What Is a Modular Wall?

A modular wall is a prefabricated wall system comprised of standardized components, typically panels and frames, which are manufactured off-site and then assembled on-site with minimal disruption.

Unlike traditional walls, modular walls don’t require bricks, drywall, or wet trades. They are designed to be installed quickly, adjusted easily, and even reused when space needs change.

We’ll cover the main benefits of modular walls, comparing how they compare to other wall systems like drywall and fixed partitions. Whether you’re in the process of designing a new office, renovating an industrial facility, or simply looking for a flexible solution, we’ll guide you through the factors you need to consider when choosing the right modular wall for your space.

What types of modular walls are there?

Not all modular walls are created equal. Depending on your space and goals, different types of modular walls offer different benefits.

1. Demountable Partition Walls

These are ideal for offices and indoor commercial spaces. They can be easily installed, removed, and reconfigured without causing any damage to floors or ceilings. Great for growing teams or changing layouts.

2. Panel Modular Wall Systems

These use pre-sized wall panels (usually solid or insulated) attached to a framing system. They are sturdy, clean-looking, and commonly used in factories, warehouses, and cleanrooms.

3. Modular Cleanroom Walls

Designed for controlled environments such as laboratories, electronics, or pharmaceutical production. These walls are built to meet hygiene, air control, and compliance standards.

4. Exterior Modular Wall Systems

Some modular walls are built for outdoor use, such as jobsite fencing, noise barriers, or temporary enclosures. These walls are typically weather-resistant and can be easily relocated or replaced.

5. Load-Bearing Modular Walls

While most modular walls are non-structural, there are systems designed to support loads. These systems are relatively uncommon and are typically utilized in specific industrial or structural applications.

Choosing the right type depends on how durable the wall needs to be, the environment in which it will be used, and how much flexibility you need later. If you’re unsure, talk to us – Our experts are here to assist you in selecting the optimal solution for your project.

What Materials Are Modular Walls Made Of?

The strength, appearance, and performance of a modular wall all depend on what it’s made of. Most systems use a combination of frame and panel materials—and each part plays a role.

Frame Materials

Modular wall frames are usually made from:

- Steel – strong, durable, ideal for industrial or heavy-duty applications

- Aluminum – lightweight, corrosion-resistant, often used in offices or clean environments

These metal frames form the backbone of the wall system and provide long-term stability.

Panel Materials

The panels are the visible part of the wall and can be customized based on function and aesthetics. Common options include:

- Laminated panels – for clean, professional finishes in offices or conference rooms

- PVC or vinyl-coated panels – easy to clean, suitable for healthcare or food processing areas

- Glass panels – often used in meeting rooms or spaces where natural light is important

- Steel panels – durable, ideal for factories or high-traffic areas

- Insulated panels – offer soundproofing and thermal control, useful in production or tech spaces

Some systems also offer fire-rated or moisture-resistant options to meet specific safety or environmental needs.

In short, modular walls aren’t one-material-fits-all. They’re built to suit your space—and your priorities.

How Is a Modular Wall Installed?

One of the biggest advantages of modular walls is how fast and clean the installation process is. Unlike traditional construction, there’s no drywall dust, no long curing times, and no noisy demolition.

The process is straightforward:

- The wall components—frames, panels, connectors—are pre-made in a factory.

- On-site, installers assemble the structure using simple tools.

- Most systems snap, slide, or bolt together with precision fittings.

This means less downtime for your business. Many projects can be completed in hours or days, not weeks. And since the installation is dry (no wet materials like cement or glue), the site stays cleaner and safer.

DIY or Professional Installation?

Certain lightweight systems are intended for DIY installation, featuring clear instructions and not necessitating specialized skills. These systems are more prevalent in small offices or temporary setups.

But for larger spaces, electrical integration, or high-performance environments like factories or labs, professional installation is usually the better choice. It ensures stability, code compliance, and clean finishing—without the trial and error.

So whether you’re building a quick partition or outfitting an entire facility, the installation process is one less thing to worry about.

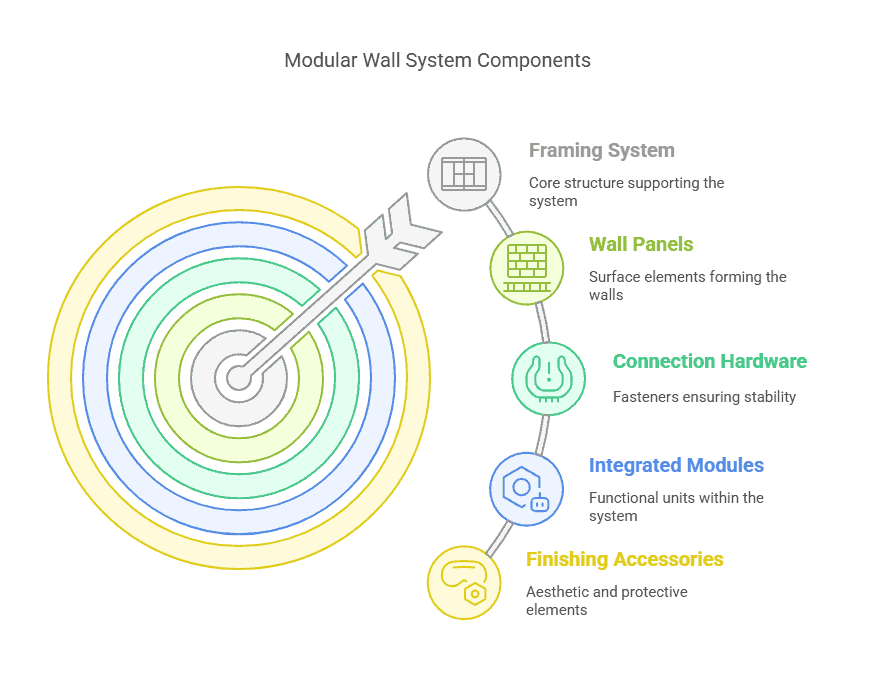

What Are the Components of a Modular Wall System?

A modular wall system is made up of several key components—not just panels. Each part has a specific role, and together they create a wall that’s fast to install, easy to reconfigure, and built to last.

1. Framing System

- The framing system is the backbone of the wall, providing structure and stability. It’s typically made from steel or aluminum, ensuring strength while also allowing for quick assembly. The frames securely hold the panels in place, ensuring a stable, long-lasting wall.

2. Wall Panels

- Wall panels form the visible surface of the modular wall. Depending on the desired functionality and aesthetic, these panels can come in solid, glazed, or insulated varieties. They come in various finishes, such as laminate, vinyl, or metal, and can be easily inserted into the frame, making it simple to adjust or reconfigure the wall when needed.

Related Reading: Types of mobile home siding

3. Connection Hardware

- Connection hardware plays an essential role in holding everything together. It includes clips, tracks, and fasteners, which ensure tight seams and clean lines between panels. This hardware also allows for easy disassembly and reassembly, making the wall reusable and adaptable for future needs.

4. Integrated Modules

- The integrated modules are additional components that add functionality to the wall system. These include doors—whether swing, sliding, or glass—windows, cable management systems for electrical or HVAC lines, and acoustic seals for soundproofing. These modules can be added to create a customized, efficient workspace.

5. Finishing Accessories

- Finishing accessories enhance the look and performance of the wall. Skirting, trims, and corner guards create a polished appearance, while ceiling and floor connectors ensure a smooth transition between the wall and other surfaces. Branding panels and signage areas can also be included to personalize the space.

Where Can Modular Walls Be Used?

| Application Area | Description | Example Use Case |

| Commercial Offices | Create private offices or meeting rooms. Flexible layouts for business needs. | Private offices, conference rooms, open workspaces. |

| Manufacturing and Industrial Facilities | Separate work zones, create cleanrooms, or install noise barriers. | Factories, warehouses, industrial plants, cleanrooms. |

| Healthcare Settings | Create sterile spaces, adjustable layouts, and easy to clean. | Hospitals, medical labs, clinics, research facilities. |

| Temporary Spaces (Events, Exhibitions, Pop-Up Stores) | Ideal for pop-up shops, trade shows, or temporary office spaces. | Events, pop-up retail spaces, exhibitions, trade shows. |

| Rented or Leased Spaces | Easy to reconfigure or move when leases change. | Short-term office setups, temporary project spaces. |

Why Choose Modular Walls Over Traditional Walls?

Modular walls offer several advantages over traditional wall systems, making them an ideal choice for businesses that need flexibility, speed, and cost-efficiency. Here’s why:

1. Faster Installation

Unlike traditional walls that require wet materials like cement or drywall, modular walls are pre-manufactured and assembled on-site. This dramatically shortens the installation time, allowing many projects to be completed within hours or days, rather than weeks. Whether you’re setting up an office or building a temporary space, the speed of installation is a major benefit.

2. Flexibility and Reusability

A notable advantage of modular walls is their ease of relocation and reconfiguration. Unlike permanent drywall, which is fixed and often requires demolition to modify, modular walls can be adjusted or relocated without much hassle. This makes them ideal for businesses with evolving space needs or those operating in rented premises.

3. Cost-Effective

Though modular walls may have a higher upfront cost compared to traditional drywall, they offer long-term savings. Their reusability, quick installation, and ease of maintenance mean you save on labor and material costs over time. Moreover, there’s no need for costly repairs since the walls are durable and easy to replace or reconfigure.

4. Minimal Disruption

Traditional wall construction can create significant disruption—dust, noise, and downtime. Modular walls, on the other hand, are installed quickly with minimal mess. This means less disruption to your daily operations, whether you’re working in an office, a factory, or a healthcare facility.

5. Design and Customization

Modular walls can be customized to fit your specific needs, whether it’s soundproofing, fire resistance, or unique aesthetics. With various panel finishes, door and window options, and the ability to integrate electrical systems, modular walls can be designed to match your business’s specific requirements, offering both functionality and visual appeal.

Are Modular Walls Durable and Compliant?

Yes. Modular walls are designed for long-lasting performance and to meet safety and building regulations.

Structural Strength and Wear Resistance: Made from durable materials like steel and aluminum, modular walls are built to withstand daily wear and tear in high-traffic areas. They’re strong and resilient, ideal for industrial or office spaces.

Fire-Rated, Soundproof, and Insulated Options: Many modular wall systems come with fire-resistant panels, providing added safety in case of fire. Additionally, modular walls can be designed for soundproofing or insulation, making them perfect for spaces that require noise control or energy efficiency.

What Is the Lifespan of a Modular Wall?

Modular walls typically last between 10–25 years, depending on usage and the materials selected. They are engineered for durability and can be readily moved, reconfigured, or repurposed over an extended period. This makes them a sustainable option for evolving spaces.

Lower Maintenance Costs: Compared to drywall, modular walls require less maintenance. Their modular nature means individual panels can be replaced or repaired with ease, reducing long-term maintenance costs.

How Do Modular Walls Compare with Other Wall Systems?

When choosing between modular walls and traditional wall systems, it’s crucial to grasp the fundamental distinctions. Here’s how modular walls stack up against drywall and other common partition options:

1. Modular Walls vs. Drywall

- Installation Time: Modular walls can be installed in hours or days, while drywall requires longer construction and drying times.

- Flexibility: Unlike drywall, which is fixed in place, modular walls can be easily reconfigured or moved when needed.

- Maintenance: Modular walls require less maintenance—if a panel is damaged, it can be replaced quickly, while drywall can crack and need repairs.

- Cost: Drywall may have a lower initial cost, but modular walls offer long-term savings due to their reusability and quick installation.

2. Modular Walls vs. Fixed Partition Systems

- Reusability: Modular walls are designed to be moved and reused. Fixed partitions, once installed, are permanent and difficult to change.

- Customization: Modular walls are highly customizable with options for finishes, doors, windows, and integrated features like wiring. Fixed systems often have limited customization options.

- Disruption: Installing modular walls is faster and less disruptive than building permanent fixed partitions, which often involve heavy construction.

3. Modular Walls vs. Glass Partitions

- Privacy: Glass partitions are great for open, transparent spaces, but they offer limited privacy. Modular walls, especially those with solid or acoustic panels, provide better soundproofing and privacy.

- Durability: Glass partitions can be fragile and more prone to damage, whereas modular walls are generally sturdier and more resistant to wear and tear.

- Cost: Glass partitions can be expensive, especially with high-end finishes. Modular walls offer a more cost-effective solution with similar or better performance.

In summary, modular walls provide superior flexibility, faster installation, and long-term cost savings in comparison to traditional wall systems. Whether you’re working in an office, factory, or retail space, modular walls provide a versatile solution that can adapt to your needs.

How Do I Choose the Right Modular Wall for My Project?

Selecting the appropriate modular wall hinges on your space’s requirements and future objectives. Here are crucial considerations to aid in your decision-making:

1. Assess Your Space Requirements

Consider the function of the space. For offices, you may need privacy and soundproofing, while industrial settings might require durable, impact-resistant walls. Modular walls offer various options to suit different environments.

2. Think About Flexibility and Future Changes

If your space will evolve, modular walls are ideal. They can be readily relocated, reconfigured, or expanded in accordance with evolving needs, making them ideal for expanding businesses or temporary arrangements.

3. Evaluate Aesthetic and Design Needs

Modular walls can be tailored with a variety of finishes, colors, and materials to suit individual preferences. Choose a system that matches your design vision, whether for a sleek office or a more industrial setting.

4. Consider Compliance and Safety

Ensure the wall system meets safety standards, especially for regulated environments like healthcare or manufacturing. Many modular walls are equipped with fire ratings, soundproofing capabilities, and compliance with local building regulations.

5. Budget and Long-Term Value

Modular walls may incur a higher initial cost, but they offer long-term cost savings. They’re durable, reusable, and require less maintenance, offering better value over time compared to traditional walls.

By considering these factors, you’ll select the right modular wall solution that fits both your current needs and future growth.

What’s Next If I’m Interested?

If you’re interested in modular walls for your project, the next steps are straightforward. Here’s what you need to get started:

What Info Do You Need to Start?

To begin, we’ll need some basic information about your project, including:

- Dimensions: The size of the area where you plan to install the walls.

- Use Case: Whether it’s an office, industrial space, or temporary setup.

- Layout: A rough idea of how you’d like the space divided and any specific requirements (e.g., doors, windows, electrical outlets).

Once we have these details, our team at SteelPRO PEB can provide a customized quote or design suggestion. We’ll recommend the best modular wall system based on your specific needs.

Can Modular Walls Be Customized?

At SteelPRO PEB, we offer full customization for your modular walls. Here’s what you can tailor to fit your space:

- Size, Color, and Material Finishes: Select from a range of finishes, colors, and materials to complement your design aesthetic.

- Doors, Windows, and Branding Elements: Add doors (swing, sliding, or glass), windows, and even branding elements like logos or signage.

- Electrical and Mechanical Integration: We can integrate electrical outlets, HVAC systems, and other mechanical features into the wall design to meet your space’s operational needs.

- Adaptable Layouts: Our walls are easily reconfigurable, giving you the flexibility to modify the layout as your space or business evolves.

If you’re ready to move forward, contact us to discuss your requirements. Our team will work closely with you to ensure the right solution is delivered on time and within budget.