Building a cow shelter isn’t just about putting up a roof—it’s about protecting your herd, improving productivity, and cutting long-term costs. Farmers and ranchers often ask: what’s the most durable and efficient way to build one? This step-by-step guide explains exactly how — from choosing the right location and laying a solid foundation, to assembling the steel frame, installing insulated roof panels, and ensuring proper ventilation, flooring, and comfort for your cattle.

You’ll also explore why a steel-framed cowshed outperforms traditional barns, discover practical construction steps, and review cattle shelter layout ideas to plan your own efficient farm setup.

As a certified Steel Structures Manufacturer & Producer, SteelPRO PEB brings over a decade of factory expertise in prefab agricultural buildings — delivering precision-engineered components and ISO-certified quality for fast, durable installation. Whether you’re raising dairy cows or beef cattle, this guide helps you build a shelter that lasts decades and strengthens your farm’s foundation.

Why Build a Cow Shelter?

A well-designed cow shelter isn’t just an extra structure on your farm—it’s a vital investment in your herd’s well-being and your operation’s profitability. From protecting against harsh weather to improving productivity, the right shelter pays for itself in the long run.

Protection from Weather

Cows are resilient, but they’re not invincible. Intense heat can induce thermal stress, resulting in decreased lactation and reproductive problems. Conversely, severe winters elevate the danger of cold injury and lung inflammation. A properly built shelter provides shade in summer, warmth in winter, and protection from wind and heavy rain, ensuring year-round comfort for your herd. Position shelters east-west to minimize midday sun exposure—your herd will graze happier.

Improved Health and Productivity

Stress-free cows are productive cows. Unprotected cattle are more prone to respiratory infections, injuries, and weight loss, which directly impacts milk yield and meat quality. A shelter with good ventilation and dry bedding helps prevent disease outbreaks and supports steady weight gain—critical for dairy and beef operations alike.

Cost Savings

Let’s talk numbers. A single case of bovine pneumonia can cost over $300 in treatment, and heat-stressed cows may produce 2 liters less milk daily. A durable shelter reduces these losses by 60–70% within three years while adding 2–3 productive years to each animal’s lifespan. Beyond protecting cattle, it significantly lowers veterinary expenses caused by pneumonia, hoof infections, and injuries from harsh conditions. Investing in a shelter isn’t just an expense—it’s a smart, long-term strategy that boosts profitability and herd sustainability.

Material Comparison Overview

While wooden and brick shelters remain common on traditional farms, steel-framed prefab models have become the modern standard. They offer faster construction, easier maintenance, and higher hygiene performance—key for large-scale or dairy operations where time and cleanliness matter most. Choosing the right material isn’t just about durability; it defines how efficiently your farm runs year-round.

Forget creaky wood beams and termite headaches. Steel shelters offer 30+ years of reliability with near-zero maintenance—no warping in humidity or rot from winter moisture. Their open-span designs allow flexible layouts (think: easy feeding alleys or calving zones), while galvanized coatings shrug off UV damage and Midwest snowloads. For forward-thinking ranchers, steel isn’t just an option; it’s the modern standard.

Step-by-Step Guide to Building a Cow Shelter

Building a cow shelter requires careful planning and execution to ensure a safe, durable, and efficient structure. By using pre-engineered kits, the process becomes more streamlined, reducing both construction time and costs while maintaining high-quality standards.

Step 1: Planning and Permits

Before starting the building process, it is crucial to determine the suitable size for the shelter. Generally, cows require 35-40 sq. ft. per animal to ensure comfort and mobility. Furthermore, verify local planning regulations and acquire the requisite licenses to steer clear of legal entanglements.

Here’s a quick planning cheat sheet:

| Planning Focus | What to Do | Pro Tip |

| Cow Stall Layout | Allow 4ft wide x 7ft long per stall | Add 10% extra space for milking areas |

| Building Materials | Use treated wood or metal for durability | Ask neighbors what’s worked best locally |

| Ventilation Placement | Install vents 10ft apart on side walls | Face vents away from winter winds |

| Drainage Plan | Slope floors 1-2% toward drainage ditches | Test slope with a level before pouring |

| Future Expansion | Leave 15ft empty space on one side | Mark expansion zones with temporary fence posts |

Struggling with getting permission? Snap photos of your planned site and draft a simple sketch showing dimensions. A quick call to your local permitting office to confirm requirements can save weeks of back-and-forth!

Step 2: Site Preparation & Foundation Installation (Drainage Design & Stability Tips)

A well-prepared site is essential for durability. Remove any debris from the area, flatten the ground, and guarantee adequate drainage to avert the accumulation of water, as it can result in hoof ailments.

For dairy cows, a full concrete slab is the best option as it provides a smooth, easy-to-clean surface that enhances hygiene and reduces the risk of hoof injuries. On uneven terrain, concrete piers can be used for structural support, but additional flooring, such as rubber mats may be needed for cow comfort. Proper curing and leveling of the foundation are crucial before assembly.

1. Clear & Clean

Remove all debris (rocks >2″ diameter, tree stumps)

Rent a brush mower for overgrown weeds ($50/day)

72% of farmers find buried rocks cause foundation cracks – probe soil with rebar every 6ft

2. Level Smartly

- Use laser level to grade 2% slope for drainage

- Keep topsoil – scrape and stockpile for later revegetation

Test: Pour 5gal water – should flow 10ft in 3mins

3. Foundation Prep

| Terrain Type | Action |

| Clay Soil | Compact 6″ crusher-run base |

| Sandy Soil | Install woven ground stabilizer |

| Sloped Site | Build retaining wall every 30ft |

4. Material Staging

- Designate 20x20ft area for concrete/wood storage

- Lay pallets to prevent moisture damage ($0.5/sqf)

We provide tailored foundation recommendations for different terrain types, ensuring stability and longevity. As part of our cow barn design process, these recommendations are typically shared on the first day of your inquiry, helping you plan efficiently.

5. Mark the Foundation Layout:

- Use stakes and string lines to outline the foundation dimensions.

- Double-check alignment and squareness to ensure accurate construction.

6. Excavate and Prepare the Base:

- For slabs, dig 6-8 inches deep, then lay a 4-6 inch gravel base.

- For piers, dig holes at least 24 inches deep and fill them with compacted gravel before pouring concrete.

7. Install Reinforcement:

- Place rebar or wire mesh for strength and durability in concrete slabs.

- Secure pier reinforcements using anchor bolts before the concrete is set.

8. Pour and Level the Concrete:

- Pour concrete evenly, ensuring a minimum thickness of 4 inches.

- Use a screed board and trowel to smooth the surface.

9. Allow Proper Curing Time:

- Concrete should cure for at least 7-10 days to reach full strength before further construction.

- Keep the surface moist during curing to prevent cracking.

Our feature: We provide essential foundation components, including anchor bolts, embedded parts, and positioning frames for securing anchor bolts and embedded parts. These ensure a stable and secure structure, making installation more efficient and precise. Anchor bolts and embedded parts are supplied directly from our SteelPRO PEB factory to ensure precise alignment and long-term structural stability.

Step 3: Frame Assembly

The steel frame serves as the skeleton of the shelter, providing structural strength. Construct the framework in accordance with the manufacturer’s guidelines, utilizing galvanized screws to thwart rust and deterioration.

- Organize Materials

- Sort labeled parts (A1, B2, etc.) into zones using colored chalk marks on the ground.

- Quick check: Count all pre-drilled holes – each beam should have 8 evenly spaced holes.

- Install Base Connections

- Thread anchor bolts until resistance increases (about 5 full turns after snug contact).

- Pro tip: Rub beeswax on bolt threads to prevent galling in humid weather.

- Assemble Vertical Supports

- Slide column bases onto anchors until you feel a firm “thud” against the foundation.

- Hold a 4-ft level vertically – bubbles centered = perfect plumb.

- Install Roof Trusses

- Align truss notches with beam grooves until they seat fully (no visible gaps).

- Listen: A smooth “clink” means connectors are fully engaged.

- Secure Frame Bracing

- Tighten cross-braces until the wrench handle deflects slightly (≈15° bend).

- Test: Push firmly on any joint – zero wobble means it’s storm-ready.

- Final Torque Check

- Set torque wrench to 90 lb-ft – a sharp “click” confirms proper tightness.

- Mark each tightened bolt head with bright paint for easy visual inspection.

Our advantage: Our kits come with pre-drilled holes and labeled parts, making assembly quicker and more efficient. Unlike traditional wood frames, our prefabricated steel systems arrive pre-drilled and torque-calibrated for error-free assembly, ensuring structural precision and long-term durability.

Step 4: Roof and Wall Installation

Durable materials are key to weather resistance. Metal roofing and siding protect against harsh conditions, while insulation helps regulate temperature in extreme climates.

- Install Roof Panels:

- Start from one corner, ensuring an overlap of at least 6 inches for each panel to avert any seepage.

- Secure panels using self-drilling screws with neoprene washers to maintain a watertight seal.

- Leave space for ridge vents to enhance ventilation.

- Attach Wall Panels:

- Start from the bottom and work upward, securing panels to the frame.

- Overlap panels slightly to prevent water infiltration.

- Use pre-cut corner trims to seal edges and improve aesthetics.

- Add Insulation (If Required):

- For extreme climates, install spray foam or rigid board insulation between wall panels.

- Reflective insulation under the roof helps reduce heat buildup in warmer regions.

- PEB insulated roof and wall panels (with polyurethane or rock wool cores) further enhance thermal efficiency, improving indoor comfort and preventing condensation in high-humidity environments.

- Seal and Finish:

- Apply weather-resistant sealant around fasteners and panel joints.

- Check for any loose panels and tighten them as needed.

- Install flashing around openings (doors, windows) to prevent leaks.

Our innovation: We offer reflective roofing options that reduce heat buildup in warm regions, improving cattle comfort.

Step 5: Ventilation and Lighting

Adequate ventilation forestalls respiratory problems and guarantees a wholesome atmosphere. Install ridge vents or sidewall openings for natural air exchange, and consider adjustable side curtains for flexible control in different seasons.

For nighttime visibility, use LED lighting to improve safety and reduce energy use. Ensure light levels around 15–20 lumens/sq. ft. in feeding and working areas to mimic natural daylight cycles.

Install solar-powered lighting systems to enhance energy efficiency — a sustainable option for farms in regions with strong sunlight exposure.

Step 6: Flooring and Bedding

Flooring should be durable, non-slip, and easy to clean. Concrete or gravel floors work best, while straw or sand bedding improves comfort and cleanliness.

Maintain a 1–2% floor slope toward drainage channels to prevent standing water and ammonia buildup. This design significantly reduces hoof and hygiene issues while improving waste flow.

Rubber mats in resting zones minimize joint stress and improve cattle comfort, especially in cold climates.

Proper flooring design minimizes hoof-related issues and simplifies waste management.

Step 7: Final Touches

A well-designed shelter goes beyond just structure. It should be practical and comfortable for both the animals and the caretakers. Thoughtful placement of feeding and watering stations ensures easy access and reduces crowding. Secure gates and fencing help keep the herd safe from predators while maintaining controlled movement.

Small additions like non-slip flooring at entry points and strategically placed shade areas improve cow comfort, reducing stress and enhancing productivity.

These modular layouts, combined with factory-built precision, are part of SteelPRO PEB’s turnkey cow shelter system, ensuring each shelter can adapt to herd growth and operational needs over time.

Cattle Shelter Design & Layout Ideas (Optional Add-on)

Every farm layout is different, and so should be your cow shelter. After completing the basic structure, planning the interior zones determines how efficiently your operation runs.

Here are three proven cattle shelter layout ideas used by modern farms:

- Free-Stall Layout: Open aisles for feeding and milking; ideal for large herds needing flexibility.

- Tie-Stall Layout: Organized rows with individual tie spaces; perfect for small dairy setups where control and cleanliness matter most.

- Open Shade Type: Simplified steel-framed structure providing quick coverage and excellent airflow, ideal for hot climates or seasonal operations.

Farmers seeking custom cattle shelter plans can adapt these models with adjustable ridge vents, wider feed alleys, or integrated manure channels. Each design can be tailored with steel structure cowshed specifications to fit your herd size and site terrain.

Need a detailed layout? SteelPRO PEB engineers can model your shelter digitally before fabrication, ensuring space efficiency and future expandability.

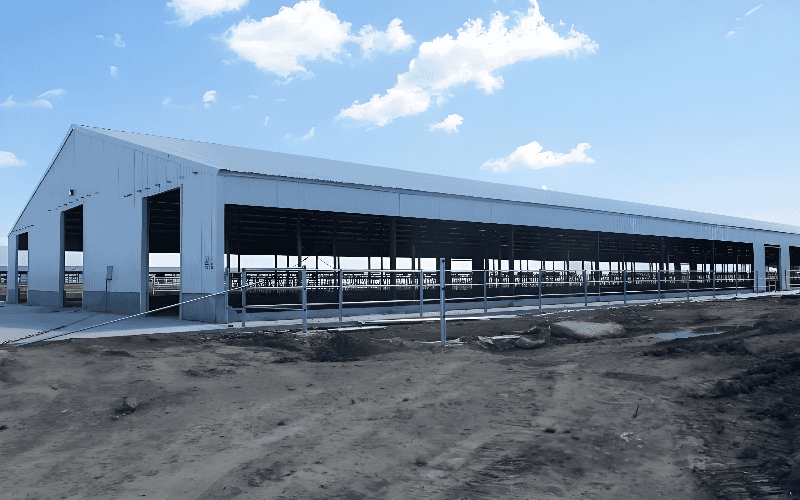

Choose Our Steel Structure Cowshed?

After learning how to build a cow shelter step by step, the next question is simple — what kind of structure truly lasts? Traditional barns often struggle against rot, humidity, and high maintenance costs. That’s why more farmers are turning to factory-built steel structures, designed for strength, speed, and long-term value.

A steel structure cowshed offers what wooden shelters can’t: rapid installation, durable galvanized framing, and insulation that keeps cows healthy through heat and cold. For sloped sites or high-ventilation regions, our monoslope cattle barn designs balance airflow and drainage with precision-engineered layouts.

Every structure we deliver is prefabricated, ISO-certified, and engineered for real farm conditions—so you spend less time fixing and more time farming. Choose a system built for your herd, not against your climate.

Contact SteelPRO PEB, your trusted Steel Structures Manufacturer & Producer, to get your custom, factory-direct quotation today.