Steel bridge pros and cons vary significantly across girder, beam, and truss designs — each offering distinct advantages in span capacity, cost, and durability. This guide provides a clear comparison of girder, beam, and truss bridge structures, helping engineers and project owners determine which type best suits their construction and budget goals.

We’ll explore the features, strengths, and weaknesses of each bridge type, analyze key factors such as span length, load performance, cost efficiency, and corrosion resistance, and examine their real-world applications. A dedicated section also reviews material and corrosion performance to ensure long-term reliability in harsh environments.

As a global steel structure manufacturer and PEB producer, SteelPRO PEB contributes engineering expertise and factory-prefabricated solutions that improve bridge quality, assembly precision, and lifecycle performance — combining technical authority with proven manufacturing experience.

Girder Bridge

What is a Girder Bridge?

A bridge girder spans between piers or abutments, supporting weight and ensuring stability. Made of steel or concrete, it efficiently distributes loads and withstands heavy traffic.

The main types are I-beams, box girders, and plate girders. I-beams have a simple design and strong load capacity. Box girders, with their hollow shape, resist twisting, making them ideal for curved and long-span bridges. Plate girders, welded or bolted from steel plates, offer custom solutions for longer spans.

You’ve likely crossed a girder bridge without noticing—they’re common in highways, urban roads, and railways. Their modular design speeds up construction and reduces costs, making them a key part of modern infrastructure.

Pros of Girder Bridges

- High Load-Bearing Capacity: Girder bridges support heavy traffic loads, making them ideal for highways, railways, and industrial zones. Their rigid structure distributes weight efficiently, ensuring long-term durability under continuous use.

- Simple Design and Fast Construction: The straightforward structure allows for efficient manufacturing and quick installation. Prefabricated components enable rapid on-site assembly, reducing labor and construction time—especially beneficial for short to medium spans where speed and cost are priorities.

- Cost-Effectiveness: For short to medium spans, girder bridges offer a cost-efficient solution due to optimized material use and simplified construction. Compared to suspension or truss bridges, they require fewer materials and less maintenance, lowering both initial and long-term costs.

- Efficient Material Use: Girder bridges minimize material waste while maintaining structural integrity. Box girders, for example, eliminate excess material to reduce dead load without sacrificing strength. Their longer span capacity compared to T-beam bridges reduces the number of piers needed, further cutting construction costs.

- High Torsional Stiffness: Steel box girders provide strong torsional resistance, essential for curved bridges and uneven loads. This enhances stability under high winds, seismic forces, and shifting traffic, ensuring safety and long-term performance in challenging environments.

- Type-Specific Advantages: Among girder types, box girders stand out for curved bridge applications due to their torsional stiffness, while plate girders are preferred for custom, long-span industrial crossings.

Cons of Girder Bridges

- Limited Span Length: Girder bridges struggle with long spans without extra support. For wide crossings, combining girders with piers or using hybrid designs can improve performance.

- Aesthetic Limitations: Their straight, utilitarian look lacks the elegance of arch or suspension bridges. Incorporating architectural elements, decorative finishes, or custom girder shapes can enhance visual appeal.

- High Maintenance Requirements: Exposure to humidity and pollutants accelerates corrosion. Using weather-resistant coatings, galvanization, or stainless steel reduces maintenance needs and extends lifespan.

- Heavy Self-Weight: Girders contribute 30–60% of total load, increasing material use and foundation demands. Optimizing steel grades, using lighter composite materials, or refining design geometry can mitigate excess weight.

Demanding Foundation Requirements: High loads require strong foundations, especially on weak soils. Pile foundations, deep footings, or soil stabilization techniques improve stability and prevent settlement.

Beam Bridge

What is a Beam Bridge?

A beam bridge is the simplest type of girder bridge, consisting of a horizontal beam supported by piers at both ends. It carries weight through bending and shear forces, making it the most practical choice for short spans such as pedestrian bridges, rural roads, and small river crossings.

Compared to plate or box girders, beam bridges are lighter, easier to build, and more cost-effective. They can be made from steel, concrete, or wood, depending on project requirements. Steel beam bridges, in particular, offer excellent strength-to-weight performance, which makes them ideal for short-span industrial applications.

Pros of Beam Bridges

- Simple and Cost-Effective: Beam bridges have a straightforward structure, making them affordable and easy to build. With fewer materials and minimal labor, they are ideal for rural roads and small crossings. Their low technical requirements mean even local builders can construct them, keeping costs down.

- Ideal for Short Spans: Designed for short-distance crossings, beam bridges work well for pedestrian walkways, small rivers, and local roads. Their efficient load distribution makes them a practical and reliable choice for low to moderate traffic conditions.

- Strength Efficiency for Short Spans: Beam bridges exhibit notable strength efficiency, combining simplicity with dependable load-bearing performance—especially when fabricated using high-strength steel components.

- Easy Component Replacement: Damaged beams can be replaced individually, avoiding costly full-scale reconstruction. If a beam is hit by a vehicle, it can be removed and replaced with a precast or prefabricated unit, reducing downtime and extending the bridge’s lifespan.

- Material Flexibility: Depending on design needs, beams can be made from reinforced concrete, composite steel, or hybrid sections. Steel beams provide lighter weight and faster installation, while concrete beams offer cost savings for small-scale civil works.

Cons of Beam Bridges

- Limited Span Capacity: Beam bridges are best suited for short distances. Longer spans require more piers, which can increase costs and disrupt waterways or traffic below.

- Vulnerable to Bending: Over time, heavy or uneven loads can cause sagging. Reinforcements like prestressed concrete or steel tensioning help improve strength and durability.

- Vertical Clearance Constraints: The beam depth directly affects clearance beneath the bridge. In industrial steel applications, deeper beams may reduce clearance for trucks or equipment, requiring customized girder-beam hybrid designs to maintain functionality.

- Construction Quality Sensitivity: Poor quality control can lead to cracks in concrete or misalignment in steel connections. Precision in tensioning, welding, and material placement is crucial to ensuring long-term performance.

- Difficult to Modify or Expand: Unlike modular truss or box girder systems, beam bridges are harder to widen or reinforce. Major changes often require additional supports or structural overhauls, increasing both cost and complexity.

Truss Bridge

What is a Truss Bridge?

A truss bridge is a structure that uses interconnected triangles to distribute weight evenly and enhance stability. This geometric configuration allows the bridge to span long distances while supporting heavy loads with minimal material.

Truss bridges are commonly used for railways, highways, and river crossings due to their exceptional strength and efficiency. Popular designs include the Warren, Pratt, and Howe trusses, each optimized for different load conditions. Their lightweight yet durable framework makes them a cost-effective solution for modern infrastructure.

Unlike girder bridges that rely on solid beams, truss bridges use open frameworks—reducing weight while maintaining high strength, which is one of the key reasons why many engineers still prefer this system for long-span steel bridge design.

Pros of Truss Bridges

- High Strength-to-Weight Ratio: Truss bridges support heavy loads with less material, thanks to their efficient triangular geometry. This makes them ideal for railways, highways, and industrial applications where load performance is critical.

- Long-Span Capability: Unlike beam or girder bridges, truss bridges can span greater distances without excessive support piers, making them perfect for wide rivers, deep valleys, and rugged terrain.

- Efficient Material Use and Cost Savings: Since truss members primarily handle axial forces (tension and compression), materials are used more efficiently. This design can reduce steel consumption by 20–30% compared to solid beam structures, leading to cost-effective solutions for large-scale projects.

- Fast and Easy Construction: Prefabricated truss components allow for quick on-site assembly, shortening project time and reducing labor costs. This makes them an excellent choice for disaster recovery or temporary bridges where time efficiency is crucial.

- Aesthetic Appeal: Many truss bridges, such as the Brooklyn Bridge, are architectural icons. Their geometric framework combines function and form, offering strong visual appeal for urban or scenic environments.

- Optimized for High-Strength Steel: Truss bridges make full use of modern high-strength steel materials, which reduce overall weight while improving stiffness and durability.

In short, the advantages and disadvantages of a truss bridge depend on the project’s priorities—whether cost, span length, or aesthetic design—but its high efficiency and proven engineering reliability keep it relevant in modern steel construction.

Cons of Truss Bridges

- Complex Construction and Skilled Labor Needs: Truss bridges require precise engineering and expert assembly, which makes them more demanding than simpler beam or girder systems. Skilled welding, bolting, and alignment are critical to ensure joint stability.

- Higher Initial Costs: Complex fabrication, high-strength steel usage, and precision assembly increase overall costs. Additional expenses also come from corrosion protection and foundation reinforcement.

- High Maintenance Requirements: With numerous joints and members, truss bridges demand regular inspection and maintenance to detect corrosion, fatigue cracks, or loose fasteners.

- Vulnerable Joint Connections: The most common truss bridge weaknesses occur at joints and gusset plates. Poor welding, misalignment, or fatigue damage can lead to localized stress failures that require timely repair.

- Fatigue Issues in High-Traffic Areas: Constant vehicle loads cause cyclic stress on diagonal and horizontal members. Without proper detailing, this can reduce service life and increase repair frequency.

- Limited Modifications: Fixed truss geometry leaves little flexibility for lane expansion or design adjustments, making later upgrades costly and structurally complex.

Modern Solutions to Truss Bridge Weaknesses

Modern fabrication by certified steel structure producers, such as SteelPRO PEB, has significantly improved the precision and durability of truss bridge systems. Through advanced CNC cutting, robotic welding, and corrosion-resistant coatings, today’s truss bridges achieve better fatigue performance and joint integrity, effectively addressing traditional truss bridge weaknesses while extending lifespan and reducing maintenance costs

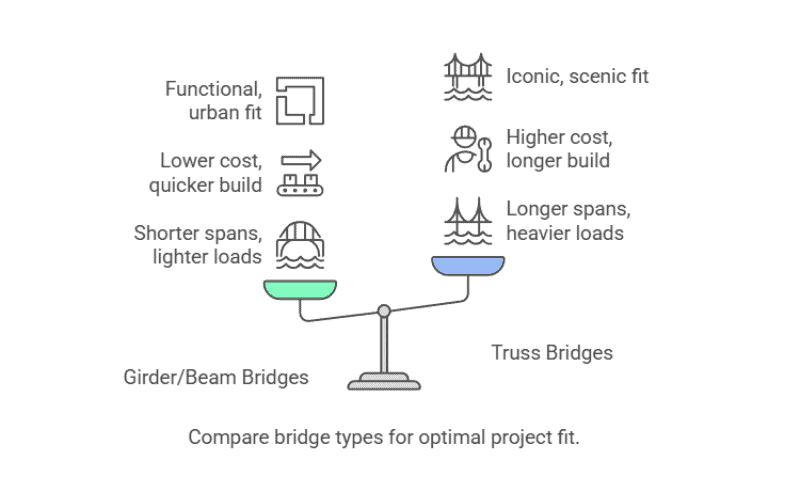

Comparative Analysis of Steel Bridge Pros and Cons

Choosing the right steel bridge type depends on project requirements such as span length, load capacity, budget, and environmental conditions. Each bridge form—girder, beam, or truss—offers distinct engineering and economic advantages.

Span Length and Load Capacity

- Girder Bridges: Best suited for short to medium spans that must support high live loads, such as highways, industrial sites, and overpasses. Their robust structure efficiently distributes weight with minimal deflection.

- Beam Bridges: Designed primarily for short spans and moderate loads like rural roads, pedestrian bridges, or small river crossings. Simplicity and low material demand make them an economical choice.

- Truss Bridges: Optimized for long spans and heavy loads, including railways and large waterways. The triangular truss geometry efficiently transfers loads through tension and compression, minimizing bending stresses.

When comparing truss vs beam bridges: truss systems handle long spans with superior structural efficiency, while beam and girder bridges dominate in short, cost-sensitive applications that demand rapid installation.

Cost and Construction Time

- Girder and Beam Bridges: Offer lower initial costs and shorter build times. Prefabricated beams and girders are easy to assemble on-site, making them ideal for fast-track infrastructure projects.

- Truss Bridges: Typically involve higher upfront investment due to complex fabrication and more extensive joint detailing. However, they provide better lifecycle economy for long-span projects where fewer piers and lower maintenance offset the initial cost.

- Modern Manufacturing Edge:

Factory-prefabricated steel components—such as those produced under controlled conditions by leading manufacturers—can further reduce installation time, ensure dimensional precision, and enhance long-term performance consistency across all bridge types.

Aesthetic and Environmental Considerations

- Girder and Beam Bridges: Prioritize practicality and are most often chosen for urban or industrial areas where cost and functionality outweigh design appeal. Their simpler geometry minimizes material use and environmental disturbance during construction.

- Truss Bridges: Stand out for their architectural character and are commonly selected for landmark projects or scenic environments. Open truss frameworks allow better wind flow and can integrate visually into natural landscapes.

Sustainability-wise, all three systems benefit from recyclable steel materials, aligning with modern green building standards.

Maintenance and Durability

- Girder and Beam Bridges: Require routine protective coatings and inspections, especially in coastal or high-humidity regions where corrosion risk is high. Periodic recoating and drainage maintenance extend service life.

- Truss Bridges: Have more components and joints to monitor, but their load distribution efficiency makes them durable under heavy cyclic loads if maintained properly. Advanced surface treatments and precision-fabricated connections now mitigate many fatigue issues once common in older truss bridges.

Each bridge type serves a distinct engineering purpose:

- Beam bridges excel in simplicity and speed.

- Girder bridges balance strength and economy for mid-span needs.

- Truss bridges dominate long spans where performance and durability justify investment.

Selecting the optimal system depends not just on cost, but on structural demand, environment, and lifecycle efficiency.

Related Reading: Is Steel Good for Building Bridges? Why Steel is the Top Choice

Material and Corrosion Performance in Steel Bridges

Corrosion is one of the most critical factors affecting the service life of steel bridges. Each bridge type—girder, beam, and truss—faces unique exposure conditions and maintenance challenges depending on its design and material configuration. Understanding how material selection and protective treatment affect performance is essential to achieving long-term durability.

Material Selection and Structural Exposure

- Beam and Girder Bridges:

These bridges often use hot-rolled structural steel or weathering steel with high yield strength. Since beams and girders have large surface areas exposed to moisture and pollutants, protective coatings or galvanization are critical for extending lifespan. In short-span highway or industrial settings, beam and girder bridges typically employ factory-painted or zinc-coated steel to resist corrosion and reduce long-term maintenance. - Truss Bridges:

The open framework design of truss bridges allows better air circulation but also exposes more surfaces and connection points to the environment. Bolted or welded joints are particularly vulnerable to rust, especially in humid or coastal regions. Advanced epoxy coatings, zinc-aluminum alloy galvanization, and corrosion-resistant high-strength steel now help mitigate these traditional truss bridge weaknesses, ensuring improved performance under variable climate conditions.

Factory Finishing and Surface Treatment

Modern steel bridge components are increasingly prefabricated in controlled factory environments, where they undergo rigorous surface treatment before shipment and assembly.

This process often includes:

- Shot blasting and cleaning to remove surface impurities.

- Metallic spray or hot-dip galvanization for corrosion resistance.

- Multi-layer protective paint systems for UV, salt, and humidity protection.

Certified manufacturers such as SteelPRO PEB implement automated surface preparation and coating systems to guarantee consistent film thickness, adhesion, and finish quality—ensuring long-term corrosion resistance and low maintenance for steel bridge structures worldwide.

Maintenance and Lifecycle Efficiency

While traditional repainting cycles for steel bridges can occur every 10–15 years, advanced protective systems have extended maintenance intervals to over 25 years.

Regular inspections, combined with factory-level coating technologies, dramatically reduce lifecycle costs and downtime—especially for long-span truss and girder bridges operating in marine or tropical environments.

In summary, effective corrosion protection begins with smart material selection, factory-applied coatings, and precision manufacturing. These combined measures ensure that modern steel bridges—whether truss, girder, or beam—maintain high structural integrity and visual appeal for decades.

Applications of Girder, Beam, and Truss Bridges

Each bridge type has its niche, and understanding their applications can help you make informed decisions.

| Bridge Type | Applications |

| Girder Bridges | Highway Overpasses – Handles heavy traffic with strength and durability. |

| Urban Roadways – Common in city infrastructure for cost-effectiveness. | |

| Industrial Access Bridges – Used in factories and ports for heavy loads. | |

| Airport Runway Bridges – Supports aircraft loads on taxiways. | |

| Floodplain Crossings – Provides stability in areas prone to flooding. | |

| Beam Bridges | Pedestrian Bridges – Lightweight and ideal for parks and city walkways. |

| Small River Crossings – Cost-effective for rural areas. | |

| Temporary Bridges – Quick assembly for disaster relief or military use. | |

| Overpasses for Railways – Safe road crossings over railway tracks. | |

| Agricultural Bridges – Used on farms to connect fields and transport. | |

| Truss Bridges | Railway Crossings – Ideal for long spans and heavy freight loads. |

| Landmark Bridges – Architectural choice for aesthetics and engineering. | |

| Large River and Canyon Crossings – Covers long, unsupported spans. | |

| Military and Emergency Bridges – Strong and modular for rapid deployment. | |

| Coastal and High-Wind Areas – Built to withstand harsh weather. |

Let’s take a look at our expert’s comparison of these three types of bridges:

- Material Efficiency – Truss bridges use less steel than girder or beam bridges for long spans. Their triangular design minimizes bending stress, making them lighter yet stronger.

- Cost vs. Performance – Beam and girder bridges are cheaper upfront, but truss bridges last longer and require less frequent major repairs. For heavy loads and long spans, investing in a truss bridge can save money over time.

- Adaptability for Future Expansion – Girder bridges allow deck widening with minimal changes, making them ideal for growing urban areas. Truss bridges, however, need extensive modifications if expanded.

- Site-Specific Suitability – Truss bridges handle high winds and seismic activity better due to their lighter weight and even load distribution. In coastal or earthquake-prone areas, they offer better stability than heavy girder structures.

The best bridge isn’t just the cheapest—it’s the one that meets load demands, adapts to future needs, and performs efficiently for decades.

Conclusion

Steel bridges, whether girders, beams, or trusses, each have their strengths and weaknesses. Girder bridges excel in cost-effectiveness and simplicity, beam bridges are perfect for short spans, and truss bridges shine in long-span and high-load applications. When selecting a bridge type, consider factors like span length, budget, and aesthetic requirements.

Looking ahead, advancements in materials and construction techniques are pushing the boundaries of steel bridge design. From sustainable materials to smart monitoring systems, the future of steel bridges is as exciting as their storied past.

In urban infrastructure, steel bridges play a key role in transportation networks, much like steel structure flyovers and corridors, which serve different purposes but share fundamental design principles. Learn more about their differences in The difference between steel structure flyover and steel structure corridor.If you’re planning a steel bridge project and need expert guidance, explore our steel bridge project portfolio to see how we’ve successfully delivered innovative and durable solutions for a variety of applications.