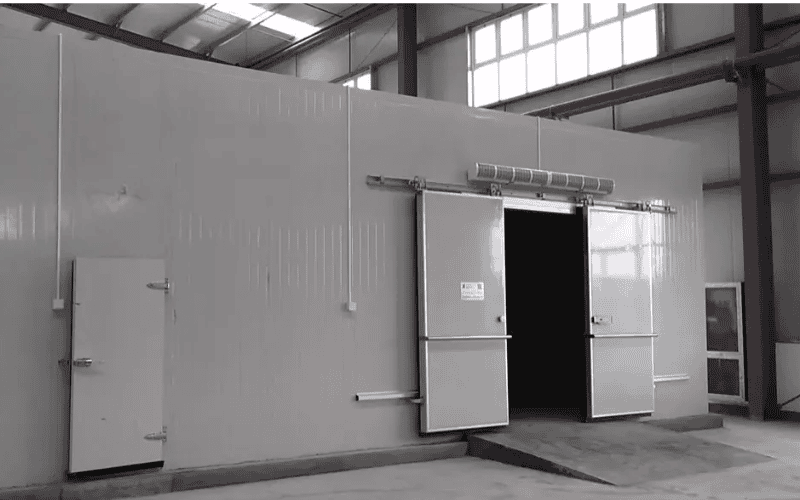

Cold storage facilities are temperature-controlled warehouses designed to store temperature-sensitive products such as fresh food, pharmaceutical products, and other perishable goods.

These facilities are an integral part of the cold chain that ensures the preservation of products from production to delivery, maintaining cold temperatures and preventing product spoilage. As demand for cold storage continues to rise, businesses need reliable cold storage warehousing partners to meet the growing needs of the cold storage market.

The operating principle of the refrigeration facility

The refrigeration system compresses, condenses, expands and evaporates the refrigerant; the insulation structure reduces heat exchange; the control system monitors temperature and humidity; the control system monitors temperature and humidity; and ensures that the air circulation temperature is uniform.

Types of Cold Storage Warehouses

Cold storage facilities are diverse in nature, tailored to meet various temperature needs and serve distinct purposes. They can be categorized based on temperature range, ownership structure, and operational models.

Classification by Temperature Range

- Refrigerated Warehouses

- Temperature Range: 2 – 8°C (35 – 55°F)

- Suitable Products: Fresh produce, dairy products, meats, seafood, etc.

- How It Works: Refrigerated warehouses maintain a controlled low temperature environment to hinder microbial growth and decelerate chemical reactions, thus prolonging the shelf life of stored products.

- Temperature Range: 2 – 8°C (35 – 55°F)

- Frozen Warehouses

- Temperature Range: -18 – -25°C (0 – -20°F)

- Suitable Products: Frozen foods, meats, seafood, etc.

- How It Works: Frozen warehouses operate at extremely low temperatures, freezing the moisture inside products, which almost entirely halts microbial activity and chemical reactions, ensuring long-term preservation.

- Temperature Range: -18 – -25°C (0 – -20°F)

- Ultra-Low Temperature Cold Storage

- Temperature Range: As low as -80°C (-112.8°F)

- Suitable Products: Temperature-sensitive biological samples, specific vaccines, etc.

- How It Works: Ultra-low temperature storage ensures the stability of sensitive biological materials and certain pharmaceuticals by maintaining extreme cold conditions.

- Temperature Range: As low as -80°C (-112.8°F)

Classification by Ownership and Operational Model

- Private Cold Storage

- Owner/Operator: Owned and operated by the business that produces or uses the stored goods

- Features: Private cold storage is often connected to a company’s manufacturing facility, providing direct control over storage and inventory management. While it offers full control and flexibility, the construction and operational costs tend to be higher. This model is suitable for companies with high storage needs that require more personalized management and quality control.

- Owner/Operator: Owned and operated by the business that produces or uses the stored goods

- Public Cold Storage

- Owner/Operator: Owned and operated by third-party logistics (3PL) providers

- Features: Public cold storage facilities provide services to multiple customers, often reducing costs through shared resources. This model provides flexibility and cost-effectiveness, making it a favored option in the United States. Firms that prefer not to invest in constructing their own storage facilities can outsource their cold storage requirements to these third-party providers.

- Owner/Operator: Owned and operated by third-party logistics (3PL) providers

Other Specialized Types

- Refrigerated Containers

- Features: Portable, small-scale cold storage units equipped with refrigeration systems, typically with a temperature range of -30°F to 70°F.

- Suitable Applications: These containers are commonly used for temporary storage during transportation or for small-batch storage. Their flexibility and customization options make them ideal for short-term cold storage needs, whether in transit or for on-site use.

- Features: Portable, small-scale cold storage units equipped with refrigeration systems, typically with a temperature range of -30°F to 70°F.

- Blast Freezers

- Features: Blast freezers use high-velocity air to rapidly lower the temperature of products.

- Suitable Applications: These are especially useful in the food industry, where products like seafood and baked goods need to be quickly frozen. The rapid freezing process aids in preserving the nutritional content, texture, and taste of the products, ensuring their quality remains intact for an extended period.

- Features: Blast freezers use high-velocity air to rapidly lower the temperature of products.

- Controlled Atmosphere Storage

- Features: This storage method modifies the levels of oxygen, carbon dioxide, humidity, and temperature to establish an optimal environment tailored for specific products.

- Suitable Applications: Controlled atmosphere storage is predominantly utilized for agricultural products, especially fruits and vegetables. By carefully regulating these environmental factors, it substantially prolongs the shelf life of perishable goods, maintaining their freshness and market value over extended periods.

- Features: This storage method modifies the levels of oxygen, carbon dioxide, humidity, and temperature to establish an optimal environment tailored for specific products.

Cold Storage Facility Applications

Cold storage plays a key role in many industries where maintaining specific temperatures and conditions is crucial for product quality.

Food and Beverage Industry

Cold storage ensures fresh products like fruits, vegetables, meats, dairy, and frozen foods stay safe and fresh by controlling temperature and slowing down spoilage processes.

Pharmaceutical and Medical Industry

Temperature-sensitive items like vaccines, medicines, and biological samples require strict cold storage to maintain their efficacy and safety. Compliance with regulations such as GMP and GDP is essential.

Floriculture and Horticulture Industry

Cold storage extends the shelf life of flowers, plants, and bulbs, keeping them fresh for transportation and sale, preserving their color and quality.

Other Industries

- Electronics: Shields sensitive components from harm induced by fluctuations in temperature and humidity.

- Specialty Chemicals: Guarantees the stability of chemicals, preventing reactions that may lead to product degradation.

- Art and Antiques: Maintains the condition of valuable items like artwork, musical instruments, and antiques by controlling temperature and humidity.

Cold Storage Challenges & Requirements

- Temperature-controlled: Ensure that the temperature is always maintained within the specified range (usually 2-8°C) and have the ability to respond quickly to temperature fluctuations.

- Efficient refrigeration system: Use efficient and energy-saving refrigeration equipment to ensure stable temperature and reduce energy consumption. The system should be maintained regularly to ensure long-term stable operation.

- Good insulation design: Use high-quality insulation materials, such as polyurethane foam, to prevent external heat from entering and reduce energy consumption.

- Humidity control: Humidity control is also crucial for some foods or products, especially items that are easily affected by humidity, such as fruits, vegetables, and flowers.

- Ventilation system: Reasonable air circulation ensures uniform temperature distribution and avoids excessive or low temperatures in certain areas, which affects the quality of stored products.

- Sanitation and cleaning: Strict hygiene standards, regular cleaning of the warehouse interior, to prevent pollutants, mold, etc. from affecting stored items.

- Safety and monitoring system: Install temperature monitoring systems and alarm devices to ensure that abnormal temperatures can be detected and measures can be taken in time to avoid losses.

- Shelves and storage layout: Design a reasonable shelf layout to ensure that products are easy to access, while avoiding excessive stacking that affects air circulation.

Factors to Consider When Choosing a Cold Storage Facility

When selecting a cold storage facility, several key factors must be taken into account to ensure that it meets the specific needs of your products and business. Here’s a breakdown of the most important considerations:

Temperature Control Capability

- Precise Temperature Requirements: A good cold storage facility should be able to consistently maintain the specific temperature your products need, whether it’s for food, pharmaceuticals, or other temperature-sensitive goods.

- Stability and Reliability: It’s not just about having the right temperature, but also ensuring that it remains stable. Facilities with advanced monitoring and adjustment systems help prevent temperature fluctuations, protecting your products from potential spoilage.

- Our cold storage units are made from high-density polyurethane foam for excellent insulation. Panels are designed to minimize thermal bridges, prevent heat loss and ensure that the temperature is maintained evenly throughout the storage space.

Storage Capacity and Flexibility

- Meeting Current and Future Needs: The facility should have enough space to store your products, not just for now, but also as your business grows.

- Layout and Capacity Flexibility: A flexible storage solution is essential to accommodate changing storage requirements over time. Our modular cold storage is designed to be easily expandable and adaptable. It can be configured to handle different temperature zones, from refrigerated to frozen storage.

Location and Transportation Accessibility

- Proximity to Production and Customers: A good location is crucial for reducing transportation time and costs, ensuring timely delivery to customers.

- Proximity to Transportation Hubs: Being close to major transportation hubs—such as ports, airports, and highways—ensures efficient logistics and helps reduce delays or temperature fluctuations during transit.

- Our modular steel cold storage can be easily deployed near key transport routes, improving access and reducing logistics costs.

Facility and Equipment

- Advanced and Reliable Equipment: The facility should be equipped with top-notch refrigeration systems, insulation materials, shelving, and handling equipment to maintain optimal storage conditions.

- Regular Maintenance: It’s essential that the facility is regularly maintained to ensure everything works smoothly and to extend the lifespan of the equipment.

- Our modular cold storage units are designed with high-quality components and are easy to maintain, offering reliability and long-term performance.

Services and Value-Added Features

- Basic Services: Basic services like inventory management, order processing, and stock tracking are essential for smooth operations.

- Value-Added Services: Supplementary services, including packaging, labeling, quality control, and excellent customer support, can bolster the efficiency of your cold storage operations.

- With our modular cold storage, you get not only reliable storage but also the flexibility to integrate additional services tailored to your specific business needs.

Compliance and Certification

- Regulatory Compliance: Cold storage facilities must comply with industry regulations, especially in sectors like food, pharmaceuticals, and chemicals, where temperature control is a safety and quality issue.

- Certification Requirements: Certifications such as Hazard Analysis and Critical Control Points (HACCP) and ISO standards ensure that the facility meets international best practices and safety standards.

- Our modular cold storage units are designed to meet stringent industry standards and certifications, helping you maintain compliance and ensure product safety.

Cost-Effectiveness

- Comprehensive Cost Considerations: When evaluating cold storage, it’s essential to consider not just storage fees, but also transportation costs and any additional service fees.

- Cost Optimization: Aim to optimize costs while ensuring that your storage needs are fully met. Our modular cold storage offers a cost-effective solution, with flexible capacity and scalability, allowing you to only pay for what you need while minimizing overhead.

Selecting the appropriate cold storage facility necessitates thorough consideration of temperature control, adaptability, location, services offered, and cost. By opting for our modular cold storage solutions, you can enjoy precise temperature control, scalability, and cost efficiency, all while ensuring your products are stored safely and efficiently.