A monoslope cattle barn offers farmers a smarter, low-maintenance way to house their herds—combining efficient drainage, better ventilation, and durable PEB steel construction. In this guide, you’ll learn exactly how to design a functional monoslope barn, from choosing the right roof pitch and orientation to mastering ventilation, flooring, lighting, and space planning that keeps cattle healthy year-round.

We’ll also break down cost and sizing factors, helping you estimate your investment and select materials that balance durability and efficiency. For farms seeking compact solutions, discover space-saving layouts that integrate with existing buildings and future-proofing strategies for herd expansion. You’ll even see why galvanized steel trusses outperform wood, and how custom add-ons—like solar-ready roofs or smart feeding systems—boost productivity and biosecurity.

Built on our decade of engineering experience, SteelPRO PEB designs and manufactures certified PEB steel structures with factory-direct quality, ISO and CE certifications, and a 50-year structural warranty.

Practical, proven, and factory-engineered—this is your complete guide to designing a long-lasting monoslope cattle barn.

What is a Monoslope Cattle Barn?

A monoslope cattle barn—often called a single-slope barn or slant-roof barn—is a modern agricultural structure with one sharply angled roof plane sloping downward to a single low side. Unlike traditional barns with symmetrical peaked roofs, this design prioritizes climate resilience and space efficiency. Picture a giant lean-to sheltering livestock: the high open side invites sunlight and airflow, while the sloped roof sheds rain, snow, and debris like a tilted umbrella.

What’s its purpose? Farmers use monoslope barns to protect cattle from extreme weather while reducing manual labor. The angled roof eliminates snow buildup (no more midnight roof shoveling!), and the open-wall design lets fresh air sweep through stalls, lowering disease risks. Dairy farmers in Wisconsin swear by them for winter calving, while ranchers in Texas rely on their shade to keep herds cool.

How is it different from traditional barns?

- Roof Design: Traditional barns use A-frame roofs that trap snow; monoslope roofs shed it effortlessly.

- Ventilation: Open-front monoslope barns need fewer fans than enclosed barns—nature does the work.

- Space Use: The single-slope structure allows tighter, heat-retaining layouts in winter, unlike drafty gable-roofed barns.

Why does this matter? Imagine two barns side by side during a blizzard. The traditional barn groans under snow weight, while the monoslope barn stays clear—saving you repair costs and sleepless nights. It’s not just a barn; it’s a weatherproofing strategy with hooves and hay.

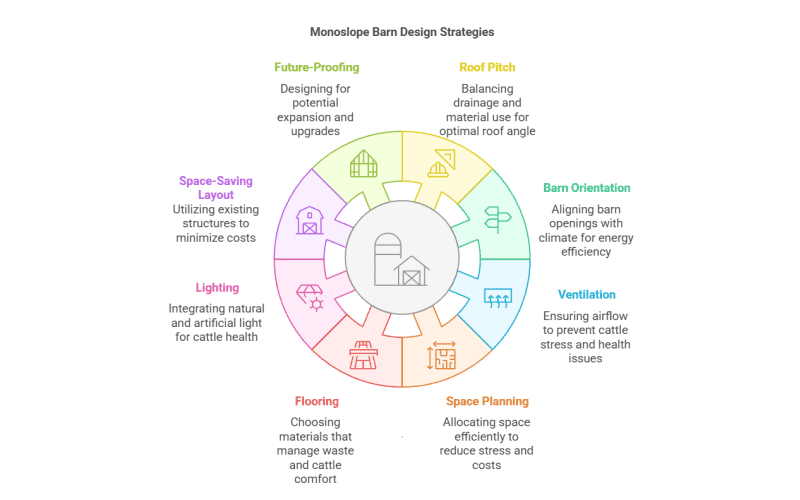

Core Design Principles for a Functional Monoslope Cattle Barn

A monoslope barn works best when every element is designed for efficiency—from directing water runoff to optimizing airflow. Here are the essential principles that make these barns a game-changer.

Best Roof Pitch for Monoslope Cattle Barns

The defining feature of a monoslope barn is its 5°–15° pitched roof, designed to efficiently shed rain and snow. A steeper pitch can increase material use, while a shallower pitch may lead to snow buildup. In many cases, a 10° pitch provides a good balance—fast drainage without unnecessary height.

Pro Tip: Pair the roof slope with a 2–3 ft overhang on the lower side to prevent rainwater from pooling near the foundation. Install gutters with a 1–2% slope toward downspouts to direct runoff away from cattle areas.

Monoslope Barn Orientation

The barn’s open side should always be positioned based on climate conditions. In cold regions, a south-facing opening captures winter sunlight to keep cattle warm. In hotter climates, a north-facing design prevents overheating by keeping the interior shaded. Getting this right can cut heating and cooling needs by up to 30%.

Location-Specific Adjustments:

| Climate Type | Orientation | Key Benefit |

| Cold/Windy | South | Solar heat gain in winter |

| Hot/Arid | North | Shade retention in summer |

| Mixed Seasons | East | Morning sun, afternoon shade |

Monoslope Cattle Barn Ventilation

Good airflow is non-negotiable—stagnant air leads to respiratory issues and heat stress. Our experience shows that a combination of ridge vents and adjustable side curtains keeps air moving while protecting cattle from harsh winds. Curtains also let you fine-tune ventilation based on weather conditions, making the barn adaptable year-round.

Upgrade Option: For larger barns (>1,500 sq ft), add a 12–18″ continuous ridge vent paired with windbreaks (e.g., slatted walls) on the closed side to create a cross-breeze effect.

Optimal Space Planning for Monoslope Barns

Cramming too many cattle into a barn leads to stress and illness, while wasted space drives up costs. For small herds (20–50 cattle), we recommend:

| Herd Size | Recommended Barn Area |

| 20–30 cattle | 600–900 sq ft |

| 40–50 cattle | 900–1,200 sq ft |

A well-planned layout ensures efficient feeding, movement, and waste management without wasted space.

Best Flooring for Monoslope Barns

The floor should slope 1–2% toward the open side to channel urine and rainwater out of the barn. Avoid concrete-only surfaces—rubber mats or textured finishes in resting areas reduce joint stress and slipping.

Flooring Comparison:

| Material | Best For | Maintenance Tip |

| Grooved Concrete | Feeding alleys | Power-wash weekly |

| Rubber Mats | Resting zones | Replace every 5–7 years |

| Compacted Gravel | Budget-friendly | Regrade annually |

Lighting for Monoslope Barns

While monoslope barns rely on natural light, add LED fixtures above feeding areas for early mornings or cloudy days. Aim for 15–20 lumens/sq ft to mimic daylight cycles—this improves cattle weight gain and simplifies tasks like health checks.

Cost-Saving Hack: Install solar-powered motion-sensor lights in less frequented areas (e.g., storage corners) to cut energy use by 40%.

Monoslope Barns Space-Saving Layout

Monoslope barns shine as space-savers by hugging existing buildings like main barns, equipment sheds, or even your farmhouse. Why build standalone when you can piggyback on sturdy walls you already own? This “lean-to” approach cuts material costs by 20–30% and turns dead space into productive cattle housing.

We provide detailed monoslope barn layout plans and structural drawings, customized to match your existing site conditions and local building requirements. These plans help visualize space use, drainage flow, and cattle movement before fabrication begins.

How to Design Around Existing Structures:

- Shared Wall Strength: Attach the barn’s high side to a load-bearing wall of your main barn. Ensure the wall can handle roof weight—reinforce with steel brackets if needed.

- Roof Alignment: Match the slope of your existing roof (if under 12°) to simplify gutter systems and prevent snow dams.

- Shared Utilities: Tap into existing water lines, electrical panels, or manure pits within 15 ft to avoid costly new installations.

Attachable Building Types & Benefits:

| Existing Structure | Ideal Use | Space Saved Per Cattle |

| Main Barn | Calving pens, sick bays | 8–10 sq ft/head |

| Grain Storage | Feeding alleys, hay storage | 12–15 sq ft/head |

| Workshop | Equipment-friendly youngstock | 6–8 sq ft/head |

Pro Tip: Leave a 2–3 ft gap between old and new structures for maintenance access. Fill it with gravel to improve drainage and discourage rodents!

By borrowing strength and space from what’s already there, you’ll slash build time and create a barn that feels like it’s always belonged.

Future-Proofing Monoslope Barns

Even small barns should allow for easy scaling. Use modular stall dividers and leave 10–15 ft of unused space on the north/east side for future pens or equipment storage. Pre-wire conduit for potential fans or automated feeders to save retrofit costs later.

Monoslope Cattle Barn Cost & Sizing Guide

Design efficiency is only half the story. Cost and scale matter just as much when planning your cattle barn. From small family operations to 100-head feedlots, each monoslope structure has unique cost drivers and material options.

Key Factors Affecting Cost

- Size & Herd Capacity – The most direct influence. A 20-head barn may use lighter steel and fewer trusses, while a 100-head setup demands heavier frames and wider bays.

- Material Choice – Galvanized steel offers 50-year durability with minimal maintenance, while hybrid (steel + wood) frames may lower upfront costs but require frequent repair.

- Roof Pitch & Height – Steeper slopes improve drainage but slightly raise fabrication costs due to additional steel tonnage.

- Regional Climate & Foundation Type – Frost-prone or high-moisture regions require deeper footings and treated concrete, increasing cost by 5–10%.

- Add-ons – Curtains, ridge vents, solar panels, and feeding systems typically account for 10–20% of total cost.

Typical Budget Ranges

| Herd Size | Approx. Area | Cost Range (Factory Supply) |

| 20–30 head | 600–900 sq ft | $9,000–$14,000 |

| 50–100 head | 1,200–2,000 sq ft | $18,000–$35,000 |

| 100+ head | 2,000–3,500+ sq ft | Custom quotation required |

Planning for the Right Size

Before ordering, consider your cattle growth plans and feeding systems. Oversizing leads to wasted material and heating costs; undersizing impacts animal comfort and health. SteelPRO PEB’s engineering team can model your layout digitally — optimizing stall count, feeding alleys, and roof pitch for your herd size and local climate.

Contact SteelPRO PEB to get a tailored cost analysis and 3D design proposal for your monoslope cattle barn.

Unique Monoslope Barn Design Tips from Our Experience

Through years of working with farmers, we’ve seen firsthand what works—and what doesn’t. These design tweaks can extend your barn’s lifespan, improve efficiency, and reduce long-term costs.

Steel vs. Wood: Why Galvanized Steel Trusses Last Longer

Based on our fabrication experience at SteelPRO PEB, galvanized steel trusses outperform wooden structures by over 5× in lifespan and structural reliability. Wood might seem like a budget-friendly option, but it rots, warps, and requires frequent repairs. We’ve seen farmers replace wooden trusses in as little as 10 years, while galvanized steel trusses last over 50 years with zero rot or pest damage. Yes, steel costs more upfront, but when you factor in maintenance, it’s the cheaper long-term choice.

All SteelPRO PEB barns are built using CE-certified steel and ISO-tested corrosion-resistant coatings, ensuring long-term durability even under high humidity or snow load conditions.

Customizable Add-Ons: Smart Features for Efficiency

Want to make your barn even more functional? These add-ons can boost productivity and lower operational costs.

- Retractable Feeding Panels – Allow for easy rotational grazing integration, giving cattle direct access to pasture without opening gates.

- Solar-Ready Roofs – A monoslope design is perfect for solar panels, making off-grid energy possible—especially useful for remote farms with high power costs.

Biosecurity Hacks: Sloped Concrete Floors with Grated Drains

We recommend sloped floor plans (1–2% grade) paired with grated drain systems as part of your blueprint—a proven way to combat manure buildup. This strategic approach guides waste away from cattle areas, reduces bacterial growth hotspots, and simplifies cleaning for farmers.

Why it matters: Proper drainage design cuts daily cleanup time by 50% compared to flat-floor barns. Though we don’t install concrete or drains ourselves, we’ll ensure your barn’s framework supports these critical features.

Now that you’ve seen how steel trusses, solar-ready roofs, and smart drainage design can transform your barn, you might be wondering: “How do I actually build this?”

For hands-on guidance—including step-by-step framing diagrams, material lists, and pro tips for avoiding common mistakes—dive into our detailed companion piece:

How to Build a Small Monoslope Cattle Barn

What is the ideal roof pitch for snow-prone regions?

For heavy snow areas, a 10°–15° monoslope roof provides the best balance between drainage and material use. This slope ensures snow sheds efficiently without adding unnecessary height or cost.

How much does a monoslope cattle barn cost per head?

On average, factory-supplied PEB monoslope barns range from $400–$700 per head, depending on material thickness, layout, and local foundation conditions. Contact SteelPRO PEB for an accurate, factory-direct quotation.

Can I attach a monoslope barn to an existing building?

Yes. Monoslope barns can easily be attached to existing agricultural or storage structures using shared walls or trusses. This approach reduces cost and construction time by 20–30%, provided the existing wall can support the roof load.

What certifications ensure SteelPRO barns’ durability?

Every SteelPRO PEB barn is built with ISO 9001-certified quality systems and CE-certified steel, offering a 50-year structural warranty and 25-year corrosion protection. These standards ensure long-term performance under diverse climates.

Ready to Build Your Ideal Monoslope Barn?

Designing a monoslope barn that nails every detail—from snow-shedding roofs to bio-secure drainage—isn’t just about blueprints. It’s about collaborating with our steel structure specialists who’ve engineered 1,000+ low-maintenance barns tailored to farms like yours.

Our Small Monoslope Cattle Barn designs pack these battle-tested principles into compact, customizable kits. Whether you’re attaching to a grain silo or starting fresh, we’ll ensure your barn:

- Integrates galvanized steel trusses (50-year lifespan guaranteed)

- Supports solar add-ons or retractable feeding panels

- Aligns perfectly with regional climate challenges

Contact SteelPRO PEB today for your factory-direct PEB monoslope barn quotation — combining certified design, precision fabrication, and 50-year durability, all from one manufacturer. Our engineering team will prepare a customized cost plan and 3D design proposal based on your herd size, site layout, and local snow load requirements.

SteelPRO PEB — Global Steel Structures Manufacturer & Producer since 2013.