Fabrication

Fabrication Services

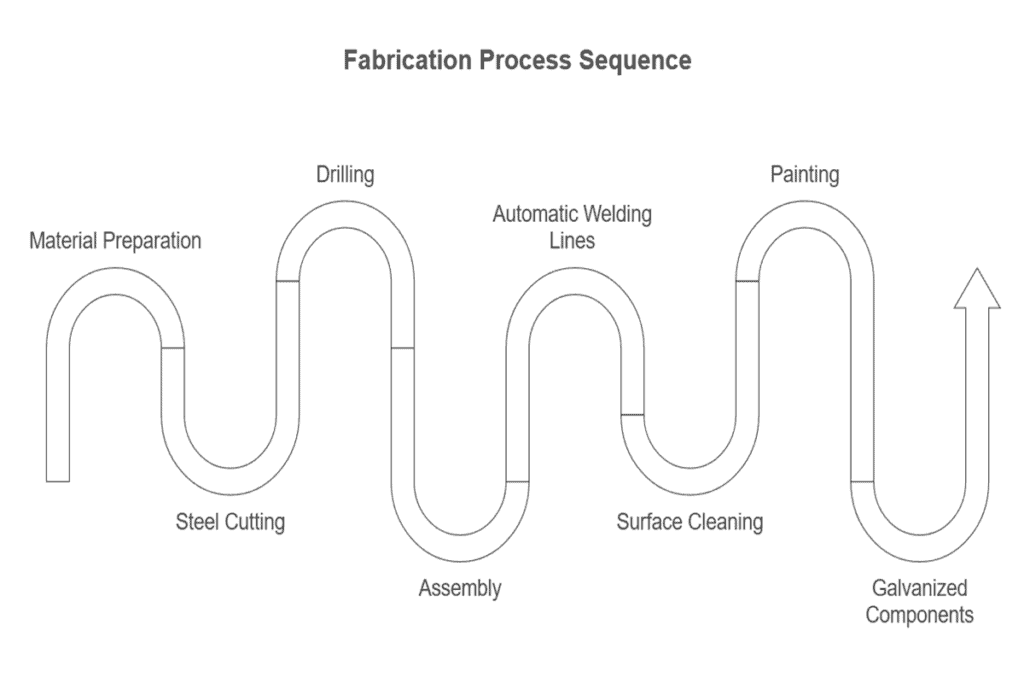

Our Fabrication Process

Material Preparation (Raw steel beams, trusses, columns)

We manufacture all raw materials, including steel beams, trusses, and columns, in our own factories. This ensures complete control over quality and precision, maintaining consistency from raw steel sheets to finished components.

Steel Cutting (Plasma, CNC, Shearing)

- Plasma Cutting: Capable of cutting steel plates up to 50mm thick.

- CNC Cutting: Provides precise cuts for plates up to 30mm thick, ensuring high accuracy.

- Shearing: Ideal for cutting thinner sheets up to 12mm thick, with clean edges.

Drilling (Precise hole placement, component alignment)

After cutting, we use CNC drilling and punching machines for precise hole placement, ensuring accurate alignment for bolts and connections, critical for stable assembly.

Assembly (Bolt connections, structural joints)

Following the design plans, components are carefully placed using lifting equipment and secured with high-strength bolts or welding, along with gaskets to enhance contact and stability.

Automatic Welding Lines (High-efficiency, precision welding)

With 8 automatic welding machines and 80 manual welding machines, we combine MIG and TIG techniques to ensure every weld meets the highest standards, guaranteeing the strength and quality of each joint.

Surface Cleaning (Shot blasting, rust removal)

Using 8 automatic shot blasting machines, we clean weld seams and steel plates, removing rust and impurities. For delicate areas, physical cleaning methods are also applied, ensuring a smooth surface for further processing.

Painting

Equipped with 5 high-pressure spray machines and 5 grinding machines, we efficiently complete painting and surface preparation. We use surface metal spray (zinc, aluminum), protection paint, and galvanized plating to provide a smooth, durable finish and ensure excellent corrosion resistance.

Galvanized Components (Purlins, girts, wall and roof sheeting, doors and windows)

All galvanized components, such as purlins, girts, wall and roof sheeting, and doors and windows, are manufactured with high-quality coatings to ensure maximum durability and protection against corrosion.

Our Testing

- Physical Property Testing

Tests tensile strength, yield strength, and elongation to ensure the material meets design standards. - Welding Quality Inspection

Uses X-ray, ultrasonic, and other non-destructive tests to check weld strength and integrity. - Dimensional Inspection

Measures all steel components to ensure they match design specifications. - Surface Treatment Inspection

Checks thickness and adhesion of protective coatings (e.g., painting, galvanizing) for compliance. - Load Testing

Tests key components for load-bearing capacity under real-world stresses. - Seismic Performance Testing

Ensures stability under extreme conditions like earthquakes. - Fire Resistance Testing

Tests the steel structure’s ability to maintain strength under fire conditions.