Types of Portal Steel Structure Workshops

Portal Steel Structure Workshops can be classified into various types based on their design, configuration, and application. Below are the 10 main categories:

- Hybrid Portal Frame: Combines portal frames with trusses or space frames for unique designs and complex projects.

- Gabled Frame Structure: Classic triangular roof, cost-effective, and perfect for industrial buildings and warehouses.

- Single-Span Portal Frame: Ideal for smaller buildings, offering a column-free space for workshops or storage.

- Multi-Span Portal Frame: Multiple spans for larger areas, perfect for factories and large warehouses.

- Clear-Span Structure: Column-free design, great for hangars, sports arenas, and exhibition halls.

- Lean-To Structure: Single-slope roof, cost-effective for adding storage or canopies.

- Tied Portal Frame: Includes tie rods for extra stability, ideal for areas with high wind or seismic activity.

- Crane-Supported Structure: Reinforced for heavy-duty operations, suitable for manufacturing plants and logistics centers.

- Curved or Arched Portal Frame: Curved beams for strength and style, ideal for sports facilities or greenhouses.

- Modular or Pre-Engineered Structure: Prefabricated for quick assembly, customizable for commercial buildings or temporary shelters.

What Content Does Our Portal Steel Structure Workshop Product Offer?

| Items | Specifications |

| Type | Light Portal Frame Structure |

| Main Steel Frame | Columns: Q235B, Q355B Welded H Section Steel |

| Beams: Q235B, Q355B Welded H Section Steel | |

| Secondary Frame | Purlins: Cold-formed C and Z Purlins |

| Knee Braces: Q235B Angle Steel | |

| Tie Rods: Q235B Circular Steel Pipe | |

| Braces: Q235B Round Bar or Steel Pipe | |

| Roofing and Wall Systems | Roof Panels: EPS, Glass Fiber, Rock Wool, PU Sandwich Panels, or Corrugated Steel Sheets |

| Wall Panels: EPS, Glass Fiber, Rock Wool, PU Sandwich Panels, or Corrugated Steel Sheets | |

| Structure Add-ons | Windows: Aluminum or PVC framed windows |

| Doors: Aluminum or Rolling Metal Doors | |

| Ventilation: Natural Ventilation Systems, Roof Vents, Louvered Shutters | |

| Crane Integration | Ability to accommodate overhead cranes up to a specific capacity, integrated directly into structure design |

| Customization Options | Wall Heights: Customizable from standard to high eave heights for varied operational needs |

| Roof Slope: Adjustable to suit both functional and aesthetic preferences | |

| Insulation Options: EPS, fiberglass wool, rock wool, PU sandwich panels for better energy efficiency | |

| Building Usage | Flexible Layout: Ideal for warehouses, factories, workshops, and storage facilities |

| Structural Strength | High-strength steel ensures long-lasting durability and superior resistance to environmental factors |

| Construction Time | Fast Construction: Pre-fabricated components enable quicker assembly and shorter project timelines |

| Sustainability | Made from recyclable materials for better environmental impact |

| Temperature Range | Can withstand temperatures from -40°C to +50°C |

| Certification | SGS, BV, ISO, SGS, BV, ISO, IBC, CE Marking |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

Characteristics of Portal Steel Structure Workshop

Strong and Durable

Our portal steel structures are made with tough materials like Q235B and Q355B welded H-section steel, built to last. They can handle heavy industrial loads and keep going strong for decades, making them a smart long-term investment.

Large Spans and Open Space

With spans from 9 to 36 meters, these structures give you a wide-open space—no pesky columns getting in the way. Whether it’s for machinery or storage, you get more usable space, making it perfect for your operations.

Lightweight and Cost-Effective

Portal steel structures are lightweight, which means less stress on foundations and lower construction costs. Plus, they use just the right size components, so you’re not paying for more material than you need—saving you money in the long run.

Flexible and Customizable

Want a layout that fits your specific needs? Portal steel structures are super flexible. Whether it’s adding cranes or adjusting for different machines, we’ve got you covered with a design that works for your business.

Great Seismic Resistance

These structures are built to handle earthquakes. Their design lets them bend without breaking, so they stay safe even in seismic areas. Plus, they handle both vertical and horizontal loads like a pro.

Low Maintenance, Big Savings

Thanks to corrosion-resistant materials, portal steel structures are a breeze to maintain. Less upkeep means more savings and less hassle, so you can focus on your business.

Perfect for Any Terrain

No matter the ground conditions, portal steel structures are adaptable. Whether it’s flat land or a tricky slope, their lightweight design makes building easier and cuts down on the need for heavy foundations.

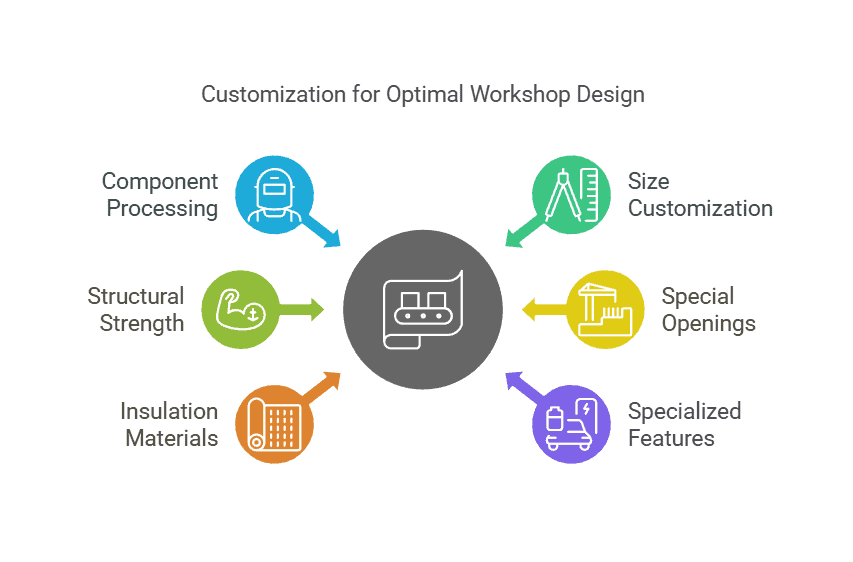

Customization Services for Portal Steel Structure Workshops

We provide a wide range of customization options to ensure your Portal Steel Structure Workshop is tailored to your specific needs. Here are the key services we offer:

- Component Processing CustomizationWe offer precision processing services, including cutting, welding, bending, punching, and decoiling. Choose from materials like Q235B or Q355B steel, and enjoy the flexibility of surface treatments like galvanizing, painting, or powder coating for added durability.

- Size CustomizationNeed flexibility with dimensions? We can customize the span width from 9 to 72 meters, adjust eave heights for cranes or large machinery, and tailor the roof slope for optimal snow drainage or aesthetic appeal.

- Structural Strength and Load-Bearing CustomizationWe can design your structure to handle specific live loads (e.g., 120 kg/m²) and dead loads, with the ability to withstand high wind loads (up to Grade 12) and heavy snow loads. We can even enhance seismic resistance (up to Grade 8) for areas prone to earthquakes.

- Special Openings and Add-onsCustomize doors, windows, and placements, integrate overhead cranes, and add ventilation systems such as natural ventilators, roof vents, or louvered shutters to improve airflow and comfort.

- Insulation and Cladding CustomizationChoose from a variety of insulation materials like EPS, fiberglass wool, or PU sandwich panels for excellent thermal efficiency, and pick cladding options that match your aesthetic, from corrugated steel sheets to sleek sandwich panels.

- Specialized Structural FeaturesNeed a clear-span design for a column-free interior? Or perhaps a hybrid frame combining portal frames with trusses for unique solutions? We also offer curved roofs for both style and aerodynamics.

- Fast-Track Construction CustomizationWe use prefabricated components and modular designs, allowing you to assemble your workshop quickly and modify it as your business grows, saving both time and cost.

We’re here to help create the perfect workshop, designed specifically for your needs!

What Needs Do You Need To Provide Us With?

| Basic Design Requirements | Details |

| 1. Project Location | Location of the project site |

| 2. Snow Load | Snow load specifications |

| 3. Wind Load | Wind load specifications |

| 4. Seismic Magnitude | Seismic magnitude for design |

| 5. Length (sidewall, m) | Length of the sidewall in meters |

| 6. Width (end wall, m) | Width of the end wall in meters |

| 7. Wall Height (eave, m) | Height of the wall at the eave in meters |

| 8. Middle Column Allowed or Not | Whether middle columns are allowed or not |

| 9. Window Quantity & Size | Number and size of windows |

| 10. Door Quantity & Size | Number and size of doors |

| 11. Brickwall Needed or Not (If Yes, 1.2m or 1.5m High) | Whether brick walls are needed, and if so, their height (1.2m or 1.5m) |

| 12. Crane Needed or Not | Whether a crane is required |

| 13. Thermal Insulation | If yes, options include EPS, fiberglass wool, rock wool, PPU sandwich panels; if not, metal steel sheets are fine. The latter is much more cost-effective. |