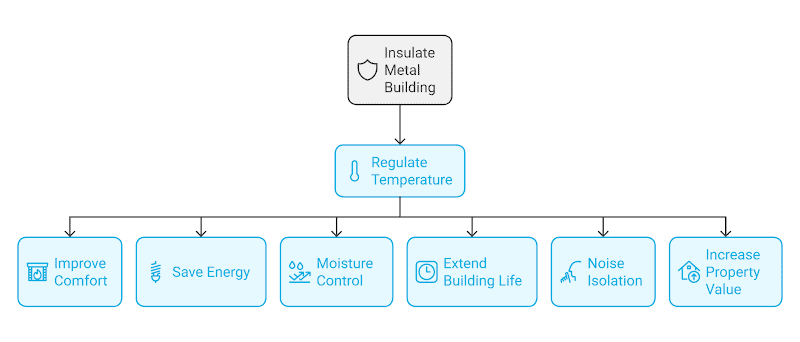

The Benefits of Insulation for Metal Buildings

Insulating your metal building not only regulates temperature, it also offers many other benefits:

- Improves comfort: Insulation can maintain a stable indoor temperature, making your metal building comfortable whether it is cold winter or hot summer.

- Saves energy: Insulation can drastically lower energy expenses by minimizing the requirement for heating and cooling. By enhancing the efficiency of your HVAC system, you can achieve long-term cost savings.

- Moisture control: A common problem with metal buildings is condensation. Effective insulation prevents moisture from penetrating, preventing rust and corrosion, and also helps prevent mold growth, keeping the environment healthy.

- Extends the life of the building: By keeping the internal temperature stable, insulation reduces the damage caused by temperature fluctuations and moisture, extending the life of the metal frame.

- Noise isolation: Insulation can also effectively block sound, reducing the distraction of outside noise, especially in a work environment, which can improve productivity and safety.

- Increases property value: A well-insulated metal building is more attractive in the market, showing your emphasis on quality and efficiency, and improving your competitiveness.

Types of Insulation Materials and Methods

When insulating a metal building, choosing the right materials and methods is key to balancing cost and performance. Here are some popular choices:

| Insulation Type | Pros | Cons |

| Fiberglass Insulation | Low cost, easy to cut and install, suitable for all building types. | Absorbs moisture, can cause mold, requires protective gear. |

| Foam Board Insulation | Higher R-value, moisture resistance, enhances structural strength. | Higher initial cost, tricky to install, often needs professional help. |

| Spray Foam Insulation | Excellent insulation, moisture barrier, air sealing. | Expensive, requires professional installation. |

| Radiant Barrier Insulation | Energy efficient, lightweight, easy to install. | Less effective against conductive heat, needs air gaps for optimal performance. |

What is the Cheapest Way to Insulate a Metal Building?

Fiberglass insulation is the most affordable and widely available option, providing a cost-effective solution for those who want to minimize expenses without sacrificing too much performance.

Fiberglass Insulation

Fiberglass is the most affordable and widely available insulation material. It’s easy to install and has a low upfront cost, making it a great choice for projects with a limited budget. Simply cut the batts or rolls to size between studs and seal with a vapor barrier to prevent moisture penetration.

Foam Board Insulation

Foam boards provide an excellent cost-performance ratio. Although somewhat pricier than fiberglass, they exhibit superior resistance to heat and moisture. Installation entails cutting the foam boards to size, securing them with adhesives or fasteners, and then sealing the edges for a snug fit.

Radiant Barrier Insulation

Radiant barriers redirect heat away from buildings, serving as a cost-effective solution in warm climates. They can be readily mounted on roofs or walls with air spaces to boost efficiency. Pairing radiant barriers with materials such as fiberglass creates an effective and economical insulation setup.

Selecting the appropriate materials and ensuring correct installation can yield exceptional outcomes without breaking the bank. SteelPRO PEB can assist you in identifying the optimal insulation choice that aligns with your budget while maintaining superior performance.

What Is the Best Insulation for Steel Buildings?

The best insulation for steel buildings depends on specific needs, but common options include:

- Fiberglass Insulation: Affordable, easy to install, and effective for thermal and acoustic insulation.

- Spray Foam Insulation: Provides superior air sealing and high R-value, ideal for energy efficiency.

- Rigid Board Insulation: Durable, moisture-resistant, and great for walls and roofs.

- Reflective Foil Insulation: Best for radiant heat control, often used in hot climates.

Factors Affecting Insulation Performance

Several variables determine the insulation efficiency of a metal building. By comprehending these factors, you can make well-informed decisions and select the most suitable insulation method.

Building Type and Use

The kind and purpose of a building are pivotal in selecting an insulation approach. We tailor insulation solutions for each building type and application to guarantee that each project fulfills its specific requirements.

- Industrial warehouses: Strong insulation is needed to maintain a stable temperature in large spaces.

- Residential garages or studios: Effective temperature control is important for comfort and functionality.

- Commercial spaces: Consistent temperature control is required to ensure the comfort of employees and customers.

Climate conditions

Local climate determines the choice of insulation materials and methods, and our expertise in climate-responsive design ensures that your metal building is effectively insulated in a variety of climates.

- Hot climates: Materials such as reflective insulation films are great for reducing heat, keeping interiors cooler, and reducing cooling bills.

- Cold climates: High R-value materials, such as spray foam and foam board, are needed to reduce heat loss and keep interiors warmer.

- Volatile climates: A combination of different types of insulation may be required to address both hot and cold needs.

Material Selection

The choice of insulation material directly affects the effectiveness and cost of the system. SteelPRO PEB helps clients find a balance between thermal resistance, moisture resistance, and cost to ensure that each material meets the specific needs and budget of the project.

- Thermal Resistance (R-Value): Generally, a higher R-value indicates superior insulation, albeit at a potentially higher cost. To attain the desired performance, strike a balance between the R-value and your budget.

- Moisture Resistance: Materials like spray foam and foam board are adept at preventing condensation and mitigating corrosion.

- Installation Simplicity: Certain materials offer easier installation, thereby reducing labor costs and overall expenditure.

Installation Quality

The key to insulation effectiveness is the quality of installation. Our attention to detail ensures that every inch of the metal building is precisely insulated, eliminating gaps, and improving insulation and system life.

- Expertise: Experienced installers ensure that insulation materials are perfectly installed and sealed for optimal results.

- Focus on Precision: Make sure to seal openings like windows and doors to prevent air leakage and ensure consistent temperature regulation.

How to Choose the Right Insulation Material and Method

Selecting the appropriate insulation for your metal building is vital for both cost management and enduring outcomes. But don’t worry, we help you choose the best insulation solution based on your needs, budget, and use. With our industry experience, we ensure you get the most efficient solution that balances quality and cost.

Understand the building’s use

- Industrial warehouses: need durable materials to accommodate temperature fluctuations in large spaces.

- Commercial offices: need effective thermal regulation to ensure a comfortable work environment.

- Agricultural sheds: need to withstand extreme temperature differences to protect goods and equipment.

Set a budget

- Low-budget: Cost-effective options such as fiberglass and foam boards.

- Medium-budget: Combining fiberglass and radiant barriers for better performance.

- High-budget: Spray foam offers the best efficiency and long-term energy savings.

Consider long-term energy savings

- Energy savings: High R-value materials such as spray foam can effectively reduce heating and cooling costs.

- Durability: Choose materials that are moisture-resistant, insect-resistant, and abrasion-resistant to ensure long-term protection of the building.

Evaluate the local climate

- Hot climates: Use reflective insulation to keep cool.

- Cold climates: High R-value materials to keep warm.

- Changing climates: A mix of materials may be needed to cope with different needs.

Step-by-Step Guide: How to Insulate Your Metal Building

Insulating a metal building might seem intricate, but it’s a straightforward task if you follow the correct procedures. Whether you’re tackling it as a DIY project or hiring professionals, here’s a streamlined, step-by-step guide to installing insulation efficiently.:

Planning & Preparation

- Evaluate the building: Identify areas that need insulation, such as walls, roofs, and areas with large temperature fluctuations.

- Choose insulation: Choose the right insulation material, such as fiberglass, foam board, spray foam, or radiant barrier, based on the building’s use, budget, and climate.

- Prepare tools and materials: Ensure you have measuring tools, scissors, adhesive, protective equipment, and all necessary installation materials prepared.

Measure & Cut

Carefully measure the area to be insulated to ensure an accurate fit, then use a knife to cut the insulation materials to the appropriate size.

Install insulation

- Fiberglass or foam board: Secure the material to the metal frame, ensuring there are no gaps.

- Spray foam: evenly apply the foam, which will then expand and solidify to create a continuous, seamless barrier.

- Radiant Barrier: Install radiant barriers on the inside of the roof or wall, ensuring there is an air gap to improve reflection.

Sealing & Finishing

Seal any gaps around windows and doors using sealant or foam, then cover the insulation with drywall or other materials for added protection and improved aesthetics, especially if the building will be occupied.

Quality Inspection & Maintenance

Inspect all areas to ensure complete insulation coverage, then perform regular checks for wear, moisture, or insect infestation, replacing or repairing as needed.

Professional Installation Support from SteelPRO PEB

While some insulation methods are suitable for DIY, others may be better suited to professional help. SteelPRO PEB specializes in steel structure design and fabrication, and provides complete insulation solutions. Our team offers comprehensive support, from planning through to implementation, to guarantee the seamless execution of every insulation project. We provide you with high-quality materials and precise installation techniques to help you achieve the best insulation results.

Insulation Tips for Maximum Efficiency

To improve the insulation efficiency of metal buildings, in addition to choosing the right materials, here are a few tips to help you optimize the results:

Solve condensation problems: Install a vapor barrier and ensure good ventilation to reduce moisture accumulation and prevent condensation from affecting insulation.

Enhance ventilation: Install exhaust fans in humid areas and ensure that there are vents in the roof to promote air circulation and prevent heat accumulation.

Optimize installation techniques: Combine different insulation materials (such as foam board and fiberglass) to ensure that the insulation layer is evenly covered to prevent heat loss.

Take advantage of reflective surfaces: Use radiant barriers to reflect heat and choose light-colored paint to reduce heat absorption.

Regular maintenance: Check the insulation layer regularly and repair any damage in time to keep it at its best performance.

SteelPRO PEB’s Approach to Insulation

At SteelPRO PEB, we provide high-quality insulation solutions tailored to meet the unique needs of each client.

Expert Advice: Our experienced team assesses your building’s use, structure and environmental conditions to recommend the most appropriate insulation materials and methods based on your needs and budget.

Custom Solutions: We recognize that each building is unique. Whether it’s a vast warehouse or a commercial office space, we tailor insulation solutions to seamlessly integrate with the building’s design and operational needs.

Top-quality Materials: We work with leading suppliers to provide environmentally friendly, high-performance insulation. This ensures durability, thermal resistance and moisture control, which improves your building’s efficiency.

Proactive Design Integration: By incorporating insulation in the early design phase, we ensure optimal energy efficiency, minimizing costly adjustments later on.

Sustainability & Quality Assurance: Our materials not only surpass performance expectations but also promote environmental sustainability. We are committed to reducing our ecological footprint while ensuring top-notch insulation quality.

End-to-End Support: From consultation to delivery, we offer consistent support to guarantee smooth project completion from inception to completion. Our objective is to foster enduring relationships rooted in trust and unparalleled service.