Steel Structure Distribution Center Product Specification

| Category | Parameters/Description |

| Structure Type | – Frame Structure |

| – Space Frame Structure (for large-span requirements) | |

| Materials | – Steel: Q235, Q345B high-strength steel |

| – Wall and Roof: Sandwich panels (rock wool, PU, EPS), metal sheets | |

| – Doors and Windows: Aluminum alloy windows, steel security doors | |

| Surface Treatment | – Hot-dip galvanized or painted for enhanced corrosion resistance |

| Span | – Maximum clear span: 300 feet (approx. 91.44 meters) |

| – Larger spans available (customizable) | |

| Height | – Standard height: 18-30 feet (approx. 5.5-9 meters) |

| – Custom heights available | |

| Length | – Unlimited, customizable based on requirements |

| Insulation Performance | – Roof and walls with high-efficiency insulation, U-value as low as 0.2 W/m²K |

| – Suitable for cold storage and temperature-controlled environments | |

| Wind Resistance | – Wind rating: 130 mph (approx. 209 km/h) |

| – Enhanced designs available for high-wind regions | |

| Seismic Resistance | – Seismic rating: Level 8 (Chinese standard) |

| – Enhanced designs available for earthquake-prone areas | |

| Fire Resistance | – Fire rating: Class A (non-combustible materials) |

| – Higher fire ratings available upon request | |

| Construction Period | – Standard construction period: 30-60 days (depending on project scale) |

| – Prefabricated steel structures significantly reduce construction time | |

| Design Life | – Design life: Over 50 years |

| – Low maintenance costs, long-term durability | |

| Environmental Features | – Steel is 100% recyclable |

Optional Configurations

| Category | Options |

| Roof Materials | – Single-layer metal sheets |

| – Double-layer insulated sandwich panels (rock wool, PU, EPS) | |

| Wall Materials | – Single-layer metal sheets |

| – Double-layer insulated sandwich panels (rock wool, PU, EPS) | |

| – Brick or concrete walls | |

| Door & Window Types | – Roll-up doors, sliding doors, swing doors |

| – Aluminum alloy windows, tempered glass windows | |

| Insulation Levels | – Standard insulation |

| – High insulation (for cold storage and temperature-controlled environments) | |

| Wind & Seismic Enhancements | – Standard wind and seismic design |

| – Enhanced designs for high-wind or earthquake-prone areas | |

| Environmental Options | – Solar roof |

| – Rainwater recycling system |

What are the benefits of choosing our steel structure distribution center?

- High-strength steel: Q345B steel is used, with a tensile strength of 470-630MPa and a lifespan extended by 20%.

- Fast construction: prefabricated modular design, construction speed increased by 50%.

- Column-free space: 300-foot large span, completely column-free design, maximized storage efficiency.

- Energy saving and environmental protection: high-performance insulated sandwich panels, 40% energy saving, 100% recyclable.

- Full-process customization: BIM technical support, precise design and visualization to meet personalized needs.

- Disaster resistance: 130 mph wind resistance, 8-level earthquake resistance, far exceeding market standards.

- Intelligent integration: support automated equipment and intelligent management systems to improve logistics efficiency.

- Cost-effectiveness: The overall cost is 20%-30% lower, with higher cost performance.

- One-stop service: from design to after-sales, full-process support to ensure efficient project implementation.

Our services and support

1. Design and consultation

Free design and quotation service: We provide free design and quotation services to help you quickly understand the cost and feasibility of the project. The professional team will tailor the best solution according to your needs.

3D model design: Through visualization tools, ensure that the design meets your expectations and reduce the cost of later modifications.

2. Installation and training

Remote installation guidance: We provide detailed installation guidance documents and video tutorials to help your team complete the installation smoothly. Through video conferencing or telephone, our technical team can answer questions during the installation process in real time.

Training service: Provide remote training for customers’ operation and maintenance teams to ensure that they are familiar with the building structure and usage methods. The training content includes daily maintenance, equipment operation and emergency handling.

3. After-sales guarantee

- Warranty service: Provide 1 year or longer warranty service, covering building structure, materials and construction quality.

- Regular maintenance recommendations: Provide detailed maintenance manuals to help customers develop scientific maintenance plans.

Our commitment

- Quick response: 24/7 customer service hotline to answer your questions at any time.

- Professional team: Engineers and technicians with many years of experience ensure service quality and efficiency.

- Customer first: From design to after-sales, we accompany you throughout the process to ensure the smooth completion of your project.

Learn about our projects

Qingdao International Cruise Home Port: We use large-span design and high-strength steel to ensure open and safe space, meet the diverse needs of cruise terminals, passenger reception buildings and commercial areas, and help improve logistics operation efficiency.

Hongdao High-speed Railway Station: Hongdao High-speed Railway Station uses a large-span steel structure to optimize transportation flow and passenger experience, and support high passenger flow operations. High-strength steel and seismic design ensure station safety and provide reliable protection for logistics and transportation hubs.

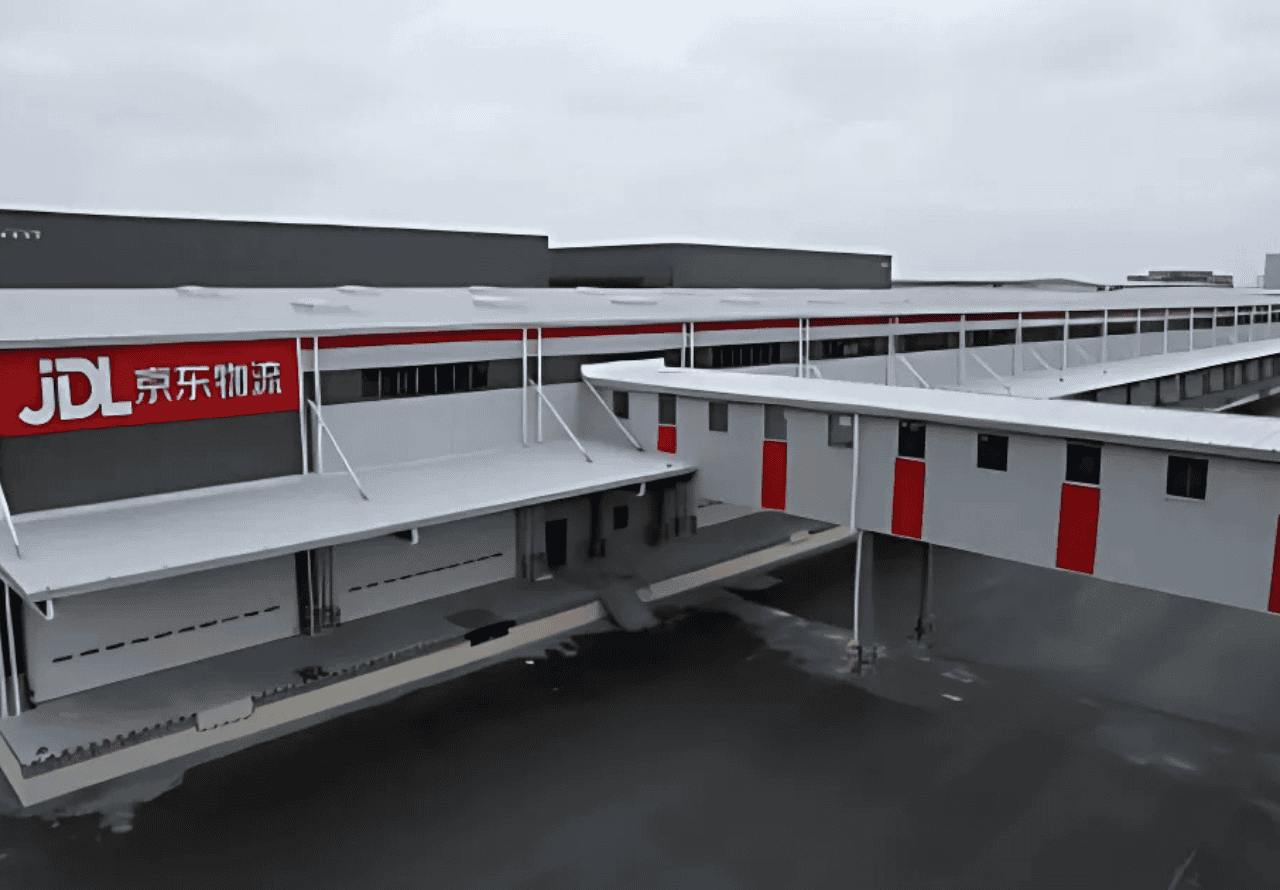

JD Asia No. 1 Qingdao Smart Logistics Park Phase II: We provide portal steel frame structure, large-span design and high load-bearing capacity to meet efficient warehousing needs. Prefabricated steel structure shortens construction period, helps logistics parks to quickly build and operate, and improves logistics processing capabilities.

FAQs

- How long is the construction period of a steel structure distribution center?

- The standard construction period is 30-60 days, depending on the size and complexity of the project. Prefabricated steel structures significantly shorten construction time and ensure fast delivery.

- What is the maximum span of a steel structure distribution center?

- Our design supports a maximum column-free span of 300 feet (about 91.44 meters) to meet large-space storage and logistics needs.

- Does the steel structure distribution center support future expansion?

- Yes, the modular design facilitates future expansion. You can flexibly increase the area or adjust the layout according to business needs.

- How is the seismic performance of the steel structure distribution center?

- We use high-strength steel (such as Q345B) and seismic design to ensure that the building remains stable in an 8-magnitude earthquake, in line with international seismic standards.

- How is the thermal insulation performance of the steel structure distribution center?

- We provide high-efficiency insulation materials (such as rock wool, polyurethane sandwich panels) with U values as low as 0.2 W/m²K, which are suitable for cold chain and constant temperature storage needs.

- Is the maintenance cost of the steel structure distribution center high?

- Steel structure buildings have low maintenance costs, steel is corrosion-resistant and does not require frequent maintenance. We provide detailed maintenance manuals and regular inspection services to further reduce maintenance costs.