As the construction industry develops rapidly, more and more designers, developers and construction companies are beginning to pay attention to an efficient and flexible construction method – Volumetric Modular Construction.

Perhaps you have heard the term “modular construction” in the news, but what does “volumetric” module mean? How is it different from the traditional construction method we are familiar with? This article will give you a comprehensive analysis of the concept, process, advantages and future development trends of Volumetric Modular Construction, and take you to understand the new future of the construction industry.

What is Volumetric Modular Construction?

Volumetric Modular Construction is a construction method that divides the entire building into three-dimensional modules (usually complete rooms or space units), which are prefabricated in the factory and then transported to the construction site for assembly. These modules have completed most of the structure, walls, floors, ceilings, and even pipes, wires, and interior decoration before leaving the factory.

How does Volumetric modular construction work?

Volumetric modular construction works like an efficient industrial production line, which moves a lot of work that used to be done on site to the factory in advance. The whole process can be roughly divided into the following key steps:

Design phase

Everything starts with design. According to the project requirements, the architect disassembles the building into multiple standard or customized modular units, and plans the details of structure, pipelines, fire protection, etc. All designs must meet the standards of transportation and assembly.

Factory prefabrication

Each module will be built in a controlled factory environment, including structural frame, wall insulation, door and window installation, water and electricity pipeline laying, and even interior decoration and painting. Compared with traditional construction sites, factory construction is more efficient, more consistent in quality, and is not affected by weather.

Transportation and hoisting

After the module is built, it is transported to the project site by truck. The size of the module will be limited by transportation specifications (usually controlled within 3~4 meters wide and 12 meters long), and the module will be put in place on site by hoisting equipment.

On-site assembly and connection

After arriving at the site, the modules will be assembled like a puzzle, connecting the structure, adjusting the level, and connecting to the overall water and electricity system. This process is much faster than traditional construction, and the building can be seen “growing” within a few weeks.

Finishing and acceptance

Finally, a small amount of edge processing, system debugging and final acceptance are carried out. The overall construction cycle is shortened by 30%-50% compared with the traditional method, and the quality is stable and there is less interference in on-site construction.

Through this operation mode, Volumetric Modular Construction has achieved “industrialization + standardization” of the construction process, which has not only improved efficiency but also reduced the error rate. It is an ideal solution for projects that have high requirements for time, cost and quality.

Main advantages of volumetric modular construction

Why is volumetric modular construction becoming more and more popular? In addition to the novel construction method, it also brings considerable practical benefits. Here are some of the core advantages of this construction method:

1. Faster construction

Because on-site construction and module prefabrication can be carried out simultaneously, many projects only take a few months from design to delivery, which is particularly suitable for commercial projects or emergency facilities with tight construction schedules.

2. More predictable cost control

Construction in a factory environment can more accurately control material waste, labor costs and construction progress. This controllability makes project budgets more stable and reduces additional expenses caused by on-site problems.

3. More consistent quality

All modules are built in a controllable and standardized factory, avoiding quality fluctuations caused by factors such as weather and personnel changes. The structure, safety, insulation and decorative effects of each module are strictly tested, and the overall building quality is more guaranteed.

4. Less environmental impact

Modular buildings have a short on-site construction time, reducing the generation of noise, dust and construction waste. Coupled with the optimized use of materials in the factory production process, it is more environmentally friendly and sustainable.

5. Higher safety and worker welfare

Volumetric module construction is mostly completed indoors, which is safer and improves the working environment of workers.

6. Easy to expand and reuse

If the project needs to be expanded, just add more modules to the original building, which is very flexible. In some cases, the modules can even be moved or reused as a whole, further improving the return on investment.

Challenges and considerations for volumetric modular buildings

Despite the significant advantages of volumetric modular buildings, the following points should still be noted in practical applications:

Transportation restrictions: The size of the modules is limited by road transportation regulations, which may affect design flexibility.

Structural connection and sealing: The quality of the splicing between modules needs to be strictly controlled to ensure the integrity and waterproof performance of the building.

Foundation and site conditions: Although on-site construction has been reduced, supporting facilities such as foundation, power supply, and drainage still need to be prepared in advance.

Regulatory approval: The regulations and approval processes for modular buildings vary from region to region, which need to be understood and planned in advance.

These problems are not insurmountable. As long as they are fully considered in the design and planning stages, volumetric modules are still a very worthwhile construction method.

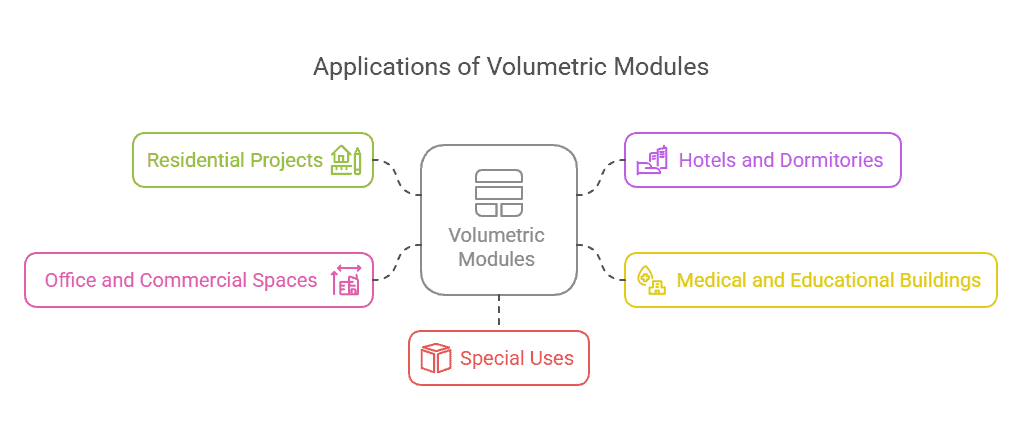

Common application scenarios of Volumetric modules

Volumetric modular buildings have been widely used in a variety of scenarios due to their high efficiency and flexibility, including:

- Residential projects: such as apartments and townhouses, most of which are standardized and repeated units, which are convenient for mass production.

- Hotels and dormitories: suitable for standard room layouts, fast construction, and unified decoration style.

- Medical and educational buildings: used for temporary clinics, wards, classrooms, student dormitories, etc., with rapid deployment.

- Office and commercial space: modular construction of office buildings, stores, etc., which is easy to replicate and expand.

- Special uses: such as construction site barracks, field facilities, temporary resettlement houses, etc., which have high requirements for timeliness and flexibility.

Volumetric vs Panelized vs Hybrid vs Modular

Modular construction isn’t a one-size-fits-all solution. Depending on the project’s needs, different modular systems may be more suitable. Below is a detailed comparison between Volumetric, Panelized, Hybrid, and general Modular systems based on key factors:

| Aspect | Volumetric (3D Modules) | Panelized (Flat Panels) | Hybrid (Mixed System) | Modular (General Term) |

| Structural Form | Fully enclosed 3D modules with structure and interior finish | Flat elements (walls, floors), assembled on-site | Combination of volumetric and panelized elements | General term, may include various modular approaches |

| Level of Completion | High – 80–95% completed in factory | Low – extensive site work needed | Medium – partial factory completion, some site construction | Depends on system used |

| Construction Method | Factory build → Transport → Crane installation → Connection | Factory makes panels → On-site assembly | Some modules prefabricated, others built on-site | Varies based on chosen method |

| Speed of Construction | Very fast – minimal on-site time | Slower – more on-site work | Moderate – balanced approach | Varies by system |

| Transport Difficulty | High – large trucks & cranes required | Low – flat-packed and easy to transport | Medium – depends on module size | Depends on module type |

| Design Flexibility | Lower – limited by transport dimensions | High – customizable on-site | Medium – flexible and scalable | Varies – flexible in most cases |

| Cost Control | Higher upfront cost, but predictable and time-saving | Lower material cost but longer timeline | Moderate – depends on complexity | Highly variable |

| Quality Consistency | Very high – factory-controlled quality | Variable – affected by on-site conditions | Medium – mixed environments | Depends on approach |

| Best Suited For | Hotels, apartments, hospitals, dormitories | Custom homes, rural buildings, complex structures | High-rise buildings, multifunctional public facilities | All modular construction types |

Summary:

- Volumetric is ideal for projects needing speed, quality consistency, and repeatable layouts (e.g., hotels, housing).

- Panelized is great for remote or irregular sites with transport limitations, offering greater design freedom but longer build time.

- Hybrid balances speed and flexibility, ideal for large or complex facilities.

- Modular is a broad term, so it’s important to clarify the specific system being used.

Future Trends of Volumetric Modular Buildings

As the construction industry continues to develop towards efficiency, environmental protection and digitalization, Volumetric modular buildings are ushering in broader application prospects. Here are a few development directions worth paying attention to:

More in-depth technology integration: BIM, digital modeling and factory automation will further improve design and construction efficiency and reduce errors.

Green and sustainable: Modular buildings are naturally environmentally friendly, and in the future they will combine more energy-saving materials and green technologies to promote low-carbon development.

More flexible and beautiful design: From “standard boxes” to more personalized architectural styles, modularity and creativity are combined.

Growth of high-rise projects: Technological advances are driving the application of modular buildings to mid- and high-rise residential and commercial buildings.

Strengthening globalization trend: With the improvement of standardization, Volumetric modules will be localized in more countries.

Volumetric modular construction is gradually changing our traditional understanding of “construction”. It is not only a faster and more efficient construction method, but also represents a more modern, standardized and sustainable construction concept. From residential to hospital, from classroom to office, it has been adopted by more and more projects and continues to show great potential.

Looking for a modern, efficient home? Our 2-story modular homes combine the speed and precision of modular construction with the flexibility to create a beautiful, functional living space. With reduced build times and customizable designs, our modular homes are the perfect solution for you.

FAQs

1. How high is the volumetric modular building suitable for?

Currently, most volumetric projects are used for low-rise to medium-rise buildings (generally no more than 10 floors), but with the development of structural technology, some medium- and high-rise projects (more than 15 floors) have also begun to adopt this method. The key lies in the professionalism of structural design and module connection.

2. Will volumetric modular buildings be more expensive than traditional construction?

The unit cost of a single module may be slightly higher than traditional construction, but the overall project cycle is shorter, and the labor and error rate are lower, so the total cost is usually more controllable and more cost-effective.

3. Can volumetric modules be customized?

Yes. Although the modules have certain size restrictions, personalized design can be achieved through module combination, appearance customization, interior changes, etc. As long as the design stage is properly planned, the flexibility is still very high.

4. Are modules easily damaged during transportation?

The modules will be structurally strengthened and packaged before leaving the factory, and the transportation plan is usually planned in advance. As long as it is responsible for the professional team, the transportation process is safe and reliable.

5. How does the volumetric module compare to 3D printed buildings?

3D printed buildings emphasize “on-site printing” and are suitable for small projects with complex shapes, but their efficiency and standardization are limited. The volumetric module is more suitable for large-scale, fast-delivered standardized buildings and is more mature and stable in actual commercial applications.