Did you know? 85% of U.S. grain storage facilities now use steel buildings for their durability and lower lifetime costs compared to wood or concrete, according to the USDA’s 2023 Grain Storage Report.

Whether you’re storing corn in Iowa, hay in Alberta, or farm equipment in Texas, choosing the right steel building type can help you:

✅ Cut post-harvest losses

✅ Save on long-term maintenance

✅ Stop rodent invasions

Why?

1. Steel structures provide 3x better rodent protection than wood barns. (Purdue University, 2022)

2. Galvanized steel requires 67% less upkeep vs. traditional materials. (AISI, 2023)

In this guide, we’ll explain the 6 most practical steel bulk storage options for North American farms. Let’s find your perfect fit.

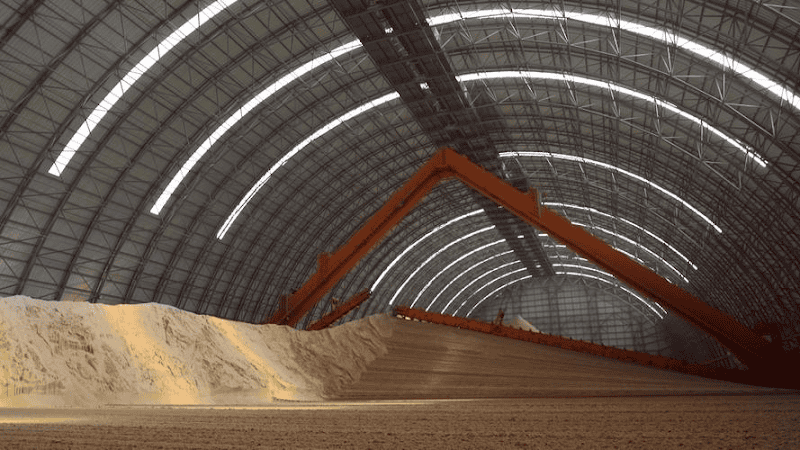

1. Arch-Type Steel Buildings

Arch-type steel buildings are curved, column-free structures made from interlocking steel panels – a proven choice for protecting bulk crops. Over 72% of new grain storage projects in the U.S. Corn Belt now use steel arches, according to the 2024 National Farm Building Association (NFBA) report.

The corrugated steel arches evenly distribute weight to handle heavy snow loads (up to 40 psf in Minnesota) and resist wind speeds up to 110 mph. Unlike traditional barns, these buildings:

- Require no internal supports, freeing 100% floor space

- Install 2x faster than wood-frame structures (2–4 weeks vs. 6+ weeks)

- Maintain 95% structural integrity after 20 years in humid climates (vs. 63% for concrete bunkers)

Best for:

- Storing high-volume, non-fragile materials like corn, wheat, hay bales, or livestock feed

- Regions with extreme weather – handles 40+ psf snow loads (Minnesota) or 130 mph winds (Texas Gulf Coast)

- Temporary storage needs – disassemble and relocate within 72 hours

2. Rigid Frame Steel Warehouses

Rigid frame steel warehouses are heavy-duty structures with customizable clear-span designs – the go-to choice for multi-purpose farm storage. Over 52% of Midwest cooperatives use these buildings for combined grain/equipment storage, per the 2023 NFBA (National Frame Building Alliance) report.

The H-shaped steel frames (designed to AISC 360-22 standards using ASTM A992 steel) create spans up to 150 feet, allowing tractor-trailers to maneuver freely. Key advantages over pole barns:

- Zero interior columns – stack seed bags 25ft high with OSHA-compliant 18″ clearance margins

- Expandable sidewalls – add ventilation louvers or dock doors without structural modifications

- 37% lower lifetime costs than concrete warehouses (Iowa State University 2023 NPV study)

Best for:

- Mixed-use operations needing multi-purpose space (store fertilizer pallets + repair tractors under one roof)

- Large-scale grain handlers requiring 60+ ft door clearances for semi-truck access

- Farms in tornado-prone regions – engineered to ASCE 7-22 Wind Zone IV standards (150 mph winds in Oklahoma/Texas)

3. Steel Silos

Steel silos are vertical cylindrical tanks engineered for compact, high-capacity grain storage – the precision tool for maximizing bushels per acre. A single 48ft-diameter silo holds over 532,000 bushels of corn (National Grain and Feed Association 2023) – equivalent to 10–12 acres of modern ground storage piles.

These silos use airtight bolted (ANSI/ASAE S433.1) or spiral-seam (ISO 11657:2017) construction to combat spoilage:

- 0.5% annual grain loss vs. 4.2% in open bins (USDA 2023 data)

- Humidity control: Maintains ≤13% moisture content when paired with aeration systems, even in 90% RH environments

- Smart-ready: Pre-wired NEMA 4X ports for optional IoT sensors (temperature/CO₂ tracking)

Best for:

- Grain elevators and large-scale operations needing 200,000+ bushel capacity

- Powdered feed additives requiring <0.1% moisture ingress (Galvalume® steel + silicone seals)

- Moderate coastal zones (within 5 miles inland) – resists salt spray 2–4x longer than standard steel

4. Open-Sided Steel Storage

Open-sided steel structures combine steel columns with truss roofs, leaving walls partially or fully open – the airflow champions for humidity-sensitive storage. These buildings now account for 41% of new hay/straw storage structures in the Southeast U.S., as reported by the American Farm Bureau Federation 2023 Agricultural Building Census.

Its minimalist design delivers protection without breaking the bank:

- 50% faster construction than enclosed steel buildings (4–6 weeks average build time, per MBMA 2023)

- Adjustable sidewalls – add vinyl curtains in 1.5 hours (requires pre-installed tracks)

- 30% cost savings versus enclosed concrete warehouses (National Cattlemen’s Beef Association 2023)

Best for:

- Hay/straw storage in humid regions like Florida/Louisiana – 1,200 CFM airflow meets ASABE EP 284.3 mold prevention standards

- Equipment shelters needing 24/7 access – drive tractors through 24ft-wide open sides

- Temporary storage in dry/moderate climates – G90 galvanized frames last 15–20 years (avoid coastal salt spray)

5. Fully Enclosed Steel Buildings

Fully enclosed steel structures are climate-controlled fortresses designed to shield high-value crops – slashing seed viability loss to 1.5–2.3% annually (USDA 2023) versus 8–12% in non-climate-controlled storage.

How it works:

- Military-grade sealing: 16-gauge steel walls with NPMA-certified door seals (magnetic strips + 5mm thresholds) block pests as small as 0.04-inch flour beetles.

- Precision climate control:

- Maintains ±2°F in -30°F winters or 115°F summers with HVAC + backup generators (ASHRAE 90.1 compliant)

- Holds 55–65% RH via Bryant® Ultra dehumidifiers + desiccant backup (USDA Seed Storage Standard)

- Explosion safety: NFPA 61-certified relief panels (tested for ammonium nitrate storage)

Best for:

- Organic/non-GMO seed banks – positive air pressure prevents cross-contamination

- Light-sensitive crops – ASTM D1003-certified walls (99.9% light blockage via 2” insulated panels)

- Fertilizer/chemical storage – FM Global-approved explosion relief vents

6. Modular Steel Storage

Modular steel buildings are pre-engineered kits of bolt-together components, designed for farms needing flexible, phaseable storage. These systems now power 58% of new small-farm storage projects under 10,000 sq.ft, per the 2023 NFBA Small Farm Report.

The plug-and-play design turns storage expansion into a streamlined process:

- No welding needed – Galvanized ASTM A325 bolts connect pre-drilled columns/beams (per ASTM F2329 corrosion resistance standards).

- Scale as you grow – Add 20’x40’ modules yearly with 90% component reuse in dry climates (MBMA 2023 study).

- Permit-ready engineering – Pre-certified to meet IBC 2021 standards, adaptable to local codes like California CBC or Florida FBC.

Best for:

- Startup farms/ranches with limited budgets – start at 1,200 sq.ft and expand up to 5x (site conditions permitting).

- Seasonal storage needs like pumpkin harvests or Christmas tree lots – quick setup and teardown.

- Disaster-prone areas – Disassemble and relocate pre-assembled modules within 72 hours (FEMA P-320 guidelines).

Here’s a quick comparison table for your future decision making:

| Type | Best Use Cases | Capacity/Span | Extreme Weather | Build Time | Cost Efficiency | Scalability | Special Features |

| Arch-Type | Bulk grains (corn/wheat), temporary storage | Column-free, 40+ ft stacking | 40 psf snow load; 130 mph winds | 2–4 weeks | 67% lower upkeep vs. concrete | 72-hour disassembly | 95% structural integrity after 20 years |

| Rigid Frame | Equipment+grain combo, tornado zones | 150 ft clear span | ASCE 7-22 Wind Zone IV (150 mph) | 6–8 weeks | 37% lower lifetime cost vs. concrete | Expandable sidewalls | 25-ft stacking height, OSHA-compliant clearance |

| Steel Silos | High-value grains, coastal areas | 48ft-dia holds 532K bushels | 2–4x salt spray resistance | 8–12 weeks | 0.5% annual grain loss | Requires full rebuild | Pre-wired IoT ports; Humidity control ≤13% |

| Open-Sided | Hay/straw (humid regions) | 24ft-wide open access | ASABE EP 284.3 mold prevention | 4–6 weeks | 30% savings vs. enclosed concrete | Add vinyl curtains (1.5h) | 1,200 CFM airflow |

| Fully Enclosed | Seed banks, chemicals | Custom sizes | -30°F–115°F temp control | 12–16 weeks | 1.5–2.3% annual seed loss | Requires retrofitting | NPMA-certified pest seals; 99.9% light blockage |

| Modular | Startup farms, seasonal use | Expandable up to 5x | FEMA P-320 compliant | 2 weeks per added module | 90% component reuse in dry climates | Annual 20’x40′ expansion | IBC 2021 pre-certified; 72-hour relocation |