Steel structure warehouse are more than just storage spaces——they’re key to optimizing operations and minimizing costs. If you’re grappling with challenges like poor space utilization or rising energy bills, you’re not alone. Designing an efficient steel structure isn’t just about strong materials—it’s about how everything fits together.

We understand these challenges and, through tailored designs, ensure your steel warehouse building isn’t just functional, but built to last with maximum efficiency and safety. Let’s dive into how we make that happen!

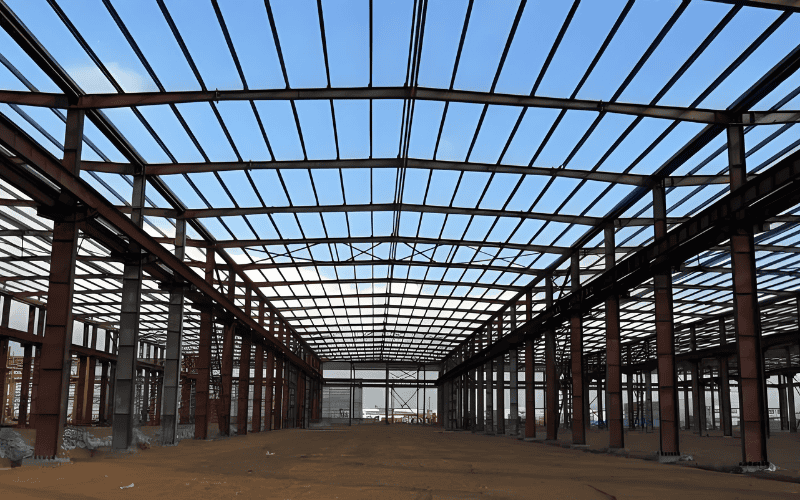

Structural Characteristics of Steel Warehouse

Steel structures offer key benefits like seismic performance and durability, making them an ideal choice for warehouse structure design and construction.

Seismic Performance and Load Capacity

Steel structures are tough when it comes to seismic performance, thanks to their flexibility and high strength-to-weight ratio. In earthquake-prone areas, the design includes things like moment-resisting frames and bracing systems to help distribute seismic forces more evenly. This can improve seismic resistance by up to 30% compared to traditional concrete, keeping things safe and secure.

Related Reading: Seismic Resistance Steel Structures

Durability and Longevity

When it comes to durability, steel structures are built to handle the toughest environments—resisting corrosion, extreme temperatures, and wear over time. Coatings like galvanizing and epoxy make them even more long-lasting. On top of that, they need less maintenance, are sustainable because they’re recyclable, and will stand the test of time.

Plasticity and Toughness

The high strength of steel structures allows them to handle heavy loads with minimal material. Their plasticity and toughness help them absorb stress and impact without failing. With a high strength-to-density ratio, they’re efficient and can take a beating, ensuring they stay strong in challenging conditions.

Mechanical Properties and Analysis

Thanks to their well-defined mechanical properties, steel structures are easy to work with, making design and calculations straightforward. They support large spans and offer flexibility, perfect for large-span warehouses. Steel’s predictable performance allows for creative designs while maintaining stability, and its uniform properties simplify simulations for fast, accurate results.

Steel Warehouse Construction Time and Precision

Only the steel structure components are prefabricated, which speeds up construction while ensuring high precision and consistent quality. This means quicker adjustments and smoother assembly, helping you finish projects faster and more cost-effectively—though some on-site work will still be needed.

Structural Design of Different Types of Steel Warehouses

The design of steel warehouses can vary depending on what you need—whether it’s maximizing space, supporting heavy loads, or meeting environmental requirements. Here’s an overview of the key considerations.

Single-Story and Multi-Story Design

- Single-Story Steel Warehouses: Focus on optimizing space and load distribution. We emphasize out-of-plane stability, ensuring steel frames can handle lateral forces. For light steel design, we usually recommend a wedge-shaped cross-section to minimize material usage while increasing strength.

- Multi-Story Steel Warehouses: The challenge is maximizing vertical space while maintaining stability. Column spacing and floor load capacity must be assessed early to prevent overload and instability. Steel’s high strength-to-weight ratio makes this possible.

Temperature-controlled and Cold Storage Warehouse Design

- Temperature-Controlled Warehouses: Steel structures complement thermal insulation. For example, double-skinned steel panels in our designs have reduced heat loss by up to 10-15%.

- Cold Storage: Combining steel’s durability with advanced cooling systems and thermal insulation can lower energy costs. We’ve helped clients save 15% on energy by optimizing the insulation in their steel frame design.

Hazardous Material Storage Design

- Fire Safety: Steel’s natural fire resistance can be enhanced with sprayed fireproofing, which we recommend for beams and columns in hazardous material storage.

- Ventilation:

- Proper ventilation is crucial in volatile environments. We suggest using mechanical systems like exhaust fans and air handling units to remove harmful gases and ensure safety, especially in warehouses with hazardous materials, in line with OSHA regulations.

- For less risky environments, natural ventilation with well-placed vents works well, while high-risk areas benefit from dedicated smoke extraction systems to prevent fire hazards and ensure quick evacuation.

Functional Space Design

- Multi-Functional Steel Warehouses: Steel’s flexibility allows for seamless integration of storage, processing, and office spaces. We recommend using modular steel partitions to divide different areas while maintaining an open, efficient warehouse layout. These partitions can be easily reconfigured, offering flexibility for future needs.

- Office and Employee Areas: Steel’s customizable frame design supports efficient office spaces that complement the operational flow of the warehouse. Adjustable office layouts ensure that both staff and operations function smoothly within the same space.

Modular Design

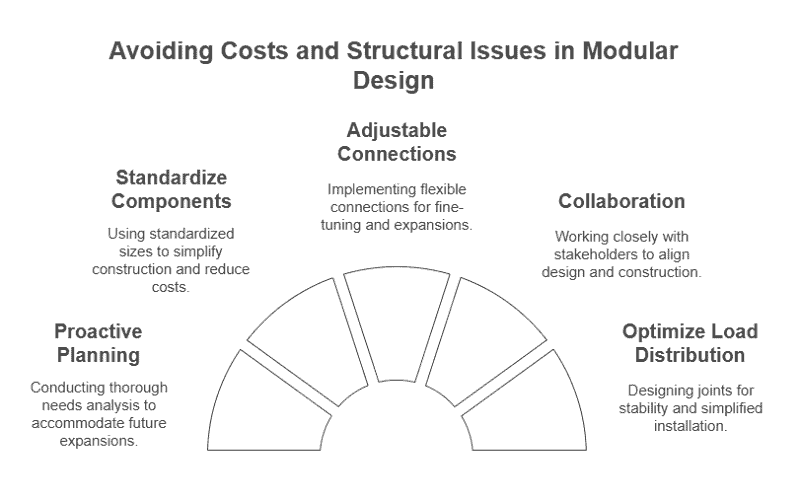

Through our experience, standardized modular components are essential for speeding up construction and enabling future expansion. Prefabricating off-site minimizes waste and reduces on-site assembly time. However, designing with flexible connections is crucial to avoid costly modifications later. Overcomplicating the modular approach can lead to unnecessary costs and potential structural issues.

To avoid unnecessary costs and potential structural issues in modular design, consider the following strategies:

Space Optimization

To optimize space, we’ve found that reducing column spacing (e.g., 6m instead of 8m) can increase usable space by up to 10%. Utilizing steel mezzanines or multi-level shelving maximizes vertical storage. But be careful—too tight a column spacing can affect load-bearing capacity, so balance is key.

Logistics System Integration

Integrating AGVs and vertical storage systems requires careful planning. 10m clearance and adequate load capacity must be considered early on. If planned well, these systems can significantly boost efficiency, but failing to account for future upgrades can lead to expensive rework.

Sustainable Design

From our projects, solar panels and natural ventilation have proven effective in reducing energy costs. We’ve seen up to 15% energy savings with properly integrated insulation and ventilation. Without adequate ventilation, energy efficiency drops, and costs increase, so it’s critical to incorporate this into the early stages of design.

Impact of Different Steel Materials on Warehouse Structure

The choice of steel material significantly affects warehouse performance, depending on factors like load requirements, environment, and desired durability.

| Steel Materials | Key Characteristics | Ideal Use | Benefits |

| High-Strength Steel (e.g., Q460, Q690) | High tensile and yield strength, reduces structure weight, larger spans with fewer support columns | Heavy-duty, large-span, or high-load warehouses | Maximizes space, reduces material use, efficient for large spans |

| Low-Alloy Steel (e.g., Q235, Q345) | Good weldability, cost-efficient, suitable for medium-sized warehouses | General-use warehouses in mild environments, lower load requirements | Affordable, easy to weld, ideal for standard warehouses |

| Corrosion-Resistant Steel (e.g., Stainless or Galvanized Steel) | Excellent rust and corrosion resistance, durable in harsh environments | Coastal regions, chemical warehouses, or environments with high humidity or corrosive materials | Low maintenance, durable in tough environments |

| Hot-Rolled Steel | Better plasticity, ideal for larger structural elements | Larger structural elements in non-precision areas | Better for large-scale elements, more flexible to shape |

| Cold-Rolled Steel | Higher strength, smooth finish, ideal for precision and aesthetic details | Detailed parts, regions requiring high aesthetics and quality standards | Ideal for precision components, high strength and smooth finish |

Based on your specific needs and location, we can apply different types of steel to various warehouse structures, maximizing your benefits and extending the lifespan of your warehouse!

Choosing Us to Enhance Your Warehouse Structure Performance

In successful projects like the Clear Span Warehouse and Steel Warehouse with Solar Energy, we used high-strength steel for large spans and incorporated solar energy systems, we not only improved structural stability but also reduced long-term operational costs.

Our strength also lies in modular construction, enabling quick, high-precision assembly to accelerate project timelines. We ensure seamless integration of design and construction, meeting your needs while adhering to our core principles:

Our design philosophy focuses on:

- Promoting Unified Design Standards: Ensuring seamless coordination between design and construction, reducing errors, and improving fire safety, durability, and construction efficiency.

- Reducing Design Complexity: Simplifying the design process for faster, more accurate execution, while minimizing equipment load and measurement errors.

- Optimizing Structural Design: Focusing on safety measures like fire and lightning protection, while improving cost-efficiency, durability, and water resistance for long-lasting performance.

By applying these principles, we deliver superior warehouse structures that not only meet your specific needs but also optimize efficiency, safety, and long-term durability!

You May be Concerned

What Is the Steel Structure of a Warehouse?

The steel structure of a warehouse consists of steel frames, columns, beams, and roof systems that provide support and stability to the building, enabling it to withstand loads and environmental factors.

What Are the Design Considerations for Steel Structures?

Steel structure design must consider factors like load distribution, material strength, seismic performance, and environmental conditions to ensure safety, durability, and efficiency.

Related Reading: Optimizing Warehouse Building Design Details

What Are the Elements of Structural Design Steel?

The key elements of structural steel design include load-bearing capacity, stability, material selection, connection types, and structural integrity to support the warehouse’s function and longevity.