Have you ever walked into a stadium, exhibition hall, or airport and wondered how they managed to create such vast, open spaces with no internal columns? How do they accommodate thousands of people while maintaining flexibility? What makes these spaces so functional yet visually striking? Long-span structures make it all possible, but how do they work, and what are the real benefits and challenges? Let’s dive in and explore how these engineering wonders shape the spaces we interact with every day.

Table of Contents

What Are Long-Span Structures?

A long span structure in construction means any building or framework capable of providing an uninterrupted open area over 30 meters (100 feet) without intermediate supports or internal columns. This span, also called “clear span” or “free span,” is a critical design concept in modern large span structures such as stadiums, exhibition halls, hangars, and warehouses. The meaning of span in construction is the distance between two supports, so a long span structure creates more flexible, open environments ideal for many industrial and public projects.

Pros & Cons of Long-Span Structures

The core advantages of long span structures include unobstructed interior space, flexible layouts, and the ability to support applications that require large span roofing without columns. Long span steel structures also provide durability and the framework for impressive architectural forms, making large span buildings both practical and iconic. However, long span construction usually requires advanced engineering, higher costs, and careful attention to structural details such as the design of long span beams for load transfer and stability.

Pros of Long-Span Structures

- No internal columns create large, open spaces, making the area flexible for various uses like sports events, exhibitions, or warehouses.

- Materials like steel and concrete are strong and durable, meaning the building lasts longer with less need for maintenance.

- Clear sightlines in arenas, auditoriums, and event spaces provide better views for large audiences.

- The large, open design makes these buildings stand out and often turns them into landmarks.

- Fewer supports allow the space to be easily adapted for new uses, such as converting a sports venue into a concert hall.

Cons of Long-Span Structures

- Special materials and complex designs can increase the cost of construction.

- Building large spans requires advanced engineering, which can extend the design and construction time.

- Large roofs and lightweight designs can be more vulnerable to extreme weather, requiring extra protection against high winds or earthquakes.

- Steel and other materials need regular inspection and care to prevent issues like rust or wear.

- Only a few materials like steel and reinforced concrete can support long spans, which limits material options.

Applications of Long-Span Structures

Long span structures and wide span buildings are widely used in sports stadiums, transportation terminals, aircraft hangars, and industrial warehouses. Their long span roof structures and open interiors allow maximum usage of floor area. For heavy-duty needs, long span steel beams and trusses are common structural choices. Large span steel structures also offer clear advantages for industrial logistics centers, arenas, and exhibition spaces where flexibility and capacity are priorities.

- Sports Stadiums: These require wide open spaces for spectators, without any columns obstructing views.

- Exhibition Halls: In exhibition spaces, flexibility and large floor areas are key to showcasing large items or accommodating large crowds.

- Airports and Hangars: Aircraft hangars, in particular, need large spaces to house planes, making long-span structures ideal.

- Industrial Buildings: Some factories or warehouses use long-span designs to allow for large machinery or bulk storage needs without interfering with workflow.

5 Iconic Long-Span Structure Examples Worldwide

Here are five iconic long-span structures that have set new standards in architecture and engineering:

1. Sydney Opera House, Sydney

The Sydney Opera House is a prime example of long-span architecture, famous for its unique roof design. The roof features precast concrete shell segments, each spanning over 15 meters. These reinforced concrete segments were a groundbreaking innovation when built (1957-1973), allowing the structure to have a large, open interior without the need for support columns.

The roof’s large spans provided expansive performance spaces beneath, offering both unobstructed views and excellent acoustics. The Sydney Opera House continues to be a masterpiece of long-span engineering, showing how shell structures can create spacious, column-free areas with stunning visual appeal.

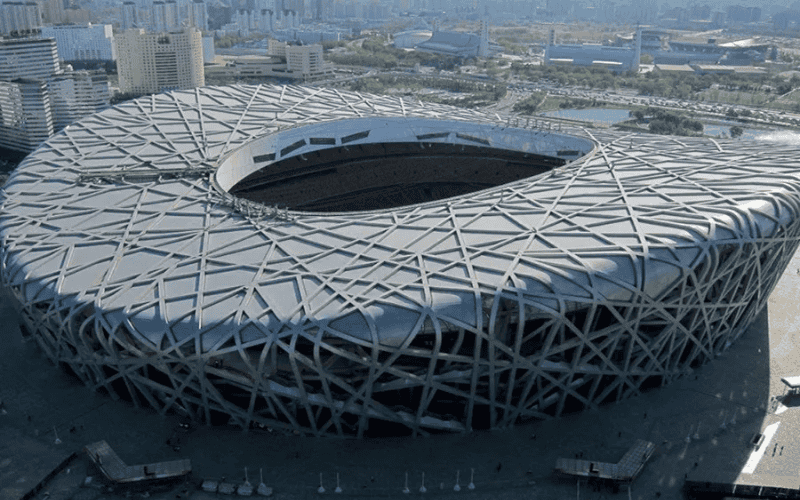

2. Beijing National Stadium (Bird’s Nest), Beijing

The Beijing National Stadium, or “Bird’s Nest,” is a modern example of long-span steel design. Built for the 2008 Summer Olympics, the stadium features a steel frame that spans over 80 meters at its widest point, with no internal supports blocking the seating area. The interwoven steel beams create a “nest” that holds up the roof, covering a space of over 330 meters without relying on load-bearing walls or columns.

This long-span design allows for large crowds to gather in a single uninterrupted space, a crucial feature for stadiums. The Bird’s Nest demonstrates how modern steel construction can create bold, expansive structures that are both functional and visually stunning.

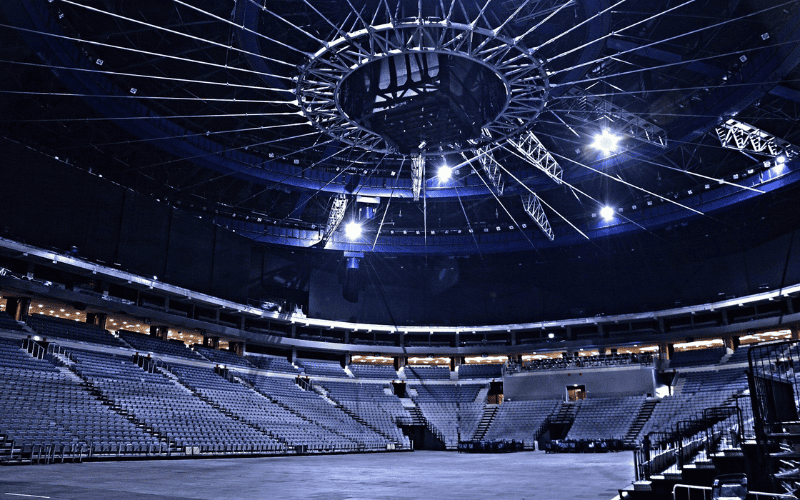

3. The O2 Arena, London

The O2 Arena is known for its iconic long-span roof, which stretches over 100 meters. The roof is made from steel and tensioned membrane fabric, supported by a series of masts and cables. This design allows the structure to be lightweight and efficient while covering a vast area without internal columns, maximizing usable space inside.

The O2 Arena’s roof design is key to its function as a multi-purpose venue, providing unobstructed views for concerts, sports events, and other large gatherings. It showcases how steel and tensioned fabric can work together to create a flexible and visually striking long-span structure.

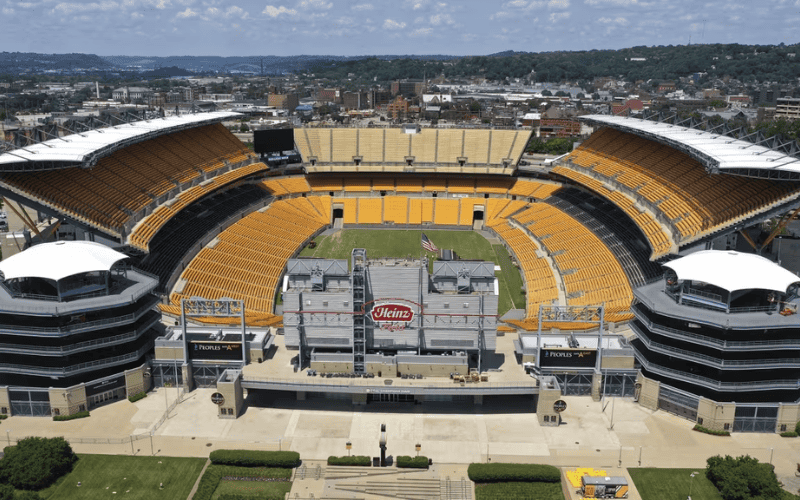

4. Heinz Field, Pittsburgh

Heinz Field in Pittsburgh is a notable example of long-span steel truss engineering in sports stadiums. The stadium features a cantilevered roof system supported by steel trusses, spanning approximately 50 meters across the seating areas. This design eliminates the need for internal columns, offering fans an unobstructed view of the field.

The steel trusses used in Heinz Field’s roof are a common solution for long-span stadiums, providing strength, efficiency, and the ability to withstand heavy loads like wind and snow. The design balances structural integrity with functionality, making it ideal for large public venues.

5. Dallas/Fort Worth International Airport (DFW), Dallas, Texas

Dallas/Fort Worth International Airport is a great example of long-span roof design in transportation infrastructure. The airport’s roofs span up to 60 meters across multiple terminals, creating spacious, open areas that improve passenger flow and the overall experience. The roofs combine steel supports (trusses and beams) with concrete slabs, creating wide, column-free terminal spaces.

This design not only increases efficiency but also enhances the airport’s aesthetic appeal, offering clear sightlines and a sense of openness in a busy, large-scale environment. DFW Airport shows how long-span structures can optimize functionality and user experience in complex public facilities.

Structural Types of Long-Span Structures

There are several types of long span structures based on structural action, including beam-based (bending) systems such as long span beams and trusses; and funicular systems including arches, domes, and tensioned cable or membrane solutions. For very large span steel structures, hybrid designs such as steel-and-concrete composites are common. The choice of long span structure type depends on application, required span, and desired architectural effect.

1. Bending Structures

Bending structures handle both pulling (tension) and pushing (compression) forces. These are often used in large buildings and bridges where the structure needs to support heavy loads over long distances.

- Trusses: A common bending structure made up of triangular units. They’re great for large spans, often seen in roofs and bridges. Steel trusses can span up to 190 meters (623 feet), making them ideal for stadiums or large exhibition halls.

- Plate Girders: These are deep beams made by welding steel plates. They can span up to 60 meters (200 feet) and are used in bridges or large roofs. However, they aren’t as material-efficient as trusses.

- Two-Way Grids: These distribute loads in both directions across a surface, forming a grid. They’re great for covering large areas, like airports or exhibition halls, and can span up to 91 meters (300 feet).

- Space Trusses: These are 3D trusses that handle very large spans (up to 190 meters/623 feet). They’re often used in large roofs or long-span bridges.

2. Funicular Structures

Funicular structures only handle either tension (pulling) or compression (pushing) forces, making them efficient for very large spans with minimal material.

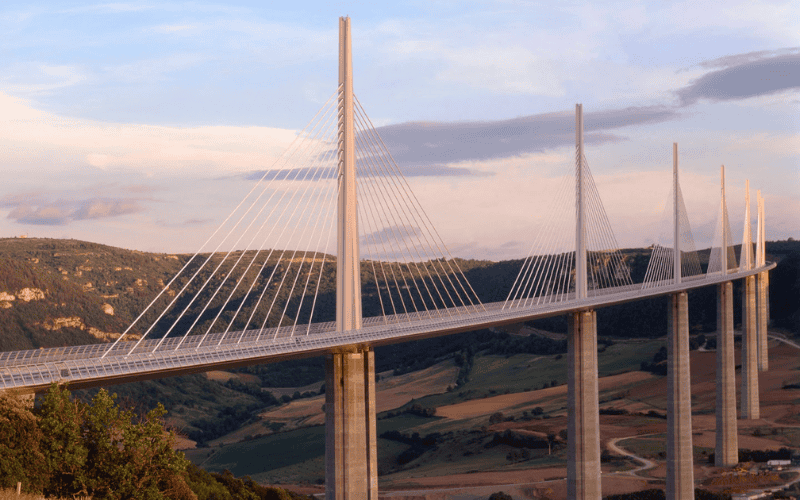

- Parabolic Arches: These arches distribute compressive forces evenly, making them ideal for long-span bridges and roofs. They often combine with steel or concrete for added strength.

- Dome Structures: Domes are compression-based structures, efficient for creating large open spaces. The largest steel domes can span over 200 meters (669 feet), often used in stadiums and public buildings.

- Tension Cable Systems: These use steel cables stretched across a span. They’re lightweight and can support large distances (up to 72 meters/236 feet). Tension-cable systems are common in sports stadiums and exhibition halls.

- Bicycle Wheel Roofs: A tension-based design where cables form a wheel-like pattern. They’re lightweight and strong, often used in temporary structures or places that need easy construction.

- Tension-Membrane Systems: These use fabric stretched over cables, creating a flexible, lightweight structure. They’re often used for sports arenas or pavilions.

3. Hybrid Systems

Some modern long-span structures combine both bending and funicular elements to achieve the best performance and look.

- Composite Roofs: These combine steel trusses with tensioned cables or fabric membranes to create lightweight, strong roofs. They are great for column-free spaces.

- Steel and Concrete Combinations: In some buildings, concrete is used for compression elements (like arches), while steel handles tension (like cables or trusses). This mix improves strength and cuts costs.

Long-Span Roofs: Design, Types & Famous Examples

Types of long span roof systems include steel truss roofs, space frame roofs, cable-supported and tension membrane roofs. These solutions are often required for long span buildings such as airports, stadiums, and large span steel structures. Famous long span roofs—like the Bird’s Nest in Beijing or the retractable dome in Singapore—prove the engineering possibilities for long span steel construction and inspire new innovation in every long span roof structure.

Why Long-Span Roofs Matter

Long-span roofs play a crucial role in large structures by providing:

- Uninterrupted open spaces – Essential for maximizing space efficiency in sports arenas, airports, and industrial buildings.

- Structural innovation – Advances in materials and engineering allow roofs to span over 300 meters without internal supports.

- Architectural impact – Many iconic buildings feature distinctive long-span roof designs, such as the Beijing National Stadium.

One of the largest free-span roofs in the world is the Khan Shatyr Entertainment Center in Kazakhstan, spanning 150 meters with a tensioned membrane structure.

Types of Long-Span Roofs

Long-span roofs vary based on structural system, material efficiency, and design requirements. The following are the most common types:

Steel Truss Roofs

- Best for: Stadiums, warehouses, aircraft hangars

- Max span: 100 – 190 meters

- Features: Uses interconnected triangular steel units to efficiently distribute loads.

- Example: Heinz Field, Pittsburgh – Features a cantilevered steel truss roof, eliminating the need for internal supports.

Space Frame Roofs

- Best for: Exhibition halls, convention centers, train stations

- Max span: 100 – 300 meters

- Features: A three-dimensional steel grid that provides strength and material efficiency.

- Example: King Abdulaziz International Airport, Saudi Arabia – Uses a large-scale space frame system for its terminal roofing.

Tension Membrane Roofs

- Best for: Arenas, amphitheaters, pavilions

- Max span: 50 – 150 meters

- Features: Lightweight, flexible fabric roofs supported by cables, offering cost efficiency and quick installation.

- Example: O2 Arena, London – Features a tensioned membrane roof supported by steel cables.

Cable-Supported Roofs

- Best for: Stadiums, transportation hubs

- Max span: 100 – 200 meters

- Features: High-tensile steel cables distribute loads efficiently, reducing weight and improving flexibility.

- Example: Olympiastadion, Munich – Uses a cable-net roof to enhance aesthetics and structural performance.

Arched & Dome Roofs

- Best for: Sports stadiums, planetariums, public buildings

- Max span: 200 – 300 meters

- Features: Utilizes compression forces to create highly stable, self-supporting structures.

- Example: National Stadium, Singapore – Features the world’s largest retractable dome roof, spanning 312 meters.

Famous Long-Span Roofs Around the World

Several buildings worldwide showcase innovative long-span roof designs:

Beijing National Stadium (Bird’s Nest, China)

- Span: 330 meters

- Material: Interwoven steel trusses

- Unique Feature: The intricate steel framework eliminates the need for internal columns.

The O2 Arena (London, UK)

- Span: 365 meters

- Material: Tensioned fabric and steel cables

- Unique Feature: One of the world’s largest fabric roofs, covering a multi-use entertainment venue.

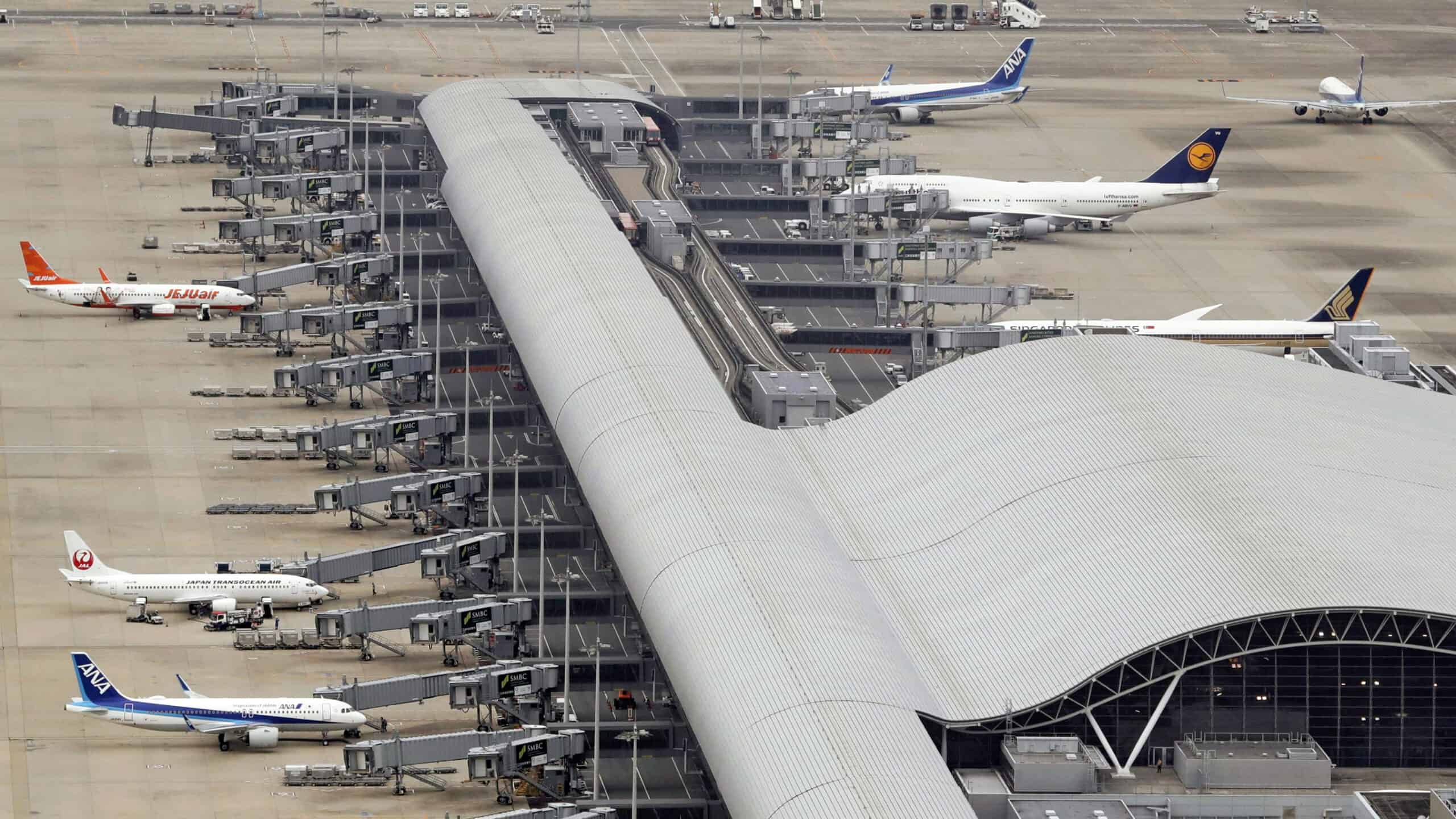

Kansai International Airport Terminal 1 (Japan)

- Span: 1.7 kilometers (roof length)

- Material: Steel and glass

- Unique Feature: Built to withstand earthquakes and typhoons while maintaining a large, open space.

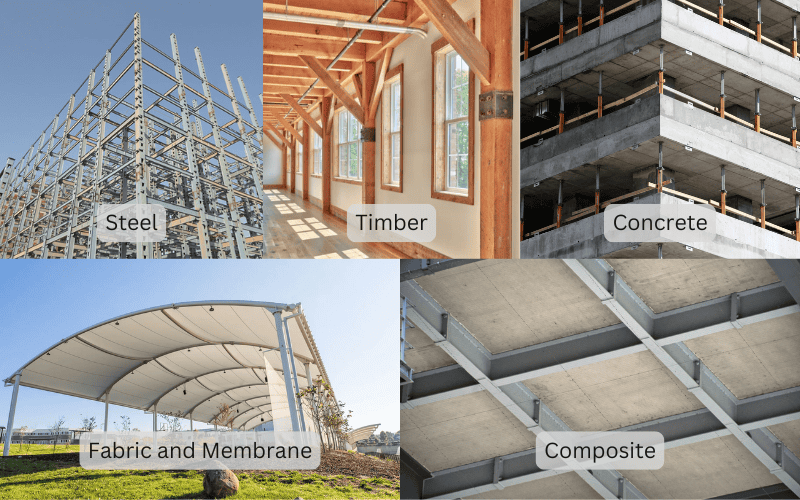

Materials for Long-Span Structures

Steel is the dominant material for long span steel construction due to its high strength-to-weight ratio. Long span steel beams, plate girders, and space trusses are engineered for large distances and heavy loads. Some large span structures use concrete, timber, or advanced composite materials, but long span steel structures remain the most versatile in modern large span roofing. Selecting the right long span beam type and material is critical for structural safety and cost-efficiency.

- Steel: Steel is often the material of choice for long spans due to its high strength-to-weight ratio. Steel trusses, plate girders, and cable systems are commonly used in long-span structures, with steel able to span up to 190 meters (623 feet) in some cases.

- Timber: Glulam (glue-laminated timber) is used in some long-span structures, especially in areas with access to forests. It’s often used for trusses and compression forms, with spans of up to 45 meters (150 feet) for trusses and 93 meters (305 feet) for domes.

- Concrete: Concrete is ideal for compression-based funicular structures, like arches and domes. It’s less common in bending structures but excels in supporting large spans with less material.

- Fabric and Membrane: Tensioned fabric structures, like those used in sports arenas, rely on lightweight materials supported by cables. These can span large areas with minimal cost and material.

- Composite: Sometimes, designers combine materials like reinforced concrete with steel or timber with metal connectors to get the best of both worlds—strength, flexibility, and lower costs.

Long-Span Steel Beams

Long-span steel beams help support large structures without using many internal columns. They are strong, durable, and widely used in stadiums, bridges, industrial buildings, and aircraft hangars. These beams allow for wide, open spaces, making buildings more flexible and efficient.

What Are Long-Span Steel Beams?

Steel beams are horizontal supports that carry weight from the roof or floors above. In long-span structures, these beams must be strong enough to span large distances while resisting bending and twisting. Engineers design them carefully to balance strength, weight, and cost.

Long-span steel beams are commonly used in:

- Warehouses and factories – To create open spaces for storage and machinery.

- Sports stadiums – To keep the view clear for spectators.

- Bridges – To span large distances while supporting heavy loads.

- Aircraft hangars – To house large planes without internal supports.

Types of Long-Span Steel Beams

Different beam types are used based on span length, load requirements, and cost.

- I-Beams and H-Beams

- Span: 30–50 meters

- Features: Strong and efficient, commonly used in roof framing and large buildings.

- Example: Many airport terminals use deep H-beams to support wide roofs.

- Plate Girders

- Span: 50–100 meters

- Features: Made by welding steel plates together, allowing longer spans than regular beams.

- Example: Used in stadium roofs and highway bridges.

- Box Girders

- Span: 80–150 meters

- Features: Hollow, box-like shape makes them strong but lightweight.

- Example: Often found in long-span bridges and railway terminals.

- Trussed Beams (Lattice Girders)

- Span: 100+ meters

- Features: A network of steel bars arranged in triangles, reducing weight while maintaining strength.

- Example: Sports arenas and exhibition halls often use these beams for roof support.

Long-Span vs. Short-Span Structures

The main comparison in the building industry is long span vs short span roof and building solutions. Long span structures cover greater distances, minimize internal supports, and create open interiors for uses such as stadiums or warehouses. In contrast, short span structures work for offices, smaller commercial buildings, and traditional homes where span is less of an architectural challenge. Understanding this difference informs both long span construction strategies and project budgeting.

Long Span Structures

- Span over 30 meters (100 feet) or more without internal columns.

- Designed to create large, open spaces.

- Requires advanced engineering, specialized materials, and often higher construction costs.

- Commonly used for sports stadiums, exhibition halls, and aircraft hangars.

Short Span Structures

- Span under 30 meters (100 feet).

- Can rely on simpler engineering solutions and may use internal columns or supports.

- More cost-effective and easier to construct.

- Suitable for smaller buildings, warehouses, and office spaces.

In summary, the key difference is the span length. Long-span structures need more complex engineering and materials to create larger, unobstructed spaces.

Long-Span vs. Large-Span Structures

Though “long span” and “large span” are often used interchangeably, they refer to different aspects of structural design:

Long Span

- Refers to structures that span over 30 meters (100 feet) without internal supports or columns.

- Focuses on the distance of the span and the engineering required to create large, uninterrupted spaces.

- Common in buildings like sports arenas and exhibition halls.

Large Span

- Refers to structures with spans over 100 meters (328 feet) or more.

- Emphasizes the overall size and scale of the space, often for massive industrial or recreational purposes.

- Examples include large airport terminals or major exhibition halls.

“Long span” is about the distance the structure covers, while “large span” is more about the overall scale and width of the structure. All large-span structures are long-span, but not all long-span structures are large-span.

Conclusion

That’s it: Long-Span Structures.