The timeline to build a container home can range from several months for traditional on-site projects to just 4–6 weeks for factory-built models. The exact duration depends on key factors such as design complexity, permits, site conditions, and material availability.

In this guide, we break down every stage of the process—from the main factors influencing build time and a detailed phase-by-phase construction timeline, to container modification and interior finishing steps that shape your home’s completion speed. We’ll also discuss external factors like location, container type, and budgeting that may affect delivery, and explain how professional manufacturing can help you save time.

As a certified steel structure and PEB housing manufacturer, SteelPRO PEB leverages automated production lines and ISO-compliant processes to deliver container homes faster, safer, and with consistent quality—helping you plan confidently and move in sooner.

Key Factors That Affect the Timeline of Building a Container Home

Building a container home is exciting, but there are key factors that can impact how long the process takes. Here’s what to consider:

- Design Complexity: More complex designs, like adding windows, doors, or multiple levels, will take longer. Simple designs are quicker to build.

- Permit and Regulatory Compliance: Zoning laws and building codes can delay your timeline. Permits can take weeks or months, so plan extra time for approvals.

- Customization: Modifying containers with extra features like insulation or custom cuts adds time. The more customizations, the longer the build.

- Weather and Site Conditions: Bad weather or tough terrain can slow things down. Prepare for potential delays due to external factors like storms or difficult access.

- Labor Availability: Finding skilled workers can be a time factor. Relying on a qualified team will ensure the build stays efficient. In factory-built projects, most of these factors—labor, weather, and materials—are controlled in-house, significantly shortening total construction time.

- Material Sourcing: Sourcing containers and materials may take time, especially if you need specific sizes. Material delays can impact your schedule. Manufacturers with integrated steel structure production lines can maintain stable supply and predictable build times.

Each of these factors can add time to your project, so be sure to account for them in your timeline.

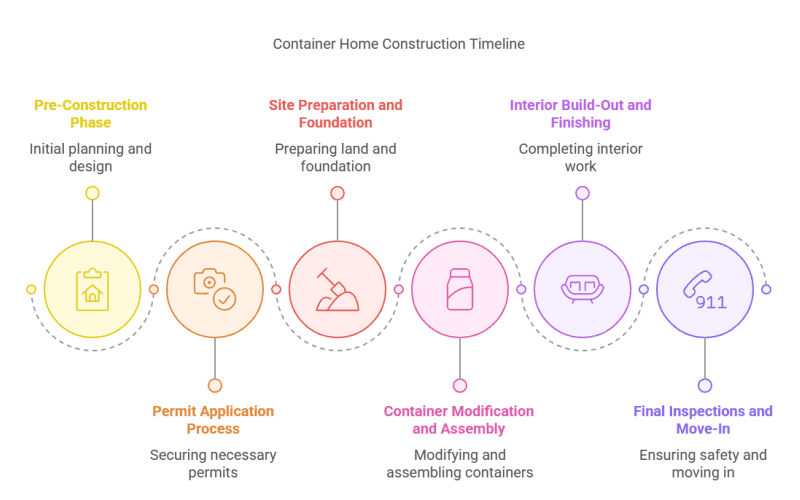

Detailed Timeline for Building a Container Home

Building a container home is an exciting project, but understanding the construction timeline helps manage expectations. Below, we’ll break down the entire build process into detailed phases to give you a clearer picture of how long each step typically takes.

While traditional on-site container home construction usually takes 4–8 months, factory-prefabricated container homes can be completed in as little as 4–6 weeks, since most structural and finishing work is completed simultaneously in a controlled environment.

Pre-Construction Phase (1-2 Months)

The pre-construction phase is critical to set a solid foundation for your container home project. From designing your home to securing necessary permits, this stage ensures that everything is ready for construction.

Planning and Design

- Initial Home Design: Generally, the process of finalizing the design takes between two to four weeks. This stage involves creating the layout, deciding the number of containers, and considering special features.

- Budget Allocation: Allocate your budget for materials, labor, and unexpected expenses within 1 week. The greater the level of detail in your budget, the fewer unexpected issues you will encounter during the construction process.

Permit Application Process

| Task | Estimated Time |

| Acquiring Building Permits | 2-6 weeks, depending on location |

| Structural and Local Engineering Approvals | 2-4 weeks |

Obtaining permit approvals is essential to ensure compliance with local building codes. The duration of this process can vary from two to six weeks, contingent upon your geographical location; therefore, it is advisable to commence this procedure as early as possible.

Site Preparation and Foundation (3-6 Weeks)

Once the planning is done, it’s time to prepare the site and lay the foundation. This stage guarantees that the ground is prepared to firmly support your container home.

Site Clearing and Access Setup

Clearing the land, which includes removing debris and ensuring access for construction vehicles, usually takes around 1-2 weeks.

Setting Up Utilities

Setting up water, electricity, and sewer systems typically takes 2 weeks. However, remote sites may experience longer delays due to limited access to infrastructure, the need for additional equipment, or the complexity of connecting utilities in hard-to-reach areas. These challenges can extend the timeline as extra effort is required to establish reliable connections.

Foundation Work

| Foundation Type | Estimated Time |

| Concrete Slab | 2-4 weeks |

| Pier Foundation | 1-2 weeks |

| Raised Foundation | 3-5 weeks |

| Crawl Space Foundation | 2-4 weeks |

| Slab-on-Grade Foundation | 3-4 weeks |

Foundation work involves preparing and setting the base that supports the structure of your container home. It ensures the home is stable, level, and securely anchored to the ground. The foundation is a crucial phase because it secures and stabilizes the home. Choosing between a concrete slab or pier foundation will affect the time needed to complete this phase.

Container Modification and Assembly (4-8 Weeks)

Now that the foundation is ready, it’s time to modify the containers and assemble them on-site. This is the phase where your envisioned concept starts to materialize.

Shipping Container Modifications

Modifying shipping containers typically takes 2-4 weeks due to several key steps that ensure your home is livable and meets your design needs:

- Cutting windows and doors: Precise cutting is required to avoid weakening the structure, which can take time.

- Reinforcing structural elements: Modifications, like cutting holes, require reinforcement to maintain stability and strength.

- Adding insulation: Insulation is essential for comfort, and adding it correctly involves multiple layers, which takes time.

Each step demands attention to detail, making this phase crucial for a safe and functional home.

In a fully automated factory line, container modification—including cutting, welding, and insulation—can be completed within 10–15 working days, thanks to controlled production conditions and synchronized workflows.

Assembling the Containers

Once all the modifications are completed, it’s time to bring the containers together to form the structure of your home. This step involves several important tasks:

- Positioning Containers: Containers are carefully placed on-site, ensuring they are aligned and securely positioned. The duration of this process may span 2-3 weeks, contingent upon the site’s configuration and ease of access.

- Stacking and Welding: After positioning, the containers are stacked and welded together to create a solid, unified structure. This involves securing each container in place and ensuring they are safely connected. The duration required for this stage may fluctuate, but generally, it spans 2-3 weeks, depending on the intricacy of the design and the quantity of containers utilized.

Each step requires precision to ensure that the structure is stable and properly aligned, which is why this phase can take a few weeks to complete.

For example, SteelPRO PEB’s automated laser-cutting and modular welding systems ensure superior precision and reduce container modification and assembly time by up to 40% compared with manual fabrication, making factory-built container homes faster, more consistent, and structurally sound.

Interior Build-Out and Finishing (4-8 Weeks)

Now that the structural framework is established, it’s time to transform your container into a livable and practical residence. This phase includes all the interior work from utilities to finishing touches.

Utility Rough-In

| Utility Task | Estimated Time |

| Plumbing, Electrical, and HVAC | 2-3 weeks |

Roughing in plumbing, electrical systems, and HVAC usually takes 2-3 weeks. This step involves running pipes, wiring, and vents throughout the home.

Interior Framing and Walls

Once the utilities are roughed in, the next step is installing insulation, drywall, and flooring. Anticipate that this process will require 2-4 weeks, depending on the scale and intricacy involved.

Final Touches

The final finishing touches, like installing fixtures, appliances, and painting, will take another 2-3 weeks to complete. This is when your container home starts to truly feel like a home.

In factory-prefabricated systems, interior modules, such as walls, flooring, insulation, and fixtures are assembled in parallel on dedicated production lines. This synchronized process enables near “turnkey delivery”, where the container home arrives almost complete, significantly reducing on-site work and total build time.

Leading manufacturers like SteelPRO PEB apply ISO-certified assembly procedures to ensure quality consistency, rapid installation, and efficient interior completion—ideal for global modular housing projects.

Final Inspections and Move-In (2-4 Weeks)

After everything is completed, your container home must undergo final inspections before moving in.

Code Compliance and Inspections

It takes about 1-2 weeks for structural, electrical, and plumbing inspections to ensure everything is up to code and safe for occupancy.

“Inspections may vary by location, so always leave room in your timeline for any unexpected delays or reworks.”

Final Clean-Up and Final Touches

After the inspections, a clean-up and any remaining landscaping will take about 1-2 weeks. This marks the concluding phase prior to your relocation and the commencement of enjoying your newly created living area.

This comprehensive schedule should provide you with a more precise understanding of the duration required to construct a container home from inception to completion. Bear in mind that unforeseen postponements might arise; however, having a well-thought-out plan will assist in mitigating obstacles and maintaining the progress of your project.

As you can see, a container residential project may take at least 6 months to complete (which is still the fastest case), depending on various factors. However, for an experienced container home manufacturer, the process is much faster. In fact, you could have a fully constructed container home—minus the furniture—delivered to your site in as little as 4 weeks. This option ensures a smooth, hassle-free experience, with all construction completed, so you can focus on adding your personal touches once it arrives.

Additional Factors That Can Affect Timeline of Building Container Home

While the main construction steps set the framework for your container home’s build time, there are other crucial factors to consider that could extend the timeline. Let’s break them down further:

Location and Site Conditions

Where your container home is being built plays a major role in determining how long it takes to complete.

- Remote or Difficult-to-Access Sites: If your site is located in a remote area or has limited access, transportation of containers and equipment may take additional time.

- Site Preparation: Challenging terrains like slopes or rocky ground require extra grading and access setup.

Factory-built delivery significantly reduces weather exposure and on-site disruption. Most assembly and finishing work is completed in controlled factory environments before the unit reaches the site.

Container Type and Quality

The condition and type of container you choose can influence how quickly your project progresses.

- New vs. Used Containers: New containers typically require less surface treatment and modification, reducing build time.

- Container Size: Standard and high-cube containers differ in height, with high-cube options offering more interior volume but slightly longer modification times.

Using new, ISO-certified containers from trusted manufacturers—such as SteelPRO PEB—ensures structural consistency and minimal rework, allowing faster project execution.

Budget Constraints and Adjustments

Budget clarity directly impacts build efficiency and scheduling.

- Underestimating Costs: Insufficient initial budgeting can lead to mid-project pauses.

- Unforeseen Expenses: Sudden material price changes or redesigns can cause delays.

Centralized factory production offers cost predictability and reduces unexpected on-site expenses, helping maintain steady progress from fabrication to delivery.

Related Reading: How Much Do Container Homes Really Cost? A Detailed Breakdown

By considering these factors early and partnering with an experienced container home manufacturer, you can minimize delays, maintain better cost control, and achieve a smoother, faster project completion.

How long does it take to build a container home?

Traditional on-site container homes take about 4–8 months, depending on permits and weather. In contrast, factory-built models—like those from SteelPRO PEB—can be finished within 4–6 weeks, as fabrication and finishing happen simultaneously.

How long does it take to build a 2BHK container home?

A 2BHK design usually requires 6–8 weeks for factory production and installation, depending on layout complexity and finishing preferences.

Is a factory-built container home faster than DIY construction?

Yes. Factory-built homes are assembled with automated systems and ready-to-install modules, saving up to 50% of total build time compared to DIY or site-based builds.

How much does a container home cost?

Costs vary by size and materials. A small single-unit model starts around USD 15,000–25,000, while multi-unit or customized homes can range higher. Factory-built systems ensure transparent, predictable pricing.

Can I customize my container home?

Absolutely. You can adjust floor plans, materials, and insulation. SteelPRO PEB provides modular customization that balances design freedom with fast delivery.

How We Can Help You Build Your Container Home

Building a container home doesn’t have to be a long or uncertain process. Many homeowners struggle with extended timelines, unpredictable costs, and complex coordination between design and construction. At SteelPRO PEB, we simplify this journey through factory-prefabricated container housing — every phase, from steel fabrication to interior finishing, is completed under one roof.

Our integrated production lines, ISO-certified processes, and automated welding systems cut build time from months to just 4–8 weeks, ensuring consistent quality and faster delivery. Whether you’re planning a 2BHK home or a multi-unit housing project, our prefabricated approach offers precision, durability, and peace of mind.

Start your project today — contact SteelPRO PEB for a factory-direct quotation and make your container home timeline shorter, smarter, and stress-free.