Hay storage is a vital part of agricultural production. The quality of feed impacts livestock health and the farm’s economic benefits. However, hay is vulnerable to rain, moisture and pests, so choosing the right storage method is particularly important.

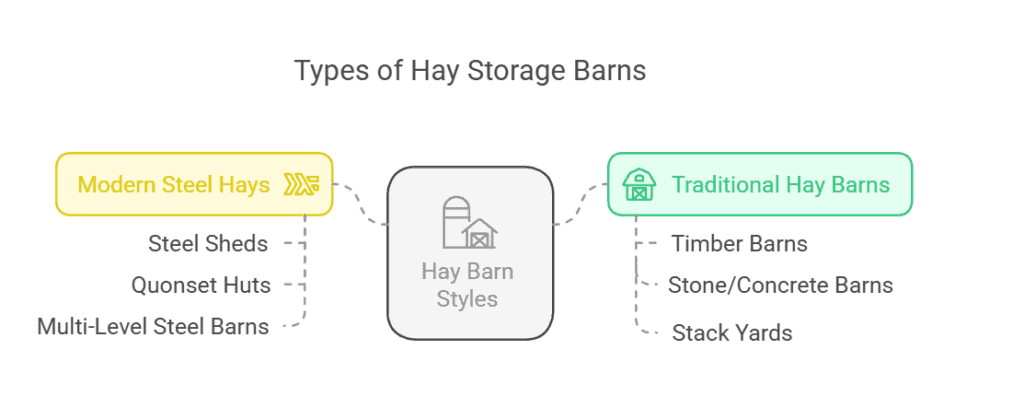

With the development of modern agriculture, the design of hay storage barns has become increasingly diverse, from traditional wooden structures to modern steel barns, each type has its own unique advantages. So what is the best building for storing hay? Reveal the answer now!

Traditional Hay Barn Styles

Timber Barns

Timber barns, made of natural wood, have a traditional look, good ventilation, and keep hay dry. Historic farms often feature them, lending a natural and warm appearance.

Limitations: Timber barns are prone to rotting, especially in humid environments. They are less fire-resistant, have a higher risk of fire, and require frequent maintenance, resulting in higher maintenance costs.

Stone/Concrete Hay Shed

Stone and concrete barns are sturdy and durable, suitable for long-term storage of hay. They can provide extremely high stability and security, especially in harsh climate conditions.

Limitations: Constructing this type of barn is costly and time-consuming. The lack of good ventilation design allows moisture to accumulate, which may have a negative impact on hay storage.

Stack Yards

Open yards are low-cost, suitable for temporary storage of large amounts of hay, and are usually covered with tarps or thatch, especially suitable for dry climate areas.

Limitations: This storage method is susceptible to weather and relies on a dry environment, so rain or humidity can cause the hay to get damp. In addition, the yard is not well protected and is susceptible to insect and rodent infestation.

Steel hay silos: a modern and efficient solution

Types of steel hay barn kit

Steel sheds

Steel sheds are typically made of open side walls and corrugated steel roofs, designed to balance ventilation and rain protection.

The open side walls enable airflow, while the corrugated steel roof is waterproof, keeping hay dry and minimizing moisture buildup.

The shed design is suitable for storing large quantities of hay, especially in areas with milder climates.

Quonset huts

Quonset huts feature a column-free semicircular vault design that maximizes space utilization, provides more storage space, and allows for more flexible interior layout.

Due to their unique arched structure, quonset huts are highly resistant to wind and snow and can withstand strong winds and snow weight. This warehouse design is particularly suitable for farms that require large-scale storage, especially large areas of hay storage.

Multi-Level Steel Barns

Multi-Level Steel Barns use vertical storage to effectively save ground space, and are particularly suitable for sites with limited land but large storage capacity.

An automated loading and unloading system can enhance hay storage and retrieval efficiency while minimizing manual tasks. This design is ideal for high-density industrial farms or hay storage where precise management is needed for efficient storage.

Temporary and portable hay storage

Temporary and portable hay storage, such as wholesale extensible portable garden sheds, are an affordable option that can be quickly built and adapted to different storage needs.

These storage options are usually designed with waterproof storage sheds to effectively prevent rainwater infiltration and can be paired with fire resistant tarps to reduce the risk of fire. Compared with traditional hay storage barns, portable structures are more maneuverable and suitable for small farms or short-term storage needs.

Container-Based Hay Storage

Container-Based Hay Storage is suitable for long-term storage, especially for farms that require fire protection, moisture resistance and high-density stacking. Steel hay barns combined with vertical storage sheds can maximize the storage of hay in a limited space, while using a stack ventilation system to optimize air circulation and prevent hay from mildew.

Short-term storage can be combined with an economy container door tarp, while long-term storage is recommended to use a steel hay barn to ensure a stable, durable and reliable structure.

Core advantages of steel hay barns

Durability: Steel structures, especially galvanized steel plates, have excellent corrosion resistance and wind and snow resistance, which can prevent corrosion and decay and ensure long-term stable use. Compared with wooden warehouses, steel structures have stronger fire resistance, effectively reducing fire risks and protecting hay and farm assets.

Economical: The prefabricated component design makes installation more efficient, saving time and cost. Steel is durable and has a service life of 30 to 50 years, far exceeding wooden and concrete warehouses, bringing long-term return on investment. In addition, steel warehouses have low maintenance costs and do not require frequent anti-corrosion treatment, reducing operating expenses.

Flexibility: The modular design allows the warehouse to be expanded or rebuilt as needed to adapt to changes in storage needs or relocation. For farms that are constantly expanding or adjusting, steel structures provide a high degree of flexibility.

Low maintenance: Steel warehouses do not require regular anti-corrosion, and are simple to clean and maintain, reducing daily maintenance work. Durable steel reduces the need for frequent repairs and reduces the burden of farm management.

Applicable scenarios for steel hay silos

Large industrial farms

- For industrial farms that need to store large amounts of hay and manage them efficiently, steel hay s provide an ideal solution. Its spacious design and efficient storage make it ideal for high-demand farms that manage large quantities of forage.

Rainy/high-humidity areas

- Steel warehouses are ideal for wet or rainy areas because they are highly resistant to corrosion and waterproof. Steel warehouses are better than wooden ones because they resist rot and moisture damage, helping to keep hay dry and maintain its quality.

High-value hay storage

- For farms that need to store high-value hay (such as organic hay or specialty grass) for a long time, steel hay s provide excellent storage conditions. Steel effectively protects hay from external climate impacts, maintaining its quality during storage.

Steel Barn vs Other Materials Comparison

| Criteria | Steel Barn | Wood Barn | Concrete Barn |

| Construction Cost | Medium-Low | Medium-High | High |

| Maintenance Cost | Very Low | High (requires treatment) | Low |

| Construction Time | 1-4 weeks (prefabricated) | 2-6 months | 3-12 months |

| Disaster Resistance | Excellent (fire/wind resistant) | Poor (flammable) | Good (weak seismic resistance) |

| Environmental Impact | High (recyclable) | Medium (depends on forest resources) | Low (high carbon footprint) |

Which building is best for storing hay?

Steel barns are the best choice for most farms. They offer low construction and maintenance costs, quick building times, and great resistance to fire and strong winds. Steel barns are also environmentally friendly due to their high recyclability.

While wooden barns have a traditional aesthetic, they require frequent maintenance to prevent rot and fire risks. Although durable, concrete barns are more expensive and time-consuming to construct, and offer less flexibility.

How to Choose the Right Hay Storage Barn

Storage Requirements

Select the appropriate barn size according to the quantity of hay you plan to store. Large farms should opt for a high-capacity barn, while small farms can select a medium-sized one. The right size ensures that the hay is well ventilated and stored in good conditions, avoiding wasted space.

Climate Conditions

Consider local climate conditions, especially precipitation, snow, and wind. Steel barns provide better protection from heavy rain, snow, and wind, keeping hay safe from moisture and damage. Make sure the barn design you choose can accommodate these special climate challenges.

Budget

While steel structures incur higher initial costs, their durability and low maintenance requirements result in significant long-term savings. Steel hay storage buildings are more cost-effective than wood or concrete barns because they lower repair and replacement costs.

Future Expansion

Choose a barn with a modular design that can be easily expanded or rebuilt in the future as needs increase. This is especially important for farms with growth plans to avoid unnecessary re-construction in the future.

We recommend:

For farms that require durability, low maintenance, and high storage capacity, steel hay silos are the best choice. They offer long-term economic benefits and an efficient storage solution, making them ideal for hay storage.

Related Reading: Factors to Consider When Choosing Hay Storage Buildings

How to Plan a Steel Hay Storage Barn

Key Points for Designing a Hay Storage Barn

- Ventilation: Adequate ventilation is crucial to prevent hay from becoming damp and moldy. The warehouse design should promote air circulation to prevent moisture buildup and keep the hay dry and high quality.

- Rain and Snow Protection: A good roof design should effectively prevent rain and snow water from penetrating into the warehouse to ensure that the hay is not affected by moisture. Waterproof materials and a sloped design facilitate water drainage and prevent accumulation.

- Durability: Steel warehouses need to be able to withstand natural conditions such as extreme weather, wind, snow pressure, etc. to ensure long-term use. High-quality steel and anti-corrosion treatment can significantly improve the durability of the warehouse and extend its service life.

- Space Efficiency: Design must optimize available space to maximize storage capacity. Reasonable layout can improve storage efficiency and reduce wasted space.

- Scalability: Reserve space for future demand expansion. Select a modular design with a flexible layout to allow easy expansion of the warehouse as hay storage needs grow.

Requirements Analysis

- Storage Capacity: Determine the size of the warehouse based on the tonnage requirements of the hay. Estimate the amount of hay stored and the annual consumption of hay to ensure that the warehouse can accommodate sufficient storage to avoid frequent handling or re-storage.

- Site Size: Select the appropriate warehouse size based on the available land area. If the site is limited, you may need to choose a multi-story design or vertical storage to save space.

- Future Expansion Needs: Forecast future storage requirements and take into account the farm’s growth and expansion plans. Make sure the warehouse design is scalable to facilitate the addition of storage space in the future.

Structural Analysis

- Roof Slope: The slope of the roof should be designed to take into account the drainage of rain and snow water. The appropriate slope ensures that moisture does not accumulate on the roof and avoid excessive structural stress caused by snow or water accumulation.

- Sidewall Ventilation: The opening design of the sidewall is critical to ventilation. The proper opening rate ensures air circulation, helps dry hay and prevents mold.

- Foundation Type: Selecting the appropriate foundation type is crucial. Concrete floors are durable and ideal for sturdy foundations, while gravel foundations work well for large warehouses with less foot traffic and offer good drainage.

Cost Optimization Tips

Choose Pre-fabricated Kits vs. Custom Design:

- Prefabricated kits usually save time and labor costs and are suitable for farms with limited budgets and need to build quickly. Custom designs can be tailored to specific needs, but they come at a higher cost. Choosing the right solution can optimize costs without sacrificing quality.

Government Agricultural Subsidies:

- Many regions provide energy-saving building subsidies or other agricultural-related subsidies, especially for buildings that take environmentally friendly measures. Understanding and leveraging these subsidy policies can effectively decrease construction costs and enhance the project’s economic efficiency.

Hay Storage Barn Suppliers

Choosing the right hay storage is crucial for both large agricultural enterprises and small farms needing efficient hay storage. Hay storage sheds are the preferred solution for many farms due to their durability, low maintenance costs, and flexibility.

Contact our team to design and build a safe hay storage silo with high-quality steel solutions tailored to your needs.