A Pod House is not just a tiny living solution – it is a factory-prefabricated modular building produced by Steel Structures / PEB Manufacturer & Producer. With certified quality, factory-direct supply, and wholesale pricing, our Pod Houses are designed for fast deployment and long-lasting performance.

Whether you need a vacation cabin, office pod, or a permanent small home, this guide will help you understand what a Pod House is, its types, costs, and benefits. Discover why more businesses and homeowners choose factory-direct modular pods from SteelPRO PEB for flexible and affordable living.

Looking for a flexible and affordable modular living solution? Contact Steel Structures / PEB Manufacturer & Producer today to get a factory-direct, certified Pod House at wholesale prices.

What is a Pod House?

A Pod House is a small, prefabricated, independent living unit that is usually produced in a standardized factory and then transported to the site for assembly. The “Pod” in its name comes from the concept of “Capsule”, which emphasizes compact and efficient space design. The area of this type of house is mostly between 15-30 square meters, and multiple modules can be expanded or combined according to needs to form a larger living space.

Core features

“Less is more”: remove unnecessary space burdens and focus on practicality and comfort.

Modular design: The structure is divided into independent units that can be flexibly spliced or stacked to adapt to different scenarios.

Prefabricated production: More than 90% of the construction process is completed in the factory, reducing on-site construction time and pollution, making it faster and more environmentally friendly.

Lightweight materials: Steel frames, composite panels or sustainable materials (such as bamboo, wood, recycled plastics) are mostly used to reduce the overall weight.

Mobility: Some designs are equipped with axles or bases for easy relocation; they can also be fixed to the foundation for long-term use.

Functional integration: The interior layout emphasizes functionality and space efficiency, and some styles can also be customized, such as adding windows, kitchen modules or connecting multiple units.

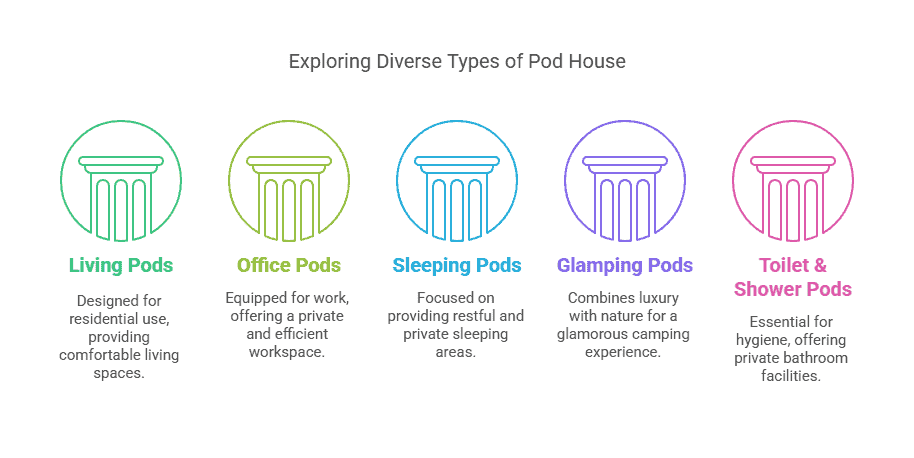

Types of Pod Houses

Pod Houses do not have only one form. They can evolve into multiple types according to different usage scenarios and functional requirements. Here are some common classification methods to help you quickly understand which Pod is best for your lifestyle:

1. Living Pods

This type of Pod is the closest version to “home”, usually including a sleeping area, a mini kitchen and a bathroom space. Some are even equipped with smart home systems, suitable for singles, couples, or as holiday cabins and long-term rental micro apartments.

2. Office Pods

After remote work became the norm, Office Pods became the ideal “backyard office” for many people. It provides a quiet, independent, and undisturbed space for work, does not occupy the living room or bedroom at home, and improves work efficiency.

3. Sleeping Pods

Focus on “the little thing of sleeping”. This type of Pod is suitable for places that require short breaks, such as airports, hospitals, and schools. It is also suitable for camping sites or homestays, providing a simple but private sleeping space.

4. Glamping Pods

“Glamping” is the abbreviation of “Glamorous Camping”. This type of Pod has a delicate appearance and comfortable interior, and is usually used in high-end camping sites. You can enjoy nature while having a bed, air conditioning, hot water and electricity.

5. Toilet & Shower Pods

This type of Pod provides functions such as toilet, shower or laundry. Some are used as supplementary modules of the main living Pod, and can also be set up independently in camps, construction sites or event sites to improve convenience and hygiene standards.

6. Modular Pod Systems

If you have higher space requirements, you can connect multiple Pod modules to form a larger living unit. For example, a living Pod + an office Pod + a bathroom Pod can be assembled into a small “single-family house”.

The flexibility of our Pod House makes it not only a “house”, but also a living solution that can be freely spliced. Whether you want to put it in the backyard, in the mountains, on the edge of the city, or even move with it, Pod can adapt to your rhythm.

What is the purpose of Pod House?

Pod House is widely used in various scenarios because of its flexible structure and diverse functions. Here are some common uses:

- Residential use: as permanent residence or temporary housing, suitable for singles, couples, and small families.

- Remote office: placed in the backyard as a private office, quiet and independent, improving efficiency.

- Short-term rental and vacation: used in Airbnb or camping sites to attract tourists and have a quick return on investment.

- Emergency accommodation: suitable for post-disaster reconstruction or temporary resettlement, quick deployment, comfortable and durable.

- Education and medical auxiliary space: can be used as a school reading room, psychological counseling room, or mobile medical point.

- Outdoor experience space: as a comfortable accommodation option in camping sites, farms, and scenic spots.

In short, as long as you have space and needs, Pod House can almost come in handy.

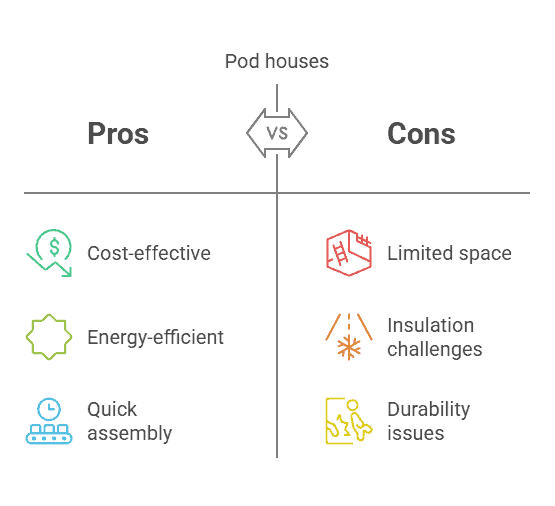

Advantages and Disadvantages of Pod House

Advantages of Pod House

Quick installation: Most of them are prefabricated in the factory, can be assembled on site, and can be moved in within a few days.

Low cost: more economical than traditional houses and some modular houses.

High flexibility: movable and combinable, suitable for different sites and uses.

Environmental protection and energy saving: small size, low energy consumption, many are equipped with solar energy and energy-saving systems.

Simple maintenance: simple structure, easy to clean materials, low maintenance cost.

Disadvantages of Pod House

Limited space: suitable for individuals or small families, may not be enough for large families.

Functional limitations: limited by volume, kitchen, storage, and bathroom functions may be relatively simplified.

Regulatory restrictions: some areas have approval requirements for small houses or mobile buildings.

Foundation and supporting issues: still need to be connected to water and electricity or foundation support, which may increase costs.

In general, Pod House is a “lightweight” but efficient living space, suitable for people who pursue a simple, flexible and cost-effective lifestyle.

How is the Pod House built?

The construction method of the Pod House is different from that of traditional houses. It is more like “manufacturing products” rather than “on-site construction”. The whole process is efficient and standardized, and can be roughly divided into the following steps:

1. Design and planning stage

Requirement confirmation:

- Determine the purpose (residence, office, vacation home, etc.), number of users, budget and whether mobile functions are required.

- Choose a basic design template or fully customize (such as adding balconies, attics, solar panels).

Compliance design:

- Adjust the structure according to local building regulations (such as earthquake resistance, fireproof materials, escape routes).

- Use BIM (Building Information Modeling) software for 3D simulation to optimize the space layout.

Main structure: light steel frame (lightweight, corrosion-resistant) or CLT (cross-laminated timber, low-carbon and environmentally friendly).

Exterior wall: composite insulation board, recycled metal board or precast concrete board.

Interior: environmentally friendly materials such as bamboo fiberboard and low formaldehyde paint.

2. Factory prefabrication stage

Modular production:

- Structural frames, walls, water and electricity pipelines are assembled on the factory assembly line with millimeter-level accuracy.

- Standardized components (such as doors, windows, and sockets) are embedded in advance to reduce on-site construction errors.

Functional preinstallation: pre-buried pipelines, integrated off-grid equipment (such as solar inverters, rainwater filters).

Quality inspection: pressure test (windproof, waterproof), circuit safety inspection to ensure that the modules meet the delivery standards.

3. Transportation and on-site installation

Transportation preparation:

- The size of a single module is usually controlled at 3-4 meters in width and 6-12 meters in length to adapt to road transportation.

- Oversized modules require special transportation permits, which increase costs by about 15-30%.

Foundation treatment:

- Mobile type: level the ground, lay gravel or concrete slabs, and install adjustable legs.

- Fixed type: cast reinforced concrete foundation, and reserve water and electricity interfaces.

Module assembly:

- Lift a single module to the foundation and fix the structure with bolts.

- When multiple modules are spliced, waterproof sealant and reinforced steel structure are used at the joints.

Average installation time: 1-2 days for single module, 3-7 days for multiple modules.

4. System connection and commissioning

Water and electricity access:

- Municipal water and electricity: connect the pre-buried pipes to the municipal pipe network, which requires professional technicians to operate.

- Off-grid system: install solar panels, battery storage groups and composting toilets (regular maintenance is required).

Interior decoration:

- Soft decoration stage: install customized furniture (such as folding beds, retractable dining tables), and decorate walls.

- Ventilation test: ensure that air circulation meets the standards to prevent moisture or formaldehyde from exceeding the standards.

5. Acceptance and maintenance

Official acceptance:

- Some areas require government inspectors to issue a Certificate of Occupancy.

- Acceptance focus: structural safety, fire prevention facilities, and sewage compliance.

Daily maintenance:

- Check the roof sealing and anti-rust coating of light steel structures every year.

- Clean solar panels, replace filters, and monitor battery life.

Are Pod Houses Legal Everywhere?

Not completely legal. The legality of Pod Houses is highly dependent on the zoning laws and building codes of the location. Some countries or regions allow them to be used as permanent or temporary residences, but some places may completely prohibit them.

How much does a Pod House cost?

The price of a Pod House varies greatly depending on the size, configuration, material and degree of customization, but in general, it is more affordable than traditional homes or some modular homes, and is suitable for people with limited budgets and who pursue quality.

Approximate price range

The following is a price reference for common Pod Houses (only an estimate, the actual price depends on the region and configuration):

- Basic sleeping Pod (single/double, 5-8㎡): about $4,000 – $9,600

- Standard residential Pod (10-20㎡, including bathroom/kitchen): about $11,000 – $27,000

- Customized combination Pod (multiple modules connected): starting from about $27,000+, increasing according to function and area

Main factors affecting the price

- Area and structure: The larger the more expensive, whether there is a steel frame, fireproof layer, and thickened insulation layer will affect the cost.

- Functional configuration: Does it include a kitchen and bathroom? Does it have solar energy, electric floor heating, and smart system? The more complete the configuration, the higher the price.

- Material selection: The cost of materials such as environmentally friendly composite panels, steel, aluminum alloy, and exterior wall decorative panels varies greatly.

- Customization degree: Standardized mass production has low cost, while personalized customization will increase design and processing costs.

- Transportation and installation: The longer the distance and the more complex the terrain, the higher the transportation and hoisting costs; the availability of existing infrastructure will also affect the budget.

Is it cost-effective in the long run?

Although the one-time investment seems large, compared with traditional houses that cost hundreds of thousands or even millions, Pod House has the following economic advantages:

- No complex foundation is required, installation is fast, and labor and construction costs are saved

- Low operating and maintenance costs (energy saving, easy maintenance)

- Flexible relocation, adaptability to different sites, and increased return on investment

- Suitable for short-term rental, camping, and office space, with commercial monetization potential

By choosing SteelPRO PEB factory-direct supply, you save 15–30% compared to distributors. Get your certified Pod House at wholesale price directly from the manufacturer. Contact us now for a free quotation.

Pod House vs. Other Small Living Options

At first glance, a Pod House might seem similar to a Tiny House, Modular Home, or even an RV. However, each of these housing types has unique characteristics when it comes to structure, mobility, build time, and use cases. Let’s take a closer look:

| Type | Structure | Mobile | Build Time | Common Use | Key Features |

| Pod House | Prefabricated module | Some are mobile | Some (days to weeks) | Living, office, rental | Flexible, quick to install, compact |

| Tiny House | Traditional or prefab | Some on wheels | Somerate (weeks to months) | Long-term living | Cozy space, traditional home feel |

| Modular Home | Factory-built + on-site assembly | Not mobile | Noterate (a few weeks) | Permanent residence | Larger space, close to standard homes |

| RV (Recreational Vehicle) | Integrated mobile unit | On wheels | No build needed | Travel & temporary stay | Highly mobile, less comfort/privacy |

Unlike DIY Tiny Houses or RVs, our factory-produced Pod Houses are built by a certified Steel Structures / PEB Manufacturer & Producer. With factory-direct supply, wholesale pricing, and international certifications (ISO & CE), we deliver durable, customizable, and affordable modular living solutions. Whether for residential, commercial, or tourism projects, choosing SteelPRO PEB means getting a Pod House that is not only flexible and modern, but also certified and cost-efficient straight from the source.

What Makes Pod Houses Stand Out?

- More comfortable and better insulated than RVs

- Faster and simpler than building a Tiny House

- More flexible and compact than full Modular Homes

- Suitable for both long-term and temporary use

History of Pod House

Although Pod House looks modern, its concept actually originated from small prefabricated buildings decades ago, and was first used in the following scenarios:

- Temporary housing: used for rapid resettlement after war and disaster, emphasizing fast construction and mobility.

- Industrial housing: simple offices, dormitories or equipment cabins at construction sites.

- Mobile accommodation: With the rise of RV culture, small habitable units began to enter the public eye.

After 2010, with the popularity of Tiny House and modular buildings, Pod House was redefined by more designers and companies. It is no longer a temporary space, but a small residence with a sense of design and long-term use.

After the epidemic, the needs of remote work, short-term rental tourism, and flexible land use have pushed Pod House into the home and commercial markets, becoming a truly practical “multi-functional living unit”.

Today, Pod House has become an important member of the small housing field, combining efficient construction, environmental protection concepts and flexible use, and is continuing to develop globally.

Why are Pod Houses becoming more and more popular?

- Economic pressure: Housing prices are rising, and the cost of Pod Houses is only 1/3-1/2 of traditional houses ($20K-$80K for a single module).

- Flexible demand: Remote work is on the rise (42% of companies support remote work), and digital nomads need mobile office and living integration.

- Environmental policy: Carbon neutrality goals drive (such as the EU requires new buildings to reduce carbon emissions by 55% by 2030), low-energy design (energy saving of 50%).

- Minimalist culture: The younger generation tends to let go, and small space living has become a trend.

Pod House market status

- Scale: $8.2 billion globally in 2023, and $14 billion expected in 2030 (CAGR 8.2%).

- Region:

- North America (35%): Relaxed policies, ADU legalization drives growth (15,000 units per year in California).

- Europe (30%): Nordic dominance, Swedish brand Naturvillan grows 25% per year.

- Asia Pacific (20%): Japan’s aging needs, China’s tourist camp applications.

- Applications: Residential (60%), tourist hotels (25%), emergency housing (15%).

Is Pod House the future of housing?

Pod House can alleviate the pressure of high housing prices and environmental protection, and is suitable for compact urban development, elderly housing and disaster prevention scenarios, but it faces incomplete regulations, fluctuating material costs and the bias of “small = bad”. In the future, it may become a mainstream option in areas with high housing prices (such as Northern Europe), while other areas will be limited to tourism or emergency purposes.

It will not replace traditional housing, but will be an important supplement. Its popularization depends on technology price reduction, policy support and changes in concepts.

What does “3 BHK + 1 Pod” mean?

“3 BHK + 1 Pod” is a housing term meaning 3 Bedrooms, Hall, Kitchen, plus one Pod unit. In real estate listings, the “Pod” usually refers to an extra modular room (office, study, or guest space) that is factory-built and attached to the main structure. At Steel Structures / PEB Manufacturer & Producer, we provide customizable Pod modules that can expand your living space quickly and cost-effectively.

Are Pod Houses prefabricated or modular?

Yes. A Pod House is essentially a prefabricated modular unit. Over 90% of the structure is built in the factory, ensuring certified quality and reducing on-site construction time. As a certified PEB manufacturer, SteelPRO PEB offers factory-direct modular pods with wholesale supply, designed for fast installation and long-term durability.

Can I buy Pod Houses directly from a China factory?

Absolutely. Steel Structures / PEB Manufacturer & Producer has its own factory in Jiaozhou, China, covering 500 acres with 24 production lines. We offer factory-direct supply of Pod Houses worldwide, with ISO and CE certifications. Whether you are in the US, Europe, or Asia, we can ship modular pods in bulk at wholesale prices.

How much does a factory-direct Pod House cost?

The cost depends on size, configuration, and customization:

- Sleeping Pod (5–8㎡): $4,000 – $9,600

- Standard Living Pod (10–20㎡ with bathroom/kitchen): $11,000 – $27,000

- Modular Combination Pods: $27,000+

By choosing SteelPRO PEB factory-direct supply, you save 15–30% compared to distributors, while ensuring certified quality and wholesale pricing. Contact us today for an exact quotation.

Are Pod Houses legal everywhere?

Not everywhere. The legality of Pod Houses depends on local zoning laws and building codes. Some regions allow them as permanent housing, while others only permit temporary use. At Steel Structures / PEB Manufacturer & Producer, we design Pod Houses that comply with international standards (ISO, CE), and we provide technical drawings to help you apply for local approval more easily.

Pod Houses are changing the way people live, work, and travel. Don’t overpay middlemen – get your factory-direct, certified Pod House from a trusted Steel Structures / PEB Manufacturer & Producer. Contact us today for a wholesale quotation and fast global delivery.