Have you ever stood beneath a soaring skyscraper or marveled at the Eiffel Tower’s intricate lattice and wondered: “How do these giants stay rooted against nature’s forces – storms, earthquakes, and the test of time?”

The answer lies not just in steel beams and concrete, but in an unsung hero working behind the scenes: the anchor plate. Think of it as the “joint” of a steel structure – small, often overlooked, yet indispensable. Without it, even the most meticulously designed steel framework would resemble a Lego masterpiece missing its glue: visually impressive, but one strong gust away from collapse.

Anchor plates are the ultimate connectors, bridging steel and concrete with silent determination. They’re the reason bridges sway but don’t snap, cranes lift tons without toppling, and your office building remains steadfast through decades of use. Let’s pull back the curtain on these hidden guardians of structural integrity.

Table of Contents

What is an Anchor Plate?

An anchor plate is, at its core, a deceptively simple piece of metal with a big job. Imagine a steel plate—roughly the size of a large pizza, though thickness varies based on its mission—pierced with strategically placed holes or studs. These holes aren’t random; they’re precision-engineered to house bolts or rods that act like metallic tentacles, gripping concrete or locking onto other steel components with unshakable resolve.

The plate itself is often square or rectangular, its edges sometimes flared or reinforced with ribs for extra strength. The bolts or rods protruding from it resemble a hybrid between a mechanical octopus and a high-tech Swiss cheese. But don’t let its modest appearance fool you—this component is the ultimate networker in the steel world.

Why “sociable”?

An anchor plate doesn’t believe in working alone. It’s always reaching out:

- To concrete foundations: Embedding itself to create a lifelong bond.

- To steel columns or beams: Welding or bolting connections that say, “We’re in this together.”

- To gravity and lateral forces: Boldly declaring, “Your move, Mother Nature.”

In essence, it’s the matchmaker of structural engineering—no connection is too ambitious, no load too intimidating.

What is the Purpose of an Anchor Plate?

An anchor plate isn’t just a metal slab with holes—it’s a structural Swiss Army knife. Let’s break down its superpowers with a mix of practicality and wit:

1. Transferring Forces

Imagine a steel column and a concrete foundation on a blind date. Without an anchor plate, they’d awkwardly stare at each other, unsure how to share the weight. The anchor plate steps in like a charismatic host, introducing the two materials and saying, “Hey concrete, meet steel. You two should really work together.”

🔹Technical translation: It transfers vertical loads (like the weight of a building) and lateral forces (like wind or seismic activity) between steel and concrete, ensuring they collaborate seamlessly.

2. Preventing “Breakups”

Concrete and steel have very different personalities. Concrete is rigid and brittle; steel is flexible but prone to rust. Under stress, they might try to part ways. The anchor plate acts like a couples’ therapist, gripping both materials with bolts and welds to say: “No splitting up on my watch!”

🔹Technical translation: It resists uplift forces (pulling) and shear forces (sliding), preventing separation during earthquakes, high winds, or heavy machinery operations.

3. Sharing the Load

If a steel column sat directly on concrete, it’d be like wearing stilettos on a sandy beach—concentrated pressure causing cracks and collapses. The anchor plate spreads the load like a snowshoe, turning a pinpoint force into a team effort.

🔹Technical translation: It distributes concentrated stresses over a wider area, protecting concrete from crushing and steel from bending.

4. Accommodating Imperfections

Construction sites aren’t perfect. Misaligned bolts? Uneven concrete? The anchor plate’s adjustable bolt holes and grout pockets swoop in like a superhero, whispering, “Don’t panic—I’ve got clearance for that.”

🔹Technical translation: It allows tolerance for installation errors, ensuring connections remain secure even if measurements aren’t millimeter-perfect.

Base Plate vs. Anchor Plate

If you’ve ever confused a base plate with an anchor plate, you’re not alone—even seasoned engineers occasionally mix up these two during coffee-deprived mornings. Let’s clear the air with a showdown that’s more fun than a Tesla vs. Ford debate.

Here’s the quick answer table:

| Aspect | Base Plate | Anchor Plate |

| Location | At the base of a column, resting on concrete | Embedded in concrete or between steel components |

| Primary Role | “Don’t let this column sink!” (Supports vertical loads) | “Don’t let these materials break up!” (Resists tension/shear) |

| Forces Tackled | Vertical compression (weight) | Uplift, shear, and sometimes compression |

| Looks Like | A thick, chunky pancake | A perforated disc with bolts/rods |

Let’s use a car as an example to make it easier for you to understand.

- Base Plate = Car’s Shock Absorber

Think of a base plate as the suspension system of your vehicle. It’s all about absorbing impacts and keeping the ride smooth—no one wants their steel column to “bottom out” on the concrete foundation. - Anchor Plate = Seatbelt Buckle

An anchor plate is like the metal clasp on your seatbelt. Its job isn’t to cushion your weight but to lock you in place when forces try to yank you sideways (or upward, in a crash). Without it, you’d go flying—just like a roof during a hurricane.

❓ Why This Distinction Matters

Choosing the wrong component is like wearing flip-flops to climb Everest:

- Base plate failure: Columns punch through concrete like a fist through Styrofoam.

- Anchor plate failure: Steel beams detach and wave hello to the ground below.

🎯 In short: Base plates handle squishing. Anchor plates handle yanking. Both are heroes but in very different capes.

Types & Applications of Anchor Plates

Think of anchor plates as the “shape-shifters” of steel construction—they adapt to whatever challenge a project throws their way. Let’s explore their most popular “costumes” and the real-world stages they shine on.

Common Anchor Plate Types

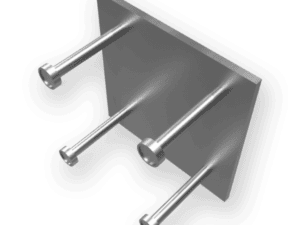

1. The Flat Plate with Studs

- Looks like: A steel pancake dotted with short, welded studs (like thumbtacks pressed into metal).

- Feature: Quick installation. Perfect for anchoring light fixtures, handrails, or prefab walls.

- Simple, versatile, and found everywhere.

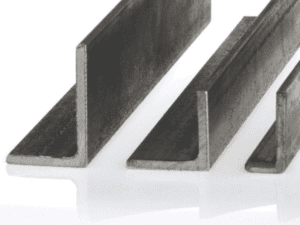

2. L-Shaped & T-Shaped Plates

- Looks like: A metal right angle (L-type) or a T-rex’s crest (T-type).

- Feature: Reinforcing edges and corners. Ideal for connecting beams to concrete walls or securing cantilevered structures.

- Ever seen a rooftop billboard? Thank the L-shaped anchor plate hugging the building’s edge.

3. Ribbed Anchor Plates

- Looks like: A plate with raised ridges or fins (think: steel waffle).

- Feature: Extra resistance against pull-out forces. The ribs dig into concrete like crampons on ice.

- Where you’ll find them: Suspended walkways, earthquake-prone regions, and anywhere “hold on tight” is the motto.

Real-World Scenarios of Anchor Plates

Scenario 1: Factory Crane Runways

Imagine a 20-ton crane gliding overhead in an automotive factory. Every time it lifts an engine block, the anchor plates in the runway beams are doing bicep curls. They’re not just holding steel—they’re absorbing vibrations, resisting lateral shifts, and whispering, “Drop another ton, I dare you.”

Scenario 2: Solar Farm Mountings

In a solar farm, anchor plates face a unique challenge: daily thermal expansion. As steel racks heat up and cool down, anchor plates flex like yoga instructors, keeping panels aligned without cracking their concrete foundations. Bonus points for resisting wind uplift—because nobody wants a solar panel kite.💨🪁

Scenario 3: Stadium Roofs

A stadium roof isn’t just heavy—it’s a giant sail. During a storm, anchor plates in the roof trusses become the ultimate tug-of-war champions. One side pulls from wind uplift; the other side yanks from the weight of rainwater. The anchor plate? Cool as a cucumber, redistributing forces like a seasoned mediator.

When Anchor Plates Go Rogue: Lessons from the Wild

- The Case of the Squeaky Bridge: A pedestrian bridge in Spain started “singing” in high winds—not due to design flair, but because undersized anchor plates allowed micro-movements. Solution? Upgrade to ribbed plates. Silence restored.

- The Warehouse Wall Collapse: A logistics center skipped anchor plates for shelf anchors, assuming concrete glue was enough. Spoiler: It wasn’t. Lesson: Even Superman needs a cape.

Industry Trivia – When Anchor Plates Steal the Spotlight (for All the Wrong Reasons)

“An anchor plate’s life is like a Netflix thriller—nobody notices it until the plot twist. Let’s make sure your project isn’t the next season finale.”

Let’s face it: Anchor plates rarely make headlines… until something goes wrong. Here’s a peek into the drama, mishaps, and jaw-dropping stats that prove why these components deserve more respect.

1. The Stadium That Cried Wolf

In 2012, a newly built sports arena in Scandinavia began emitting eerie metallic groans during games. Fans joked it was “ghostly cheers,” but engineers soon traced the noise to anchor plate slippage. The culprit? Over-polished bolt threads that acted like a greased slide. The fix? Replace 1,200 anchor plates with sandblasted bolts. Moral of the story: Even a microscopic oversight can turn anchors into divas.

2. The Bridge That Took a Coffee Break

A pedestrian bridge in Melbourne, Australia, once sagged 5 centimeters overnight—not due to heavy traffic, but because corroded anchor plates in its concrete abutments gave up the fight. Turns out, salty coastal air had turned the plates into Swiss cheese. The repair bill? A cool $2 million. Lesson learned: Stainless steel anchors are worth every penny near oceans.

3. By the Numbers: Anchor Plate Fails That’ll Make Your Wallet Scream

- 💸 $3.8 billion: Estimated annual global cost of anchor-related repairs (enough to buy 10 Boeing 747s… or 38 million pepperoni pizzas).

- ⏳ 63%: Percentage of structural failures linked to connection issues—with anchor plates often playing a starring role.

- 🔧 28 days: Average time saved by skipping anchor plate inspections… and the average time added to project delays when things go sideways.

4. The “Blame Game” Hall of Fame

Anchors plates have been wrongfully accused of crimes they didn’t commit:

- The Case of the Leaning Warehouse Rack: A logistics firm blamed anchor plates for tilted shelving. Forensic engineers later revealed: workers had drilled through anchor bolts to install WiFi cables. Oops.

- The “Haunted” Office Building: Unexplained vibrations in a Tokyo high-rise were initially pinned on faulty anchors. The real villain? A rooftop HVAC unit installed without isolating vibrations. Anchors: 1, HVAC crew: 0.

Why This Should Matter to You

These stories aren’t just gossip—they’re cautionary tales. Anchor plates are the last place to cut corners. A single miscalculation in material grade, bolt spacing, or corrosion protection can turn a $10,000 anchor job into a $1 million lawsuit.

But here’s the silver lining: When done right, anchor plates are the silent workhorses that outlive the structures they hold together. (Fun fact: The anchor plates in the Golden Gate Bridge’s original 1937 construction? Still going strong.)

Small Plates, Big Legacy

In the grand narrative of steel structures, anchor plates may not claim the spotlight, but they are undeniably the backbone of every safe and resilient design. From skyscrapers that kiss the clouds to bridges that span roaring rivers, these unassuming connectors ensure that steel and concrete don’t just coexist—they collaborate.

🤫 Our Silent Promise to You

Every anchor plate we design or fabricate carries a silent promise: to be the unshakable link between ambition and reality. We don’t just build connections; we build legacies. And in a world where “good enough” is never enough, we stand for precision, durability, and the quiet confidence that comes from knowing every joint is overengineered for safety.

👋 Your Next Step

Ready to anchor your project in excellence? Here’s how we can help:

- Consult Our Experts: Tap into 20+ years of collective wisdom and 1000+ successful cases worldwide—no sales pitch, just straight talk.

- Request a Custom Quote: Let us craft anchor solutions as unique as your vision.

💭 Final Thought:

“Great structures aren’t defined by their steel or concrete, but by the connections that hold them together. Choose wisely, build boldly, and remember: the mightiest skyscrapers rise from the smallest plates.”

— The SteelPRO PEB Team