What is Prefabricated Steel Building?

Prefabricated steel structure buildings refer to buildings in which steel components (such as columns, beams, roof panels, etc.) are prefabricated in factories and then transported to the construction site for rapid assembly into complete steel structures.

The fundamental distinction between this method and conventional construction techniques lies in the decoupling of component manufacturing from on-site assembly. In traditional construction, all components are produced and assembled on-site, which tends to be time-consuming and more susceptible to weather delays. In contrast, prefabricated steel buildings offer enhanced construction speed and better quality control.

Types of PEB Steel Structure Buildings

Prefabricated steel buildings are generally classified into various types depending on their function and specific requirements. SteelPRO PEB offers a wide range of building solutions to meet a variety of needs in the industrial, commercial, agricultural and residential sectors.

Heavy Prefabricated Steel Structures

Heavy steel structures are used for large industrial building kits such as factories, warehouses and logistics centers, which require high load-bearing capacity. SteelPRO PEB’s heavy steel structures are designed with high-strength materials to ensure stability and safety even in the harshest conditions.

Light Prefab Steel Structure

Ideal for smaller industrial buildings such as compact warehouses, production halls and smaller commercial spaces, we offer tailor-made solutions for light steel structures to maximize space utilization and provide a cost-effective, durable option for businesses with limited space requirements.

Long Span Prefab Steel Buildings

Ideal for buildings that require large open spaces without internal supports or columns, such as stadiums, exhibition centers and large warehouses. Our long span design ensures maximum usable space while minimizing costs, making it ideal for commercial and industrial spaces that require large open areas.

Container and Modular Steel Buildings

SteelPRO PEB also offers container and modular solutions, including container offices, mobile classrooms, container homes and modular medical clinics. Our modular container buildings are easy to transport, assemble, and adapt to a variety of needs, providing a flexible and cost-effective solution for temporary housing or office space.

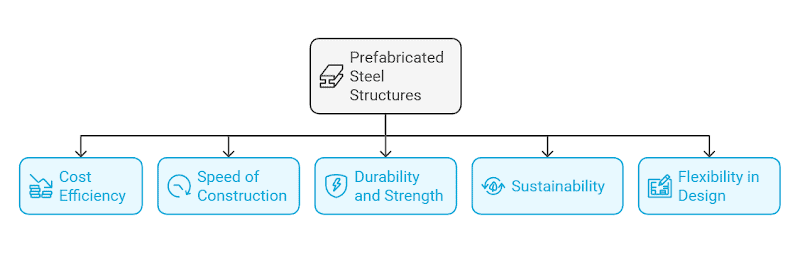

Advantages of Prefabricated Steel Structures

- Cost Efficiency: With pre-manufactured components, on-site construction requires less labor and material, minimizing waste. Steel’s durability and low maintenance costs lead to significant long-term savings. Choosing SteelPRO PEB’s prefabricated steel structures reduces initial costs and delivers a higher return on investment.

- Speed of Construction: Prefabricated steel structures dramatically expedite the construction timeline. By fabricating components in the factory, the on-site tasks are confined to swift assembly, thereby cutting down the construction duration by up to 30% or even more. Our streamlined manufacturing and prompt delivery guarantee timely project completion, even under stringent deadlines.

- Durability and Strength: Steel’s high strength enables prefabricated buildings to withstand severe weather, earthquakes, and other challenges. Its corrosion and wind resistance ensure long-lasting performance with minimal maintenance.

- Sustainability: Steel is recyclable, making prefabricated steel buildings an eco-friendly choice. They reduce construction waste, meet green building standards, and offer high energy efficiency, supporting sustainability.

- Flexibility in Design: Our prefabricated steel buildings offer full customization to suit your needs. From exterior design to internal layout, we provide flexible options to meet every requirement. SteelPRO PEB collaborates with you from the design phase to ensure every detail aligns with your project’s vision, delivering a tailored solution.

What Are the Disadvantages of Prefabricated Buildings?

1. Limited Aesthetic Appeal: While prefabricated metal buildings offer functional advantages, they often lack the architectural variety of traditional buildings like wood or concrete structures. Customization is possible, but the options may vary depending on the manufacturer and building materials used.

2. Higher Initial Costs for Customization: A steel building kit is cost-effective for standard designs, but custom metal building projects with unique features or high-end finishes can increase building prices near your location.

3. Condensation and Insulation Issues: Without proper insulation, a metal structure may be prone to condensation, which can lead to rust and corrosion over time. This makes steel storage, metal garages, and metal workshops susceptible to moisture-related damage.

4. Zoning and Permitting Challenges: Certain areas have strict building codes that may restrict the use of custom steel buildings. Consulting building experts beforehand is crucial to ensure compliance.

Applications of Prefabricated Steel Buildings

Prefabricated steel buildings are ideal for a wide range of applications, thanks to their versatility and strength. These buildings are widely used in:

Industrial Construction

SteelPRO PEB provides robust prefabricated steel buildings for warehouses, production workshops, logistics centers, and manufacturing plants. With the ability to support heavy loads, our buildings are designed for high-efficiency operations.

Agricultural Steel Buildings

Steel structures are ideal for agricultural applications such as metal barns, farm equipment sheds, livestock sheds, and grain storage buildings. SteelPRO PEB specializes in custom agricultural steel buildings that protect valuable crops, livestock, and equipment while ensuring long life and low maintenance costs.

Residential Prefab Metal Buildings

For residential projects, we offer a wide range of prefabricated steel buildings. These structures combine the practicality and durability of steel with residential design flexibility, energy efficiency, and low maintenance.

Commercial Construction

Our steel buildings are perfect for shopping centers, office buildings, garage, exhibition halls, and retail spaces, offering modern aesthetics and practical functionality.

How Much Does Prefabricated Steel Buildings Cost?

The price of a prefabricated steel building depends on several factors:

- Design complexity: Custom designs or non-standard structures can increase costs.

- Building size: Larger buildings require more materials and a higher labor cost.

- Materials: The choice of materials, such as insulation, steel grade, and finishes, can also influence the cost.

SteelPRO PEB offers competitive, transparent pricing and can provide a customized quote tailored to your needs. We work closely with you to ensure the best value for your budget while maintaining the highest quality standards.

What Are the Components of a Prefabricated Steel Structure?

Our prefabricated steel buildings consist of high-quality components designed for durability and stability. Each component is crafted in strict adherence to international standards, guaranteeing a high-quality, reliable product.

- Primary Structure: It is composed of steel columns, steel beams, support systems, etc., usually H-shaped steel or box-shaped steel is used to bear the main load of the building.

- Secondary Structure: It includes purlins, wall beams, floor decking, etc., usually made of C-shaped steel or Z-shaped steel, which plays a connecting and supporting role.

- Enclosure System: It is composed of roof panels, wall panels, doors and windows, etc., and often uses color steel plates, sandwich panels or aluminum-magnesium-manganese plates to provide protection and aesthetic functions.

- Fastening System: It includes high-strength bolts, welded connectors, rivets, etc., which are used to fix various components to ensure the stability of the structure.

- Foundation System: It is usually a concrete foundation, which provides stable support and is connected to the steel structure frame.

- Drainage and Ventilation System: It includes gutters, downspouts, and ventilation equipment to ensure good ventilation inside the building and prevent water accumulation from affecting the structure.

- Decoration and Additional Features: Insulation layer, fire-retardant coating, lighting system, partitions, etc. can be added as needed to improve comfort and functionality.

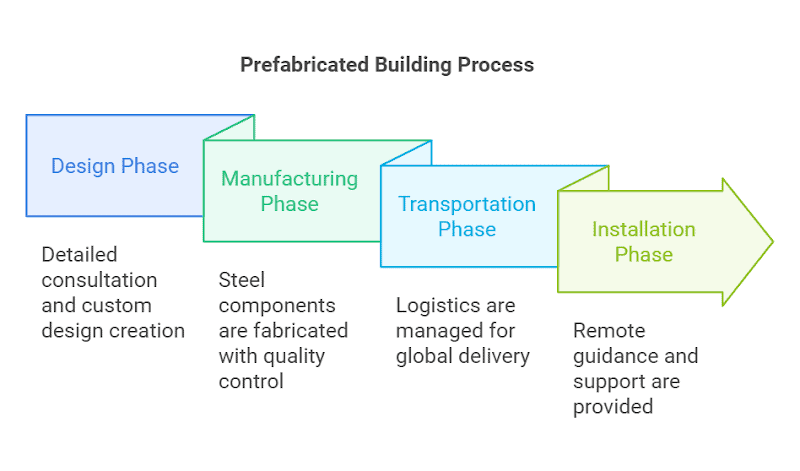

Construction Process of Prefabricated Steel Building Structure

We adhere to a comprehensive process that guarantees the efficient execution and utmost quality of every project.

- Design Phase: We begin with an in-depth consultation to understand your project requirements, then use a 3D building design tool to design a building that meets your building needs. We generate meticulous 3D models to guarantee that every minute detail is meticulously addressed.

- Manufacturing Phase: Prefabricated Steel Buildings adopts modular manufacturing + on-site assembly. Before leaving the factory, the steel is processed by CNC cutting, bending, drilling and welding, and sandblasted, anti-corrosion coating or galvanized to enhance durability. Transportation Phase: Once the components are ready, we classify and pack according to the construction sequence, and use modular packaging to ensure that the components are not damaged during transportation.

- Installation Phase: While we do not provide on-site installation, we offer remote guidance and technical support throughout the installation process. Our team guarantees that you receive the necessary information and support to install your prefabricated building with assurance.

Maintenance and Longevity of Prefabricated Buildings

One of the key benefits of prefabricated steel buildings is their durability and low maintenance requirements. Nonetheless, similar to any construction, regular upkeep is vital for preserving their lifespan. We recommend:

Routine Inspections

Carrying out periodic inspections to scrutinize for any signs of wear and tear, particularly in heavily used areas or those exposed to severe weather conditions. This proactive approach aids in detecting potential issues promptly, thereby averting larger problems in the future.

Simple Repairs

Steel buildings are resistant to many common issues like rot, termites, or extreme weather, but minor repairs may be needed occasionally, such as repainting to prevent rust or fixing damaged panels. These repairs are typically quick and inexpensive.

Long-Term Performance

With proper care, a steel building can last for several decades. SteelPRO PEB offers long-term maintenance support and ensures that all materials used in the construction are of the highest quality, extending the life of the building.

By partnering with SteelPRO PEB, you’re not merely investing in a building; you’re safeguarding its optimal condition for many years ahead. Our after-sales support and maintenance services are tailored to provide you with assurance, knowing that your investment is secured for the long haul.

Comparison between Prefabricated Steel Structures and Other Building Types

| Comparison Criteria | Prefabricated Steel Structure | Traditional Concrete Building | Brick-Masonry Structure | Light Wood Structure | Precast Concrete Structure |

|---|---|---|---|---|---|

| Construction Speed | Factory prefabrication, rapid on-site assembly, short construction period | On-site pouring and curing take a long time, extended construction period | On-site masonry, extensive wet work | Fast construction but highly weather-dependent | Factory-produced precast components, on-site assembly |

| Structural Weight | Lightweight and high strength, reducing foundation costs | Heavyweight, high foundation requirements | Heavyweight, high foundation requirements | Lightweight, low foundation requirements | Heavyweight, high foundation requirements |

| Durability | Requires anti-corrosion treatment, but has a long lifespan | Good corrosion resistance, but weaker seismic performance | Good durability but vulnerable to earthquakes | Prone to moisture and pests, requires special treatment | Highly durable but complex crack repairs |

| Construction Environmental Impact | Less pollution on-site, recyclable materials | Generates a lot of dust, noise, and construction waste | Generates a large amount of waste on-site | Sustainable timber, but deforestation affects ecology | Reduces wet work, but transportation costs are high |

| Application | Suitable for industrial plants, large-span buildings | Suitable for high-rise buildings and residential structures | Suitable for low-rise residential and small commercial buildings | Suitable for residential and small-scale buildings | Suitable for high-rise buildings, bridges, etc. |

What is an example of prefabrication?

Prefabricated steel buildings have gained popularity due to their durability, cost-effectiveness, and quick construction times. Here are some famous examples of prefabricated steel buildings around the world:

1. The Eiffel Tower (Paris, France)

Although not a building in the traditional sense, the Eiffel Tower is a famous example of prefabricated steel construction. Gustave Eiffel’s company prefabricated the iron components off-site, which were then assembled on-site in just over two years.

3. The Crystal (London, UK)

Part of the Royal Victoria Docks, The Crystal is a sustainable cities initiative by Siemens. It is a striking example of a prefabricated steel structure designed to be energy-efficient and environmentally friendly.

4. The Sydney Opera House (Sydney, Australia)

While primarily known for its iconic concrete shells, the Sydney Opera House also features significant steel components that were prefabricated and assembled on-site. The steel roof structure was a critical part of the design.

5. The Hearst Tower (New York, USA)

This skyscraper is a modern example of prefabricated steel construction. The Hearst Tower’s diagrid steel frame was prefabricated off-site, allowing for faster and more efficient construction.

6. The Beijing National Stadium (Beijing, China)

Also known as the “Bird’s Nest,” this stadium was constructed for the 2008 Olympics. Its intricate steel framework was prefabricated and then assembled on-site, creating one of the most recognizable structures in the world.

Future Trends in Prefabricated Steel Buildings

The future of prefabricated steel buildings looks bright with several exciting trends shaping the industry:

- Technology and Automation: The use of advanced robotics and AI in manufacturing processes will lead to even more precise and cost-effective production. This will enhance design capabilities and reduce lead times.

- Sustainability: With increasing demand for green building practices, steel buildings are expected to become even more eco-friendly. Advancements in steel recycling and the incorporation of energy-efficient materials will further diminish the carbon footprint.

- Smart Buildings: The incorporation of intelligent technologies, including IoT sensors for monitoring building performance, is anticipated to expand. These technologies will enhance energy efficiency, maintenance operations, and overall building performance.

SteelPRO PEB remains at the vanguard of these innovations, utilizing novel materials and state-of-the-art technology to bolster the performance and sustainability of our offerings.

Prefabricated Steel Building Supplier

SteelPRO PEB offers a diverse range of prefabricated steel buildings, encompassing industrial, commercial, agricultural, long-span, modular, and residential designs. Regardless of the size or scope of your project, SteelPRO PEB’s team will guide you through every step, from initial design to final delivery. Each structure is designed with the highest quality materials to ensure durability and energy efficiency, and is completed on time, within your budget, and to the highest standards.

FAQs

1. How long do prefabricated steel buildings last?

With adequate maintenance, prefabricated steel buildings can endure for 50 years or longer. Steel’s exceptional resistance to corrosion, pests, and weather-induced damage guarantees long-lasting durability.

2. How do I choose the right steel building design?

Our team can assist you in selecting the right design based on your specific needs, whether for residential, commercial, or industrial use. Key factors include building size, function, climate conditions, and budget.

3. Do prefabricated steel buildings require special maintenance?

No. Steel buildings require minimal maintenance. Regular inspections for rust or damage, cleaning of exterior surfaces, and checking the roof for leaks are usually sufficient to maintain their integrity.

4. Can prefabricated steel buildings be customized?

Yes. Steel buildings are highly customizable, from structural layout to finishes like doors, windows, insulation, and more. SteelPRO PEB works with you to create a building that meets your specific requirements.

5. What is the difference between pre-engineered and prefabricated buildings?

Pre-engineered buildings (PEBs) are custom-designed steel structures where all components are manufactured off-site for efficient assembly. Prefabricated buildings is a broader term that includes any structure with pre-made components, including steel, concrete, and modular buildings. PEBs are a type of prefabrication, but not all prefabricated buildings are PEBs.

6. What is the difference between PEB and steel structures?

PEBs are factory-designed, lightweight, and optimized for fast assembly, mainly used in warehouses and factories. Conventional steel structures (CSS) are built on-site with manually fabricated steel elements, offering more flexibility but requiring more time and labor.

7. What is the difference between precast and prefabricated construction?

Precast construction refers specifically to concrete components made off-site and assembled on-site. Prefabricated construction is a broader category, including precast concrete, steel structures, and modular buildings. All precast is prefabricated, but not all prefabrication involves precast concrete..