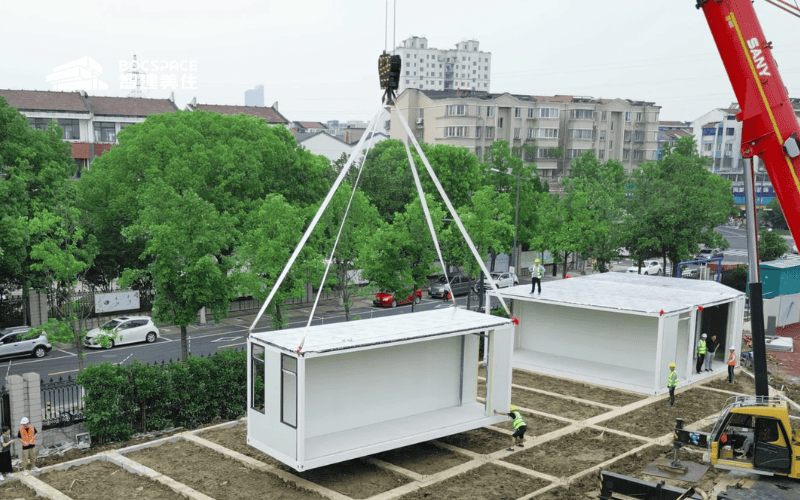

In recent years, the proportion of modular construction in new construction projects has increased year by year. Data shows that modular construction will account for 6.64% of new construction projects worldwide in 2023.

According to the latest industry analysis, by 2029, the global multi-family modular and prefabricated residential construction market is expected to reach US$73.84 billion, with a compound annual growth rate (CAGR) of more than 7%.

This trend not only brings new growth points to the construction industry, but also provides a broad space for development for steel structure companies.

Modularization ≠ Building Blocks: Three Irreplaceable Characteristics of Steel Structure

1. Precision Control: Hard Threshold for Industrial-Grade Construction

The dimensional error of concrete modules often exceeds ±5cm, while steel structure modules can achieve ±1mm accuracy through laser cutting-this is the core guarantee for “tight fit” when high-rise modular units are stacked. Actual measurements of a super-high-rise residential project show that the verticality deviation of the steel structure module is only 1/8 of that of the concrete module.

2. Lifecycle cost revolution

Although the initial cost of steel structure modules is 8-12% higher than that of traditional buildings, the following hidden benefits are considered:

The construction period is shortened by 40%, and the capital recovery period is shortened by 6 months.

During the 30-year operation and maintenance phase, the removable bolt connection reduces the renovation cost by 60%.

When the building is scrapped, the steel recovery value can reach 75% of the raw material cost.

3. Disaster resistance performance reconstruction safety standards

In a recent modular apartment project in a seismic zone, the steel structure frame is designed with “buckling restraint support + modular node”, and the seismic performance is 1.5 times that of traditional buildings. This explains why steel structures account for 89% of modular buildings in Japan.

Four major challenges in the steel structure industry

1. Intelligent breakthrough in connection technology

Traditional welding nodes restrict the efficiency of module disassembly and assembly, and leading companies are testing:

- Intelligent bolt system (pressure sensing + self-locking).

- Electromagnetic adsorption pre-positioning technology.

- UAV-assisted precise docking in the air.

2. Technical breakthrough of enclosure system

For the acoustic bridge effect of steel structure modules, new solutions have achieved breakthroughs:

- 3D printing elastic sound insulation layer (insertion loss increased by 12dB).

- Vacuum insulation panel (VIP) exterior wall system, thickness reduced by 50%.

3. Long-term battle of corrosion protection

According to the measured data of coastal projects, the rust rate of steel components with nano-ceramic coating is only 1/3 of that of traditional hot-dip galvanizing in 20 years. In addition, the research and development of new weathering steel materials is also continuously advancing, and it is expected that the cost will be reduced by 15% in the next five years.

Modular market regional analysis

Asia Pacific: As the world’s largest modular building market, the rapid growth of Asia Pacific is mainly due to the accelerated urbanization process in China, India and other countries and the government’s emphasis on infrastructure construction.

North America and Europe: Market growth in these regions is mainly driven by green building policies and housing shortages.

Africa: It is expected to be the fastest growing region, and urbanization and population growth provide huge market potential for modular buildings.

Four strategic directions of steel structure enterprises

1. Technology research and development:from manufacturing to intelligent manufacturing

Steel structure enterprises need to increase investment in intelligent technology, for example:

Introduce AI-driven design optimization system to improve the standardization of modular units.

Lay out automated production lines to realize the full process intelligence from cutting, welding to spraying.

2. Industry chain integration: create an ecological closed loop

Establish in-depth cooperation with design institutes, developers, and construction parties to form an integrated platform of “design-manufacturing-construction” to improve overall efficiency. For example, a leading enterprise has shortened the project delivery cycle by 40% through this model.

3. Global layout: seize emerging markets

Although the Asia-Pacific region is currently the largest market for modular buildings, emerging markets such as Africa and South America are rising rapidly at a double-digit growth rate. Steel structure enterprises can seize the opportunity in these markets through technology output and localized cooperation.

4. Green transformation: leading sustainable development

The combination of modular buildings and steel structures naturally fits the development trend of green buildings. Enterprises can strengthen this advantage by:

- Research and develop low-carbon steel to reduce carbon emissions during the production process.

- Promote the application of modular buildings in the renovation of old urban areas to achieve resource recycling.

Modular buildings are not only the future trend of the construction industry, but also a new outlet for the steel structure industry.

With the continuous innovation of technology and the continuous expansion of the market, steel structure modular buildings are expected to become a key force in solving global housing and environmental protection problems. As industry practitioners, we must not only keep up with the trend, but also take the initiative to innovate and seize this historic opportunity.