The price of a modular home typically ranges from $50,000 to $300,000, depending on size, structure type, and customization level.

In this complete pricing guide, SteelPRO PEB — a certified modular home manufacturer and factory-direct supplier — breaks down every factor that affects cost, from base materials to land and installation.

You’ll learn how much modular homes really cost, what hidden and additional expenses to expect, and how prices vary by home type — including tiny, double-wide, expandable, luxury, and steel-frame modular homes. We’ll also cover the real cost of placing a modular home on land, offer practical ways to save money, and explain why modular homes remain a smart long-term investment compared with traditional builds.

Built on over a decade of global manufacturing experience, SteelPRO PEB provides transparent, factory-based insight to help you make an informed, cost-efficient modular home decision.

How Much Does a Modular Home Really Cost?

A basic modular home typically costs between $50,000 and $150,000, depending on its size, location, and customization. This price typically covers smaller homes or basic models, with larger or more customized homes costing more.

Modular Home Price Breakdown

Here’s a rough breakdown of what’s included in the price of a modular home:

- Base Home: This includes the structure itself—walls, floors, roof, etc. The typical cost ranges from approximately $50 to $100 per square foot.

- Land: If you don’t already own land, purchasing it will be an additional cost. Land can range from $5,000 to $100,000 or more depending on location.

- Site Preparation and Foundation: Preparing the land (grading, clearing) and laying the foundation can cost between $5,000 and $20,000.

- Delivery and Installation: The expenses for transporting and setting up the modular home at the site generally vary between $10,000 to $20,000 depending on the distance involved and the level of complexity.

- Customization and Upgrades: If you choose custom finishes, floor plans, or features, expect to pay anywhere from $10,000 to $50,000 depending on what you select.

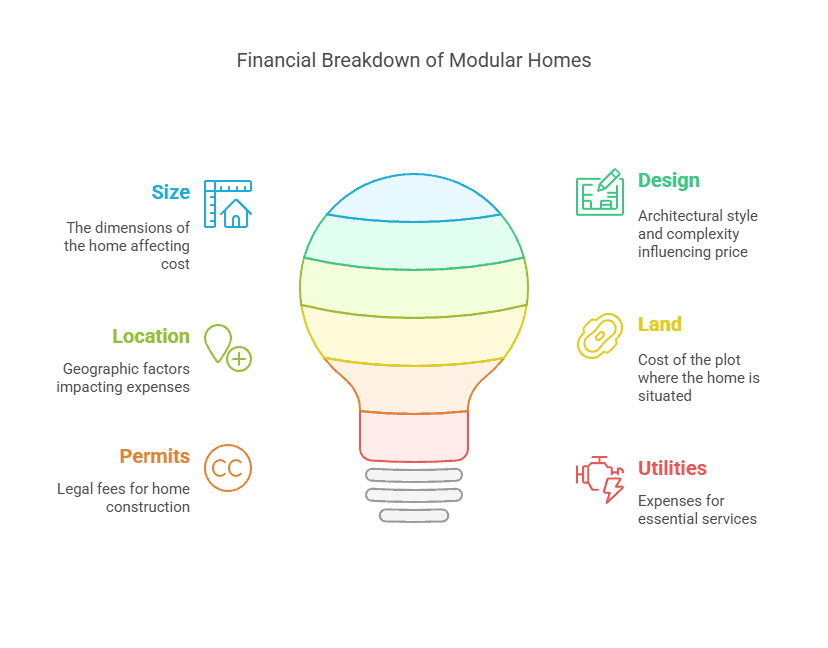

Factors Affecting the Modular Home Price

Several factors can influence the final cost of your modular home:

- Size and Layout: Larger homes or more intricate layouts will elevate the overall cost. The more bedrooms and bathrooms you need, the higher the price.

- Materials and Quality: The choice of materials (e.g., wood vs. steel frame) and construction quality will impact the price. Premium finishes like granite countertops or hardwood floors will also increase the cost.

- Location: The price of land can vary considerably based on the location where you are building. Construction costs, including delivery and installation, can also rise if you’re in a remote or high-demand area.

- Customization: The more custom features you want—such as unique floor plans, energy-efficient options, or luxury finishes—the more expensive the home will be.

Related Reading: Prefab house cost

Hidden and Additional Costs to Consider

While the base price of a modular home is clear, there are other costs you should plan for that might not be immediately obvious.

Land Development Costs

If you’re purchasing new land, you might need to invest in additional developments like roads, driveways, or landscaping. These costs can fluctuate significantly depending on the condition and location of the land. Preparing land for construction could also require soil testing or environmental impact assessments, adding an extra $1,000 to $5,000.

Permit and Inspection Fees

Building permits and local inspections are required for any construction project, including modular homes. Depending on where you’re building, these fees can range from $500 to $5,000. It’s essential to check with your local authorities to understand the specific requirements for modular home construction in your area.

Insurance

Insurance is required for your modular home, both throughout the construction phase and after it has been completed. Construction insurance can cost $1,000 to $3,000 depending on the scope of the project, while homeowner’s insurance for the finished home typically ranges from $500 to $2,000 annually.

Utility Upgrades

In some areas, you might need to upgrade existing utilities (water, electricity, sewer) to accommodate your modular home. If your land lacks these connections, or if they need to be upgraded to meet local codes, costs can range from $2,000 to $10,000.

Site Access and Terrain Issues

If your site is difficult to access, additional costs may arise for special equipment (like cranes for delivery or terrain modification). For sites with poor accessibility, these costs can be as high as $5,000 or more.

Additional Financing Costs

If you’re financing your modular home, you may incur additional costs such as loan origination fees, appraisal fees, and other charges. Be sure to ask about any hidden costs when discussing financing options, which can add up to $1,000 to $3,000.

How Much Does It Cost to Put a Modular Home on Land?

Installing a modular home on land involves several additional expenses beyond the structure itself, including foundation construction, site preparation, delivery, and utility connections. On average, these combined costs can range between $15,000 and $30,000, depending on the location, terrain, and size of the home.

Typical Land-Related Expenses:

- Foundation & Site Preparation: $5,000–$15,000

- Utility Connections (Water, Power, Sewer): $2,000–$10,000

- Transportation & Crane Installation: $3,000–$5,000

Unlike dealer-based modular home sales, SteelPRO PEB provides factory-to-site turnkey service, including fabrication, delivery, and installation. Our engineering team ensures that every modular home is designed, manufactured, and assembled according to ISO and CE standards, with all land-related adjustments handled professionally to save time and reduce cost.

Factory Tip: Choosing a manufacturer that offers complete installation and foundation services can reduce total project time by up to 30% and avoid hidden costs from multiple contractors.

Cost Breakdown by Modular Home Types

Tiny Modular Homes

Tiny modular homes are the most affordable option, making them a great choice for individuals or couples looking to downsize or for a vacation home. The cost typically ranges from $50,000 to $75,000 for a basic model. These homes are usually compact, with fewer rooms and simpler layouts, which keeps the cost low.

- Ideal For: First-time homeowners, individuals, or those in search of a second residence or vacation property.

- Advantages: Lower cost, fast construction, and reduced maintenance.

Double Wide Modular Homes

Double wide modular homes are larger and provide more space, often having 2-4 bedrooms and multiple bathrooms. They typically cost between $80,000 and $150,000, depending on their size and the degree of customization.

- Ideal For: Larger families or individuals who are looking for additional space without having to bear the typical high cost of a house.

- Advantages: More room, still faster and cheaper than traditional homes, with options for customization.

Expandable Modular Homes

Expandable homes start as smaller units but can be extended in the future. This makes them a flexible option for people who want to start small and expand later as their needs grow. The cost for expandable homes starts around $70,000 and can go up to $200,000 or more when fully expanded.

- Ideal For: Families requiring versatility in their living space and potentially anticipating growth over time.

- Advantages: Can grow with your family, offering long-term value.

Luxury Modular Homes

Luxury modular homes offer high-end finishes, more customization options, and advanced features. The cost of luxury modular homes generally falls between 150,000and300,000, depending on the degree of customization and materials utilized.

- Ideal For: Buyers seeking a more luxurious, custom-built home without the typical high expenses.

- Advantages: High-end finishes, full customization, and premium features.

Steel Frame Modular Homes

Steel frame modular homes feature a pre-engineered steel structure, offering outstanding durability and strength. Typically, these homes are priced between $120,000 to $250,000, depending on their size and level of customization.

Compared with wood-frame modular homes, steel modular homes provide stronger wind resistance, better corrosion protection, and lower lifetime maintenance cost. SteelPRO PEB utilizes advanced PEB (Pre-Engineered Building) technology with ISO/CE certifications and a 50-year structural warranty, ensuring safety, durability, and cost-efficiency.

- Ideal For: Buyers prioritizing long-term value and enhanced strength, especially in areas with extreme weather conditions.

- Advantages: Stronger, longer-lasting, and resistant to corrosion, pests, and fire.

Multi-Family Modular Homes

Multi-family modular homes are designed to accommodate multiple families or living units within one structure. They are an excellent choice for investors or larger families who want to share living space without sacrificing privacy. Prices for multi-family modular homes typically range from $150,000 to $300,000 or more, depending on the number of units and level of customization.

- Ideal For: Investors aiming to construct rental properties or large families requiring separate living quarters.

- Advantages: Cost-effective compared to building multiple separate homes, efficient use of space, and quick construction.

Foldable Modular Homes

Foldable modular homes are a relatively new innovation that allows the structure to be compacted for easy transport and then unfolded into a fully functional home. These homes are typically smaller and more affordable, with costs ranging from $50,000 to $100,000, depending on size and features.

- Ideal For: People seeking temporary or portable housing, or those in need of a home that can be easily relocated.

- Advantages: Flexibility, mobility, and a fast setup process, making them ideal for short-term or transitional living situations.

| Type | Size Range | Average Price (USD) | Frame Type | Key Advantage |

| Tiny Modular | 200–400 sq.ft | 50,000–75,000 | Wood/Steel | Compact, cost-efficient |

| Double Wide | 800–1,500 sq.ft | 80,000–150,000 | Wood | Spacious, affordable |

| Steel Frame Modular | 1,000–3,000 sq.ft | 120,000–250,000 | Steel (PEB) | Durable, factory-built, long lifespan |

| Expandable Modular | 800–2,000 sq.ft | 70,000–200,000 | Mixed | Flexible, upgradeable |

| Luxury Modular | 1,500–3,500 sq.ft | 150,000–300,000 | Wood/Steel | Premium finish, high customization |

| Multi-Family Modular | 1,500–3,500 sq.ft | 150,000–300,000+ | Mixed | Shared cost, efficient use of space |

| Foldable Modular | 200–800 sq.ft | 50,000–100,000 | Steel | Portable, easy setup |

How to Save Money on a Modular Home

Building or buying a modular home can be an affordable option, but there are several ways to reduce costs even further. Here are some tips to help you save money throughout the entire process:

1. Choose a Smaller Size

The size of your modular home directly affects its cost. Opting for a smaller model can significantly reduce both the base price and additional costs like site preparation and utilities. For those with a limited budget, consider initiating with a compact modular home or a smaller design, with the possibility of expanding it in the future.

2. Simplify Your Design

Customization and luxury upgrades can add up quickly. Sticking to a more basic design with fewer custom features will save you money. Focus on essential features and avoid costly upgrades like high-end flooring, custom cabinetry, or extensive changes to the floor plan. Standard models with fewer customizations will keep costs down.

3. Choose Standard Materials

Using premium materials like granite countertops or hardwood floors can rapidly elevate the cost of your modular home. Instead, choose standard materials that offer durability without the high price tag. For example, laminate or vinyl flooring, and less expensive countertops can give you a beautiful home at a fraction of the cost.

4. Shop Around for Land

If you don’t already own land, carefully consider where you purchase it. Land in high-demand areas can be expensive, so look for more affordable plots outside of the city or in less developed areas. Just make sure the land is suitable for building and that you factor in any additional costs, like access to utilities.

5. Do Some Work Yourself

If you have some construction knowledge, consider taking on some of the labor yourself. For example, you might be able to handle landscaping, painting, or even some minor interior work to save on contractor fees. However, be cautious about undertaking tasks that might compromise the structural integrity of the home; it’s best to leave those to the experts.

6. Look for Discounts or Promotions

Many modular home manufacturers offer seasonal promotions, discounts, or financing deals. Look for sales or limited-time offers to save money on your modular home purchase. Negotiate with manufacturers or dealers for better prices or additional perks.

7. Invest in Energy Efficiency

Energy-efficient features may cost more initially, but they can lower your utility bills and save you money over time. Opting for energy-efficient appliances, insulation, and windows can lower your monthly expenses, making it worth the investment over time.

8. Plan for the Long-Term

To save money on the long-term, plan for the home’s longevity. Choosing durable materials and high-quality construction will ultimately help decrease maintenance and repair expenses. It’s also worth considering modular homes with warranties that cover key systems, so you don’t have to worry about unexpected expenses.

Is a Modular Home Worth the Investment?

Yes! Modular homes offer lower upfront costs, faster construction, and energy savings.

- Durability: Built in a controlled factory environment, modular homes are strong and resilient, especially steel-framed models that handle extreme weather better than traditional wood-framed homes.

- Maintenance: These homes are designed to require less upkeep, with low-maintenance exteriors, energy-efficient systems, and durable materials. This translates to fewer repairs and lower ongoing expenses.

- Energy Efficiency: Many modular homes are constructed using energy-efficient materials, which contribute to lower utility bills and offer long-term savings.

Modular Homes vs. Traditional Homes:

- Cost: Modular homes are generally more economically priced compared to traditional homes. On average, modular homes cost between $50,000 to $150,000, while traditional homes can easily exceed $200,000. The faster construction timeline and lower labor costs make modular homes a more economically viable option.

- Construction Time: Modular homes are built much faster—often within a few weeks—compared to the several months it typically takes to construct a traditional home.

- Longevity: Modular homes are constructed to endure, adhering to the same building codes and standards as traditional homes, thereby offering long-term value with appropriate maintenance.

Modular Homes vs. Manufactured Homes:

- Cost: Manufactured homes are usually less expensive than modular homes, with prices starting around $40,000 to $70,000. However, modular homes generally provide higher quality and better long-term value, making them a more reliable investment.

- Construction Quality: Modular homes are built to adhere to the same building codes and standards as conventional homes. In contrast, manufactured homes frequently have lower construction standards, which may impact their durability and long-term worth.

- Value: While manufactured homes may be cheaper upfront, modular homes tend to offer greater value in terms of quality, customization, and long-term maintenance costs.

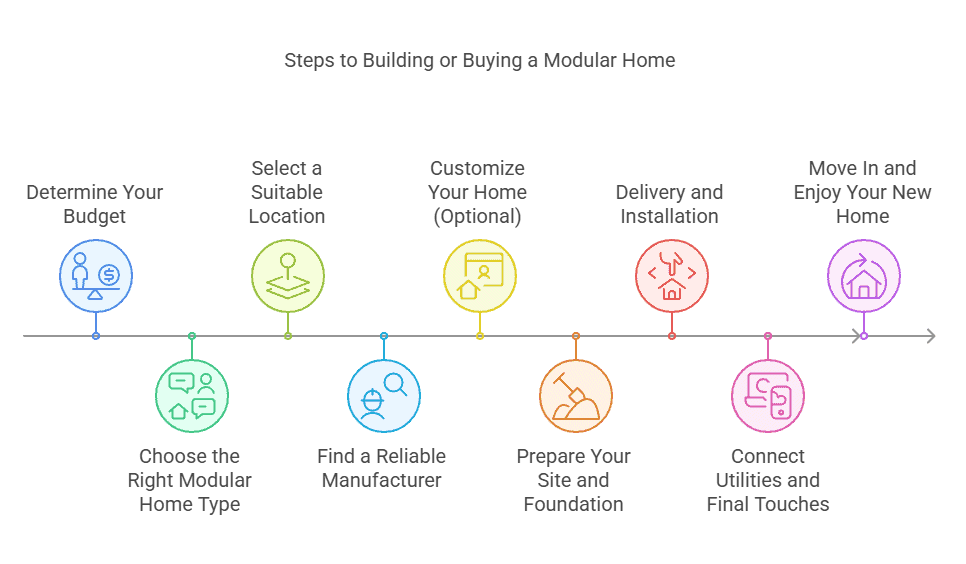

How to Get Started: Steps to Building or Buying a Modular Home

Getting started with a modular home involves several key steps to ensure that you select the right option for your needs and budget. Here’s a simplified guide to help you through the process.

1. Determine Your Budget

Before diving into the details of building or buying a modular home, it’s important to set a clear budget. Factor in the cost of the home itself, land, site preparation, installation, and any customizations or upgrades you may want. This will help you narrow down your options and avoid exceeding your budget.

2. Choose the Right Modular Home Type

Modular homes are available in various sizes, from small, compact units to larger multi-family structures. Think about your space requirements, long-term plans, and budget when choosing the type of modular home. Consider whether you need a smaller, cost-effective option or something larger and more customized.

3. Select a Suitable Location

Selecting the appropriate plot of land is essential. Ensure that the land is viable for construction and located in an area that you are content with. If you already own land, check that it’s zoned for modular home construction and that there are no building restrictions. If you need to purchase land, look for an affordable plot that is accessible and has the necessary utilities (water, electricity, etc.).

4. Find a Reliable Manufacturer

Research different modular home manufacturers to find one with a good reputation and experience. Examine customer feedback, warranty offerings, and customization services provided by the manufacturer. Make sure they comply with local building codes and regulations.

5. Customize Your Home (Optional)

Once you’ve chosen a manufacturer, you can begin customizing your modular home. This may involve selecting the floor plan, finishes, and upgrades that best align with your personal style and requirements. Remember that customizations can increase the total cost, so prioritize what matters most to you.

6. Prepare Your Site and Foundation

After picking your home and land, the next step is to ready the site and lay the foundation. This typically involves clearing and grading the land, and preparing it for the installation of the modular home. You might need to engage a contractor for this phase, particularly if the task is more intricate.

7. Delivery and Installation

Once the home has been constructed, it will be transported to your site and put together. This step may require specialized equipment, such as cranes or trucks, depending on the size and complexity of the home. The installation process typically lasts from a few days to a few weeks, depending on the size of the modular home.

8. Connect Utilities and Final Touches

Following installation, you will need to hook up utilities such as water, electricity, and sewage to your modular home. This step may also include adding any final details, such as landscaping or interior decor. Make sure that everything is correctly installed before moving in.

9. Move In and Enjoy Your New Home

Once all tasks are finished and all utilities are connected, you are ready to move into your new modular home. With proper maintenance, your modular home will provide long-term comfort and savings, making it a great investment.

What is the cost of a 4-bedroom modular home?

A 4-bedroom modular home typically ranges from $120,000 to $250,000, depending on floor plan, finishes, and whether it uses a wood or steel frame. SteelPRO PEB offers factory-direct pricing for steel-frame modular homes, ensuring long-term durability and cost efficiency.

Can I customize the design directly with the manufacturer?

Yes. At SteelPRO PEB, you can work directly with our engineering team to modify layouts, materials, and finishes. We offer full OEM/ODM modular home customization, designed and produced according to ISO and CE international standards.

Do you offer modular homes for export (like Virginia or BC regions)?

Absolutely. SteelPRO PEB exports modular homes to North America, Australia, Europe, and Southeast Asia. All models can be adapted to regional building codes, including Canadian (BC) standards and U.S. residential codes, with global shipping and on-site installation options.

What’s included in your modular home package?

Each package includes the structural steel frame, wall and roof systems, insulation, windows, and basic finishes. Optional add-ons include electrical and plumbing systems, interior decor, and energy-efficient appliances, allowing you to choose the right configuration for your budget.

How long does it take to deliver and install?

Typical production time ranges from 4–8 weeks, followed by 1–2 weeks of delivery and installation, depending on home size and distance. Our factory-to-site logistics system ensures on-time, quality-controlled assembly for every modular home project.

Is a Modular Home Right for You?

Factory-Direct Modular Home Price Quote from SteelPRO PEB

Most “modular home quotes” online come from resellers — not real factories. That means you’re paying extra for middlemen, not better materials.

With SteelPRO PEB, you get your modular home built, priced, and shipped directly from our factory, under the same roof. No layers. No markup. Just real numbers and certified quality.

Get Your True Factory Quote Today

Tell us your layout or square footage — and we’ll send you a custom, factory-based cost breakdown within 24 hours.

You’ll know the exact price, the delivery timeline, and how much you save by cutting the middlemen out.

Because when you buy straight from the source, your home isn’t just affordable — it’s honest.