Selecting the appropriate material for your barn transcends mere practicality—it constitutes a long-term investment. Wooden barns may evoke a timeless, traditional allure, yet contemporary steel structures provide unmatched durability and efficiency. Many assume wood is the cheaper option, but hidden costs like maintenance and repairs can quickly add up.

From harsh weather resistance to fire safety, the debate between steel and wood hinges on critical factors that impact your budget and peace of mind. Therefore, which choice truly withstands the test of time? Let’s delve into the essential factors to assist you in making a wiser construction decision.

13 Differences Between Metal Structures and Wood Structures

1. Durability and Lifespan

Steel: Steel barns are known for their outstanding durability, especially when made with corrosion-resistant coatings like Galvalume®. These barns often endure for more than 50 years and are resistant to pest and mold damage. Requiring minimal maintenance, steel barns can withstand severe weather conditions and environmental degradation.

Wood: Conversely, wooden barns typically have a shorter lifespan, ranging from approximately 20 to 30 years. Wood is more susceptible to rot, especially in humid environments, and requires regular maintenance such as treatments for termites and moisture resistance. These additional upkeep efforts can lead to higher long-term costs.

2. Weather Resistance

Steel: Steel structures excel in weather resistance. They are engineered to withstand extreme conditions, including hurricanes and heavy snowfall. Steel barns can be engineered to withstand winds up to 150mph and snow loads of 40+ pounds per square foot, ensuring stability in harsh climates.

Wood: Wooden barns, on the other hand, are more vulnerable to high winds and heavy snow. High wind speeds can cause structural deformation, and the weight of snow may lead to roof collapse. Therefore, wooden barns are less safe in extreme weather conditions, often requiring additional reinforcements.

3. Cost Comparison (Lifecycle)

| Factor | Steel Barn | Wooden Barn |

| Initial Cost | Higher upfront cost, but prefabricated options reduce construction costs by 15-30% | Lower initial cost, more budget-friendly |

| Maintenance | Low maintenance, durable, and requires minimal upkeep | High maintenance due to regular treatments for pests and decay |

| Residual Value | Can be recycled and sold as scrap metal | Wood degrades over time with no significant resale value |

Regarding lifetime costs, although steel barns have a higher upfront investment, their extended lifespan and minimal maintenance expenses render them more cost-effective in the long run. Wooden barns may be attractive due to their lower initial cost, but the frequent maintenance and repairs needed will increase long-term expenses.

4. Construction Time and Labor

Steel: Steel barns benefit from prefabricated modular systems, which significantly reduce construction time. For example, a 1000m² steel barn can be installed in just 2 weeks, as the components are pre-cut and assembled at the site, requiring less on-site labor and minimizing delays.

Wood: Wooden barns typically require on-site cutting and custom fitting, which can be time-consuming. The construction process is more prone to delays due to weather conditions such as rain, which can halt work and increase labor costs.

5. Safety Features

Fire Resistance: Steel barns offer Class A fire resistance, which means they are highly resistant to fire. This renders them a safer option, particularly in regions susceptible to wildfires or where fire risks are a concern. In contrast, wooden barns are highly flammable, with about 70% of barn fires in the U.S. originating from wooden structures.

Earthquake Resistance: Steel structures are highly flexible and can absorb and withstand seismic forces, making them more earthquake-resistant. On the other hand, wooden barns are more vulnerable to earthquakes, as their joint connections can break easily under seismic stress, leading to structural failure.

6. Flexibility in Expansion and Layout

Steel: Steel barns allow for large open spans (up to 60 meters), providing column-free spaces that are perfect for various uses like storage, livestock, and machinery. Their modular design allows for easy future expansions, whether it’s adding additional floors or expanding side wings.

Wood: Wooden barns are generally limited by the length of the timber used, which typically cannot exceed 12 meters. Expanding a wooden barn may require dismantling or restructuring parts of the existing building, making future expansion more complex and costly compared to steel.

7. Cleanliness and Hygiene

Steel: Steel barns feature smooth surfaces that are easy to wash, and the seamless design prevents the buildup of dirt and bacteria. This makes them ideal for settings where hygiene is paramount, such as livestock accommodation. The lack of crevices makes cleaning straightforward, reducing the risk of contamination.

Wood: Wooden barns are more difficult to keep clean due to the presence of gaps and cracks where dust and debris can accumulate. These spaces can also harbor parasites and bacteria, making disinfection more challenging. Consequently, wood may necessitate more frequent and thorough cleaning to uphold a hygienic environment.

8. Insulation and Soundproofing

Steel: Steel barns generally require additional insulation materials such as rock wool or polyurethane sandwich panels to achieve effective thermal performance. These materials can be customized to provide R-30+ insulation values, ensuring excellent energy efficiency. Steel barns also have superior soundproofing qualities, reducing noise transmission.

Wood: Wood naturally offers some insulation properties, with R-values ranging from R-5 to R-10, making it a moderate option for temperature regulation. However, wood performs poorly in sound insulation, meaning livestock noise or external sounds may easily pass through the structure, potentially causing disruptions in noisy environments.

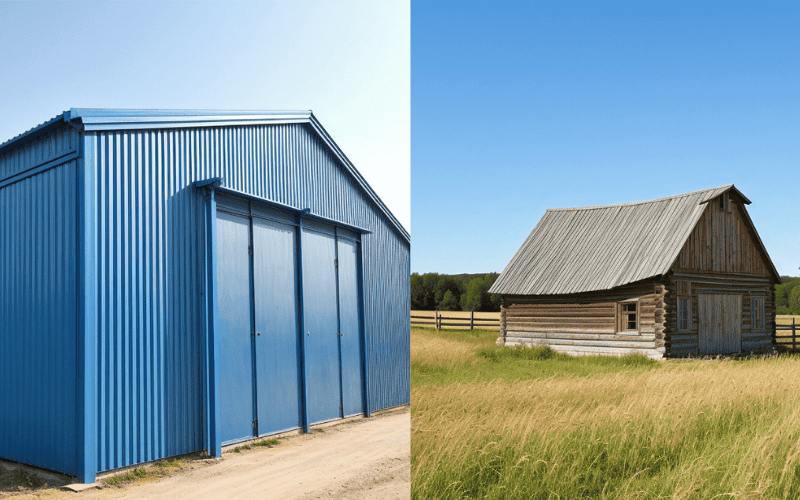

9. Aesthetic Appeal

Steel: Steel barns have a modern industrial look, often associated with functionality and durability. However, they can be customized with wood grain finishes (such as Kynar® coatings) to mimic the appearance of traditional wood while retaining the benefits of steel’s strength and durability.

Wood: Wooden barns are often favored for their traditional rural charm and natural aesthetic, making them ideal for picturesque farm settings. However, they are prone to fading and aging over time, with the wood’s appearance deteriorating due to exposure to the elements. Routine maintenance, such as staining or painting, is essential to maintain the wood’s aesthetics.

10. Environmental Impact

Steel: Steel is comprised of up to 75% recycled materials and is fully recyclable, rendering it an eco-friendly choice regarding end-of-life disposal. However, the energy-intensive processes involved in steel production contribute to a significant carbon footprint. Over time, this carbon cost can be offset by the long lifespan and recyclability of the material, making steel a sustainable choice in the long run.

Wood: Wood is a renewable resource, provided it is sourced sustainably. Nonetheless, deforestation resulting from excessive logging can cause substantial ecological damage, encompassing habitat destruction and biodiversity loss. Opting for FSC-certified (Forest Stewardship Council) wood guarantees that it originates from responsibly managed forests, thereby lessening environmental impact.

11. Foundation Requirements

Steel: Steel structures are much lighter than wood, weighing about 60% less. As a result, they often require less substantial foundations, leading to savings of 20-40% in foundation costs. This makes steel barns especially advantageous in areas with soft soils or shallow bedrock, where building foundations would typically be more expensive.

Wood: Wooden barns have a heavier structure, necessitating deeper, more robust foundations. This is especially true in wetlands or marshy areas, where the cost of foundation work can skyrocket. The supplementary foundation needs can substantially elevate overall construction expenses, particularly in difficult terrains.

12. Roof

Steel: Steel barns typically feature metal panels that are durable, weather-resistant, and require minimal maintenance. Galvanized steel roofing resists hail and corrosion, making it ideal for harsh weather. Steel roofs also have a longer lifespan and are more energy-efficient with insulation like spray foam.

Wood: Wooden barns often use wooden framing for their roofs, offering a natural aesthetic. However, wood is prone to moisture and insect damage, requiring more maintenance. Wooden roofs also need proper insulation and ventilation, especially in barns like horse barns.

13. Building Materials

Steel: Steel construction offers corrosion resistance and durability. Metal barns are resistant to insect damage and weathering and require fewer repairs. They also work well with spray foam insulation, making them energy-efficient and cost-effective in the long term.

Wood: Wooden barns are built with wooden framing and wooden siding, offering good natural insulation but are more prone to rot and pests. While cheaper to build initially, they need more maintenance over time, which can lead to higher long-term costs.

Wood vs Steel Barn Pros and Cons

| 🏗️ Steel Barn | 🌳 Wooden Barn |

| ✅ Advantages | |

| Super durable: insect-proof, fireproof, corrosion-resistant, with a lifespan of over 50 years | Natural aesthetics: warm texture, traditional farm style |

| Easy maintenance: galvanized/coated, almost maintenance-free | Economic and flexible: low initial cost, easy to obtain local materials |

| Quick construction: prefabricated modular, installation takes only a few weeks | Natural insulation: wood has good thermal insulation, warm in winter and cool in summer |

| Disaster-resistant: withstand strong winds, heavy snow, and extreme climates | Environmentally friendly recycling: wood is renewable (sustainable certification required) |

| Environmentally friendly recycling: steel is 100% recyclable | |

| ❌ Disadvantages | |

| Higher cost: high initial material costs (steel prices fluctuate) | Maintenance is complicated: regular anti-corrosion and insect prevention are required, and renovation is required every 10-20 years |

| Industrial appearance: cold and hard style, limited design options | High fragility: afraid of moisture and insect infestation, weak disaster resistance |

| Insulation shortcoming: metal conducts heat quickly, requiring additional insulation | Time-consuming construction: processing + construction takes several months, dependent on the weather |

Comparison of metal barns and wooden barns in different application

Choose Steel Structures for:

- High Disaster Risk Areas (Fire, Hurricanes, etc.):

- Steel structures offer excellent fire resistance, wind resistance, and seismic performance, making them ideal for regions prone to extreme weather events or natural disasters.

- Long-Term Use Needs (e.g., Commercial Farms, Industrial Warehouses):

- Due to their durability and low maintenance costs, steel barns are well-suited for long-term, heavy-duty storage needs, particularly in commercial and industrial applications.

- Low Maintenance and Fast Construction (Pre-engineered Steel Structures Cut Construction Time by 30-50%):

- Steel structures require less maintenance and can be quickly assembled due to pre-fabricated components. This makes them an excellent option for projects necessitating swift completion or minimal ongoing maintenance.

Choose Wooden Structures for:

- Limited Budget and Short-Term Use (e.g., Temporary Storage):

- Wooden barns are generally less expensive to build, making them a good option for those on a budget or requiring storage for a limited time, such as small farms or temporary storage needs.

- Emphasis on Traditional Rural Aesthetics (e.g., Farm Tourism, Stables):

- The natural look and warm feel of wooden barns blend well with rural or countryside environments. They are suited for applications where aesthetic appeal is crucial, like in tourist farms or stables.

Steel barn vs wooden barn:common myth-busting

Myth 1: Steel constructions are “not environmentally friendly”?

→ Clarification: Steel structures are actually very environmentally friendly. Steel has a high recycling rate and can be completely recycled and reused at the end of its life cycle. In addition, modern steel structure design focuses on energy conservation, and the materials and construction methods used strive to reduce energy consumption and meet the standards of green buildings.

Myth 2: Wood is “warmer and more natural”?

→ Clarification: Although the natural texture and tone of wood do bring a warm feeling, modern steel can achieve a similar visual effect by matching insulation and wood exterior finishes while maintaining the durability and stability of steel structures. Today’s steel structure designs can not only have a modern feel, but also blend with the natural beauty of wood.

Myth 3: Metal building are “too expensive”?

→ Clarification: Although the initial investment of steel structures may be higher than that of wood structures, from the perspective of full life cycle costs, steel structures have lower long-term maintenance costs and strong durability, avoiding the corrosion and pest problems of wood. Hence, in the long term, the overall cost of steel structures proves to be more economical.

Steel vs Wood Pole Barn

When choosing between a steel or wood pole barn, each has its own benefits depending on your needs.

Cost and Construction: A metal pole barn is often cheaper to build and quicker to construct, with pre-engineered metal buildings and building kits available for easy assembly. Wooden pole barns might take more time and labor, but their traditional aesthetic can be appealing.

Durability: Steel construction is more durable, resistant to hail, insect damage, and corrosion. Wooden pole barns, while strong, require more maintenance due to rot and pests.

Insulation: Metal barns often need added insulation, like spray foam, for energy efficiency, especially in warmer climates. Wooden barns provide natural insulation, reducing energy costs.

Customization: Both options can be customized. Wooden barns offer a classic look, while metal and wood barns combine modern strength with rustic charm.

Whether you need a durable, safe, or warm, natural steel barn, we can provide you with a tailor-made solution. Our team has extensive design and construction experience and can provide one-stop services from preliminary design to completion delivery according to your building project needs.

Contact our expert team directly, whether you are planning a new warehouse or need to optimize the existing space, we can provide you with the most suitable options. Let us work together to create an ideal storage space that meets your needs!