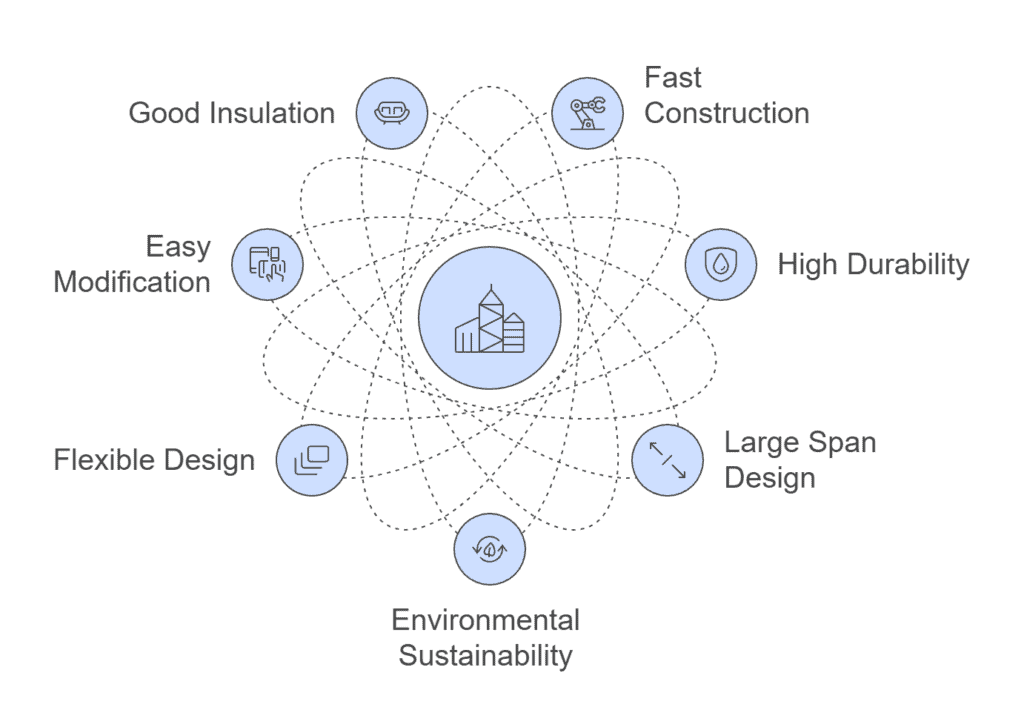

Advantages of Light Steel Structure

Picture 1. Advantages of Light Gauge Steel Structure

1. Fast and Cost-Effective Construction

The prefabricated components allow for quick on-site assembly, significantly reducing construction time and labor costs. The materials are lightweight and easy to handle, requiring only basic tools, which makes the process more efficient, especially in remote or restricted locations.

2. High Durability and Resistance to Harsh Conditions

Light steel structures are highly resistant to wind, earthquakes, and extreme weather. The steel’s toughness and elasticity provide stability, ensuring the structure remains safe and functional in challenging environments. Made with corrosion-resistant steel and high-strength materials, these structures also offer long-term durability, reducing maintenance costs.

3. Large Span Design

The high-strength steel enables larger spans with fewer interior columns, optimizing building space and offering more flexible design layouts. This is particularly beneficial for industrial buildings and warehouses, where open space is a priority.

4. Environmental Sustainability

Light steel is fully recyclable and can be disassembled and reused, making it an eco-friendly choice. The construction process generates minimal waste, supports green building initiatives, and reduces the environmental footprint.

5. Flexible and Customizable Design

Light steel structures can be adapted to various forms and materials for cladding and insulation, offering both functional and aesthetic flexibility. Businesses can tailor designs to meet specific needs, whether for commercial, industrial, or residential projects. The option for custom colors and finishes further enhances the aesthetic appeal.

6. Easy Modification and Future Expansion

The bolt-connected system makes it easy to modify, expand, or reinforce light steel structures as business needs evolve. This adaptability is ideal for businesses anticipating future growth or changes in their operational requirements.

7. Good Insulation and Soundproofing

The use of high-efficiency insulation materials ensures excellent thermal and acoustical insulation, reducing energy consumption and creating more comfortable work or living environments. Light steel structures can offer up to 50% energy savings.

Different Forms of Light Steel Structures

We provide customized solutions to ensure the best fit for your project’s unique requirements. Our experts will work with you to select the most appropriate structure form, recommend suitable materials, and optimize design for strength, stability, and cost-efficiency.

Purlin Structure

The purlin system supports the roof and comes in several types, such as solid thin-walled steel, open-web, and truss-type purlins. These options are tailored based on load-bearing needs, roof design, and span, ensuring an optimal balance of strength, stability, and cost-efficiency for your project.

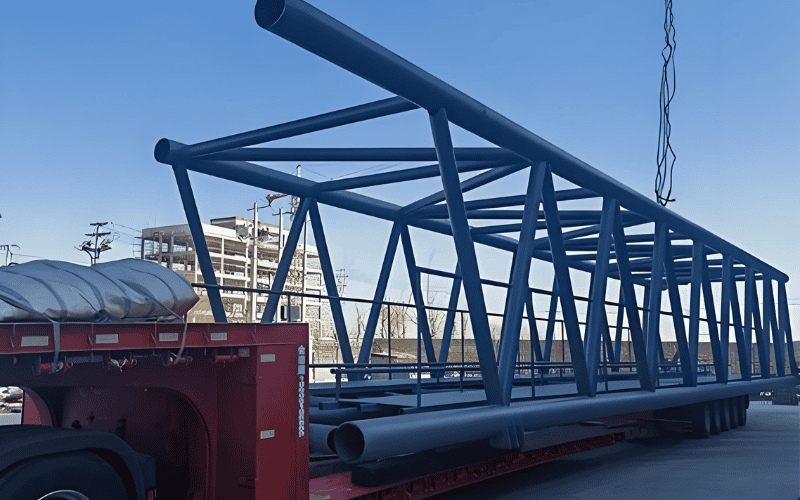

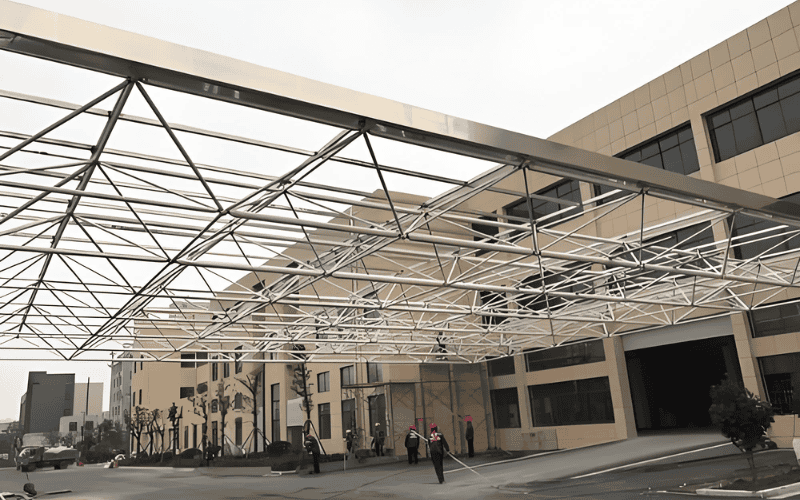

Truss Structure

Trusses serve as the main load-bearing components of the roof. Available in various forms like triangular and trapezoidal, they are tailored to meet specific span and load requirements. The choice of materials, such as angle steel and tubular sections, is made to enhance both the structural performance and aesthetic appeal of your building.

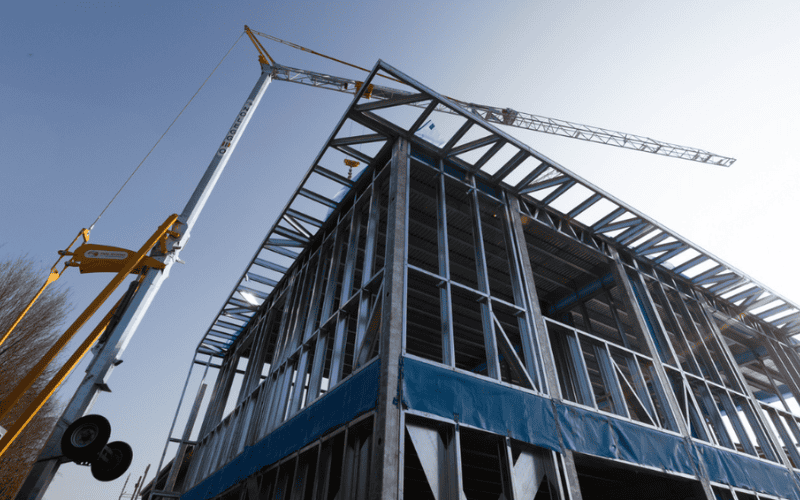

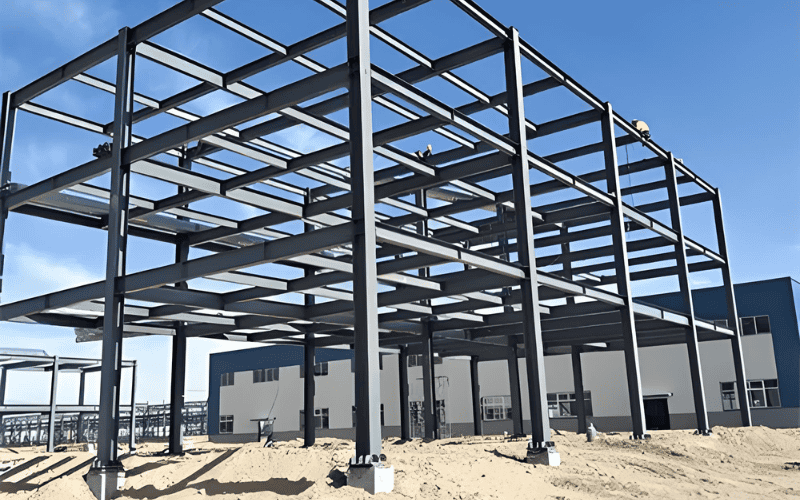

Steel Frame Structure

Steel frames can be single-story or multi-story, each designed to optimize space and ensure stability. Single-story frames are ideal for low-rise buildings, while multi-story frames are customized to meet the needs of taller structures, offering enhanced seismic resistance and overall efficiency.

Grid Frame Structure

Grid frame structures provide superior rigidity and load-bearing capacity, ideal for large-span or dynamic load-bearing projects. They are customized to meet seismic requirements and designed for long-term safety and stability, especially in earthquake-prone areas.

Application Examples of Light Gauge Steel Buildings

Light steel structures provide flexible design options and excellent performance in a wide range of applications. Below are several typical examples where light steel structures are effectively used. You can choose the most suitable design based on your specific needs.

Light Steel Workshop

Light steel structures are widely used in industrial production settings like machine processing factories and assembly lines. These structures are designed for large spans, offering ample space for operations.

Depending on project requirements, you can choose from single-span, double-span, or multi-span layouts for optimal space usage and flexibility. Crane specifications, including 20-ton or larger overhead cranes, can be customized based on your heavy equipment needs. The roof features polyurethane panels with self-cleaning properties, reducing dust accumulation and keeping the workshop clean.

Light Steel Warehouse

Light steel warehouses are ideal for various storage and logistics applications. They can be designed as single or multi-story structures, with large spans to improve storage efficiency.

You can select suitable materials for the roof and walls, such as color-coated steel or sandwich panels, to enhance thermal insulation and reduce energy consumption. The warehouse design can also be tailored to the load-bearing requirements, ensuring optimal configuration based on your storage needs. The advantages of light steel include quick construction, high fire resistance, and excellent corrosion resistance.

Multi-Story Light Steel Building

Multi-story light steel buildings are perfect for office, commercial, and residential use. The structure combines the flexibility of light steel with the robustness of concrete, ensuring stability even for taller buildings.

Designs range from two-story to multi-story configurations, and materials like polyurethane panels or color-coated sandwich panels can be customized for the roof and walls. These buildings offer both energy efficiency and aesthetic appeal, making them a sustainable and attractive choice for modern construction projects.

Main Components and Materials

The main components of light steel structures include the primary structure, secondary structure, and cladding systems. SteelPRO PEB offers a range of customizable solutions for each of these components, ensuring that the design and materials are perfectly suited to your project’s specific requirements.

Primary Structure

Main components: steel columns, steel beams, runway beams, and bracing systems. We typically use high-quality Q235B or Q345B steel for durability and strength.

- Steel Columns and Beams: We offer H-shaped steel or C-channel steel options, both known for their structural efficiency and strength. For projects requiring higher load-bearing capacity, we can provide Q345B steel, which offers enhanced performance under heavy loads.

- Runway Beams: These beams are essential for supporting overhead crane systems, commonly found in industrial and warehouse environments. Our designs are optimized to meet the specific load and operational needs of your building, ensuring that the beams are placed at the appropriate height and are designed to handle dynamic loads from the cranes.

- Bracing Systems: Bracing systems are critical for enhancing the overall stability of the structure, designed to resist lateral forces such as wind, seismic activity, and other dynamic loads. These systems typically include diagonal braces or shear walls and are strategically placed to maintain structural integrity in large or tall buildings, ensuring the structure can withstand high external forces.

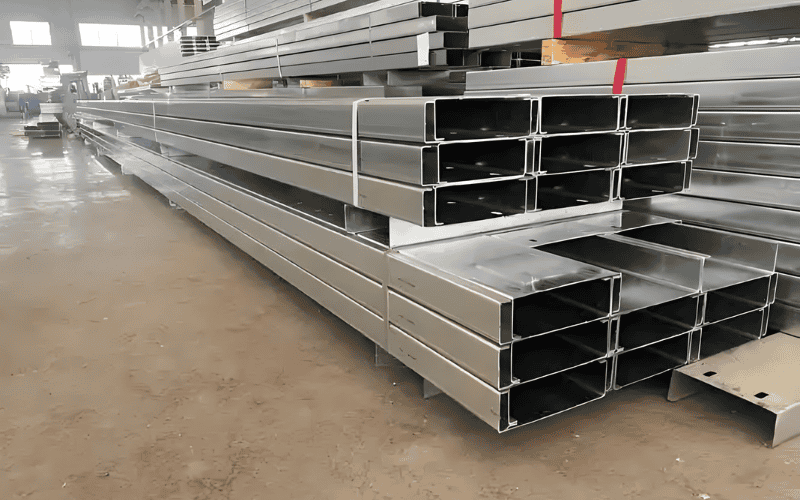

Secondary Structure

Main components: purlins (C-shaped, Z-shaped), and support systems.

- Purlins: These horizontal beams are critical for supporting roof and wall panels. C-shaped purlins are typically used for general applications, while Z-shaped purlins are ideal for large spans or steep roof slopes, offering greater stability. The standard thickness for purlins ranges from 2.5mm to 3mm, but this can be adjusted based on the specific load requirements of the project.

- Support Systems: These support elements include beams and columns that stabilize the roof and wall panels. Commonly used in secondary structures, these systems ensure the overall stability of the roof and wall assemblies by distributing loads efficiently.

Cladding System

Common materials: color-coated steel panels, insulation panels, and sandwich panels.

- Color-Coated Steel Panels: Our color-coated steel panels are up to 0.8mm thick, providing a durable, weather-resistant exterior that also enhances the aesthetic appeal of your building.

- Sandwich Panels: These panels, which range in thickness from 50mm to 150mm, are designed for high thermal insulation. They offer excellent energy efficiency and help maintain comfortable indoor temperatures year-round. Panels of 50mm thickness are ideal for moderate climates, while 150mm panels provide higher thermal insulation for colder regions or environments with higher energy efficiency demands.

- Roofing Solutions: We offer a combination of color-coated steel tiles, insulation cotton, and steel mesh for roofing. This combination enhances thermal performance and durability, reducing heat loss and improving energy efficiency. Our custom roofing solutions are designed to meet specific energy-saving standards, reducing long-term operational costs.

- Lighting Panels: To optimize energy efficiency, we can incorporate lighting panels into the roof design. These panels allow natural light to filter into the building, reducing electricity consumption while improving indoor lighting quality and enhancing the overall work environment.

Is Light Steel Structure the Smart Choice for Your Project? Let’s Prove It!

Are you worried that light steel structures might not be strong enough to withstand harsh conditions like strong winds or earthquakes? Concerned about insulation or soundproofing not meeting your expectations? Or perhaps you’re unsure if the upfront costs align with your budget despite its eco-friendly appeal. And so much more…

We’ve addressed these concerns for countless clients:

- Durable and Reliable: Our light steel structures are designed to withstand winds up to 12 on the Beaufort scale and earthquakes up to magnitude 8, ensuring safety in all environments.

- Comfortable and Efficient: With 50mm to 150mm high-performance insulation materials, our buildings are warm in winter, cool in summer, and significantly reduce noise pollution.

- Cost-Effective: Prefabricated and modularized production reduces construction time by over 30%, saving labor costs and keeping your budget under control.

- Customizable Design: Whether it’s for industrial, commercial, or residential use, we offer tailored solutions that balance functionality and aesthetics.

With 20+ years of expertise and 1,000+ successful projects, we’ve helped clients worldwide turn challenges into results. Ready to see how light steel structures can elevate your project?

Act now! Contact us today for a free design consultation and preliminary budget estimate. Let’s make your next project faster, stronger, and smarter!