Are you looking for ways to optimize your building’s interior space without the hassle of internal columns? Clear-span structures might be the perfect solution. Whether it’s a large warehouse, sports facility, or exhibition hall, clear-span design offers vast, uninterrupted spaces that make operations smoother and more efficient. But how do these structures achieve such flexibility and strength? And why should you consider them for your next project?

In this article, we’ll explore how clear-span structures work, the benefits they bring to various industries, and the key design elements that make them so versatile. From structural frame to foundation design, you’ll gain insight into how these structures are designed and what makes them a smart choice for your next building project.

By the end, you will understand the essential features of clear-span structures, how they can enhance your space, and why they are becoming a popular option in industries ranging from logistics to agriculture and beyond.

What is a Clear-Span Structure?

A clear-span structure is a building design with no internal columns or supports. This creates a large, open space without obstacles. It is widely used in warehouses, sports arenas, exhibition halls, and aircraft hangars, where open floor space is essential.

Unlike traditional buildings that rely on internal columns, clear-span structures use strong steel frames, trusses, or pre-stressed concrete beams. These materials allow the roof to be supported by external walls and load-bearing frames, making spans of 20 to over 300 meters possible.

Key features of clear-span structures:

- No Internal Columns – Maximizes usable space for storage, equipment, or seating.

- Large Spans – Covers 20m to 300m+ without interior supports.

- Strong & Durable – Uses steel, trusses, or reinforced concrete to hold heavy loads.

- Flexible Applications – Ideal for logistics, aviation, sports, and agriculture.

Clear-Span vs. Effective Span: What’s the Difference?

Many people confuse clear span and effective span, but they mean different things:

| Feature | Clear Span | Effective Span |

| Definition | A single, open span with no internal supports. | The calculated span between two support points, which may include columns. |

| Interior Space | 100% open floor space. | May have columns that divide space. |

| Load Support | Weight is carried by external frames or trusses. | Weight is distributed through columns and beams. |

| Applications | Warehouses, stadiums, hangars, exhibition halls. | Bridges, office buildings, multi-span factories. |

| Cost | Higher initial cost, but lower maintenance. | Lower initial cost, but columns may need reinforcement over time. |

Clear-span structures are the best choice for industries that need large, open, and adaptable spaces.

How Do Clear-Span Structures Work?

Clear-span structures stay strong and stable without internal columns by distributing weight and forces efficiently to external supports. They rely on rigid frames, trusses, or arches to hold up the roof while resisting wind, gravity, and other forces.

How Do They Support the Roof?

Since there are no interior columns, the weight of the roof must be transferred outward to the building’s external walls and foundation. This is achieved in three main ways:

- Rigid Frames – Thick steel or concrete frames act like a skeleton, holding up the roof and preventing it from bending.

- Trusses – These triangular structures spread the weight evenly, making long spans possible while keeping materials lightweight.

- Arches & Tension Systems – Curved or cable-supported structures use their shape to naturally distribute weight and stay stable.

How Do They Stay Stable in Wind & Earthquakes?

Because there are no interior supports, lateral forces (like wind or earthquakes) could make the building sway or collapse. To prevent this, clear-span buildings use:

- Bracing Systems – Steel cables or diagonal beams help resist side-to-side movement.

- Shear Walls – Solid walls that act like strong backbones, keeping the structure from shifting.

- Rigid Joints – Specially designed connections between beams and columns that hold the structure firm under pressure.

How Do They Avoid Sagging Over Time?

Long spans can bend or sag if not properly designed. Engineers prevent this by:

- Using deep beams or reinforced trusses to strengthen the structure.

- Choosing lightweight materials like steel or pre-stressed concrete to reduce stress on the frame.

- Designing with slightly curved beams that naturally counteract sagging over time.

The Result?

A strong, open, and flexible space that allows for maximum usability in warehouses, stadiums, aircraft hangars, and more.

Where Can Clear-Span Structures Be Used?

Clear-span structures are used in many industries because they create large, open spaces without internal columns. They are ideal for warehouses, factories, sports arenas, exhibition halls, aircraft hangars, greenhouses, and more. Here’s how different industries benefit from clear-span buildings.

Industrial Buildings

Clear-span structures are perfect for warehouses, manufacturing plants, and distribution centers. They provide more usable space, improve logistics, and allow easy movement of equipment.

- More Storage Space: No columns means better layout and more room for inventory.

- Efficient Workflows: Forklifts, conveyors, and automated systems move freely.

- Scalable Layouts: The open space can be adjusted as business needs change.

Example:

Amazon’s fulfillment centers use clear-span designs to maximize storage and improve order processing.

Commercial Buildings

Clear-span structures help create large, open spaces for retail stores, sports venues, and exhibition halls.

- Unobstructed Views: Ideal for stadiums, shopping malls, and theaters.

- Flexible Layouts: Spaces can change easily for events, trade shows, or sports.

- Better Customer Experience: Open spaces make venues more comfortable and visually appealing.

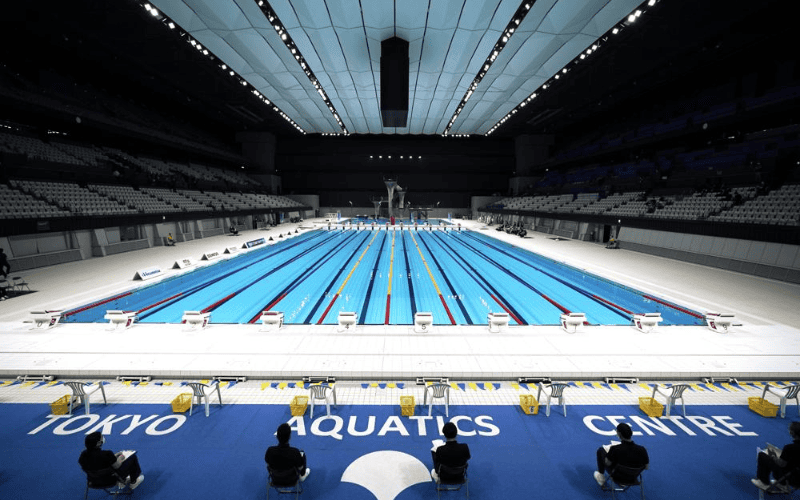

Example:

The Tokyo Olympic Swimming Center was built with a clear-span steel structure, providing open views and better spectator experience.

Agricultural Buildings

Farms and food production facilities use clear-span structures for livestock housing, greenhouses, and equipment storage.

- More Sunlight for Plants: No columns mean better light exposure in greenhouses.

- Easy Movement for Equipment: Tractors and storage units can be moved without obstacles.

- Strong & Weather-Resistant: Designed to withstand harsh weather and reduce maintenance costs.

Example:

AeroFarms, a leader in vertical farming, uses clear-span structures to create climate-controlled growing spaces, increasing food production.

Transportation Infrastructure

Airports, train stations, and aircraft hangars need large, open spaces for smooth operations. Clear-span structures provide wide, column-free areas for aircraft, cargo, and passengers.

- Spacious Hangars: Aircraft need wide, open areas for storage and maintenance.

- Easy Passenger Flow: Airports and train stations use large concourses for better movement.

- Built for Durability: Engineered to handle high winds, heavy loads, and extreme weather.

Example:

The Boeing Twin-Bay Hangar at Detroit Metropolitan Airport has a clear-span steel frame over 100 meters wide, allowing two Boeing 747s to be serviced at once.

How Are Clear-Span Structures Designed?

The design of a clear-span structure focuses on creating a strong, stable framework that can support large spans without needing internal support. Here are some of the key design elements:

Structural Frame Design

Most clear-span structures use a steel frame because steel provides the strength needed for large spans while being lightweight. Steel structures are also durable and can withstand harsh weather conditions. However, other materials are also used depending on the specific requirements of the project:

- Pre-stressed concrete (often used in large, industrial structures requiring high load-bearing capacity)

- Aluminum (in smaller to medium-sized spans, often in corrosive environments)

- Timber (in smaller-scale or eco-friendly projects; for natural aesthetic)

- Fabric and Membrane (in lightweight structures, often for sports arenas, exhibition halls, and temporary buildings requiring large spans with quick construction)

- Composite Materials (in specialized applications where high strength-to-weight ratios are needed, such as in aerospace-related buildings or lightweight structures)

Each of these materials offers different strengths in terms of weight, cost, and flexibility, and the choice depends on the design goals, building size, and environmental factors.

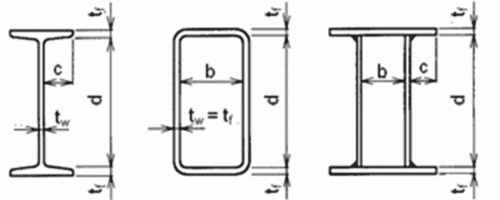

Typical Cross-Section Designs

The cross-section of the structural frame plays a significant role in the load-bearing capacity and overall stability of the building. Here are some typical cross-sectional designs used in clear-span structures:

- Box Beams: These are hollow, rectangular beams that provide high strength-to-weight ratios, making them ideal for large spans. The box shape distributes weight evenly and is often used in longer spans where weight reduction is important.

- I-Beams: I-shaped beams, or wide-flange beams, are frequently used in clear-span designs. They provide excellent load-bearing capacity while being relatively lightweight. Their wide flanges make them ideal for distributing vertical loads effectively.

- Lattice Girders: These are formed using interconnected steel or metal rods to create a lattice pattern. They are often used for longer spans where maximum strength with reduced material weight is required.

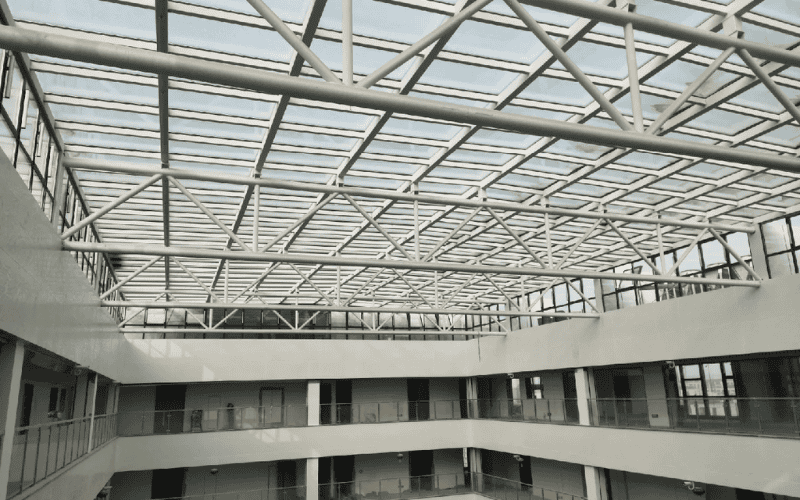

Trusses

Trusses are triangular frameworks that distribute the weight of the roof evenly, allowing for large spans without internal columns. Common types include Pratt and Warren trusses, each designed to handle different loads efficiently.

In addition to 2D trusses, 3D trusses are often used in large buildings like aircraft hangars. These three-dimensional trusses offer greater support for massive spans while keeping the structure lightweight. Their design improves stability and reduces the need for internal supports, making them ideal for spaces that need to accommodate large aircraft and equipment.

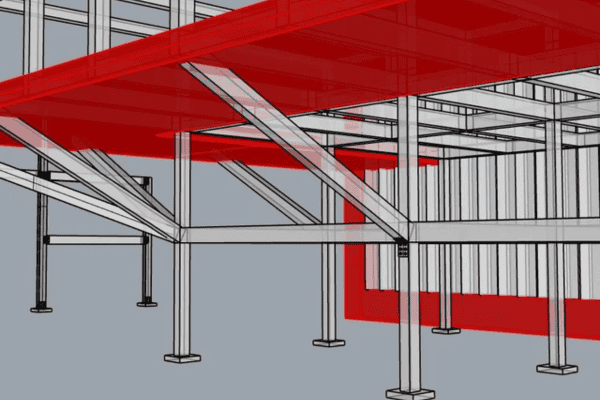

Support Systems

Support systems are essential for ensuring the stability of clear-span structures. While clear-span designs minimize internal columns, they still require external support to handle forces such as wind and seismic loads. Common support systems include:

- Bracing Systems: Diagonal braces (like X-bracing) or shear walls help resist lateral forces.

- Moment Resisting Frames: These frames provide stability by resisting bending and twisting forces.

- Tie Systems: Used to connect opposing sides of the structure to prevent movement, often seen in larger spans.

The right support system is critical for maintaining the structure’s integrity, especially for large or tall clear-span buildings exposed to extreme weather conditions.

Roof Design

The roof is an important part of clear-span structures. Common roof types include gable roofs, arched roofs, and mono-pitched roofs.

To make sure the roof can hold weight, last longer, and save energy, the design must consider materials, shape, and weather conditions. A good roof distributes weight evenly, resists weather damage, and helps keep the building energy-efficient.

Innovative roofs, like ETFE membrane roofs, are lightweight and durable. They let in natural light while saving energy, and they are used in places like the Beijing Water Cube. Another option is the double-skin roof, which has two layers with a gap between them. This design helps with insulation and ventilation, making the building more energy-efficient.

Foundation Design

The foundation of a clear-span structure must support heavy loads and prevent shifting over time. The type of foundation depends on soil conditions, groundwater levels, and the building’s size. For example, soft or unstable soils may require deep foundations, such as piles, to reach stable soil layers. In contrast, stable ground may allow for simpler, shallow foundations, like spread footings or slab foundations.

It’s also important that the foundation is securely connected to the structure above. This connection helps prevent movement from external forces like strong winds or earthquakes. Common methods of connection include steel anchor bolts or reinforced concrete columns. Additionally, the foundation should account for potential soil shifts or moisture changes to maintain long-term stability.

How Are Clear-Span Structures Erected?

The process of erecting a clear-span structure involves several key steps to ensure that the design is accurately implemented and that the building is safe and durable.

✅ Site Preparation: Level the ground and prepare foundations to support the structure’s load.

✅ Material Fabrication: Pre-engineered steel components (trusses, beams, columns) are manufactured off-site.

✅ Primary Framework Assembly: Erect main support columns first, then connect horizontal beams to create the base structure.

✅ Roof System Installation: Install rigid main frames, secondary purlins, and roof panels.

✅ Wall Construction: Attach wall girts and install exterior cladding/siding materials.

✅ Bracing & Reinforcement: Add cross-bracing and diagonal supports to ensure structural integrity.

✅ Final Touches: Install doors, windows, insulation, and interior/exterior finishes.

Why Choose Clear-Span Structures?

There are several compelling reasons why clear-span structures are a great choice for many types of buildings:

- Space Flexibility: The open design allows for dynamic layouts and easy customization of the interior space.

- Cost-Effective: With no internal columns, these buildings can reduce long-term maintenance costs, as there are fewer structural elements to repair or maintain.

- Fast Construction: Pre-fabricated components and modular designs help speed up the construction process, reducing building time by up to 50% compared to traditional designs.

- Multifunctional: Clear-span structures can be adapted to include features like solar panel roofs, smart ventilation systems, or energy-efficient designs, making them suitable for a wide range of modern needs.

What is the Difference Between Clear Span and Multi Span Structures?

Clear-span and multi-span structures are two common building designs. Each has its advantages depending on cost, space needs, and structural strength.

| Feature | Clear Span Structures | Multi Span Structures |

| Design | No internal columns, single large open space. | Uses internal columns for additional support. |

| Space Utilization | 100% open space, ideal for large equipment, storage, or open seating. | Space divided by columns, suitable for partitioned areas. |

| Span Length | Typically 20m – 300m+, used for warehouses, aircraft hangars, and stadiums. | Shorter spans (20m – 100m per section), suitable for factories, offices, retail spaces. |

| Structural Strength | Requires stronger materials like steel, trusses, or reinforced concrete to support large spans. | More stable for smaller spans, as columns provide additional load distribution. |

| Construction Speed | Faster when using pre-engineered designs; fewer components mean quicker assembly. | Moderate speed, as additional columns and connections require more work. |

| Cost Efficiency | Higher upfront cost due to stronger materials but lower long-term maintenance. | Lower upfront cost, but columns may increase maintenance costs over time. |

| Best For | Warehouses, aircraft hangars, stadiums, logistics centers. | Factories, retail stores, multi-floor office buildings. |

Which One Should You Choose?

Choose Clear Span if you need:

- A large, open floor plan (e.g., sports arenas, warehouses).

- Flexibility for future layout changes (e.g., multi-use exhibition halls).

- Uninterrupted movement space (e.g., aircraft hangars, logistics hubs).

Choose Multi Span if you need:

- A cost-effective solution for smaller spaces (e.g., office buildings, retail stores).

- Defined zones for specific uses (e.g., separate workspaces in a factory).

- A structure that supports multiple floors (e.g., commercial complexes).

Your Next Clear-Span Steel Structure is Right Here

Looking for a flexible, cost-effective solution that provides uninterrupted space for your next building project? With over 20 years of experience and more than 1,000 successful projects worldwide, we specialize in designing and delivering high-quality steel structures for different building types tailored to your needs. Whether you have a design in mind or need us to create one from scratch, we offer a full-service solution—from design and manufacturing to transportation and installation support. Our expert team is here to guide you every step of the way, ensuring your project is completed on time and to the highest standards. Contact us today to get started!