A well-designed steel beam can safely span 20 meters or more, but achieving that distance requires precise engineering.

Span capacity depends on several key factors, including beam type, depth ratio, load distribution, and support spacing. In modern pre-engineered steel buildings (PEB), factory-fabricated beams and trusses allow for efficient, column-free interiors with spans reaching 20–40 meters.

This guide explains which factors determine span performance, the benefits and beam types best suited for 20m+ applications, and key engineering considerations for achieving strength, efficiency, and precision in factory-engineered steel structures.

Factors That Affect How Far a Steel Beam Can Span

The maximum span of a steel beam depends on several technical and design factors that influence strength, stiffness, and cost efficiency. Engineers evaluate these parameters to determine whether a beam can safely cover 10 meters, 20 meters, or even beyond without intermediate supports.

Beam Type and Material

Different beam materials—such as mild steel, structural steel, or composite beams—have distinct load capacities. For large-span applications (20m+), I-beams, H-beams, and truss beams are preferred because they provide higher bending resistance while keeping weight manageable.

Load Conditions

The amount and type of load—dead, live, wind, or seismic—directly affect how far a beam can span. Industrial structures often require beams that can resist heavy dynamic loads, while commercial or residential buildings might prioritize lighter span solutions.

Support Method

Simply supported, continuous, or cantilevered beams each distribute forces differently. A continuous beam can span longer distances than a single-span beam of the same section due to load redistribution.

Beam Depth and Section Size

As a general rule, the deeper the beam, the greater its span capacity. Engineers often follow a span-to-depth ratio of about 1:20 — meaning a 20-meter beam should be roughly 1 meter deep for optimal performance and deflection control.

Engineering Design and Software Tools

Modern design software such as STAADPRO, TEKLA, and ETABS, used by professional steel structure manufacturers, enables precise modeling, load simulation, and deflection analysis to ensure beam efficiency and safety.

Manufacturing Quality

Precision cutting, welding, and alignment are critical. Factory-engineered beams—produced under strict ISO and CE quality systems—ensure consistency and accuracy, especially for large-span projects where small deviations can lead to significant structural effects.

Benefits of Using Large-Span Beams (Over 20m)

Large-span steel beams offer significant advantages in both design flexibility and structural efficiency, especially for modern industrial, commercial, and logistics buildings where wide, open areas are essential. By reducing the need for intermediate columns, they help create unobstructed, functional spaces that enhance usability and workflow efficiency.

Greater Design Freedom and Space Utilization

With fewer internal supports, architects and engineers can design open layouts ideal for factories, warehouses, gymnasiums, and showrooms. This allows large equipment, production lines, and customer spaces to operate freely under a single-span roof.

Cost Efficiency and Faster Construction

Fewer columns mean simpler foundations and lighter structural systems, resulting in lower material and labor costs. Pre-engineered and factory-fabricated beams also minimize on-site work, cutting project timelines and ensuring precise fit-up during installation.

Structural Strength and Stability

Large-span beams distribute loads evenly, providing strong resistance to bending, vibration, and wind. Engineered steel sections—such as H-beams or trusses—are optimized to balance weight and load capacity, maintaining safety even under demanding conditions.

Sustainability and Longevity

Modern steel beams are produced from recyclable and low-waste materials, aligning with green building standards. When properly coated and maintained, they offer a service life of 50 years or more with minimal corrosion or maintenance costs.

Integrated Design and Fabrication Advantage

When beams are factory-engineered under ISO and CE-certified processes, quality control is consistent from cutting to welding. This integration ensures accuracy, durability, and long-term cost savings—especially for PEB (Pre-Engineered Building) projects where span precision is critical.

5 Types of Large-Span Beams and Their Key Features

Selecting the right beam type is essential for ensuring both strength and cost-efficiency in long-span building design. The choice depends on the required span length, building function, and project budget. Below are the five most common beam types used for spans of 10 to 30 meters—each suited for different industrial, commercial, and PEB structure applications.

Composite Beams with Web Openings

Composite beams combine steel and concrete to achieve excellent bending resistance and stiffness. When designed with web openings, they allow HVAC, plumbing, and electrical systems to pass through the structure—reducing floor depth and improving integration efficiency.

- Applications: Industrial buildings, office complexes, and bridges requiring service integration within limited height.

- Typical Span: 15–30 meters

- Advantages: Reduced floor height, efficient material use, compatible with modular and prefabricated construction.

- Manufacturing Note: Factory-fabricated composite beams ensure precise web cutting and alignment, minimizing installation time on site.

Cellular Beams

Cellular beams feature evenly spaced circular or hexagonal holes along the web, reducing weight while maintaining structural strength. Their lightweight, high-efficiency design makes them ideal for wide-span roofs and architectural structures.

- Applications: Warehouses, stadiums, and steel-framed commercial halls.

- Typical Span: 20–35 meters

- Advantages: Lightweight, aesthetic, easy to integrate with ducts and lighting systems.

- Manufacturing Note: Produced using CNC cutting and automated welding systems to achieve consistent geometry and hole precision.

Prestressed Concrete Beams

Prestressed concrete beams use pre-applied compressive stress to handle large spans and heavy loads effectively. They are preferred in areas where concrete is locally available and where maintenance access is limited.

- Applications: Bridges, high-rise podiums, parking structures.

- Typical Span: 15–30 meters

- Advantages: Excellent compressive performance, minimal deflection, long service life.

- Consideration: Heavier than steel options and require precise on-site installation.

Steel Truss Beams

Steel truss beams are designed with triangular configurations that efficiently distribute loads across long spans. They are widely used in industrial workshops, sports arenas, and warehouses, offering high strength-to-weight ratio and flexibility in design.

- Applications: PEB workshops, logistics centers, aircraft hangars, gymnasiums.

- Typical Span: 20–50 meters

- Advantages: Long-span capacity, low weight, modular fabrication possible.

- Manufacturing Note: Truss systems are typically prefabricated in sections, allowing faster on-site assembly and precise fit-up under factory-engineered standards (ISO/CE).

Hybrid Beams (Steel–Concrete Combinations)

Hybrid beams combine the tensile strength of steel with the compressive strength of concrete, making them ideal for multi-storey or mixed-use buildings requiring both span and stiffness.

- Applications: Office towers, large commercial complexes, bridge decks.

- Typical Span: 10–25 meters

- Advantages: Balanced load distribution, reduced vibration, aesthetic flexibility.

- Manufacturing Note: These beams are custom-engineered per project, integrating steel cores with concrete decking for optimal performance.

Summary Insight

For 20m+ single-span structures, steel truss and cellular beams are the most efficient solutions, combining light weight, factory-controlled quality, and ease of erection. When engineered and fabricated under certified standards, these systems deliver consistent results across industrial and commercial applications.

Key Considerations When Using Large Span Beams

Designing and constructing large-span steel beams requires more than just strength—it’s about achieving the right balance between safety, cost, manufacturability, and long-term performance. Each design decision, from material selection to span ratio, directly affects how efficiently a structure performs. The following key considerations provide practical guidance for projects using 20m+ steel spans in industrial, commercial, or prefabricated building applications.

Building Codes and Standards

All large-span beam designs must comply with regional and international codes to ensure structural integrity and safety.

- Common Standards: AISC 360, Eurocode 3, GB 50017, ASCE 7, and ISO 9001.

- Design Software Integration: Engineers typically use TEKLA, STAADPRO, and ETABS to simulate loads and verify compliance.

- Practical Insight: For export projects, align both local (e.g., Eurocode) and manufacturing standards (e.g., ISO / CE) early to prevent fabrication mismatches.

PEB manufacturers like SteelPRO PEB ensure all beams are factory-engineered to meet these dual standards—streamlining international project delivery.

Building Type and Functional Requirements

Different structures demand different beam configurations:

- Industrial Buildings: Favor large single spans (20–40m) using trusses or welded H-beams to accommodate cranes and open work areas.

- Commercial Spaces: Require wide, column-free interiors for retail or exhibition layouts—cellular beams work best for aesthetic integration.

- Residential or Institutional: Often use smaller composite beams for strength without bulk.

Matching beam type to building use improves both cost-efficiency and structural performance.

Structural Type and Load Behavior

The material and cross-section type determine how a beam handles tension, compression, and deflection:

- Steel I/H-Beams: Excellent for high bending strength and reduced self-weight.

- Truss Beams: Best for ultra-long spans (20–50m) with minimal deflection.

- Composite Beams: Balance stiffness and sound insulation for multi-storey use.

To optimize performance, engineers model how live loads (people, machinery) and dynamic loads (wind, seismic) interact with span geometry.

Factory-engineered precision in welding and assembly ensures consistent load distribution—critical for long-span reliability.

Beam Depth and Cost Efficiency

Beam depth directly affects both material use and cost:

- Rule of Thumb: Span-to-depth ratio ≈ 20:1 → A 20m span beam ≈ 1m depth.

- Economics: Deeper beams can carry more load per unit weight, lowering total steel usage.

- Design Strategy: For PEB structures, use tapered or variable-depth beams to minimize waste while maintaining strength.

Optimized beam depth not only saves materials but also simplifies fabrication and transport.

Cantilever Design Principles

For structures that extend outward without full support—such as canopies, mezzanines, or projection roofs—cantilever proportioning is critical.

- General Rule: Cantilever length ≤ 1/3 of total beam span.

- Example: For a 30m beam, cantilever should not exceed 10m.

- Safety Check: Use reinforced flanges and additional bracing at the fixed end to counterbalance bending moments.

Precision welding and alignment during factory fabrication ensure cantilever beams maintain stability under live load variations.

Beam Span vs. Support Spacing

The distance between supporting columns or walls determines how far a beam can span safely and efficiently. Wider spacing increases the required beam depth and section size, which affects both cost and material weight.

- Design Insight: For a 20m beam, supports are often placed at 6m–10m intervals, depending on live loads and beam type.

- Column Optimization: Proper column spacing reduces deflection and material usage across the entire frame.

- Engineering Tip: Align span and support layout early in design—this helps factory engineers pre-cut and pre-drill components for precise on-site assembly.

In PEB structures, optimizing support spacing through 3D modeling reduces installation errors and improves load balance.

Recommended Span-to-Depth Ratios

Beam proportions directly affect performance and cost. The span-to-depth ratio defines how deep a beam should be relative to its length to prevent excessive deflection.

| Beam Type | Typical Span-to-Depth Ratio | Example (20m Span) |

| Steel I-Beam | 20:1 | 1.0 m depth |

| Truss Beam | 25–30:1 | 0.7–0.8 m equivalent depth |

| Composite Beam | 18:1 | 1.1 m depth |

Maintaining the correct ratio ensures efficient material use while meeting deflection limits (typically L/360 to L/500).

Factory simulation tools like STAADPRO and TEKLA help engineers verify optimal span-to-depth ratios before fabrication.

Size and Tolerances

Precision is critical in long-span fabrication. Even small dimensional deviations can lead to misalignment or load imbalance during assembly.

- Tolerances: Typically ±2mm for beam flanges and ±3mm for web alignment in certified steel manufacturing.

- Quality Assurance: Automated CNC cutting and laser measurement ensure each component fits perfectly during site installation.

- Why It Matters: Tight tolerances reduce on-site correction, welding stress, and deflection under load.

All SteelPRO beams undergo dimensional inspection before delivery—ensuring reliable fit-up across large-span assemblies.

Aspect Ratio and Stability

The aspect ratio (span-to-height proportion) greatly influences deflection and vibration performance. A higher ratio (e.g., very long but shallow beam) may lead to lateral buckling.

- Ideal Range: 15:1 to 25:1 for most steel spans.

- Correction Methods: Add lateral bracing or increase section modulus.

- Design Note: For slender beams, structural engineers often combine open-web trusses with solid flanges for enhanced stability.

In long-span warehouses or gymnasiums, maintaining correct aspect ratios ensures the structure resists lateral sway and fatigue over decades.

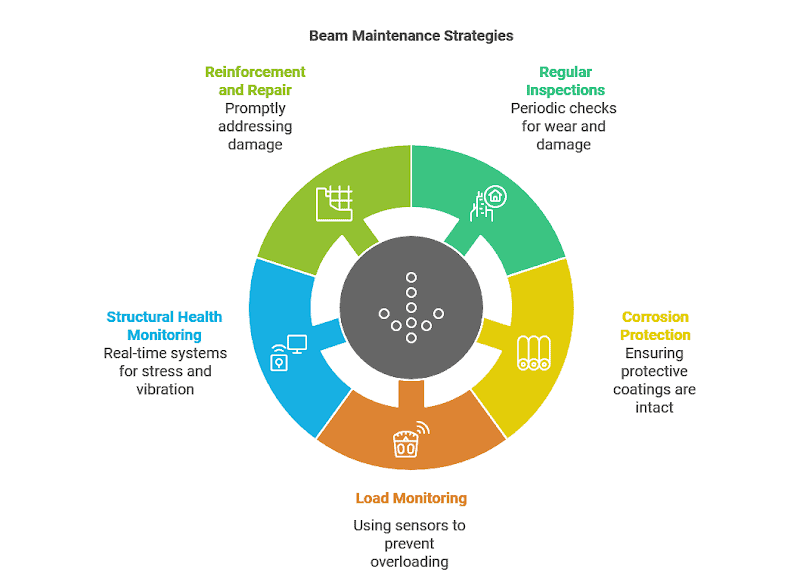

Maintenance and Monitoring of Large-Span Beams

Long-span beams require periodic inspection to ensure long-term durability:

- Routine Checks: Inspect weld seams, paint coatings, and bolt tightness annually.

- Corrosion Control: Recoat exposed areas every 5–10 years, especially in humid or coastal regions.

- Structural Monitoring: Use deflection sensors or visual markers to detect early bending or fatigue.

Factory-galvanized and coated beams, produced under ISO standards, can maintain their structural integrity for over 50 years with minimal upkeep.

Our Large Span Steel Structure Solutions

At SteelPRO PEB, we specialize in designing and manufacturing large-span steel structure buildings that achieve exceptional strength, stability, and open-space performance. Our integrated process—from design modeling to precision fabrication—ensures every beam and connection is engineered to meet the exact span, load, and deflection requirements of your project.

Each structure is factory-produced under ISO and CE-certified standards, guaranteeing consistent quality and rapid installation on-site. With 24 production lines and advanced CNC fabrication, we deliver reliable steel solutions for buildings requiring spans of 20 meters and beyond—from industrial warehouses and logistics centers to sports arenas and exhibition halls.

Looking to optimize your 20m+ steel beam span?

Our engineers can help you determine the ideal beam type, depth ratio, and support spacing—using certified, factory-engineered systems tailored to your structure.

Contact us for a technical span assessment and cost-efficient beam design recommendation.

Related Reading: What Are The Long-Span Structures in Architecture?