What is Light Steel Structure?

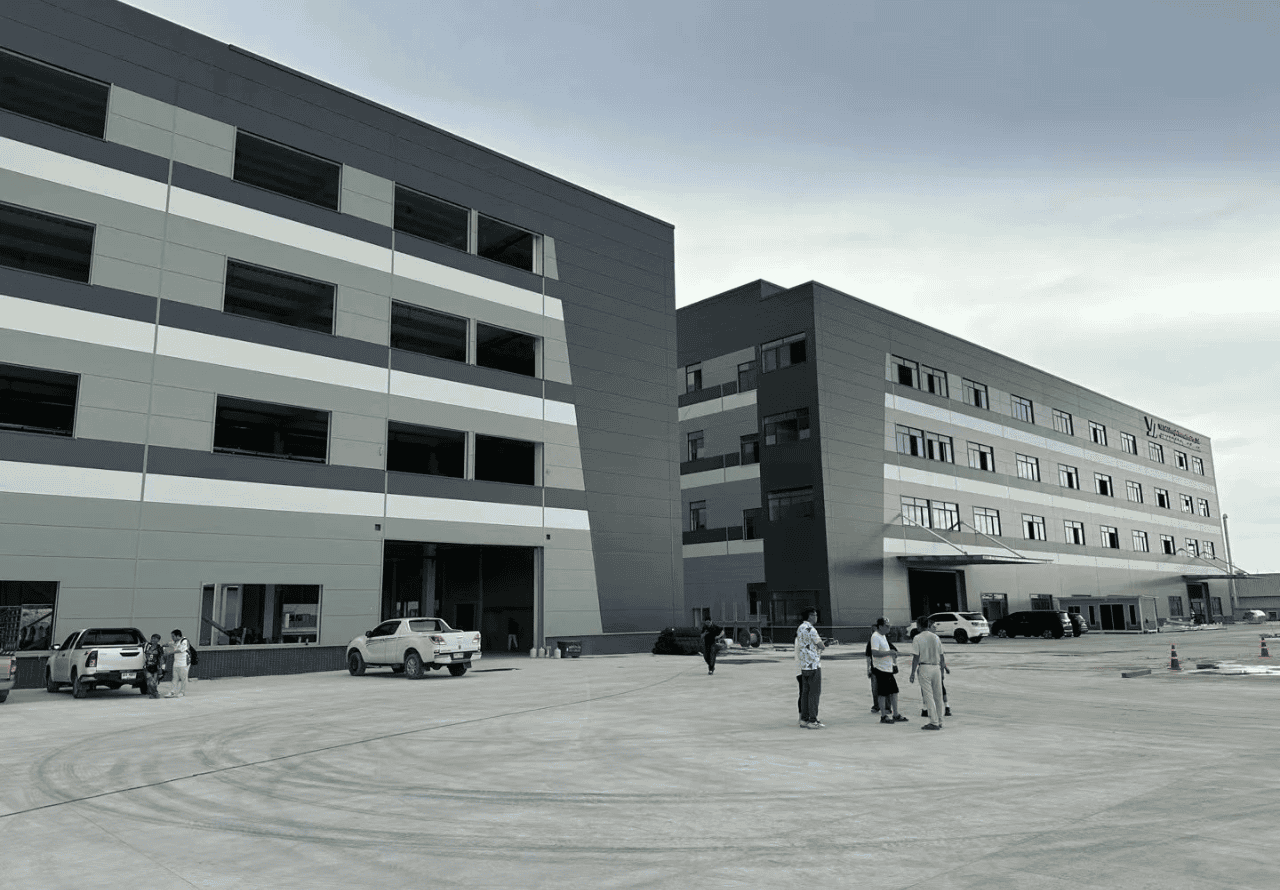

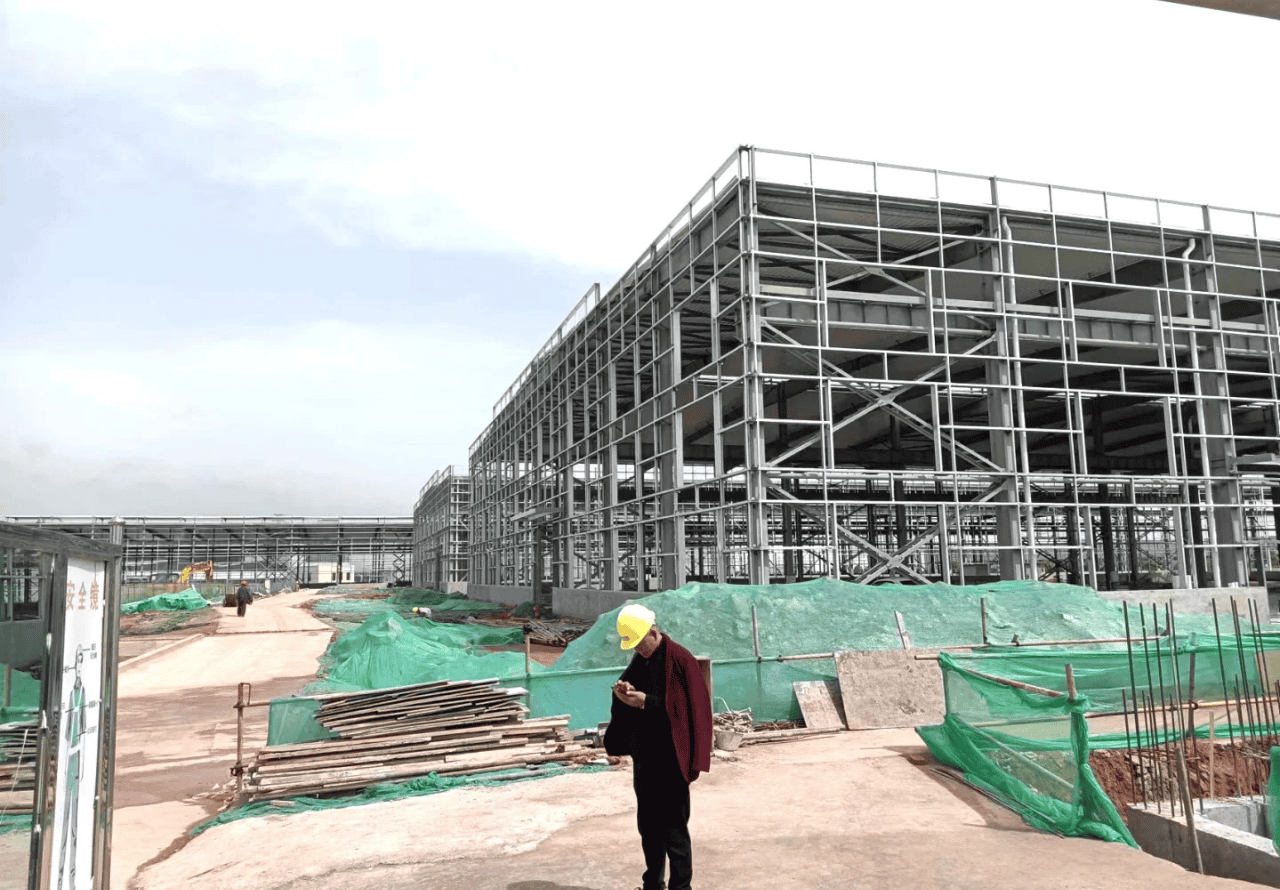

A Light Steel Structure is a modern framework made from thin, high-strength steel, often pre-assembled for easy transport and quick setup. It’s lightweight yet strong, supporting heavy loads with ease—perfect for fast, flexible construction. These structures are cost-effective, durable, and adaptable, ideal for workshops, warehouses, commercial spaces, and homes. They’re seismic-resistant, quick to build, and eco-friendly, with fully recyclable materials.

Compared to heavy steel or concrete, they use less material, lower foundation costs, and speed up assembly, making them a smart choice for today’s construction needs. Light steel structure workshops are a new generation, developed from traditional steel structures, including all steel components under lightweight roofs.

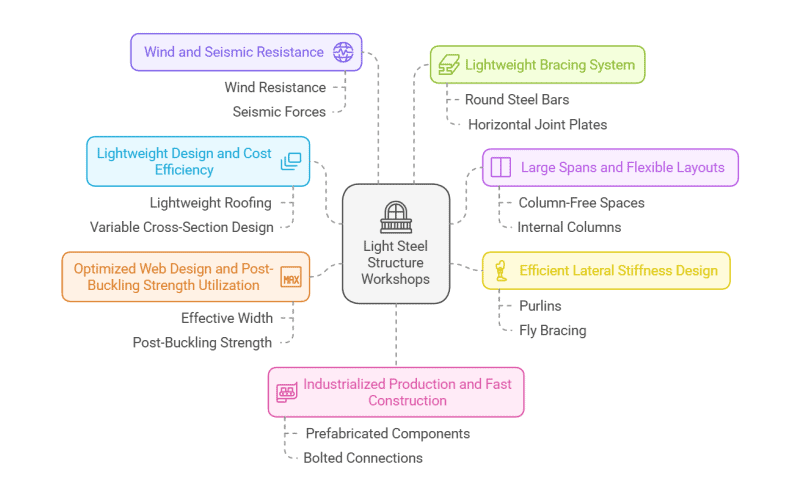

Features of Light Steel Structure Workshops

Here are 7 key features of light steel structure workshops, combining design advantages, construction efficiency, and cost-effectiveness in a friendly and approachable tone:

1. Lightweight Design and Cost Efficiency

- Using lightweight roofing and high-efficiency materials not only reduces the cross-sectional size of beams and columns but also lowers the foundation load and overall costs. Through variable cross-section design, the height and thickness of beams can be adjusted according to bending moment requirements, optimizing material usage and further saving costs.

2. Large Spans and Flexible Layouts

- Light steel structures can achieve large spans (typically 9 to 72 meters), providing open, column-free spaces ideal for large equipment and storage needs. In multi-span buildings, the use of internal columns reduces beam spans, further optimizing layout and costs.

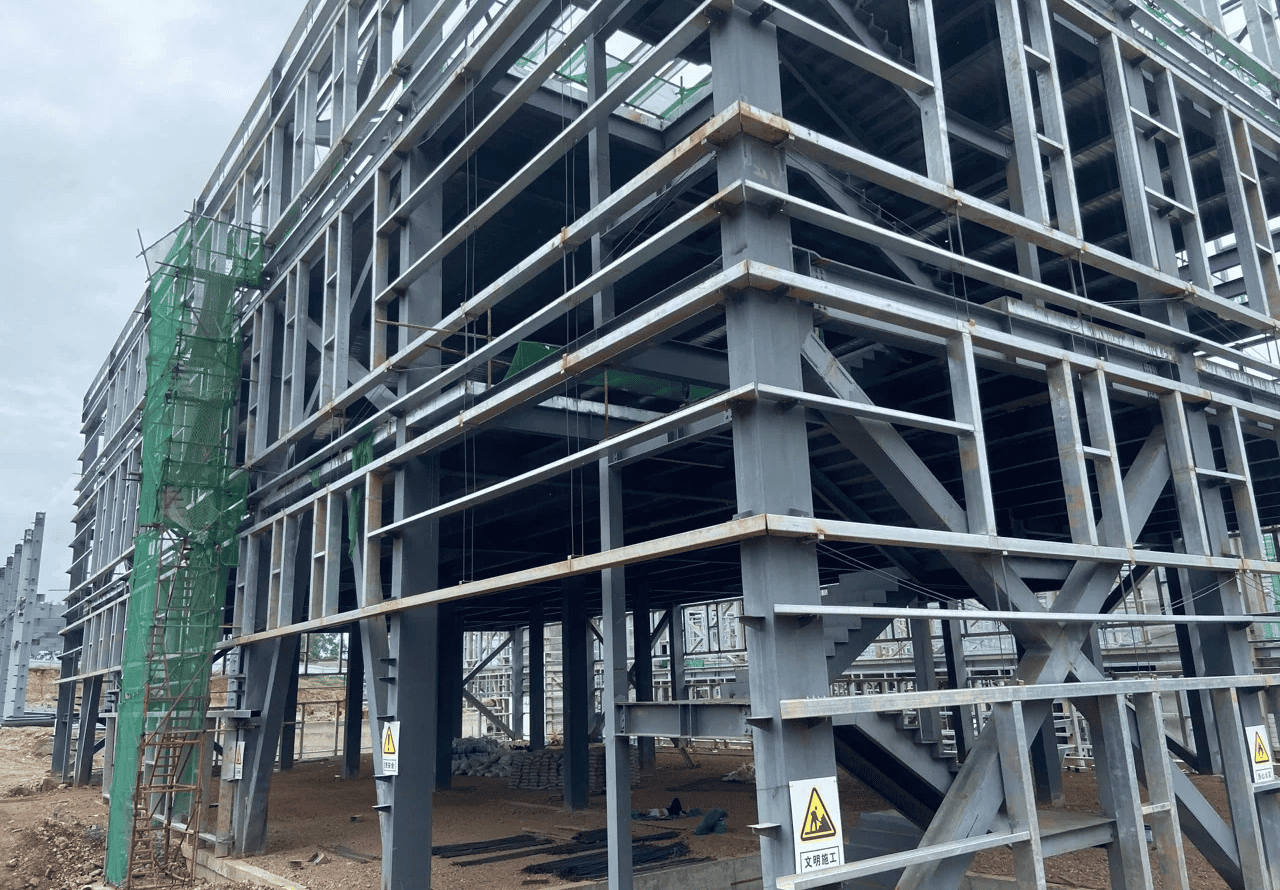

3. Efficient Lateral Stiffness Design

- The lateral stiffness of the frame is ensured by purlins and fly bracing, eliminating the need for additional longitudinal rigid members and reducing beam width and material usage. This design not only enhances structural stability but also lowers overall weight and costs.

4. Optimized Web Design and Post-Buckling Strength Utilization

- The web of the steel frame is designed based on effective width, allowing some webs to utilize post-buckling strength. This approach maximizes material efficiency, reduces waste, and ensures structural safety and cost-effectiveness.

5. Wind and Seismic Resistance

- Light steel structures are primarily designed for vertical loads, but in high-wind or tall workshops, wind loads cannot be ignored. The lightweight gable frame offers excellent wind resistance, while seismic forces typically do not control the design, simplifying the structure further.

6. Lightweight Bracing System

- The bracing system uses round steel bars, which are lightweight and easy to install. Braces can be connected directly or via horizontal joint plates to the beam web, simplifying construction while ensuring overall structural stability.

7. Industrialized Production and Fast Construction

- All structural components are prefabricated in factories, ensuring a high level of industrialization. Units can be divided according to transportation conditions and quickly assembled on-site using bolted connections, making installation convenient and fast. Additionally, the minimal civil engineering work required further reduces construction time and costs.

What Can You Get?

| Component | Common Specifications |

| Height | Customizable |

| Length | Customizable |

| Width | Customizable |

| Type | Light Portal Frame Structure |

| Connection Form | Bolt Connection |

| Steel Frame | H-Section Steel |

| wall and Roof | EPS/Rockwool sandwich panels/PU/Pre-painted Galvanized Steel Sheet |

| Door | Rolled up door or Sliding door, Customizable |

| Windows | Aluminum alloy window, Customizable |

| Skylight | Opitional |

| Roof & Wall | Precast pre-painted steel sheet or sandwich panel. |

| Required design Load | Rainfall/Wind load/Snow load/Seismic magnitude |

| Certification | SGS, BV, ISO, SGS, BV, ISO, IBC, CE Marking |

| Surface Treatment | Hot DIP Ganlvanized, Painted |

| Service Life | Up to 50 Years |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Materials | Q345b, Q355b, Q235, Q345B, Q235B |

What Do We Not Offer?

While we specialize in manufacturing and delivering high-quality Light Steel Structure Workshops, there are certain services we do not provide to ensure focus on our core expertise:

- On-Site Installation: We do not offer on-site assembly or installation of the workshop structure.

- Interior Finishing: Services such as interior wall cladding, flooring, or ceiling installations are not included.

- Electrical System Installation: We do not handle the installation of electrical wiring, lighting, or power systems.

- Industrial Automation System Integration: Design or integration of automation control systems for machinery or processes is not part of our offerings.

By focusing on what we do best—designing and manufacturing premium light steel structures—we ensure the highest quality and efficiency for your project. For services we do not provide, we recommend partnering with specialized contractors to complete your workshop setup.