The demand for cold storage is growing fast, driven by industries like food, pharmaceuticals, and logistics that need reliable, efficient ways to store temperature-sensitive goods. With global trade booming and customers expecting fresher products, businesses are looking for smarter storage solutions. Pre-engineered steel buildings (PEB) are becoming the go-to choice for cold storage, offering strength, cost-efficiency, and fast build times. Modular designs are especially popular, giving businesses the flexibility to grow as their needs increase.

In this article, we’ll walk you through why PEB cold storage is a game-changer – from durability and energy efficiency to scalability. Ready to see how this can work for you? Keep reading to find out!

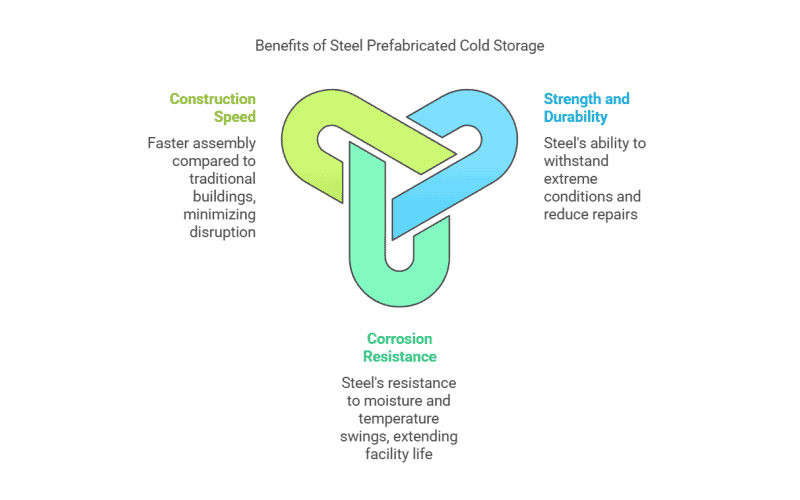

Advantages of Using Steel Structure Prefabricated Cold Storage

Looking for a faster, stronger, and more reliable solution for your cold storage needs? Steel prefabricated buildings are here to transform your approach to temperature-sensitive storage.

Strength and Durability

Steel structures are tough – they can bear more weight and handle extreme temperatures better than traditional materials, making them perfect for cold storage. This strength ensures your warehouse stays solid, no matter the conditions, and cuts down on expensive repairs over time. A steel building is an investment that pays off for years.

Corrosion Resistance

One of steel’s best qualities is its resistance to corrosion, which is crucial in cold storage environments where moisture and temperature swings are common. Thanks to coatings and galvanizing, steel buildings hold up beautifully over decades, saving you on maintenance and extending the life of your facility.

Construction Speed

With prefabricated steel systems, construction is a breeze. They can be assembled much faster than traditional buildings, often slashing build time by up to 50%. That means less disruption and quicker operation – getting you up and running in no time.

Choosing the Right Location for Your Cold Storage Facility

Before designing your cold storage warehouse, it’s important to first consider the location. The key is ensuring compliance with local laws and securing all necessary permits. This sets a solid foundation for the project. Once that’s done, here are a few things to keep in mind:

Accessibility and Transportation

Being close to major transport hubs like highways, railways, or ports makes moving goods much easier and more cost-effective. A well-connected location helps lower transportation costs, speeds up delivery times, and reduces the risks associated with long-distance shipping.

Proximity to Clients and Suppliers

Choosing a location near your main customers and suppliers is a smart move. It cuts down on logistics costs, helps you meet customer demands more quickly, and keeps your supply chain running smoothly. The closer you are to key partners, the more efficient your entire operation becomes.

With the right location, your cold storage facility can work harder for you, improving both efficiency and profitability. Next, let’s explore our cold storage design philosophy to see how we can make your project even more successful.

Modular Design and Flexibility for Cold Storage

Want a more efficient, flexible cold storage solution? Modular design is the way to go. Here’s how it works for you.

Efficient Production and Quality Control

Our modular cold storage systems feature precision-engineered steel structures designed for temperature-controlled environments. Pre-punched connections and custom-fit frames enable quick assembly with airtight performance.

Each module is structurally load-tested to support refrigeration, shelving, and goods. With defect rates below 0.05% and assembly 80% faster than traditional methods, these systems offer fast, reliable cold storage solutions.

Scalability and Flexibility

The steel structure’s modular design enables flexibility in cold storage configuration and expansion. Key design features include:

- Pre-fabricated Steel Frames: Standardized steel modules can be connected horizontally or vertically, supporting multi-tier storage or future facility expansions without structural compromise.

- Load-Bearing Capacity: Each steel frame is designed to handle heavy insulation panels and shelving systems while maintaining structural stability. For example, a single frame can support up to 50 tons of distributed load, ideal for high-density storage solutions.

This approach allows businesses to adjust their cold storage size and layout based on operational demands, all while ensuring structural integrity.

Optimized Functional Zones

The modular steel design supports customized zoning through innovative structural features:

- Partition Walls: Steel columns and beams enable the integration of insulated partitions without compromising overall strength. This allows for different storage zones within the same building, such as fresh produce or frozen goods areas.

- High Clearance Designs: Steel frameworks can be tailored to provide ceilings of up to 12 meters, maximizing vertical storage space for pallet racks or automated storage systems.

- Energy-Saving Roof Structures: The steel roofing system incorporates pre-engineered slope designs, improving insulation coverage and minimizing thermal transfer, leading to up to 20% energy savings compared to traditional flat roofs.

These structural elements ensure your cold storage facility is not only functional but also efficient, durable, and easily adaptable for future growth.

Optimization of Prefabricated Cold Storage Space Layout

Peb steel sections can be rearranged to create open spans of up to 30 meters, accommodating large storage areas or partitioned functional zones as required.

Column-Free Spaces

Steel frames provide wide, open areas without interior columns, allowing cold storage facilities to maximize usable space. These column-free zones are especially beneficial for large-scale cold storage, where seamless maneuvering of forklifts or pallet jacks is essential for loading and unloading goods. It also makes it easier to install high-density shelving or racking systems for both refrigerated and frozen products.

Functional Zoning

Carefully planned layouts can divide cold storage into dedicated zones for refrigeration, freezing, and buffering. By separating cold storage areas (e.g., 4°C zones for fresh produce) from freezing zones (e.g., -18°C for frozen goods), you can optimize energy efficiency and prevent cross-contamination. Adding a buffer area between loading docks and cold rooms minimizes temperature fluctuations during operations, ensuring consistent product quality.

Multi-Level Designs

For facilities with limited land, steel structures make it easy to create multi-level cold storage solutions. Vertical expansion increases storage capacity, allowing for separate temperature zones on different levels or additional areas for administrative tasks. This approach not only maximizes land use but also reduces operational costs by consolidating storage into one building.

Auxiliary Spaces

Cold storage facilities can also benefit from incorporating auxiliary spaces such as staff offices, equipment rooms, and repair areas within the same steel structure. These spaces can be strategically located adjacent to cold storage zones for convenience while maintaining energy efficiency. For instance, placing staff areas near buffer zones reduces exposure to cold environments and improves workflow.

With these design optimizations, your prefabricated cold storage facility will support efficient operations, minimize energy costs, and provide the flexibility to adapt to future needs.

Wall System and Insulated Panel Design

Efficient wall insulation is the backbone of a reliable cold storage facility, keeping temperatures stable while saving energy.

Efficient Insulation System

Our wall systems use high-performance insulated panels, like polyurethane (PU) foam and mineral wool, to maintain stable internal temperatures in cold storage. PU panels, tested to reduce thermal transfer by up to 40% compared to traditional materials, ensure consistent cooling and energy efficiency under demanding conditions.

Energy Savings and Cost Control

The low thermal conductivity of expanded polystyrene (EPS) foam and mineral wool further boosts energy efficiency and reduces operational costs. By minimizing heat leakage, these panels help businesses maintain consistent temperatures while cutting energy expenses, making them a cost-effective choice.

Quick Installation and Maintenance

Prefabricated insulated panels allow for rapid, modular installation, saving time without compromising quality. Durable materials like PU and mineral wool extend the building’s lifespan and simplify maintenance, ensuring fewer repairs and reliable cold storage for years.

These insulated panels help cold storage facilities maintain consistent temperatures, reduce energy consumption, and extend the lifespan of the structure, ensuring reliable performance for years to come.

Comparison between Prefabricated Cold Storage and Traditional Cold Storage

The table below compares the key differences between prefabricated cold storage and traditional cold storage in terms of construction speed, flexibility, and quality.

| Aspect | Prefabricated Cold Storage | Traditional Cold Storage |

| Construction Process | ||

| Build Speed | Prefabricated modules are factory-made in 2–3 weeks; on-site assembly takes 1–2 months, reducing total time. | Built entirely on-site; 500 m³ facility may take 3–6 months due to complex processes like concrete pouring. |

| Difficulty & Quality | Factory-controlled production ensures precision (e.g., wall panel tolerance ±2mm). Simple assembly on-site. | Weather and manual work impact quality; complex coordination increases difficulty and risk of errors. |

| Space Utilization | ||

| Layout Flexibility | Modules can be added for expansion or reconfiguration, e.g., adjusting storage/freezing zones. | Fixed layout; altering zones requires demolition and reinstallation, making changes costly and time-intensive. |

| Space Efficiency | Efficient design allows for 70–80% utilization with adjustable shelving systems. | Structural limitations result in dead spaces near walls and columns, achieving only 60–70% utilization. |

| Refrigeration System | ||

| Installation & Maintenance | Integrated systems tested in the factory for faster, simpler installation. Modules can be replaced easily. | Installed on-site with complex piping; repairs may require breaking structures, causing long downtimes. |

| Cooling Efficiency | Uniform insulation quality (thermal conductivity 0.02–0.03W/m·K); advanced systems save 15–20% energy. | Inconsistent insulation leads to energy loss; traditional systems are less efficient, consuming more power. |

| Costs | ||

| Initial Cost | Higher initial cost (10–20% more) due to advanced materials and factory assembly. | Lower initial cost with traditional materials and on-site construction. |

| Operating & Lifecycle Cost | Lower long-term costs due to energy savings and durability (20–30 years lifespan). | Higher energy and maintenance costs over 15–20 years lifespan. |

Choose Us to Build Your Peb Cold Storage Building

Prefabricated steel cold storage building combine efficient construction, flexible space design, and high-performance insulation, making them perfect for modern storage needs. They provide reliable temperature control, energy savings, and long-term durability to handle dynamic industry demands.

Unlike traditional cold storage, our prefabricated solutions are built faster and fully tested. We test the refrigeration system at our factory, ensuring it’s ready on arrival. This avoids on-site system failures and repair delays common with traditional builds. Let us create a smarter, more efficient cold storage solution for you.

Let us help you create a smarter, more efficient cold storage solution tailored to your needs!