We Can Design According to Your Standards

We have over 20 years of export experience and can deliver to global markets according to the following standards:

Americas – AISC 360-16, EN 1090, etc. – approved by NSF, ICC-ES

Exported to: United States, Mexico, Canada, Brazil, Argentina, Chile, etc.

Europe – EN 1090 EXC2, Eurocode 3 (EN 1993), etc. – approved by CE

Exported to: Germany, France, United Kingdom, Spain, Italy, Romania, etc.

Middle East – EN 1090, BS 5950, etc. – approved by CE BV SGS

Exported to: Saudi Arabia, United Arab Emirates, Qatar, Oman, Kuwait, Bahrain, etc.

Southeast Asia – BS 5950-2, GB, etc. – approved by BV SGS

Exported to: Singapore, Malaysia, Thailand, Indonesia, Vietnam, Philippines, etc.

Australia and New Zealand – AS 4100-1998, etc. – approved by SGS

Exported to: Australia, New Zealand

Central Asia – EN 1090, etc. – approved by CE BV SGS

Exported to: Kazakhstan, Uzbekistan, Turkmenistan, Kyrgyzstan, Tajikistan

Africa – EN 1090, etc. – approved by CE BV SGS

Exported to: South Africa, Nigeria, Kenya, Ghana, Egypt, Morocco, etc.

Where Should You Locate Your Steel Horse Arena Building?

- Planning Permission: Before starting, check with your local council. Zoning rules and neighbor concerns can impact what you can build.

- Location: Choose a spot near your stable and other facilities, but away from noisy roads to keep your horses calm and focused.

- Safety: Ensure the site is free from hazards like power lines or highways. Your horses and riders need to be safe at all times.

- Land & Drainage: Pick flat, well-draining land to avoid construction issues and waterlogging. This saves time and money in the long run.

- Weather: A sunny spot can melt frost or snow quicker. Avoid areas prone to strong winds, which can disrupt riding.

- Noise & Environment: Choose a quiet area far from busy roads. Horses perform better in peaceful surroundings.

- Visibility: Position your arena so you can easily see it from your yard. This makes it easier to monitor riders and handle emergencies.

- Transport & Parking: Ensure the site is accessible for riders and spectators, with enough parking space.

- Proximity to Facilities: The closer your arena is to your tack room, wash bays, and stables, the more convenient your daily operations will be.

- Infrastructure: Make sure your site has access to water, electricity, and other essential utilities for smooth operation.

- Environmental Protection: Consider the environmental impact, especially if near sensitive natural areas. Protecting the environment should always be a priority.

- Long-Term Plans: Think about how your needs may change in the future. You might want to expand or add facilities, so choose a site that can accommodate growth.

Popular Sizes

| Arena Type | Length (m) | Width (m) | Height (m) | Purpose |

|---|---|---|---|---|

| Standard Riding Arena | 60 | 20 | 4.5-6 | Suitable for international competitions and training. |

| Indoor Riding Arena | 60-80 | 20-30 | 6-8 | Suitable for year-round training and competitions. |

| Multi-purpose Arena | 50-70 | 20-30 | 4.5-6 | Suitable for various equestrian activities. |

| Small Riding Arena | 40 | 20 | 4.5-6 | Suitable for beginners and daily training. |

Product Specifications

Check the standard specifications for our steel horse arena buildings below. Most can be customized, and we are very capable of doing so. Please contact us if you have specific requirements.

Building Components

| Category | Items | Specification |

|---|---|---|

| Main Frame | Column & Beam | Q235, Q345 Welded H Section Steel |

| Tie Beam | Round pipe, Square tube, or as requested | |

| Secondary Frame | Tie Rod | Q235 Circular Steel Pipe |

| Sag Rod | Steel Round Bar, Angle, C Purlin, etc. | |

| Vertical and Horizontal Support | Q235 Angle Steel, Round Bar, or Steel Pipe | |

| Knee Brace | Q235 Angle Steel | |

| X Brace | Round Steel Bar, Angle Steel, or as requested | |

| Purlin | C purlin, Z purlin, thickness 2.0mm, 2.2mm, 2.5mm, 3.0mm | |

| Cladding System | Roof & Wall Panel | Sandwich Panel / Single Steel Sheet, EPS, mineral wool, PU sandwich Panel (Thickness: 50mm, 75mm, 100mm, 150mm, 200mm) |

| Accessories | Door | Sliding Sandwich Panel Door / Rolling Metal Door / Personal Door |

| Exit Door | Plastic Steel Swing Door / Aluminum Alloy Swing Door / Steel Swing Door / Sliding Door | |

| Window | Aluminum Alloy Window, PVC Window, Sandwich Panel Window, Plastic Steel Sliding Window, Aluminum Alloy Sliding Window | |

| Gate | Electric Roller Shutter Door | |

| Rainspout | PVC | |

| Other Accessories | Gutter, Flash Trimming Cover, Down Spout, Ventilation Fitting, Skylight Belt, Bolt, Anchor Bolt, Self Tapping Screw, etc. |

Structural Dimensions

| Items | Specification |

|---|---|

| Clear Span (Width) | 6~50m without middle column |

| Height | 2~20m |

| Length | As per requirement |

Structural Performance

| Items | Specification |

|---|---|

| Live Load on Roof | 120 kg/Sqm (Color steel panel surrounded) |

| Wind Resistance Grade | 12 Grades |

| Earthquake-resistance | 8 Grades |

| Structure Usage | Up to 50 years |

Painting & Coatings

| Items | Specification |

|---|---|

| Paint Options | Alkyd Painting, Two Primary Paintings, Two Finish Paintings (Gray Paint, Red Paint, White Paint, Epoxy Zinc, etc.) or Galvanized |

Packaging & Certification

| Items | Specification |

|---|---|

| Package | Main steel frame load in 40’OT, roof and wall panel load in 40’HQ, or as requested |

| Certificate | ISO9001, CE EN1090 EXC2, IWE, etc. |

| Inspection | Third-party inspection (SGS, ASIA INSPECTION) accepted |

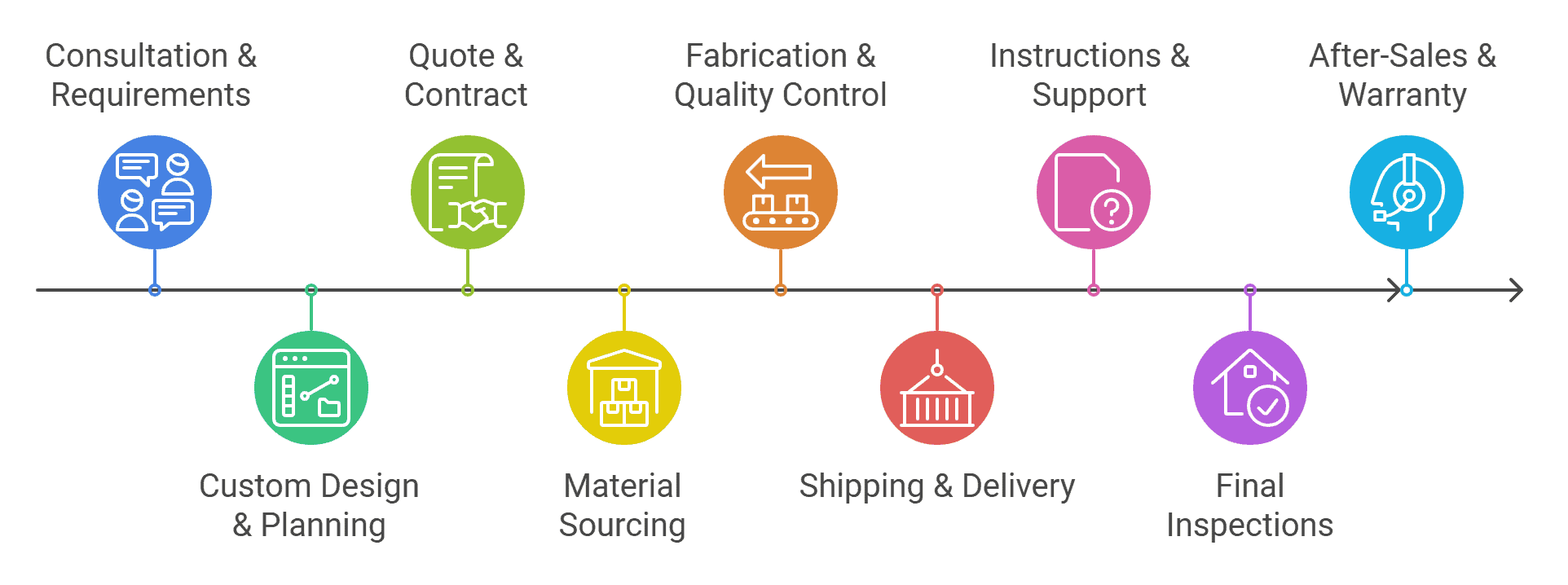

How It Works

FAQs

1. Could you describe the nature of your company?

We are a manufacturing company. Our steel is produced in-house, so you’ll get high-quality products, better prices, and faster delivery times.

2. Do you offer installation instructions on-site?

We provide comprehensive installation guidance, along with detailed manuals and instructional videos. If necessary, we can also send engineers to provide on-site assistance. However, the related expenses will be borne by the buyer.

3. How can I purchase the ideal products from you?

You can send us your drawings, and we will manufacture the product according to your specifications, or provide us with your detailed requirements. We have in-house designers and can provide full custom solutions and competitive pricing based on your requirements.

4. Can I visit your factory?

We warmly welcome our customers to visit our factory. Please contact us in advance so that we can arrange a suitable schedule for your