When it comes to steel construction, choosing the right type of building is crucial for durability, cost-efficiency, and ease of installation. Two of the most common options are Red Iron steel buildings and Prefabricated steel buildings, each with its own advantages and best-use scenarios.

Red Iron steel structures, known for their strength and load-bearing capacity, are often used in large commercial and industrial projects. On the contrary, prefabricated steel buildings provide a quicker and more economical solution, featuring pre-engineered components for simpler assembly. Grasping the fundamental distinctions between these two alternatives will aid you in deciding which one aligns best with your unique requirements.

What is Red Iron Steel?

Red Iron Steel, also known as red oxide-coated structural steel, is a type of heavy-duty steel commonly used in large-scale construction projects. The term “Red Iron” originates from the red oxide primer applied to the steel components, which safeguards them against rust and corrosion. This type of steel is primarily made from hot-rolled structural steel sections, which are designed to provide exceptional strength and durability for buildings that need to withstand heavy loads and harsh weather conditions.

Common Uses in Construction

Red Iron Steel is widely used in large commercial, industrial, and agricultural buildings where a strong structural framework is essential. Some common applications include:

- Warehouses and factories – Designed to support heavy machinery and equipment.

- Aircraft hangars – Large-span structures requiring strong, stable framing.

- Retail centers and office buildings – Used for multi-story structures that need durability.

- Agricultural buildings – Such as barns, storage facilities, and grain silos.

- Bridges and large infrastructure projects – Due to its load-bearing capacity.

Structural Benefits

One of the primary benefits of Red Iron Steel lies in its remarkable strength and durability. The components are engineered to withstand high wind pressures, seismic activities, and substantial snow accumulations, rendering them perfect for permanent, large-scale structures. Other benefits include:

- Superior load-bearing capacity – Red Iron structures can support significant vertical and horizontal loads, making them ideal for high-rise and industrial applications.

- Extended Lifespan – The red oxide coating acts as a shield against rust, thereby prolonging the life of the steel.

- Fire Resistance – Steel’s inherent non-combustibility makes it a safer choice for extensive structures.

Typical Components

Red Iron Steel buildings are made up of various heavy-duty steel components, including:

- I-Beams – The primary structural element, used for columns and rafters to provide maximum support.

- Columns – Vertical supports that help distribute weight throughout the structure.

- Purlins – Horizontal beams that provide additional support to the roof and walls.

- Girts – Similar to purlins but used for walls, reinforcing the building’s frame.

- Base Plates & Connections – Secure the structure to the foundation and connect different steel elements.

What is a Prefabricated Steel Building?

A prefabricated steel building, alternatively termed as a pre-engineered metal building (PEMB), is a structure that is fabricated in a factory away from the construction site and subsequently transported there for assembly. Unlike traditional steel buildings that require on-site cutting, welding, and heavy labor, prefabricated steel buildings come with pre-cut, pre-drilled, and pre-welded components, making installation faster and easier.

Key features of prefabricated steel buildings include:

- Factory-made components – Ensuring precision and reducing on-site labor.

- Bolt-together assembly – No need for welding during construction.

- Lightweight but strong – Designed to withstand harsh weather while being easy to handle.

- Customizable design – Can be adapted to various applications with different layouts and finishes.

Types of Prefabricated Steel Buildings

There are several types of prefabricated steel buildings, each suited for different applications:

- Rigid Frame (Clear-Span) Buildings –

- Features a strong steel frame with no interior support columns, maximizing open space.

- It is ideal for warehouses, aircraft hangars, and expansive workshops where ample open floor space is crucial.

- Arch (Quonset) Buildings –

- Recognizable by their semi-circular, curved design, offering strength with minimal materials.

- Commonly used for storage sheds, garages, and agricultural buildings.

- Modular Steel Buildings –

- Built using pre-fabricated sections (modules) that can be connected like building blocks.

- Suitable for offices, temporary housing, or industrial buildings that need future expansion.

Advantages of Prefabrication

Compared to traditional steel structures, prefabricated steel buildings offer several advantages:

- Ease of Assembly –

- Components are pre-engineered and labeled, reducing construction time and labor costs.

- They can be assembled using basic tools and with minimal reliance on heavy equipment.

- Cost Savings –

- Lower labor costs due to simplified installation.

- Reduced material waste, as factory production ensures precise measurements.

- Shorter construction timelines, leading to lower overall project costs.

- Durability and Low Maintenance –

- Made from galvanized or coated steel, offering high resistance to rust and corrosion.

- It requires minimal maintenance, making it a financially prudent long-term investment.

Common Applications

Prefabricated steel buildings are versatile and used in many industries:

- Agricultural – Storage barns, livestock shelters, and grain storage facilities.

- Commercial – Retail stores, office buildings, and auto repair shops.

- Industrial – Warehouses, manufacturing plants, and logistics centers.

- Residential – Prefab homes, garages, and workshops.

Manufacturing and Construction Comparison: Red Iron Steel vs. Prefabricated Steel Buildings

The manufacturing and construction processes of Red Iron Steel and Prefabricated Steel Buildings differ significantly. Below is a detailed comparison:

1. Manufacturing Process

| Aspect | Red Iron Steel | Prefabricated Steel |

| Material Composition | Heavy-duty I-beams, H-columns, purlins, and thick steel plates | Lighter C-channel, Z-purlins, and modular steel panels |

| Fabrication Process | Cut, drilled, and welded at fabrication plants, then primed with red oxide coating | Factory pre-engineered, cut, drilled, and sometimes pre-welded before shipping |

| Coating & Protection | Red oxide primer applied for corrosion resistance | Galvanized or powder-coated for better rust prevention |

| Customizability | Fully customizable but requires engineering expertise | Some level of customization, but mostly standardized designs |

🔹 Key Takeaway:

- Red Iron Steel requires more fabrication and processing, making it better for custom projects.

- Prefabricated Steel is mass-produced utilizing standardized components, resulting in quicker and more economical manufacturing processes.

2. Construction Process

| Aspect | Red Iron Steel | Prefabricated Steel |

| Foundation Requirements | Requires heavy-duty concrete foundation to support large steel sections | Lighter structure means less demanding foundation requirements |

| On-Site Assembly | Requires welding, cutting, and drilling on-site | Bolt-together design for faster assembly |

| Construction Time | Longer installation process due to heavy materials and on-site fabrication | Much faster installation since components are pre-cut and pre-drilled |

| Labor Requirements | Requires skilled labor for welding and assembly | Can be installed with a smaller, less specialized crew |

| Equipment Needed | Cranes, welding tools, heavy machinery | Basic tools like wrenches, drills, and lifting equipment |

🔹 Key Takeaway:

- Red Iron Steel construction is labor-intensive, requiring specialized workers and longer assembly time.

- Prefabricated Steel Buildings are significantly easier to assemble, thereby decreasing labor expenses and shortening construction timelines.

3. Overall Efficiency & Suitability

| Factor | Red Iron Steel | Prefabricated Steel |

| Speed of Construction | Slower, due to welding and on-site fabrication | Faster, thanks to pre-engineered components |

| Labor Cost | Higher, requiring more skilled labor | Lower, as assembly is simpler |

| Project Size Suitability | Ideal for large industrial, commercial, and high-load projects | Best for medium to small-scale buildings |

| Project Complexity | Can accommodate complex, custom designs | Best for simple, modular structures |

| Transportation | Large and heavy components, expensive to transport and require large trucks and lifting equipment. | Generally lighter, more economical to transport, and suitable for transporting over long distances. |

🔹 Final Verdict:

- For large-scale, highly customized projects, Red Iron Steel is the best option, despite higher costs and longer build times.

- For cost-effective, quick-to-build structures, Prefabricated Steel Buildings are the ideal choice due to their fast assembly and lower labor requirements.

Each type has its place in construction, and choosing between them depends on your budget, project size, and construction timeline.

Red Iron Steel vs. Prefabricated Steel Buildings: Other Comparisons

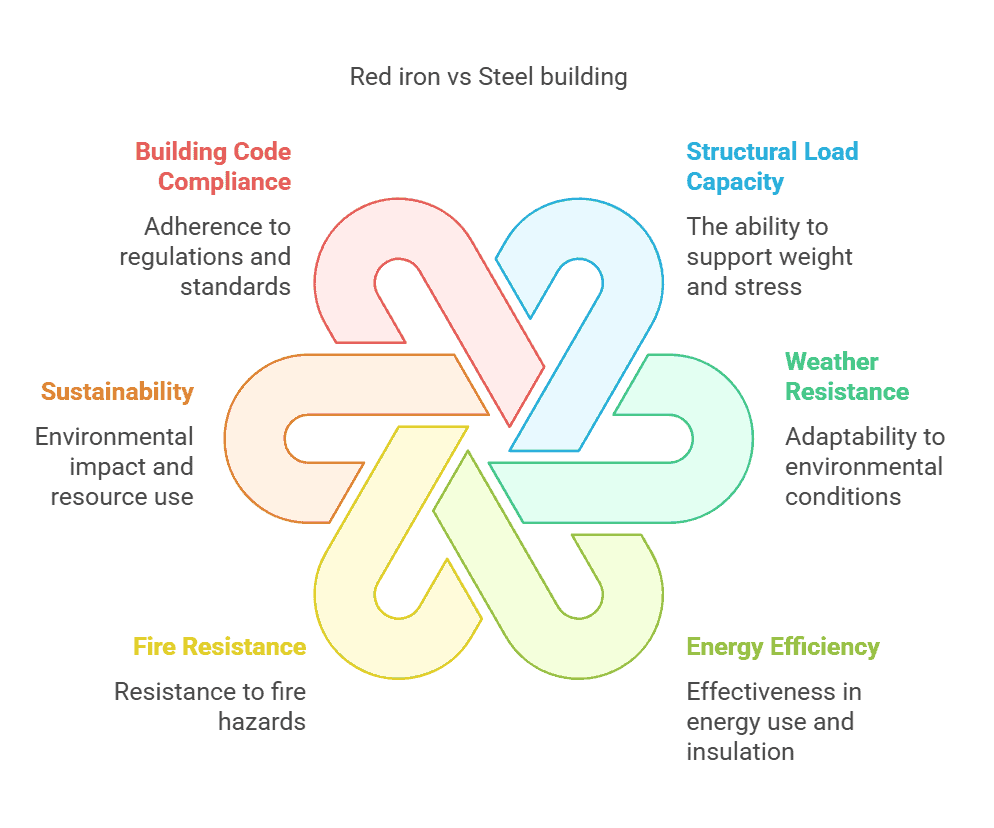

1. Structural Load Capacity

Red Iron Steel: Suitable for high-load buildings, can withstand greater wind and snow pressure, earthquake loads and the weight of industrial equipment.

Prefabricated Steel: Suitable for standard loads, suitable for small to medium-sized structures, but the load-bearing capacity is lower than that of red iron steel.

2. Weather Resistance & Environmental Adaptability

Red Iron Steel: Suitable for extreme climates, such as high wind speeds and heavy snow areas, and suitable for buildings exposed to the outdoors for a long time.

Prefabricated Steel: Suitable for general climate conditions, if galvanized steel is used, it can improve corrosion resistance.

3. Energy Efficiency & Insulation

Red Iron Steel: Structurally stable, it can support high-performance insulation systems, but usually requires additional insulation.

Prefabricated Steel: Insulation materials such as sandwich panels or prefabricated insulated wall panels can be integrated to improve energy efficiency and temperature control capabilities.

4. Fire Resistance

Red Iron Steel: It has strong fire resistance, but it may deform at high temperatures and usually requires additional fireproof coatings.

Prefabricated Steel: Prefabricated components may contain fire-resistant materials, such as fire-resistant coatings or fire walls.

5. Sustainability & Environmental Impact

Red Iron Steel: While it is recyclable, the manufacturing process is energy-intensive and carries a significant carbon footprint.

Prefabricated Steel: More environmentally friendly to produce, reduces on-site waste, and usually meets green building standards.

6. Compliance with Building Codes & Regulations

Red Iron Steel: Suitable for all types of high-standard buildings and meets strict industrial and commercial building codes.

Prefabricated Steel: Prefabricated components usually comply with national standards, but there may be restrictions in some areas.

Which One Should You Choose?

| Factor | Red Iron Steel | Prefabricated Steel |

| Best for | Large commercial and industrial buildings | Small to mid-sized buildings (farms, storage, workshops) |

| Budget | Higher upfront cost, long-term investment | Lower cost, budget-friendly |

| Construction Speed | Longer installation, requires welding | Fast installation, pre-engineered components |

| Customization | Fully customizable for unique designs | Limited customization options |

| Best Use Cases | Factories, aircraft hangars, warehouses, large-scale projects | Garages, farm buildings, small warehouses, commercial retail |

Choose Red Iron Steel if:

✔ You are constructing a large commercial or industrial building.

✔ You require utmost strength, durability, and load-bearing capacity.

✔ Your project has a flexible timeline and requires high customization.

Choose Prefabricated Steel if:

✔ You necessitate a cost-efficient and expeditious construction solution.

✔ Your project is small to mid-sized, such as a farm building, storage facility, or workshop.

✔ You desire minimal maintenance and swift installation.

Ultimately, the decision that best suits your needs hinges on your budget, timeline, and specific building requirements.

Making the Right Choice for Your Steel Building

Whether you need a strong, durable red iron steel structure for a large industrial project, or a prefabricated steel building that is cost-effective and quickly assembled, choosing the right solution is critical for your business or property. Each option has its advantages, and the best choice depends on your budget, timeline, and project requirements.

At SteelPRO PEB, we specialize in high-quality steel structures, providing custom design, fabrication, and delivery to meet your exact needs. If you’re looking for a reliable, durable, and cost-effective steel building, contact us today – our team is ready to help you design the perfect structure for your project!