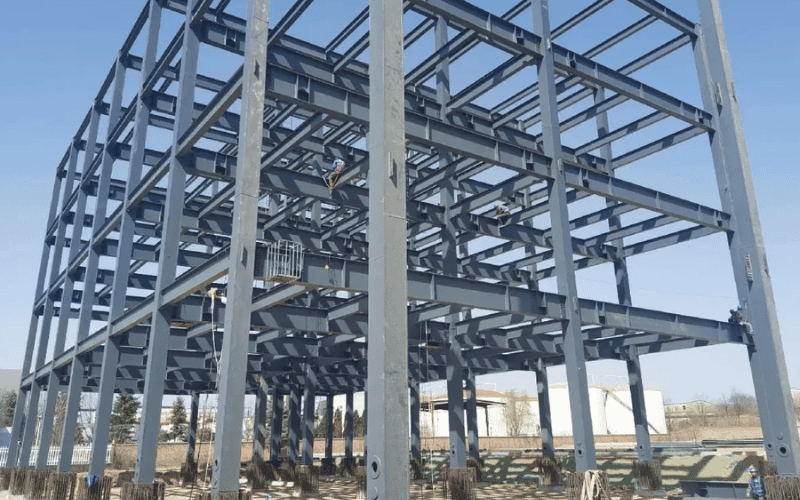

Steel frameworks are the foundation of contemporary building, recognized for their toughness, longevity, and adaptability. But the real challenge comes in making sure they stay stable and safe—because stability is everything. By sticking to some key design principles and applying practical experience, you can create steel structures that not only look impressive but also perform reliably under pressure.

This article explores the essentials of structural stability, offering valuable tips and insights to help ensure your steel frames stand strong and steady, no matter the conditions. Follow our steel structure experts on this journey!

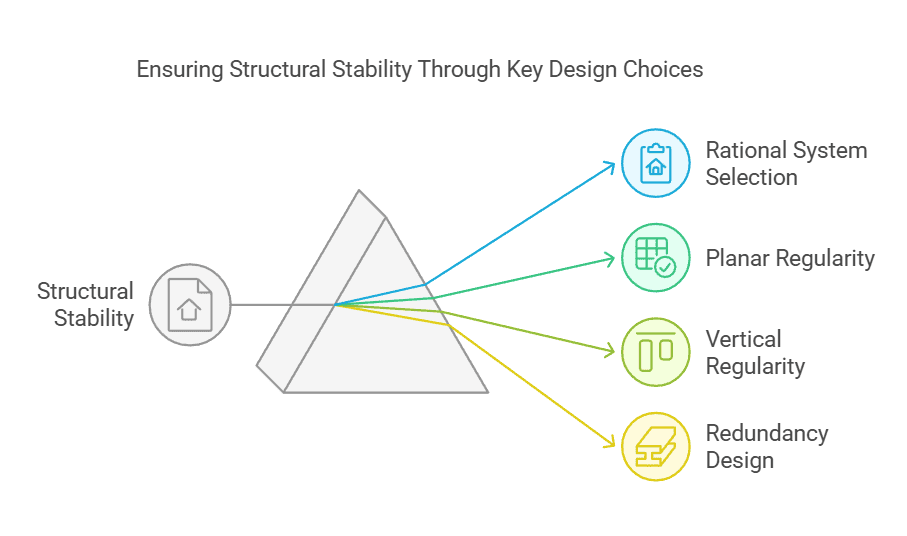

Rational Structural System Selection

The choice of structural system is the bedrock of stability. It defines how forces are spread and how the framework reacts to external pressures. A well-selected system minimizes stress concentrations and ensures uniform load transfer.

Planar Regularity

Simplicity is key when it comes to stability.

Symmetrical and straightforward layouts are the best way to keep things solid. When a building has irregular shapes, like L or T configurations, it introduces twisting effects under lateral forces, which can lead to uneven stress and weak points. A real-life example of this is when we worked on a project with a tricky layout—we added symmetrical bracing to resist wind-induced twists, keeping everything in line and stable.

Vertical Regularity

Smooth and consistent load transfer from top to bottom is crucial for stability.

When there’s a sharp change in stiffness or mass between floors, like moving from commercial to residential spaces, weak zones can develop. The key here is a gradual reduction in stiffness as you move down, with careful attention to detail at transition points—this keeps the structure balanced and avoids unwanted stress build-up.

Redundancy Design

Redundancy isn’t just a nice-to-have feature; it’s a must.

Multiple load paths are vital because they ensure the structure can handle localized failures without causing a collapse. For example, in multi-span continuous beams, if one span fails, the load is redistributed to the others, maintaining stability.

This can be achieved through thoughtful design, such as adding extra beams or braces that can take on the load if another component fails, ensuring continued stability.

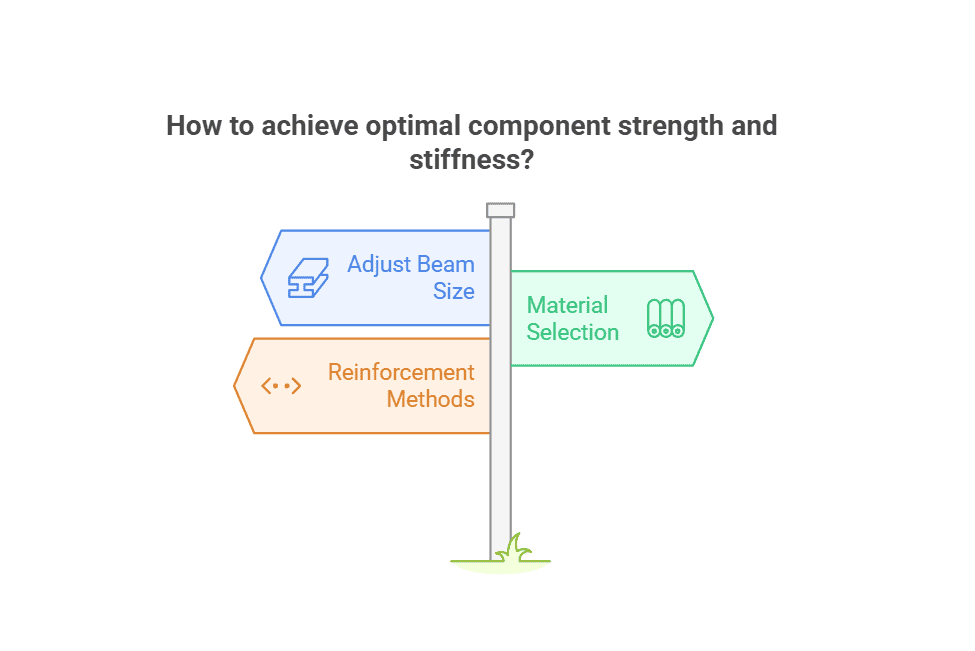

Component Strength and Stiffness Compatibility

The interplay between strength and stiffness is crucial for stability. Each component must be designed to handle its specific load while harmonizing with the overall structure.

Strength Reserve

When designing for strength reserve, it’s important to anticipate extreme loads, like those from rare seismic events or intense windstorms. Components like columns and beams should be sized with a significant safety margin—typically 1.5 to 2 times the maximum expected load. This provides a robust cushion against unexpected stress, ensuring the structure can endure in extreme conditions.

Stiffness Matching

Ensuring proper stiffness compatibility between components is crucial to prevent uneven load transfer and potential failure. In moment-resisting frames, for instance, the stiffness ratio between beams and columns should be carefully tuned—typically aiming for a beam stiffness that’s 60-70% of the column’s stiffness. This aids in spreading horizontal forces more uniformly, lowering the chance of concentrated damage.

To achieve this, the following adjustments may be necessary:

- Adjust Beam Size: Increase the beam’s cross-sectional area, such as opting for a deeper or wider I-beam, to enhance stiffness and support heavier loads.

- Material Selection: Choose a stronger material for the beam, such as switching from standard steel to high-strength steel for better stiffness alignment with the columns.

- Reinforcement Methods: Add diagonal bracing or stiffeners, like angle brackets, to the beams to enhance their load-carrying capacity and stiffness without altering the primary frame design.

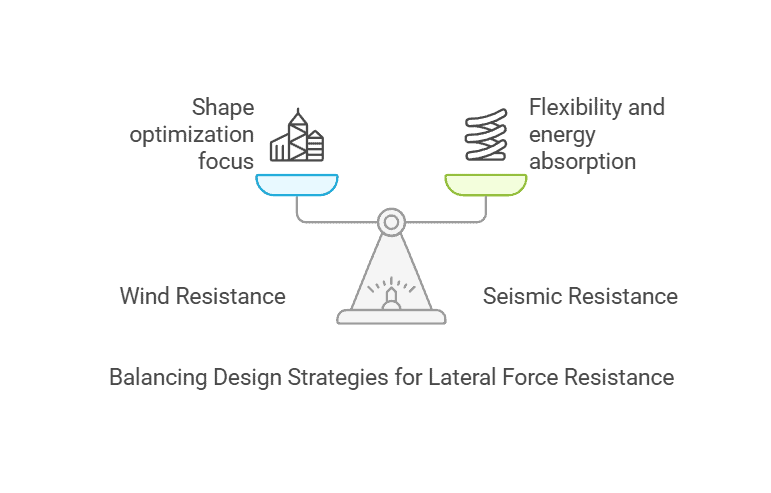

Effective Resistance to Lateral Forces

Lateral forces, such as wind and seismic loads, pose significant challenges to structural stability. Addressing these forces requires a combination of strategic design and precise calculations.

Wind Resistance Design

Optimizing a building’s shape to handle wind is all about reducing the stress caused by strong gusts. By designing the building’s exterior to minimize wind pressure, and adding features like cross-bracing or outriggers, we can improve lateral stiffness. For example, in a coastal project, we shaped the building with curved edges and added strategic bracing, which helped dramatically cut down wind loads. In simpler terms, this means we make sure the wind can flow around the building more smoothly, so it doesn’t push the structure too hard.

Seismic Resistance Design

When designing for seismic zones, it’s all about flexibility and absorbing the energy from earthquakes. Structures should be built to “give” in controlled ways, like beam-to-column connections allowing some movement during an earthquake. This flexibility prevents brittle failure and keeps the building from collapsing. Simply put, it’s like having a building that can “bend” without breaking during a shake, which keeps everything intact.

For more details, please read our article: Seismic resistant steel structures.

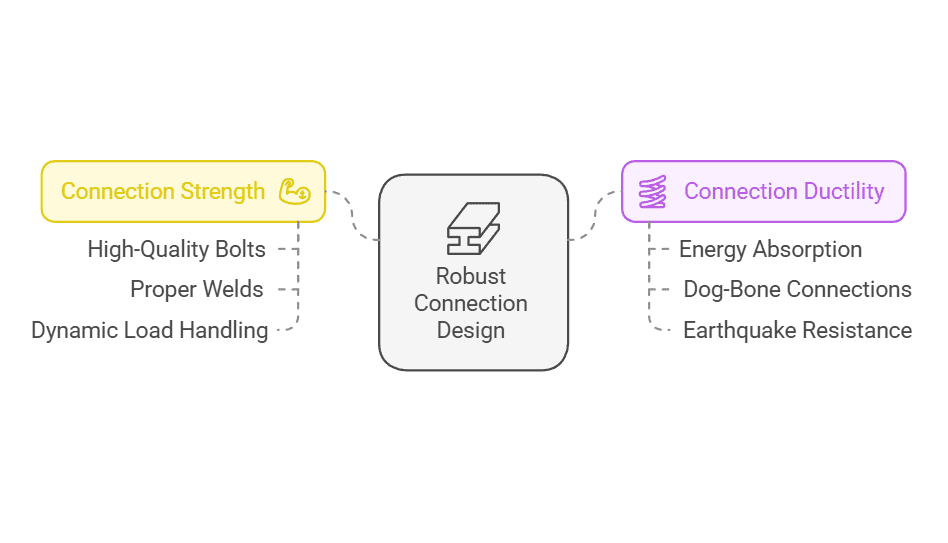

Robust Connection Design

Connections are the backbone of any steel structure. Their robustness and adaptability dictate how effectively the structure can endure external forces.

Connection Strength

Strong connections are the backbone of any stable structure. It’s essential to use top-grade bolts and ensure proper execution of welds. For example, in a high-rise project, we upgraded the bolts to handle dynamic loads, making sure the building stays secure long-term. In simple terms, the connections are like glue holding everything together, so they need to be extra strong to handle forces without failing.

Connection Ductility

For seismic performance, connections need to “give” without breaking. Designing connections that yield under extreme loads absorbs energy during an earthquake, protecting the structure. Using dog-bone connections at beam-to-column joints helps these critical points bend safely, reducing the risk of failure. In simple terms, the connections are designed to bend and absorb the shock, keeping the rest of the structure safe during an earthquake.

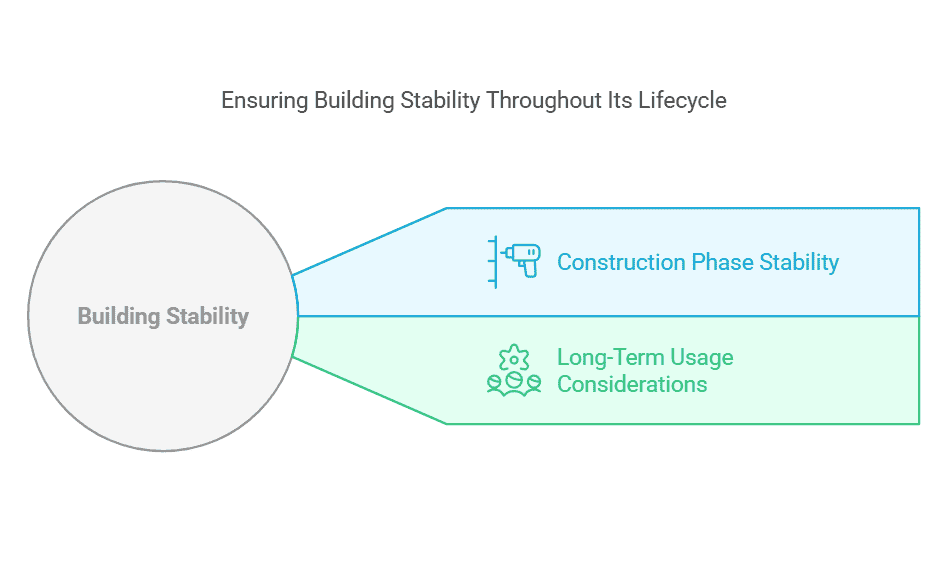

Considering Construction and Usage Phases

Stability isn’t just about the final structure; it’s about ensuring safety throughout the building’s lifecycle, from construction to long-term use.

Construction Phase Stability

During construction, temporary supports and staging play a vital role in maintaining stability. Proper planning and sequencing are key to preventing issues during assembly. For example, using advanced modeling can help place temporary supports in the right spots to avoid any instability as the building comes together. In other words, it’s about thinking ahead and ensuring every step keeps the structure balanced and secure.

Long-Term Usage Considerations

Designing with flexibility in mind is crucial, especially for future changes like renovations or added loads. Regular maintenance and inspections are essential to keep the structure in top shape over time, as materials can wear out and environmental factors take a toll. It’s about anticipating potential problems and ensuring long-term stability.

Related Reading: Steel structure design

Conclusion

Designing stable steel structures relies on a mix of solid principles, accurate calculations, and hands-on experience. Focusing on key factors like redundancy, strength, and adaptability ensures that each structure is built to last and withstand various challenges. We assess static and dynamic forces to optimize stability through methods like finite element analysis and time-history simulations.

Our approach goes beyond just meeting safety standards—it aims to exceed them. Whether it’s withstanding extreme weather or accommodating future modifications, our commitment to stability ensures that every project remains reliable and durable for years to come.

FAQ About Design of Steel Structure Stability

What Is Stability in Structural Design?

Stability in structural design ensures a structure can withstand loads and forces without collapsing or experiencing excessive deformation, maintaining safety and performance over time.

How to Balance the Stability and Economy of Steel Structures?

Achieving balance requires optimizing material use without compromising safety, often through efficient design techniques that reduce unnecessary material while maintaining strength and durability.

How to Cope with Extreme Weather Conditions in the Stability Design of Steel Structures?

Designing for extreme weather involves incorporating features like wind resistance, seismic flexibility, and durable materials to ensure the structure remains safe under harsh conditions.

How to Consider Human Factors (Such as Construction Errors or Improper Use) in the Stability Design of Steel Structures?

Designs should account for possible human errors by incorporating redundancy, safety margins, and clear guidelines to mitigate the impact of mistakes during construction or use.

How to Cope with Future Changes in Building Functions in the Stability Design of Steel Structures?

Flexible design and the use of adaptable materials can accommodate future changes, ensuring the structure remains stable and functional even if the building’s use or load increases over time.