Need to quickly expand your storage space at minimal cost? Looking for a practical and beautiful farm outbuilding solution? Lean-to Pole Barn not only maximizes the use of existing sites, but also allows for flexible customization of farm machinery parking areas, tool warehouses or commercial storage space according to needs, and the average construction cost is more than 30% lower than that of free-standing structures.

Next, we will take a deep look at the benefits of Lean to Pole Barn, its uses, and how to choose the best option for your project. Let’s explore the endless possibilities of this versatile building together!

What is lean to pole barn?

A Lean-to Pole Barn is a lightweight steel extension that is attached to an existing building (such as a house, barn or other structure). Its name comes from two core features:

1️⃣ “Lean-to”: a roof that is tilted on only one side, relying on the main building wall as a support point, forming a natural drainage slope from high to low;

2️⃣ “Pole Barn”: using deep buried steel columns as the load-bearing skeleton, replacing the continuous foundation of traditional buildings, significantly reducing construction costs.

Typical structural composition

- Main frame: galvanized steel columns + truss system

- Roof/wall: corrugated metal sheet

- Connection method: rigidly connected to the main building through earthquake-resistant bolts

Lean-to Pole Barn Types

| Category | Type | Structural Features | Typical Dimensions | Use Cases | Advantages |

| Connection Type | Attached | Shares the main building’s wall; roof slope aligns with the main structure. | Width: 4-12m | Farm equipment storage, residential tool sheds | Saves support structure costs, reduces installation time by 40%. |

| Detached | Self-supporting steel frame connected via a corridor. | Span: 6-15m | Commercial storage, pool equipment rooms | Flexible layout, adjustable orientation. | |

| Roof Design | Classic Single Slope | Single drainage slope (1:4–1:6), straight ridge. | Slope: 15°–25° | Heavy rain/snow regions | High drainage efficiency, reduces corrosion risk. |

| Modified Double Slope | Combines the main building’s double-slope roof with a lean-to extension; Z-flashing for waterproofing. | Junction height: ≥3m | Large logistics centers | Seamless integration with main building aesthetics, enhanced leak-proofing. | |

| Function Focus | Heavy-Duty Agricultural | Denser steel columns (spacing ≤2.4m), compression-resistant floor (5000psi concrete). | Door width: ≥4.8m | Heavy machinery storage | Load capacity up to 5 tons/m², reinforced doorframes. |

| Residential Aesthetic | Wood-grain steel panels, translucent polycarbonate roof (30% coverage). | Height: 2.5–3.5m | Garden sheds, home gyms | Visually appealing, noise reduction, optimized lighting. | |

| Material Mix | All-Steel Structure | Galvanized steel frame + corrugated steel panels. | Panel thickness: 0.4–0.7mm | Coastal/industrial areas | 50+ year lifespan, maintenance-free, 100% recyclable. |

| Steel-Wood Hybrid | Steel columns + wood trusses/asphalt shingle roof. | Wood treatment grade: UC4B | Low-cost temporary builds | 20% lower upfront cost, requires periodic maintenance. | |

| Design Style | Standard Single Slope | Basic single-slope roof, no added features, direct drainage. | Span: 5-10m | Budget-friendly storage | 15% material cost savings, simple construction. |

| Eave-Enhanced Design | Extended eaves (30–60cm) with integrated gutters. | Eave depth: 0.3–0.6m | High-rainfall regions, retail displays | Protects walls from rain, enhances aesthetics. | |

| Multi-Section Design | Segmented roof slopes (2–3 sections with varying heights/slopes). | Total span: 12–24m | Large farms, industrial workshops | Customizable zones (e.g., high section for equipment, low section for workspace). |

Lean to Pole Barn Main Features

- Single slope steel structure design: close to the main building, one-way drainage (slope 1:4~1:6), galvanized steel columns are wind-resistant and earthquake-resistant, with a service life of 50+ years.

- Large span column-free space: the clear span is 12-15 meters, and agricultural machinery/vehicles can be accommodated without obstacles.

- Fast and low-cost construction: modular installation only takes 2-3 days, and the cost is 30% lower than traditional buildings.

- Multifunctional and flexible: Applicable scenarios: storage, workshops, tool rooms, etc., walls/roofs can be upgraded for insulation/light transmission.

- Ultra-low maintenance: rust-proof and corrosion-resistant, annual maintenance fee <$50, no wood anti-corrosion required.

- Environmental protection and value preservation: steel recycling rate >90%, improve property value, and meet international building standards.

Application areas of Lean to Pole Barn

Agriculture and farms: tractor/harvester parking, feed storage, milking hall, livestock shed

Industrial storage: raw material temporary storage area, equipment maintenance workshop, logistics transit warehouse

Commercial facilities: retail store outdoor inventory area, restaurant cold storage, car 4S shop maintenance shed

Civilian residence: backyard tool room, home gym, swimming pool equipment room, electric car charging garage

Public facilities: community fire equipment warehouse, school sports equipment storage, municipal temporary materials warehouse

Leisure and entertainment: equestrian training shed, camping equipment warehouse, outdoor dining area

New energy: solar panel mounting bracket platform, wind turbine component storage shed

Lean to Pole Barn Design

The design selection of Lean to Pole Barn involves multiple considerations and customizable accessories to meet different usage needs.

1. Design considerations

- Roof slope: Choose the appropriate slope according to the geographical location and climate conditions. A steeper slope helps drainage and is suitable for areas with more snow.

- Size and layout: Determine the required building space size, taking into account the type and quantity of stored items and the available land space.

- Wall material: Choose a suitable wall material (such as wood, metal or polycarbonate), and make a choice based on insulation, ventilation needs and aesthetic requirements.

- Opening location and number: The number and location of doors and windows directly affect ventilation and lighting. Set appropriate doors, windows and vents according to usage requirements.

- Structural type: Choose a single-slope or multi-slope roof to ensure the stability and aesthetics of the building, especially considering the integration of the building’s appearance with the surrounding environment.

- Foundation: The foundation type depends on the soil conditions and the purpose of the building. You can choose a concrete base or other types of supporting structures.

2. Addable accessories and features

We offer a variety of add-on options to ensure that each Lean to Pole Barn is perfectly suited to your specific needs. We can tailor the ideal structure for you based on your budget and functional requirements.

- Additional eaves: Adding eaves can provide more sheltered areas, help with drainage, and increase the space around the building.

- Partition walls: Add partition walls inside the building to separate storage areas or create different functional areas.

- Skylights: Adding skylights can increase natural light and ventilation, reducing energy consumption.

- Windows and vents: Installing windows and vents, especially high-positioned vents, can effectively improve air circulation.

- Roller or sliding doors: For large openings, you can choose roller or sliding doors that are easy to open and close to increase operational convenience.

- Power and lighting systems: If used as a garage, workshop or studio, add power supply and lighting facilities to improve ease of use.

- Insulation and thermal insulation materials: To improve energy efficiency, you can choose insulated wall or roof materials to adapt to temperature changes in different seasons.

- Rainwater collection system: Set up a rainwater drainage and collection system to help manage water sources and improve the environmental friendliness of the building.

- Automated door control system: Doors that open and close automatically can improve security and reduce the need for manual operation.

Advantages and Disadvantages of Adding Lean to Pole Barn to Metal Buildings

Advantages of Lean to Pole Barn

- Low Cost: Due to its simple design and the use of less materials, the construction cost of Lean to Pole Barn is relatively low, which is suitable for projects with limited budgets.

- Quick Construction: The simplified structure means a short construction period and can be put into use quickly.

- High Durability: Metal materials have good wind and corrosion resistance, adapt to various climate conditions, and ensure long-term stable use.

- High Flexibility: It can be customized according to needs and is suitable for a variety of uses such as storage, garages, studios, etc., and can be easily expanded or modified.

- Easy to Maintain: Relatively low maintenance costs, metal surfaces are easy to clean and maintain.

Disadvantages of Lean to Pole Barn

- Weak Aesthetics: The appearance of Lean to Pole Barn is relatively simple, which may not be suitable for places with high requirements for building appearance.

- Poor Thermal Insulation: Metal structures have poor thermal insulation and may require additional insulation materials to improve winter comfort.

- May Require More Maintenance: Although metal is corrosion-resistant, it still needs regular inspection and maintenance to avoid rust when exposed to harsh environments for a long time.

- Space and height restrictions: The roof has a small slope, which is suitable for simpler storage or workspaces, but may not be suitable for uses that require large space or high structural strength.

- Affected by extreme weather: Lean to Pole Barn may be more susceptible to extreme weather (such as strong winds or heavy snow) than other complex structures and may be less stable.

Overall, Lean to Pole Barn provides an economical and versatile option, but its appearance, insulation and climate adaptability limitations need to be considered.

✅ Recommended scenarios:

- Quick and low-cost expansion of storage/production space is required

- The main building is a metal structure and meets the load-bearing standards

- The environment is rainy/high humidity (areas where wood is prone to decay)

❌ Use with caution:

- The main building is old or the structure is unstable

- Storing items that are sensitive to humidity (such as antiques, electronic components) without moisture-proof treatment

- Residential areas have strict appearance restrictions (no decorative steel panels are used)

Step-by-Step Guide to Adding a Lean-to to an Existing Pole Barn

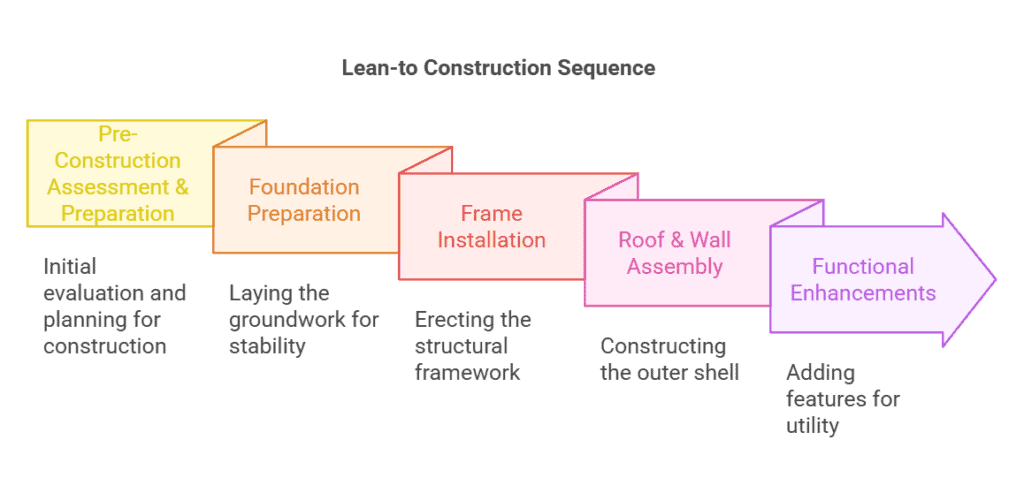

Pre-Construction Assessment & Preparation

- Structural Inspection

- Verify the load-bearing capacity of the main pole barn’s steel columns and roof condition (no corrosion/deformation).

- Measure the eave height and available wall length of the main structure (determines lean-to width).

- Compliance Check

- Research local setback requirements and size limits for accessory structures (e.g., some U.S. states cap lean-to area at ≤50% of the main building).

- Apply for construction permits (if required).

- Tools & Materials Checklist

- Steel components: Galvanized C-section columns, Z-purlins, corrugated metal panels.

- Connectors: Seismic-resistant bolts (e.g., ASTM A325), waterproof sealant, flashing.

- Tools: Laser level, impact wrench, metal-cutting saw.

Step 1: Foundation Preparation

- Options:

- Economical: Bury steel columns 1.2–1.5m deep, avoiding the main building’s foundation.

- Reinforced: Pour concrete footings (30x30x60cm) with anchor plates (for soft soil).

Step 2: Frame Installation

- Mount vertical steel columns along the main barn’s wall (spaced 2.4–3.6m apart), secured to the main structure via L-brackets.

- Install sloped roof beams (1:4–1:6 pitch), ensuring the low end has ≥2.4m clearance for drainage.

Step 3: Roof & Wall Assembly

- Purlins: Attach Z-purlins horizontally to roof beams (spaced 0.6–1.2m apart), keeping level error ≤3mm.

- Metal Panels:

- Overlap panels by 15cm, fasten with self-drilling screws and rubber washers.

- Seal roof junctions with Z-flashing and waterproof sealant (critical at the main barn’s roofline).

Step 4: Functional Enhancements

- Ventilation: Install turbine vents (1 per 20m²).

- Drainage: Add gutters at the low end to direct rainwater.

- Doors/Windows: Cut openings for sliding doors or polycarbonate panels (use metal hole saws for clean edges).

Key Considerations

- Structural Safety

- Ensure thermal expansion compatibility between old and new steel.

- Add cross braces (45° steel angles) in high-wind zones.

- Rust Prevention

- Apply zinc-rich primer (e.g., Rust-Oleum Cold Galvanizing) to cut edges and drilled holes.

- Electrical Integration

- Run wiring from the main barn in metal conduits (follow NEC electrical codes).

- Common Mistakes to Avoid

- ❌ Welding new steel directly to old → Use bolted connections (allows minor movement).

- ❌ Overloading the main barn’s roof → Calculate combined snow/dead loads (ensure main beams have ≥20% capacity margin).

Choose SteelPRO PEB to build your perfect expansion space!

If you are looking for an affordable and versatile building solution, our Pole Barn with Lean to is definitely the ideal choice for you!

Customized design: Free 3D modeling to accurately match your site and needs.

Fast delivery: Prefabricated steel structure components, installed in as fast as 72 hours.

Transparent pricing: Instant online quotes, no hidden fees, 15% lower than the industry average!