Peb Structure

Why Choose Our Prefabricated Steel Buildings?

Durability

Tired of long construction timelines, budget overruns, and quality inconsistencies? It’s time to consider pre engineered steel buildings! Built with high-strength steel, these buildings are durable and flexible, withstanding extreme weather, earthquakes, and pests. Their low maintenance and long lifespan help reduce costs over time.

Flexibility and Expandability

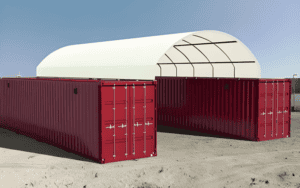

Steel structures are flexible, adapting to current needs and future expansions. New steel components can be easily added through welding or bolted connections, creating a unified whole. They also support adding steel mezzanines within existing spaces, maximizing vertical room for offices, storage, or other uses. Pre engineered buildings provide endless possibilities.

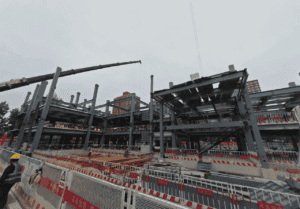

Fast Construction

We’re proud of the efficiency of our system. Unlike traditional construction, which takes months, our prefabricated buildings are designed, manufactured, and delivered in 4 to 8 weeks. As a leading peb structure manufacturer, we ensure seamless processes. Share your needs, and we’ll handle everything—from customization to quick on-site installation.

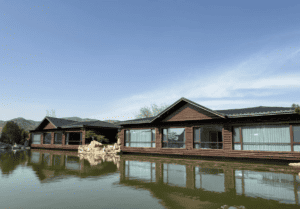

Space Efficiency and Aesthetics

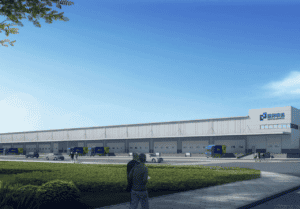

The column-free design of steel structures significantly improves space utilization compared to traditional buildings. This not only enhances functionality but also adds to the aesthetic appeal of the structure. Best of all, choosing prefabricated steel buildings can save up to 30% on labor and material costs, making it a highly economical option.

Wide Applications

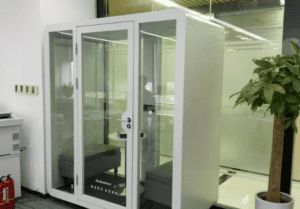

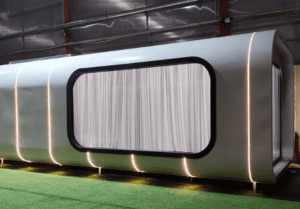

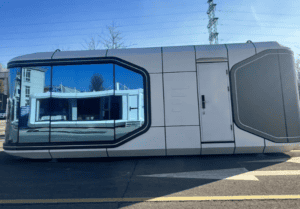

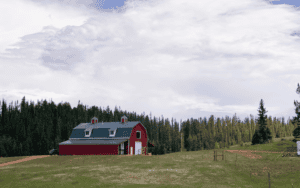

Prefabricated steel buildings are suitable for a wide range of projects, including residential, commercial, industrial, warehouse logistics centers, agricultural facilities, sports venues, schools, hospitals, and temporary structures. Their flexible design and fast construction cycles make them an ideal choice for emergency needs or rapid expansion projects.

Eco-Friendliness and Sustainability

Prefabricated steel buildings aren’t just functional—they’re eco-friendly. Steel is fully recyclable, and the process minimizes waste and emissions. By choosing pre engineered buildings, you’re investing in quality and sustainability

Customized Options for Prefabricated Steel Structures

Tailored Designs: We create layouts designed to meet your specific needs, including custom door and window placements, roof configurations, and additional features like mezzanines or open spans to optimize your space.

High-Quality Materials: Only premium materials are used, including Q235 or Q345 steel, with options for galvanized or color-coated finishes. Wall and roof panels can be customized with sandwich panels, fiber cement, or PU-coated materials for durability and style.

Precision Manufacturing: All components are manufactured with advanced CNC equipment to ensure perfect fits and seamless assembly on-site. Pre-drilled connections further simplify installation while minimizing errors.

Scalable Solutions: Projects of any size can be accommodated, from compact modular units to expansive multi-span facilities. These designs are ideal for warehouses, workshops, and commercial spaces.

Expert Consultation: We guide you through every step, from refining layouts to selecting materials and finalizing technical details. Detailed 3D renderings and plans ensure the results meet your vision.

Components of Prefabricated Steel Buildings

1. Frame System

The frame system is the main load-bearing structure, including steel columns, beams, and connecting components. Steel columns support the building’s weight and transfer loads to the foundation, while steel beams connect the columns and handle horizontal loads like floors and roofs. Secured with high-strength bolts and plates, this system ensures stability and strength, safely bearing its own weight and external forces like wind, snow, and earthquakes.

2. Support System

The support system, including the steel structure bracing system, strengthens the frame against horizontal forces. It includes bracing rods, diagonal braces, shear walls, and connectors. Steel structure bracing systems, installed in cross or diagonal patterns, effectively resist wind and seismic loads, while shear walls enhance rigidity. This ensures the building remains secure and stable under stress.

3. Enclosure System

The enclosure system includes wall panels, steel roof systems, doors, windows, and accessories like sealants and fasteners. Steel roof systems, made with high-strength steel sheets and engineered drainage solutions, ensure durability, waterproofing, and thermal performance.

Wall and roof panels, made from sandwich panels or steel sheets, offer reliable insulation, waterproofing, and fire resistance. Doors and windows, secured with specialized connectors, enhance lighting, ventilation, and soundproofing for greater functionality. Designed with customizable materials, the enclosure system ensures protection and adds a polished, aesthetic touch to the building.

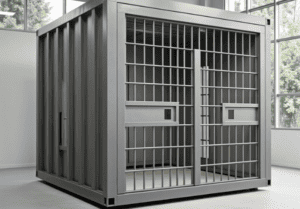

Please visit our prefabricated steel building product page to explore our offerings, including peb building, container housing, and modular construction solutions.