At a glance, a shipping container looks like a simple steel box. But what holds it together—and makes it work—are the small, often overlooked parts. These accessories aren’t just extras—they’re essential for strength, security, and usability.As prefab container builders, we’ve seen how the right (or wrong) components can affect everything from durability to daily use. In this guide, we’re breaking down the must-have components, the helpful extras, and the specialized gear for modified containers, so you can make better decisions—whether you’re shipping cargo or building something extraordinary.

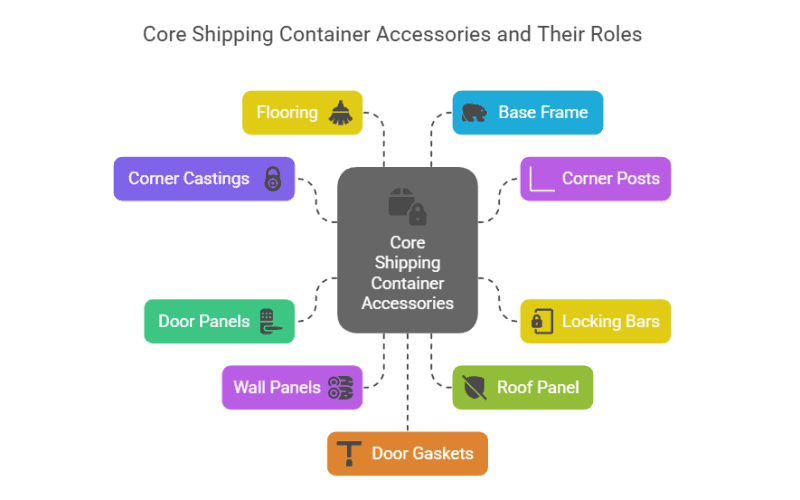

Core Shipping Container Accessories That Make Up the Structure

These essential components form the backbone of any shipping container, whether it’s used for transport or converted into a living or working space.

Corner Castings – Lifting and Locking Stability

Corner castings are solid, reinforced steel blocks welded into all eight corners of a shipping container.

They’re not just for show—these blocks are the key to safe lifting, locking, and stacking, whether you’re moving a container across oceans or assembling a modular building on-site. Twist-locks fit precisely into these castings, so it’s crucial to align them properly during installation or transport. If they’re even slightly off, it can cause connection issues or create dangerous stress points in stacked units.

Corner Posts – Structural Strength and Support

Corner posts run vertically between the top and bottom corner castings, and they’re the hidden heroes of structural integrity.

They take on vertical loads during stacking and secure the container’s overall shape. In prefab building conversions, we always keep an eye on the condition of these posts, especially if the container is being cut or modified—they need to remain aligned and undamaged to keep the entire unit stable.

Locking Bars – Secure Door Closure

Locking bars are the long vertical rods you see on each container door—they’re simple but incredibly effective.

Each bar engages with cam keepers on the top and bottom, sealing the doors tight against the frame. These are critical for both theft prevention and weather resistance. When converting containers into storage or living units, some clients upgrade to tamper-resistant bars for added peace of mind.

Door Panels – Heavy Duty Use

Standard shipping container doors are made of heavy-gauge steel and come with built-in rubber gaskets for sealing.

If you’re repurposing a container for long-term use, especially in wet or windy areas, it’s smart to inspect those gaskets regularly. We’ve found that small cracks or warping can lead to water ingress over time—a quick check can save a big headache later.

Wondering about the level of protection these containers provide? You might want to check out our article on are shipping containers waterproof to understand how well they stand up to the elements in various conditions.

Wall Panels – Built-In Rigidity

The container’s side and end wall panels are corrugated steel sheets designed for maximum rigidity.

This corrugation isn’t just a design choice—it allows the panels to handle extreme pressure during shipping. When converting for insulation or interior walls, it’s important to factor in this shape; flat cladding or spray foam has to follow the panel’s profile unless additional framing is added.

Roof Panel – Added Protection in Conversions

The roof is usually a single corrugated or flat steel panel, fully welded to keep out rain and debris.

In container housing or prefab offices, we often reinforce the roof or even replace it entirely, especially if it’s been used heavily or exposed to harsh climates. Flat roofs can pool water, so drainage planning is also key.

Flooring – Lasts in Harsh Conditions

Standard container floors are typically made from marine-grade plywood or treated bamboo.

While these materials hold up well in dry environments, they can warp or degrade when exposed to constant moisture. For cold storage or tropical climates, steel plate flooring can be a smart swap, offering long-term durability and easier cleaning.

Base Frame – Bears All the Load

The base frame is the structural foundation of a shipping container, made up of bottom side rails and a series of steel crossmembers that span the width beneath the floor.

This frame carries all the container’s weight, including cargo, modifications, and stacked loads. It’s especially critical in builds where the container is raised on piers, mounted on wheels, or stacked in multi-unit configurations. If the base frame is bent, corroded, or uneven, it can cause structural stress and compromise the entire build. We always recommend checking frame condition carefully before starting any conversion.

Door Gaskets – Keep the Elements Out

These rubber seals line the edges of the container doors and help keep out wind, water, and pests.

They may seem minor, but we’ve seen many clients overlook them until mold or leaks appear. Regular maintenance or quick replacements go a long way in extending the container’s life—especially in climate-controlled or high-traffic conversions.

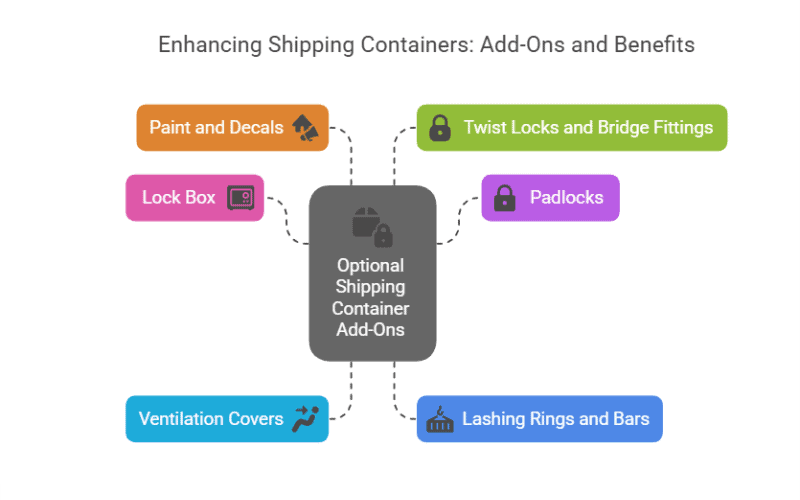

Optional Shipping Container Add-Ons Worth Considering

These aren’t structural must-haves, but they can seriously boost security, comfort, and flexibility—especially in converted container spaces.

Lock Box for Enhanced Container Security

A lock box is a simple but highly effective upgrade that’s welded over the container’s door locking area.

Instead of leaving padlocks exposed, a steel shroud covers the latch, making it much harder to cut or tamper with. It’s a popular add-on for container homes, retail shops, or tool storage—anywhere theft risk is higher. If your container will sit on a jobsite or remote area, this one’s a no-brainer.

Padlocks Tailored to Container Conversions

Not all padlocks are created equal—and in building projects, most clients don’t stick with the default ones.

We’ve seen everything from heavy-duty disc locks to custom-coded systems depending on how the container is used. For example, retail containers often need locks with controlled key access, while personal storage units might go with simpler, user-friendly padlocks that are easy to replace. It’s all about finding the balance between convenience and safety.

Ventilation Covers to Protect Interior Airflow

Shipping containers come with standard vents—but they’re basic and unprotected from rain or pests.

That’s where ventilation covers come in. These are added over the original vents to allow airflow while blocking water, bugs, and rodents. Especially in tropical or humid areas, this small upgrade keeps your container dry, breathable, and cleaner inside, which matters a lot in long-term use or any kind of human occupancy.

Lashing Rings and Bars for Safe Cargo Handling

Lashing rings and lashing bars are often overlooked, but they can make a world of difference—especially for mobile storage or workshop containers.

These are mounted inside the walls or floor and used to anchor cargo or secure tools and equipment. We’ve had clients convert containers into bike shops, gear storage, or even mobile clinics, and proper lashing points were critical to keep things in place during transport or daily use.

Here’s a quick breakdown:

| Add-On | Common Use Case | Key Benefit |

| Lashing Rings | Inside container walls/floor | Cargo tie-downs |

| Lashing Bars | Around full-length side walls | Heavy-duty equipment support |

Paint and Decals for Durability and Branding

While paint might seem like just a cosmetic upgrade, it plays a bigger role in container conversions than many think.

Repainting the exterior adds a layer of protection against rust, sun damage, and weathering—especially if the container is in harsh climates or coastal regions. For businesses using containers as part of their operations, custom decals and branding help reinforce brand identity and make the structure stand out. Whether it’s for a customer-facing pop-up or a remote project site, presenting a professional image starts with how your container looks.

Twist Locks and Bridge Fittings for Modular Container Setups

When you’re stacking or placing containers side-by-side, twist locks and bridge fittings are essential.

These metal connectors lock multiple containers together at the corners or along their base rails, keeping them aligned and secure. For example, in two-story modular homes or container schools, twist locks are what keep everything stable—even during wind or seismic activity. It’s one of those things that seems small until it’s missing. They’re also widely used in shipping logistics to secure containers on trucks, ships, or rail—ensuring they stay safely in place during transit.

Specialized Container Accessories for Modified or Purpose-Built Units

These accessories don’t show up in every build—but they’re absolutely essential when you’re dealing with refrigeration, oversized cargo, or specialized logistics needs.

Reefer Container Accessories for Cold Chain Shipping

Reefer containers need more than insulation—they rely on a full system of components to keep the interior at just the right temperature.

Here’s what’s typically involved:

- Refrigeration Unit: This is the heart of the reefer. A built-in compressor circulates chilled air, maintaining stable temperatures ranging from deep freeze to mild cooling, depending on the cargo.

- Power Socket: Most reefers use a standard 3-phase industrial connector. In practice, this means you’ll need proper power setup on-site or a generator during transport.

- Temperature Control Panel: These programmable panels let you set and monitor internal temperatures. Make sure the panel is easily accessible and mounted where it won’t get damaged during loading.

- Air Duct Panels: These help ensure even airflow from front to back, avoiding hot spots and making sure all contents are kept uniformly cool. We’ve seen failures here cause partial spoilage—small fix, big impact.

When setting up a reefer container for on-site use (like in food processing or pharmaceuticals), make sure all four elements are integrated and tested as a full system. One weak point can throw the whole thing off.

Open Top Container Add-Ons for Oversized Cargo

Open top containers are made for the kind of cargo that just won’t fit through a regular door—but they still need a little help when it comes to weather protection and load stability.

Two key components matter here:

- Removable Roof Bow: These horizontal steel bars run across the top opening to support the tarpaulin. We’ve found that it’s best to double-check spacing and attachment points, especially if the container will face strong winds or movement during transit.

- Tarpaulin Cover: A heavy-duty, waterproof fabric that covers the top. It’s flexible but strong—and usually comes with eyelets for secure fastening. This isn’t something you want to cheap out on, especially when transporting delicate or moisture-sensitive goods.

These accessories make sure open-top units stay just as safe and functional as standard containers, even when carrying machinery, pipes, or other tall cargo.

Flat Rack Container Fittings for Heavy-Duty Transport

Flat rack containers are the go-to for large, irregular items—think industrial machines, vehicles, or steel beams—but they come with their own set of accessories.

From our experience, two additions make all the difference:

| Accessory | Function | Why It Matters |

| Collapsible Ends | Fold-down frames at both short ends | Saves storage space when racks are empty |

| Heavy-duty Twist Locks | Reinforced corner connectors | Holds uneven loads securely during transit |

Collapsible ends are great when storing multiple units—they flatten out, making stacks much easier to manage in limited yard space. As for the twist locks, always make sure they’re rated for the actual cargo weight—we’ve seen issues when generic locks were used with heavy industrial freight.

Our Insights as a Prefab Container Building Manufacturer

After working with thousands of containers, we’ve found that practical upgrades matter more than surface-level changes.

Structural Accessories Matter More Than Finishes

Looks aren’t everything. If corner castings, gaskets, or locking bars are worn, the unit’s safety and stability are at risk—no matter how nice the exterior looks.

Standard Containers Need Prep Work Before Build-Out

Most containers aren’t ready to convert straight away. Floors often need reinforcement, side panels may be dented, and roof gaps must be sealed to prevent leaks or heat loss.

Accessory Fit Is Critical in Prefab Builds

Using mismatched vents, locks, or fittings can cause rust, poor sealing, or early failure. Always check for compatibility, especially with long-term or stacked setups.

Custom Builds Need Purpose-Driven Choices

Every use case—whether cold storage, offices, or modular homes—needs different accessories. It’s not about more parts, but the right ones for function, safety, and longevity.

Conclusion: Accessorizing with Purpose—And Building with Precision

Every accessory plays a role—and when you’re turning containers into buildings, these details matter even more than you’d think.

We’ve learned from experience that components like reinforced wall panels, upgraded floor structures, and waterproof roof coatings aren’t just nice-to-haves—they’re necessary when converting a basic shipping container into a durable, long-term structure. For example, in many of our builds, we upgrade standard gaskets and seals to improve insulation, or install heavy-duty twist locks when stacking multi-unit homes or offices.

Whether you’re planning cold storage, a container office, or a container café, the right accessories are what turn ideas into functional, safe, and efficient spaces. It’s not about adding more—it’s about adding smarter.

As a prefab container building manufacturer, we don’t just build steel frames—we help match each build with the right accessories for lasting performance. Ready to start your next container project? Let’s build it strong, from the inside out.