Yes, steel is a fantastic choice for building bridges! Its high strength, lightweight, and corrosion resistance make it the perfect material for handling heavy loads and all kinds of stress. And with its versatility, steel can handle everything from complex designs to tricky environmental conditions. In this article, we’ll explore exactly why steel is such a strong contender for bridges, and which types of steel are best for the job.

Why Use Steel to Build Bridges?

Steel is perfect for bridges due to its strength, light weight, and durability. It handles heavy loads and complex stress, while reducing foundation pressure and costs. Let’s see how steel’s strength and lightness make it the top choice for bridges.

High Strength and Lightweight

Steel’s high strength allows it to withstand significant tension and compression, making it ideal for heavy loads and diverse stress conditions. Compared to concrete, steel is lighter, which significantly reduces the weight of the bridge and the demands on the foundation. Here’s why this matters:

High Strength in Action

Steel’s strength means less material is needed while still resisting extreme loads. It can handle complex stress states, like those experienced in large-scale or heavily trafficked bridges, ensuring reliability and safety in challenging environments.

Lightweight Benefits

The reduced weight of steel means less pressure on the foundation, which cuts down on the need for expensive, time-consuming soil treatment. It also helps prevent long-term deformations, ensuring the bridge stays stable for many years.

Durability and Corrosion Resistance

Steel’s resilience is a game-changer for bridges. With galvanizing or coatings, steel resists corrosion, boosting longevity. It also excels in fatigue resistance and seismic performance, standing strong against repeated loads and extreme conditions. Let’s break it down:

1. Durability in Action

Steel’s fatigue resistance allows it to withstand constant stress from traffic, wind, or temperature changes. Plus, its impact resistance helps absorb sudden shocks, like collisions or earthquakes, minimizing damage and keeping the steel structure bridge safe in the long run.

2. Corrosion Resistance

Weathering steel, like Corten, forms a protective oxide layer that prevents further corrosion, making it perfect for bridges in wet or corrosive environments. Modern coatings (epoxy, polyurethane, or galvanization) act as a shield, keeping steel safe from saltwater or industrial exposure.

3. Advanced Protection

For submerged or buried parts of the bridge, cathodic protection (using sacrificial anodes or electrical current) ensures that corrosion doesn’t stand a chance. This tech guarantees your bridge stays tough and reliable for years, even in the harshest conditions.

Cost-Effectiveness

Steel bridge construction offers impressive value for money over its lifespan. While the initial costs can be higher, the overall lifecycle cost is often more economical. Here’s why:

- Fast Installation

Steel components are pre-fabricated in a factory and quickly assembled on-site. This speeds up construction, cuts labor costs, and reduces the project timeline. Less build time = less cost, which is a win for everyone. - Low Maintenance Costs

Steel’s durability and corrosion resistance mean bridges require much less maintenance. They handle fatigue and extreme conditions without constant repairs, saving you from expensive upkeep. - Long-Term Savings

The real payoff with steel comes over time. With low maintenance and longer lifespans, metal bridge structures provide a better return on investment. Even if the upfront cost is higher, fewer repairs and lower ongoing costs add up to big savings—it’s like investing in lasting peace of mind.

Formability and Design Flexibility

Steel is easily shaped into various forms, meeting even the most complex design needs. It supports flexible bridge structures through welding and connections, enabling diverse and modern designs.

Formability

Steel can be cut, bent, stamped, or rolled into all kinds of shapes—like I-beams, box beams, or custom cross-sections—allowing for intricate designs like curved or arched bridges. Its adaptability to complex stress distributions is a big plus, especially at joints where stress paths can be optimized. Steel’s high strength also makes thin-walled structures possible, reducing weight while maximizing material efficiency.

Design Flexibility

Steel offers endless connection options and structural diversity, easily accommodating complex geometries and supporting innovative, aesthetic designs that meet modern engineering standards. The design possibilities are virtually limitless.

Structural Stability

Steel’s uniformity and weldability ensure the structural stability of bridges, allowing them to withstand complex loads and extreme conditions with ease.

1. Steel Uniformity

Steel’s consistent mechanical properties and uniform load distribution ensure a reliable performance across the entire structure. Its ability to deform in a coordinated manner under stress further contributes to overall stability.

2. Weldability

Steel’s outstanding weldability creates rigid, unified structures that not only increase redundancy but also enhance the overall strength. This ensures the bridge can confidently handle unexpected forces.

Maintenance and Repairability

Steel bridges are easy to inspect and repair, ensuring long-term performance.

Maintenance

Steel’s visibility makes inspections quick. Inspectors can easily spot issues like corrosion or cracks. Non-destructive methods like ultrasonic or magnetic testing can find hidden flaws. Daily upkeep is simple, requiring just regular painting or cleaning, and basic checks on bolts or joints keep everything running smoothly.

Repairability

Steel is highly weldable, so cracks can be easily filled, restoring strength. Larger damages are fixed by replacing sections. Steel parts are standardized, so replacing a broken part is fast and simple. Bolted or riveted connections allow for easy disassembly, reducing repair time and cost. For example, a damaged steel box girder can be quickly replaced with pre-fabricated parts.

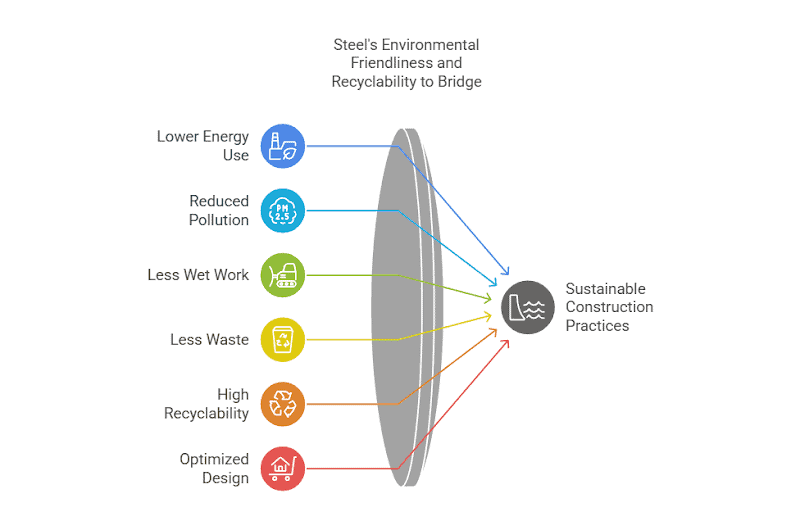

Environmental Friendliness and Recyclability

Steel bridges are eco-friendly and fully recyclable, reducing waste.

Environmental Benefits

- Lower energy use: Modern steel production methods like oxygen-blown converters cut energy use, lowering carbon emissions.

- Reduced pollution: Advanced tech controls emissions like sulfur and nitrogen oxides, keeping the environment cleaner.

Construction Benefits

- Less wet work: Steel minimizes wet work on-site, cutting down on noise and dust—making life easier for both workers and neighbors.

- Less waste: Any leftover steel is easily recycled, keeping it out of landfills.

Recyclability

- High recyclability: Steel can be recycled 100% without losing strength—it’s perfect for new bridges or buildings.

- Sustainability: Steel’s recyclability means less need for raw materials, reducing mining and minimizing environmental impact.

Impact on Design and Construction

- Optimized design: Steel’s recyclability encourages easy-to-dismantle designs, making construction more efficient and cost-effective.

- Sustainable construction: Builders take care to manage steel properly, ensuring it gets recycled when the project’s life cycle ends.

Disaster Resilience and Recovery

Steel bridges shine when it comes to bouncing back after disasters, keeping repairs to a minimum.

Disaster Resistance

- Earthquakes: Steel’s flexibility helps it absorb seismic shock, reducing damage and keeping the structure safe.

- Wind: Steel’s high strength lets it stand firm against strong winds, with designs that limit vibrations.

- Floods: With proper coatings, steel can resist water and debris, holding up well in flood conditions.

Resilience

- Quick Inspections: Steel’s smooth surfaces make it easy to spot damage, so inspections are quick and thorough.

- Fast Repairs: Welding and part replacements are simple and fast, getting bridges back up and running in no time.

- Reusability: Steel can be recycled, reducing waste and speeding up rebuilds after damage.

Adapting to Long Spans and Extreme Conditions

Steel bridges excel when it comes to spanning vast distances and withstanding harsh conditions.

Long Span Adaptation

- High Strength, Low Weight: Steel’s strength and lightness allow for longer spans without sacrificing support, perfect for bridges like suspension and cable-stayed.

- Design Flexibility: Steel is easy to shape and fabricate, enabling complex designs that meet both structural and aesthetic needs for long-span bridges.

- Modular Construction: Prefabricated steel modules simplify transportation and assembly, making them ideal for large-scale bridge projects.

Extreme Condition Adaptation

- Wind Resistance: Steel’s strength and flexibility help it endure strong winds, minimizing wind-related vibrations in large-span bridges.

- Earthquake Resistance: Steel absorbs energy and deforms without breaking, reducing damage during seismic events.

- Weather Resistance: With coatings like galvanizing or weathering steel, steel bridges stand strong against extreme climates—whether heat, cold, or salty air—ensuring long-term durability.

Types of Steel for Building Bridges

When choosing steel for building bridges, it’s essential to understand the specific properties and advantages of different steel types. Each type of steel has its own strengths and weaknesses, making it suitable for different bridge designs and environmental conditions.

| Steel Type | Overview | Advantages | Disadvantages |

| Carbon Steel | Most common for bridge construction. Offers strength at a low cost. | – High strength-to-weight- Cost-effective | – Corrosion-prone without treatment- Needs coatings for durability |

| Alloy Steel | Made by adding elements like chromium or nickel to carbon steel. | – Stronger, tougher, more wear-resistant- Better corrosion resistance | – More expensive- Harder to weld and fabricate |

| Stainless Steel | Chromium-rich steel, excellent for corrosion resistance in wet/salty areas. | – Great corrosion resistance- Long lifespan | – High cost- Harder to weld |

| Weathering Steel (Corten) | Forms a protective rust-like layer for corrosion resistance in variable weather. | – Corrosion-resistant without coatings- Low maintenance | – Not ideal for high-stress areas- Rust look may not be preferred |

| HSLA Steel | Carbon steel with elements like copper for enhanced strength and toughness. | – High strength- Corrosion-resistant- Lighter weight | – More expensive- Limited availability in some areas |

| Duplex Stainless Steel | A mix of austenitic and ferritic stainless steels, balancing strength and corrosion resistance. | – High strength-to-weight- Excellent corrosion resistance | – Very high cost- Harder to weld without special equipment |

Best Type of Steel for Bridge Construction

While each steel type has its benefits, High-Strength Low-Alloy (HSLA) Steel is often the best choice for bridge construction. It strikes the right balance of strength, durability, and cost-effectiveness, making it ideal for both short and long-span bridges. With excellent corrosion resistance, weldability, and a strong strength-to-weight ratio, HSLA steel ensures bridges are durable and low-maintenance. It’s the top pick for standard and high-performance designs.

Conclusion

In conclusion, steel is hands down the best material for building bridges, offering unbeatable strength, lightness, and durability. It can handle heavy loads, resist corrosion, and adapt to even the most complex designs—making it the perfect choice for bridges that need to last. Plus, its cost-effectiveness and eco-friendly benefits make steel not only practical but also sustainable.With over 20 years of experience crafting exceptional steel structures, our team has brought countless steel bridge construction projects to life. Want to see the quality we deliver? Check out our Steel Structure Projects page to explore some of our standout steel bridgeprojects.