When it comes to building urban infrastructure or large commercial spaces, one of the biggest headaches can be deciding how to best connect different areas or overcome obstacles. That’s where steel structure flyovers and steel structure corridors come in—but how do you know which one’s right for the job? Whether it’s the complexities of flyover construction or the practical needs of corridor design, the right choice makes all the difference.

In this article, we’ll dive into the key differences between these two steel structures and explore their roles in steel frame construction, steel building construction, and structural steel fabrication—helping you make the best decision for your project.

What is a Steel Structure Flyover?

A steel structure flyover is a robust bridge designed to span across roads, railways, or other barriers. Constructed using steel frame construction, these flyovers offer enhanced strength, stability, and critical advantages, such as high load-bearing capacity and resistance to environmental stressors like wind and seismic activity, especially when dealing with large spans. Their primary function is to connect two elevated points, facilitating the passage of pedestrians or vehicles safely and efficiently.

Steel flyovers are commonly used in urban infrastructure, such as highway interchanges, railway crossings, and transportation hubs, where durable and reliable connections are essential.

What is a Steel Structure Corridor?

A steel structure corridor is a passageway designed to connect different parts of a building or multiple buildings. Unlike flyovers, steel structure corridors are not intended for vehicle passage but serve as safe, efficient walkways. Commonly found in commercial buildings, hospitals, and airports, these corridors are constructed using steel frame construction, which ensures durability, space optimization, and a visually appealing design.

With their ability to support large foot traffic while maintaining structural integrity, steel structure corridors are ideal for high-traffic areas where safety and functionality are paramount.

Structural Design of Steel Structure Flyovers vs Corridors

A flyover that can’t handle shifting loads risks structural failure, while a corridor with poor design disrupts flow and wastes space—each demands a distinct engineering approach.

Steel Structure Flyover Design

Designing a steel structure flyover involves several key considerations:

- Large Spans: Flyovers require design solutions that can handle significant distances while ensuring stability and strength.

- Environmental Stresses: Wind and seismic loads are crucial factors. Proper engineering must account for these forces to avoid structural failure.

- Common Structural Forms: Trusses and box girders are the most popular designs. Box girders are ideal for long spans and heavy traffic loads, while trusses offer material efficiency with their triangulated design.

Design Tip:

When aiming to reduce material use without sacrificing stability, diagonal bracing in trusses is a great solution. It minimizes weight while maintaining the flyover’s integrity. Additionally, modular fabrication ensures that all components fit seamlessly, speeding up construction and ensuring long-term safety.

Additionally, staggered bolted connections help distribute forces more evenly, reducing long-term stress on critical sections. Modular fabrication ensures that all components fit seamlessly, speeding up construction and ensuring long-term safety.

Steel Structure Corridor Design

Steel structure corridors, typically with shorter spans, focus on:

- Pedestrian Flow: These corridors are designed primarily for people, optimizing space while ensuring smooth movement between building sections.

- Aesthetic Integration: In commercial buildings, hospitals, and airports, corridors need to blend functionality with visual appeal.

- Common Structural Forms: Framed structures and cantilever designs are frequently used, offering stability and design flexibility.

Design Tip:

To prevent bottlenecks and improve flow, consider varying column spacing based on foot traffic. In high-traffic areas, vibration dampers help minimize oscillations, enhancing comfort and longevity. Combining steel frames with lightweight materials offers flexibility and strength, while open-web trusses reduce weight and improve airflow.

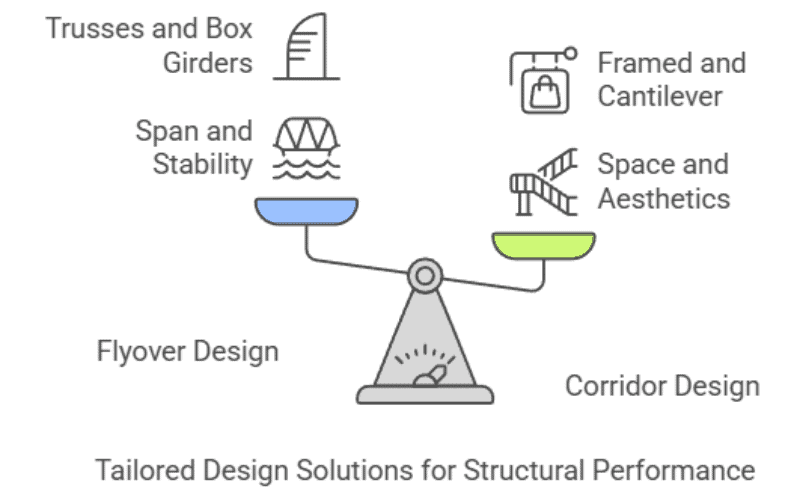

In short, while flyovers emphasize span and environmental resilience, corridors focus on space efficiency and aesthetic harmony. A key takeaway for both: tailored design solutions—whether it’s reducing material use or enhancing airflow—are essential for achieving both performance and visual appeal.

Construction and Installation of Steel Structure Flyovers vs Corridors

The key difference between steel structure flyovers and corridors lies in the complexity and scale of construction, with flyovers requiring heavy machinery and extensive on-site work, while corridors benefit from prefabrication and more streamlined installation methods.

| Aspect | Steel Structure Flyover Construction and Installation | Steel Structure Corridor Construction and Installation |

| Scope & Complexity | Complex logistics, large-scale equipment required due to long spans and heavy traffic loads. | Streamlined and flexible process, typically shorter and lighter structures. |

| Prefabrication | Certain components (e.g., beams) can be prefabricated, but most work requires on-site installation. | Predominantly prefabricated in a factory, enabling modular assembly on-site. |

| Installation Method | Segmental or full-span lifting, heavy machinery (cranes, specialized equipment) for precision. | Modular installation or onsite welding with smaller cranes and fewer resources needed. |

| Construction Time | Longer due to large-scale installation and environmental considerations (e.g., wind, seismic load). | Faster due to prefabrication, reduced labor, and more efficient assembly methods. |

| On-Site Workload | High, requiring cranes and coordination with steel fabricators for precision. | Lower, with less on-site labor and reduced need for specialized machinery. |

| Cost Efficiency | Higher due to heavy machinery, large-scale coordination, and extended installation period. | More cost-effective, thanks to modular methods and reduced construction time. |

Since our establishment, we have successfully constructed steel structure commercial buildings across several countries, including the JD Pinggu Smart Logistics Park in China, where we implemented steel structure corridors to optimize space and enhance functionality.

Use Cases of Steel Structure Flyovers and Corridors

Steel structure flyovers are designed for large spans and heavy traffic, whereas corridors prioritize spatial efficiency and flexibility, making them suited to entirely different environments. The following table highlights where each structure type excels.

| Use Case | Steel Structure Flyovers | Steel Structure Corridors |

| Urban Transportation Hubs | ✅ | ❌ |

| Highways and Roads | ✅ | ❌ |

| Railway Intersections | ✅ | ❌ |

| Large Shopping Malls | ❌ | ✅ |

| Airports | ❌ | ✅ |

| Hospitals | ❌ | ✅ |

| Schools | ❌ | ✅ |

| Connecting Buildings | ❌ | ✅ |

| Bridges for Heavy Traffic | ✅ | ❌ |

| City Overpasses | ✅ | ❌ |

| Public Transport Stations | ✅ | ❌ |

| Parking Garages | ❌ | ✅ |

| Factory and Industrial Complexes | ❌ | ✅ |

| Large-Scale Logistic Hubs | ✅ | ❌ |

| Pedestrian Walkways in City Centers | ❌ | ✅ |

| Pedestrian Bridges | ✅ | ❌ |

| Port Terminals | ✅ | ❌ |

| Transit Centers | ✅ | ❌ |

| Emergency Evacuation Routes | ✅ | ❌ |

| Retail Complexes | ❌ | ✅ |

Maintenance and Management of Steel Structure Flyovers vs Corridors

When comparing the maintenance of steel structure flyovers and corridors, it’s clear that the complexity and scale of each structure influence the level of care and attention required.

Steel Structure Flyover Maintenance

Maintaining a steel structure flyover should focus on regular inspections of its structural integrity, especially given its exposure to heavy traffic and environmental factors like wind and corrosion. Regular load testing and corrosion control measures are vital to ensuring long-term durability. Proper care in these areas helps maintain the flyover’s strength and resilience, preventing costly repairs down the line.

Steel Structure Corridor Maintenance

For steel structure corridors, maintenance revolves around simpler yet essential tasks like daily cleaning and fire prevention. However, inspections of joints and connections should still be done regularly to ensure the structure’s safety. Though maintenance is less complex compared to flyovers, a focus on safety and small repairs will keep the corridor running smoothly for years.

Cost Comparison of Steel Structure Flyovers and Corridors

The cost differences between steel structure flyovers and corridors stem primarily from their design complexity and construction scale, with flyovers demanding more resources while corridors offer a more budget-friendly option.

Steel Structure Flyover Costs

Steel structure flyovers generally incur higher costs due to their large spans and complex construction. The use of advanced fabrication techniques ensures precision and durability, but the need for specialized materials and equipment increases the overall expense. Additionally, the scale and heavy load-bearing capacity demand more robust structural elements, which further drive costs up.

Steel Structure Corridor Costs

In comparison, steel structure corridors are more cost-effective. Their smaller span and simpler design result in lower material and labor costs. By focusing on efficient fabrication and modular construction, these corridors can be built faster and at a fraction of the cost of flyovers, making them a suitable choice for projects with tighter budgets or shorter construction timelines.

Final Thoughts on Steel Structure Flyovers and Corridors

When it comes to steel structure flyovers and corridors, there’s no denying their importance. Flyovers handle heavy traffic and keep cities moving, while corridors are all about connecting spaces efficiently. Both rely on precision steel fabrication to ensure they’re safe, durable, and built to last.

Similar to how steel structure flyovers and corridors are engineered to meet specific needs, steel structure platforms provide robust and adaptable solutions across industries. Whether used for elevated walkways, industrial platforms, or large-scale logistical hubs, they share the same principles of stability and precision.

We’ve got plenty of experience building top-notch Steel Structure Corridors—whether for factories, campuses, or commercial buildings. With our advanced modular systems, we can streamline construction, saving time and costs, while making sure everything stays rock-solid and safe. Reach out to us, and let’s bring your project to life!

Check out our steel structure bridge projects for more insights into how we make complex designs work seamlessly.

Interested in learning more about steel’s versatility? Check out Is Steel Good for Building Bridges? Why Steel is the Top Choice?